Low temperature distillation method and device for high volatile component weak viscosity coal

A high-volatile, weakly sticky coal technology, used in special forms of dry distillation, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as shutdown, charge blockage, gas channel flow, etc. The effect of increasing strength, preventing sticking, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

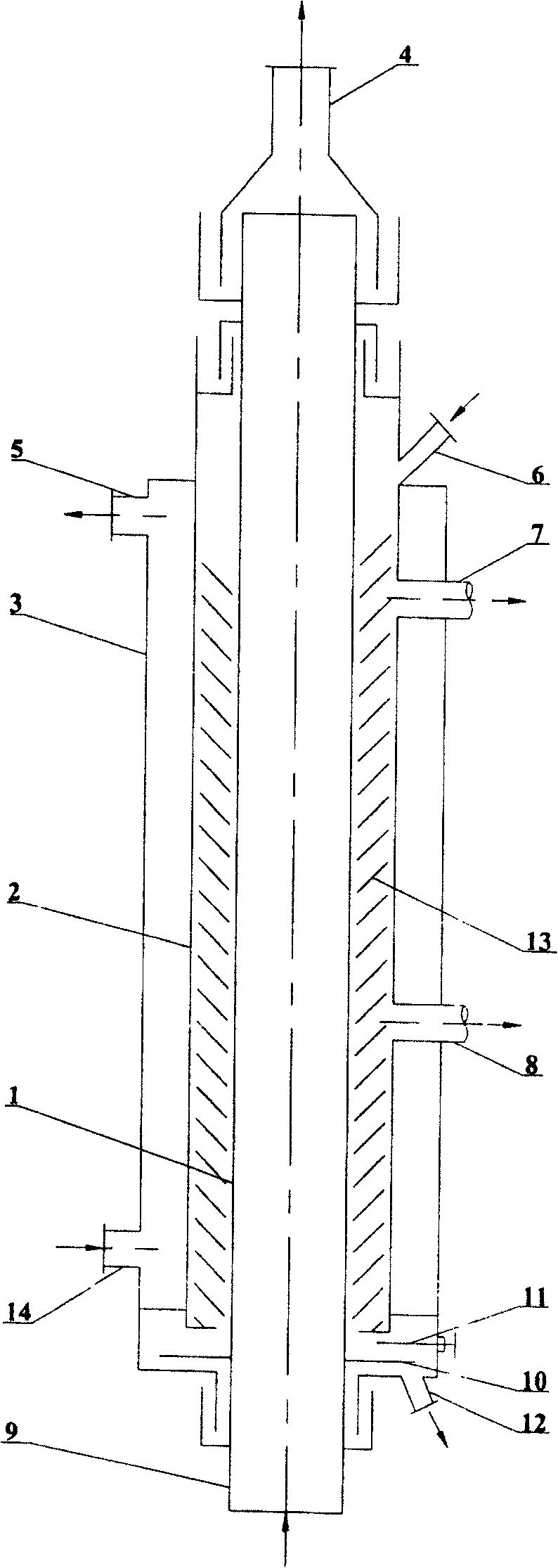

[0028] Dried raw coal with a diameter of 1mm to 13mm (Fugu coal sample: water content M ad =5.5%, volatile matter V ad= 35.05%) The input riser moves the two side-by-side coal scuttles on the top of the external thermal retort furnace on both sides, and flows through the coal scuttle continuously through the coal scuttle from the coal inlet 6 at the upper end of the middle casing 2 to flow between the middle casing 2 and the inner casing 1 The coal material stays in the furnace for 30 minutes and the coal material is separated from each other by the multi-layer inverted cone baffle plate 13 during the downward movement, and the coal material is separated by the rotation of the inner casing 1. Agitation, displacement, and surface renewal, while being indirectly heated by high-temperature flue gas on both sides to precipitate moisture and volatile products, and finally produce semi-coke that is continuously discharged from the bottom of the carbonization furnace. When the carbo...

Embodiment 2

[0030] Example 2: The residence time of the coal in the retort furnace is within 70 minutes. When the retort temperature (the temperature at the bottom of the retort furnace body) is 540° C., the semi-coke V after retort is ad =18.3% (corresponding to 48% of the total volatile matter that has been removed).

Embodiment 3

[0031] Example 3: The residence time of the coal material in the retort furnace is within 50 minutes. When the retort temperature (the bottom temperature of the retort furnace body) is 658° C., the semi-coke V after retort is ad =12.9% (corresponding to 63% of the total volatile matter that has been removed).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com