Grid-shaped electrostatic discharge protection device

An electrostatic discharge protection and grid-like technology, applied in the field of electrostatic discharge protection devices, can solve problems such as the unsatisfactory anti-static effect and the inability to flexibly adjust the voltage value of the trigger point, so as to increase the effective circulation area and flexibly The effect of adjusting and increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in conjunction with the drawings and embodiments of the description.

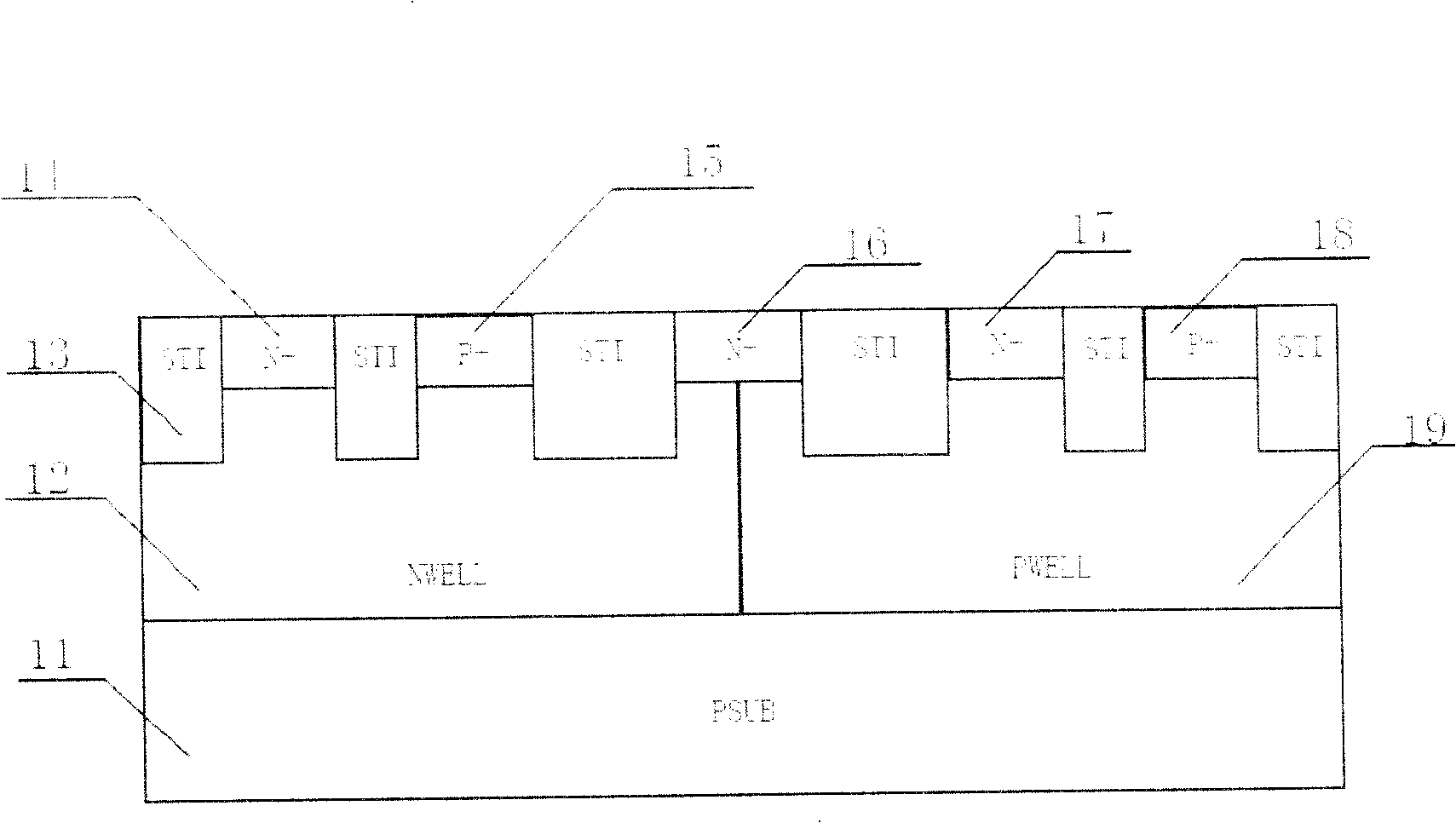

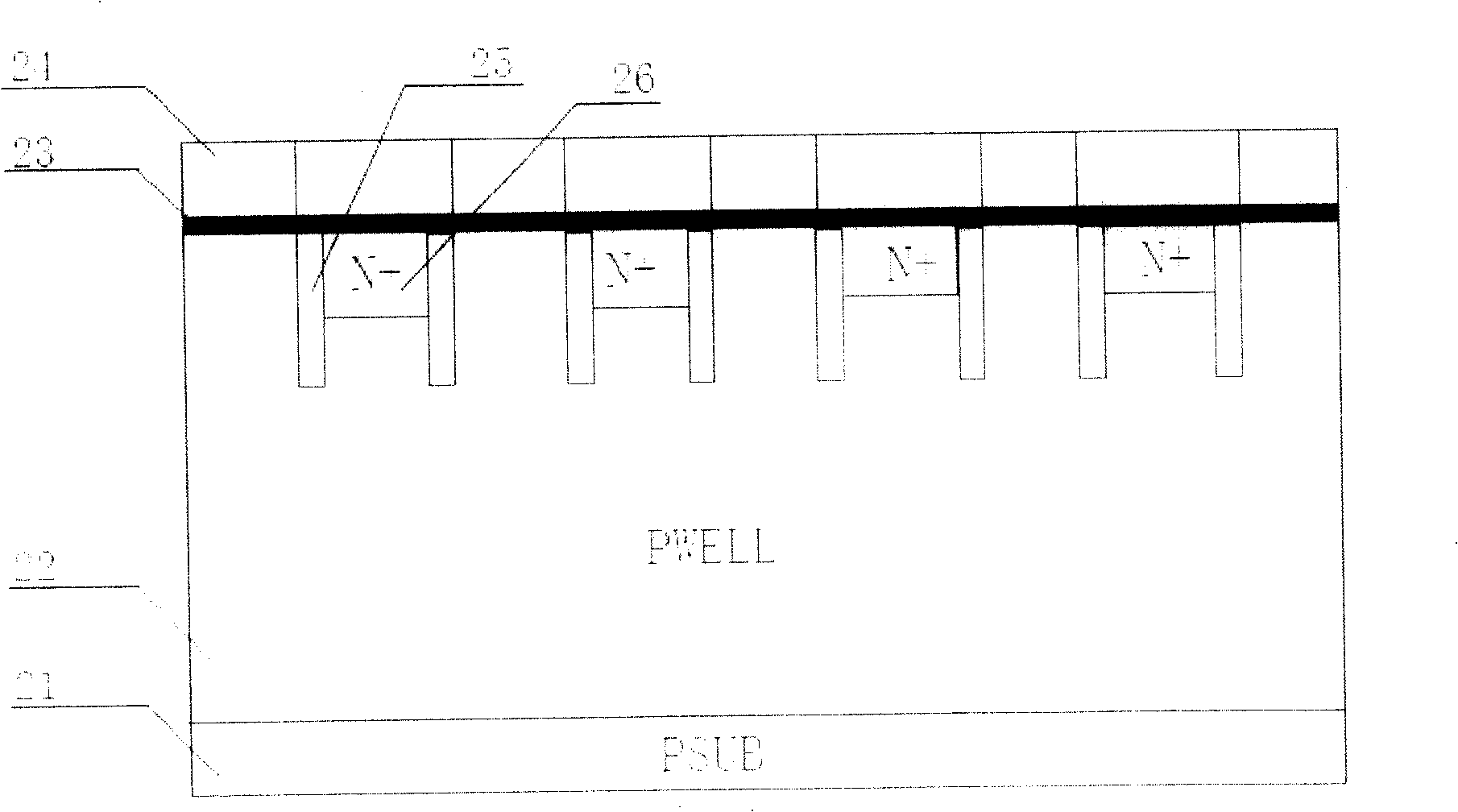

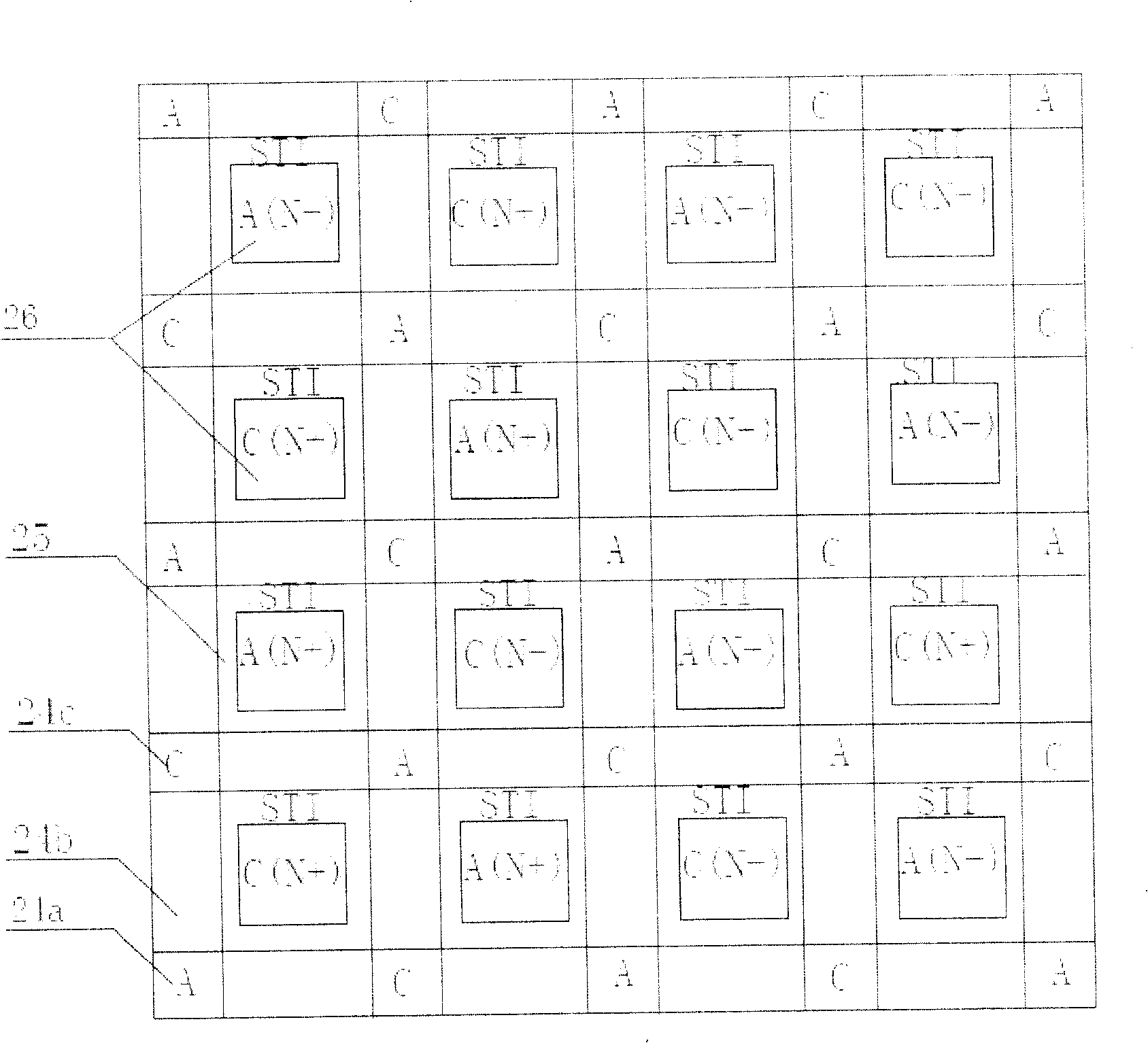

[0013] Such as figure 2 and image 3 As shown, a grid-shaped electrostatic discharge protection device includes a P-type substrate 21 on which a P-well 22 is arranged. Above the P well 22 is a fishnet-shaped polysilicon region (24a, 24b, 24c), and just below the polysilicon region (24a, 24b, 24c) is a SiO2 region of the same shape. 2 Oxide layer 23, SiO 2 The lower surface of oxide layer 23 is in contact with the upper surface of P well 22 . The nodes (24a, 24c) of the fishnet-shaped polysilicon regions are doped with P-type impurities or N-type impurities to become P-type polysilicon regions 24a or N-type polysilicon regions 24c respectively, while adjacent nodes (P-type polysilicon regions 24a and N-type polysilicon regions 24a and N-type Intrinsic polysilicon regions 24b are provided between the polysilicon regions 24c). The P-type polysilicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com