Alkaline battery positive pole material and preparing method

A positive electrode material, alkaline battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation process and poor storage performance, and achieve simple and easy-to-obtain materials, perfect storage performance, Mg-O bond strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

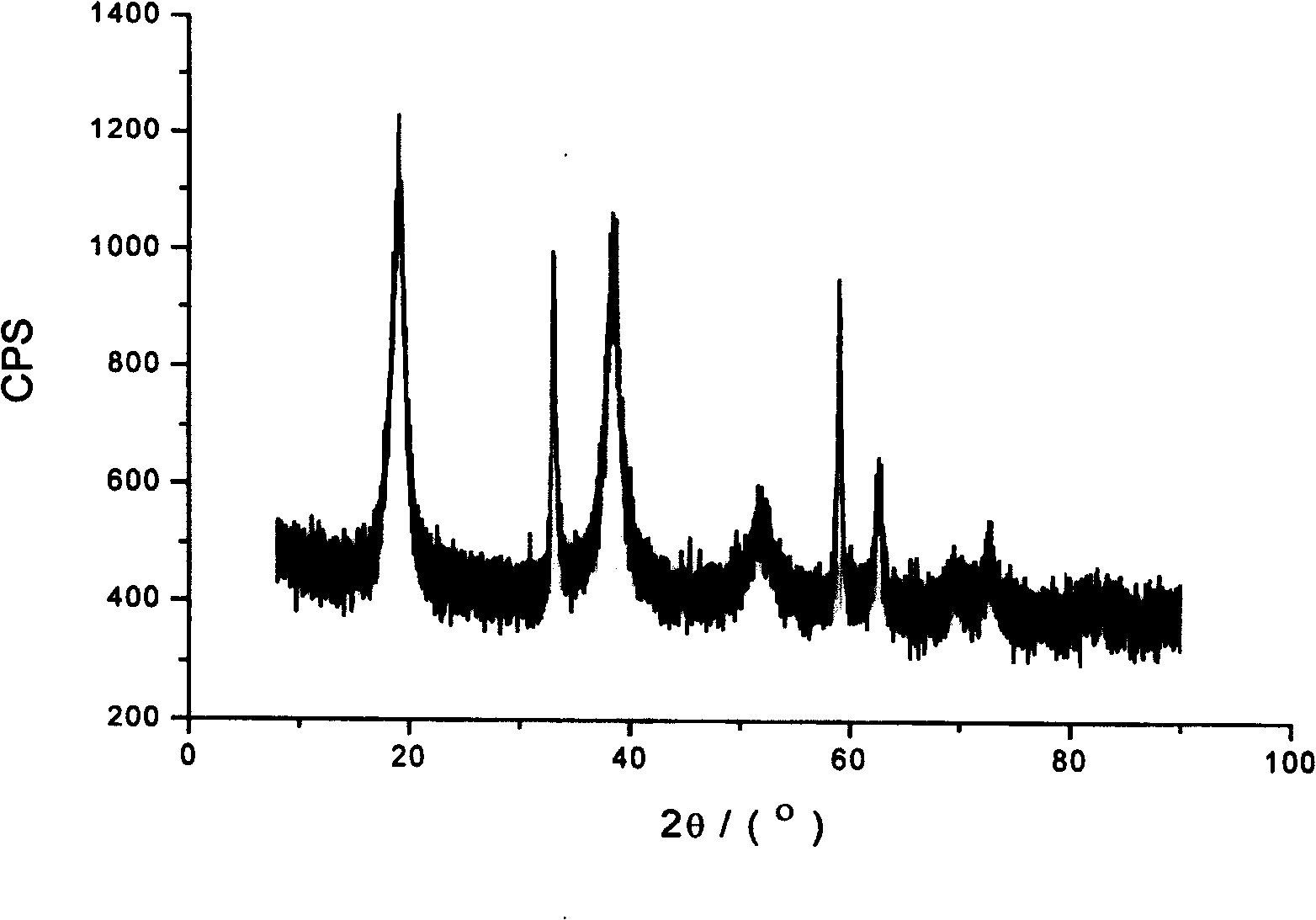

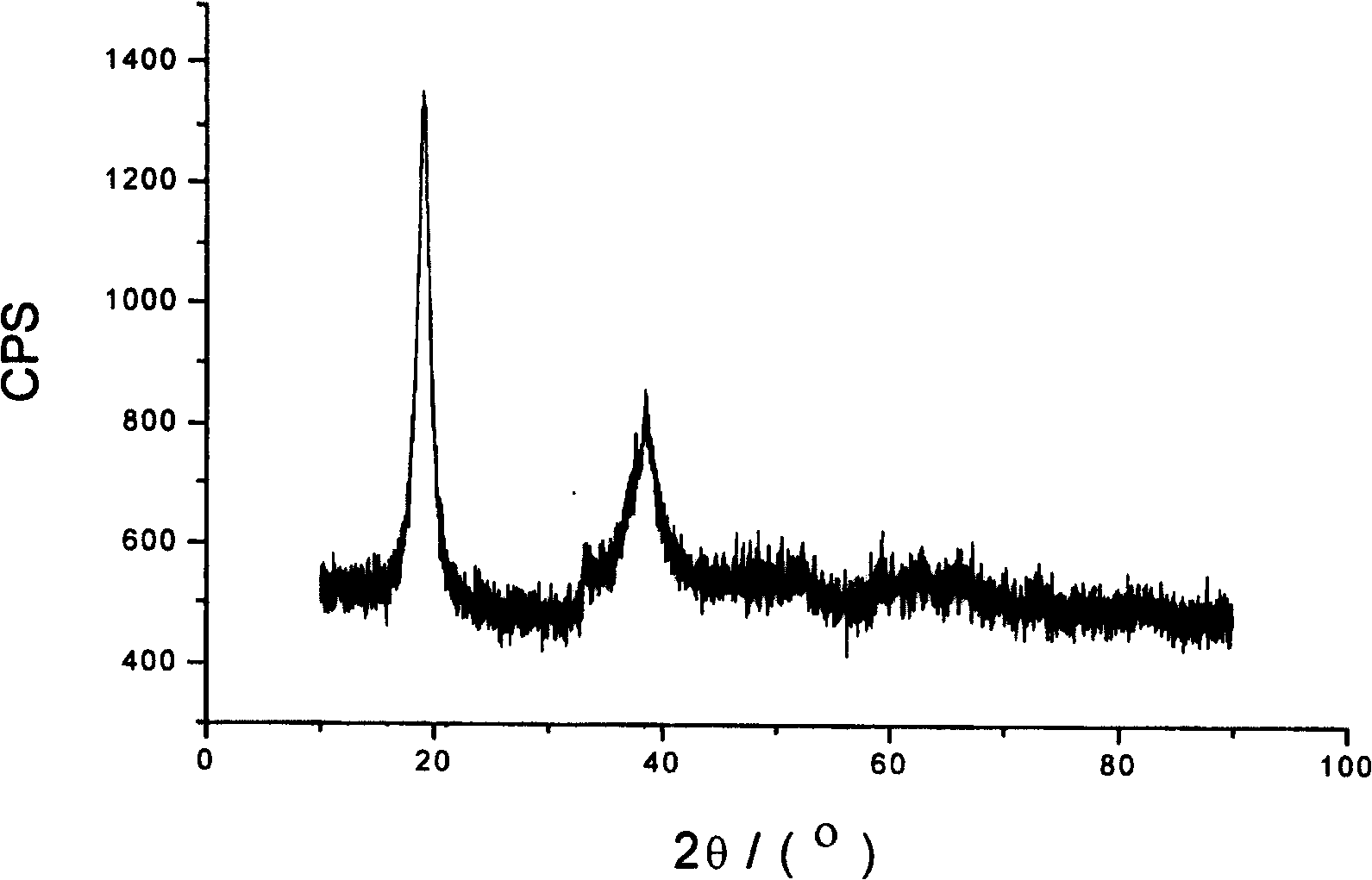

Embodiment 1

[0023] Embodiment 1: the NiSO of 1.0mol / L 4 solution and 1.0mol / L MgSO 4 The solution is mixed uniformly according to the mass ratio of nickel and magnesium to 92:8 to form a nickel-magnesium solution and a 2mol / L NaOH solution. The complexing agent is a 13mol / L concentrated ammonia solution to control a certain flow ratio, and use a flow pump to flow into the reaction In the still, stir at a medium speed at the same time, control the pH value in the reaction kettle to keep it in the range of 10±0.5, control the reaction temperature at 60°C in a water bath, react for 8h, and then wash the green reaction product twice with distilled water until with BaCl 2 The solution does not detect SO 4 2- filter, and dry at 120°C for 10 hours. Then the nickel-magnesium hydroxide product prepared above is dispersed into the KOH solution of 1mol / L, and at the same time, according to the mass ratio of the oxidizing agent to the nickel-magnesium hydroxide is 3:1, the solid powder K 2 S 2 ...

Embodiment 2

[0024] Embodiment 2: the Ni(NO of 2.0mol / L 3 ) 2 solution and 2.0mol / L Mg(NO 3 ) 2 The solution is uniformly mixed into a nickel-magnesium solution according to the mass ratio of nickel and magnesium of 95:5, and 4mol / L NaOH alkaline solution, and the complexing agent is a 13mol / L concentrated ammonia solution to control a certain flow ratio, and use a flow pump to flow in parallel In the reaction kettle, stir at a medium speed at the same time, control the pH value in the reaction kettle to remain within the range of 10.50±0.5, control the reaction temperature at 60°C in a water bath, react for 10 hours, and then wash the green reaction product 3 times with distilled water, Filter and dry at 120°C for 10h. Then the nickel-magnesium hydroxide product prepared above is dispersed into the KOH solution of 2mol / L, and at the same time, the mass ratio of the oxidizing agent to the nickel-magnesium hydroxide is 3.5:1, and the solid powder K 2 S 2 o 8 , stirred vigorously, and ...

Embodiment 3

[0025] Embodiment 3: the NiCl of 1.0mol / L 2 solution and 1.0mol / L MgCl 2 The solution is mixed uniformly according to the mass ratio of nickel and magnesium of 85:15 to form a nickel-magnesium solution and a 2mol / L NaOH solution. The complexing agent is a 13mol / L concentrated ammonia solution to control a certain flow ratio, and use a flow pump to flow into the reaction In the kettle, stir at a medium speed at the same time, control the pH value in the reaction kettle to keep it in the range of 11±0.5, control the reaction temperature at 50°C in a water bath, react for 8 hours, and then wash the green reaction product 3 times with distilled water until with AgNO 3 Filter the solution until no Cl- is detected, and dry at 120°C for 12 hours. Then the nickel-magnesium hydroxide product prepared above is dispersed into the KOH solution of 1mol / L, and at the same time, according to the mass ratio of the oxidizing agent to the nickel-magnesium hydroxide is 3:1, the solid powder K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com