Decoupling reactive ion etching chamber containing multiple processing platforms

A processing chamber and etching chamber technology, applied in the field of plasma processing chambers, can solve the problems of not being able to ensure strict performance specifications, increasing the complexity of the structure and configuration of the processing chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

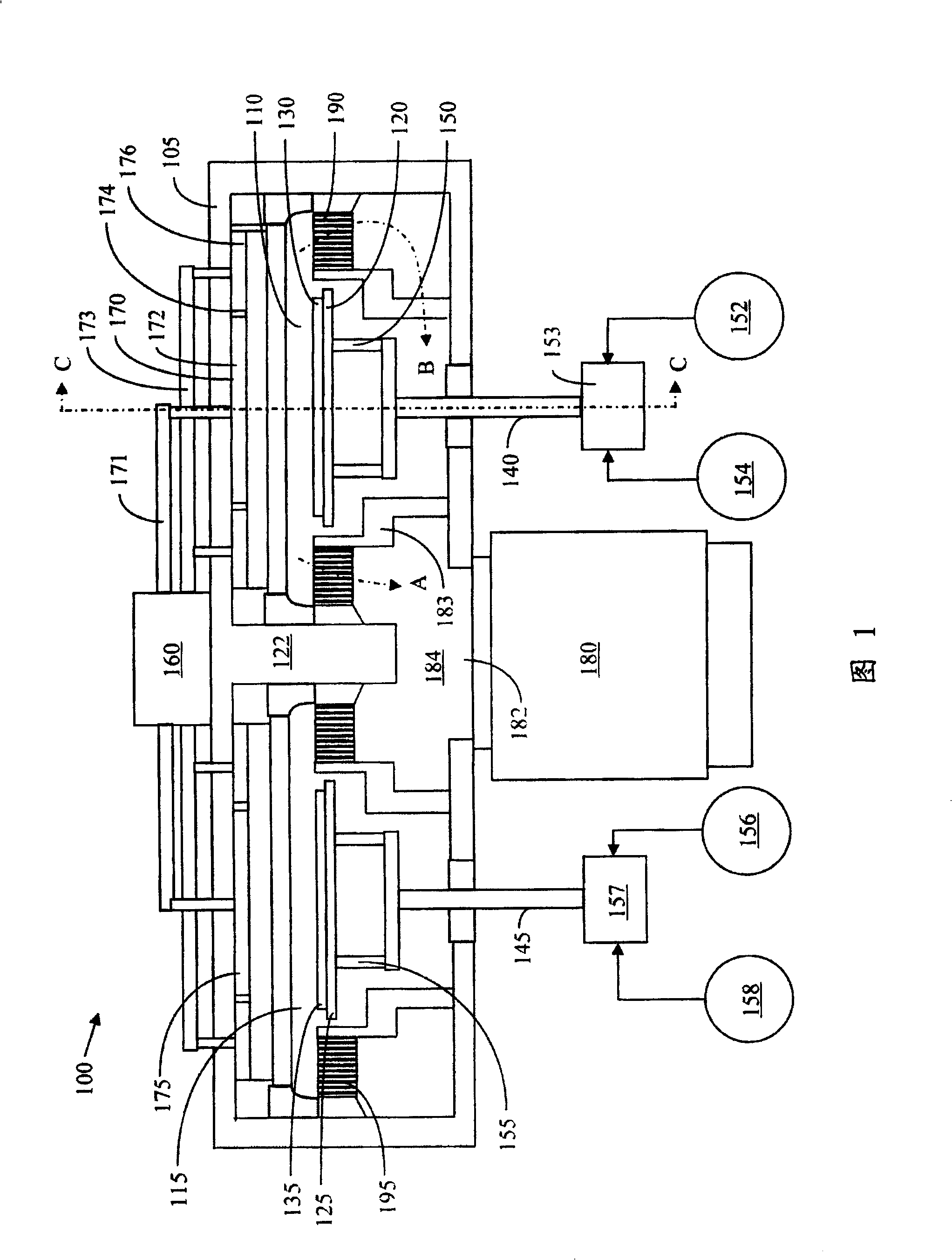

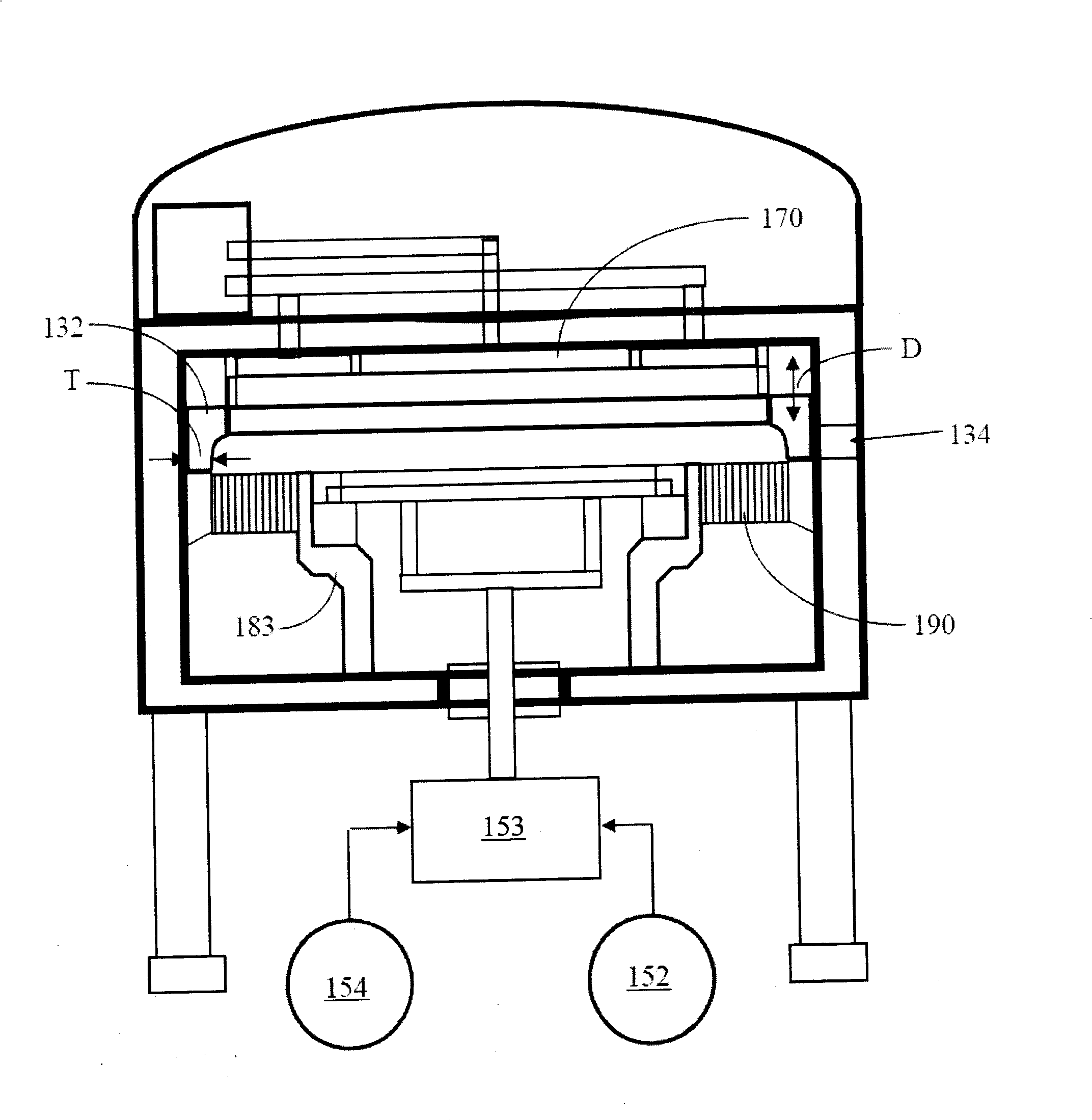

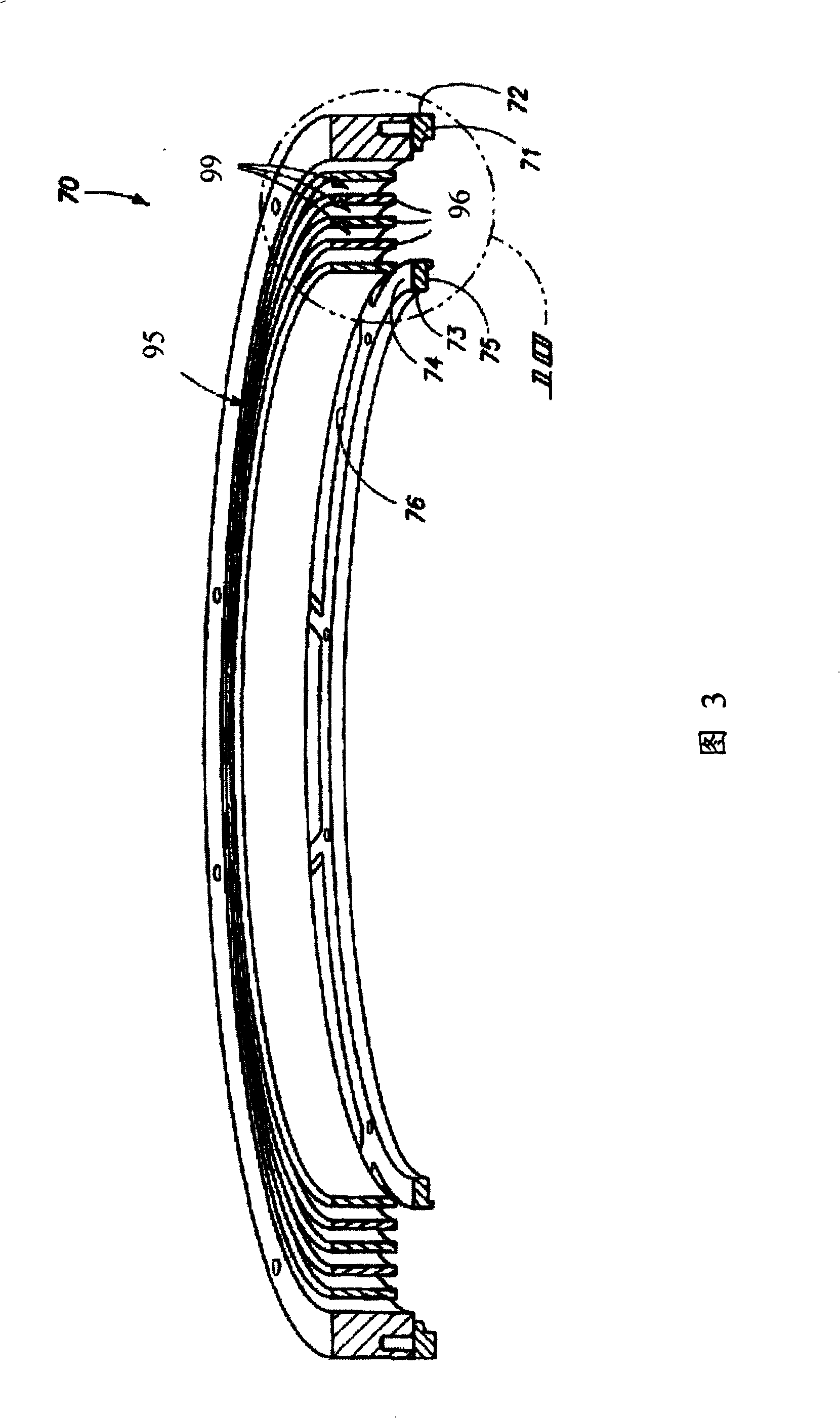

[0023] Embodiments of the present invention provide a versatile plasma chamber that can provide high precision uniformity processing at high throughput. The invention can realize the stability and consistency of the plasma in each processing area, and the obtained processing results meet the high-precision requirements in advanced semiconductor processing. The present invention provides a multi-station decoupled reactive ion etch chamber having multiple processing platforms or processing regions, wherein each processing region is applied with multiple RF power sources. The present invention adopts various characteristics and designs to prevent frequency fluctuation and radio frequency crosstalk between two adjacent parallel processing areas. In particular, to date no one has proposed feeding two or more RF frequencies to the cathodes of each processing zone in parallel processing chambers to achieve decoupled reactive ion etching.

[0024] 1 is a cross-sectional view of a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com