Oxide cathode for electron gun with a differentially doped metallic substrate

A technology of oxide cathode and metal substrate, applied in the direction of discharge tube solid thermionic cathode, discharge tube main electrode, circuit, etc., can solve the problem of good operation and harmfulness, and achieve the effect of optimizing the on-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to simplify the description and to demonstrate the differences and advantages of the present invention over the prior art, the same reference symbols will be used to denote elements providing the same functions.

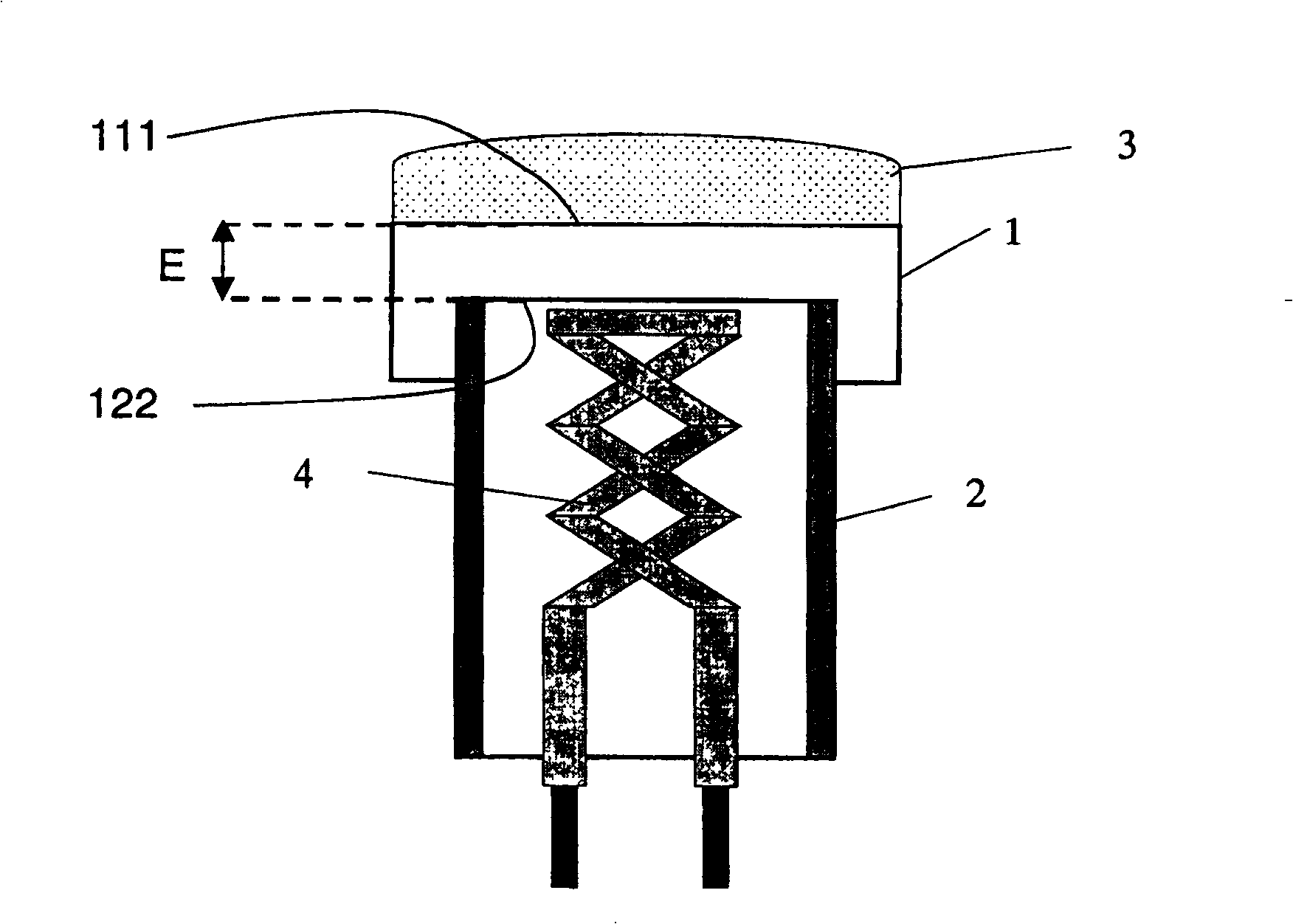

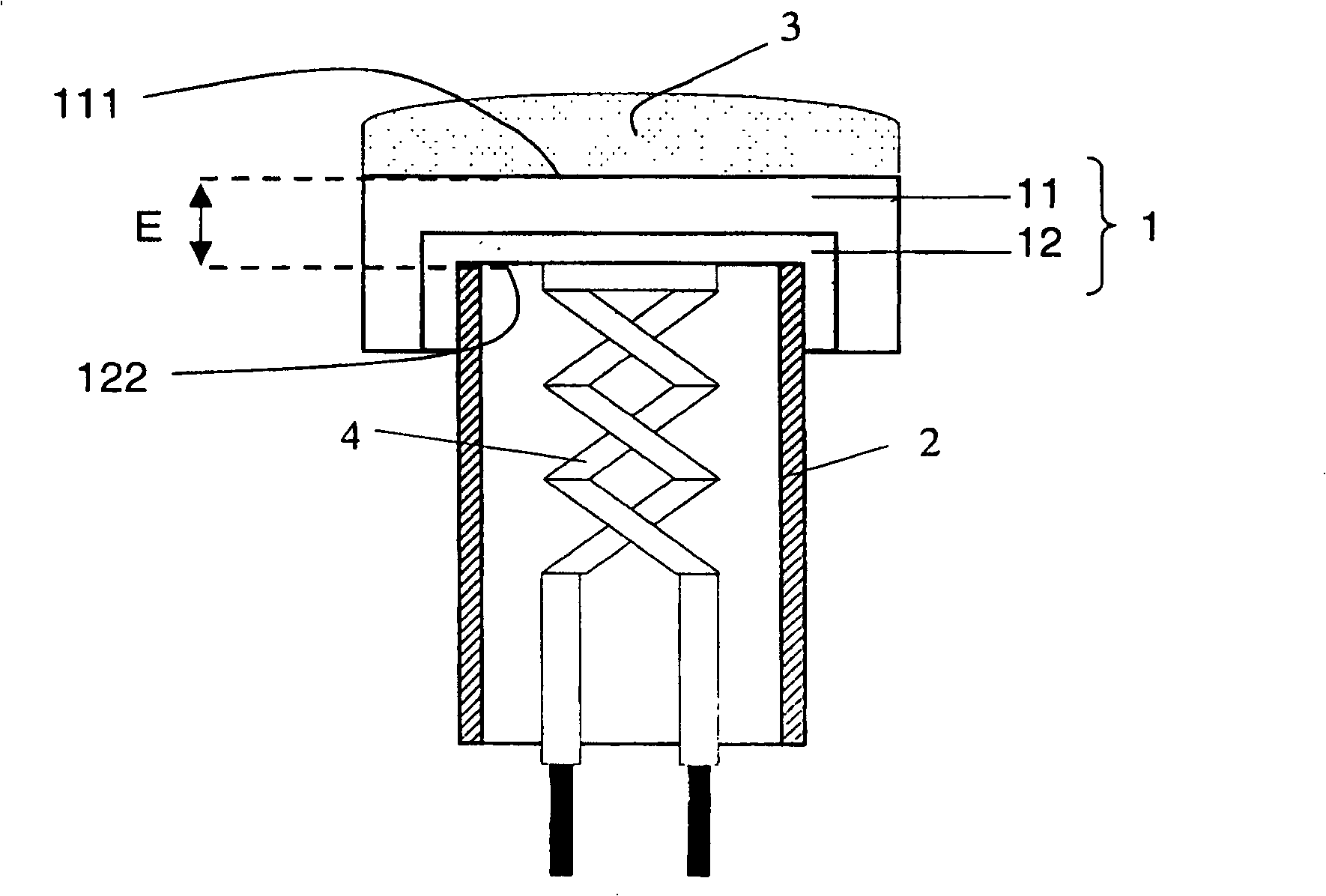

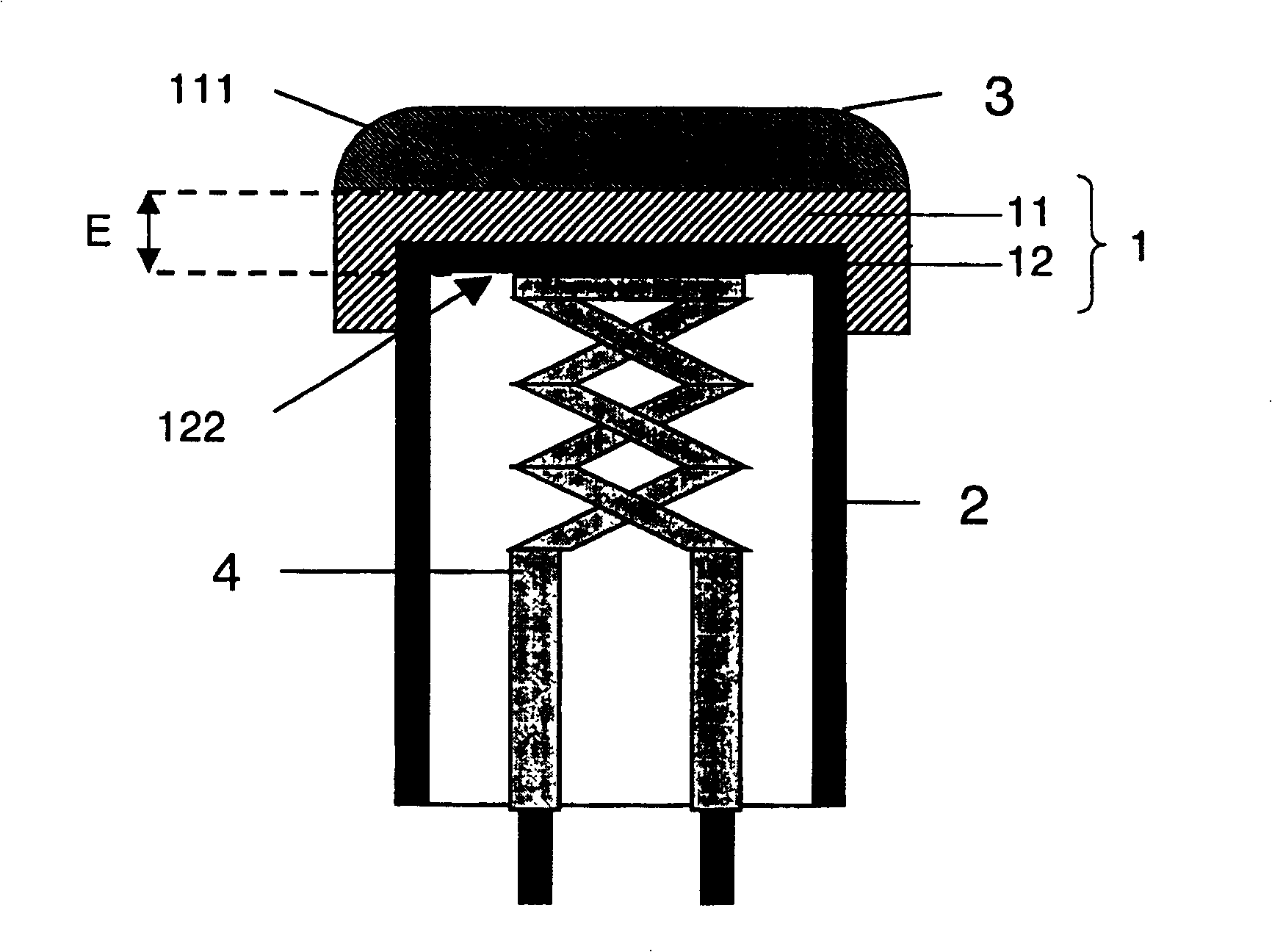

[0070] Now, we will use the main components described for such as image 3 The bimetallic substrate 1 of the one-piece cathode is shown to describe the invention. As any bimetal, this bimetal consists of two superimposed connected layers, a top layer 11 with a top surface 111 in contact with the cathode emitter layer 3 and a bottom layer with its outer bottom surface 122 facing the heater 4 inside the casing 2 .

[0071] The top layer consists mainly of nickel; its thickness is approximately 60 μm.

[0072] The bottom layer consists mainly of a nickel alloy with 20% chromium, known as nichrome; its thickness is approximately 30 μm.

[0073] The substrate 1 according to the invention is made of a 70-100 μm thick bimetal; even if the W concentration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com