Plate type solid oxide fuel cell cathode flexible contact material and battery pile structure

A fuel cell cathode and solid oxide technology, which is applied in the direction of solid electrolyte fuel cells, fuel cell groups, fuel cell components, etc., can solve problems such as easy blockage of gas channels, difficult control of sintering state, and irregular distribution of pores. Achieve the effects of improving reliability and operating life, ensuring long-term stability, and regular microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

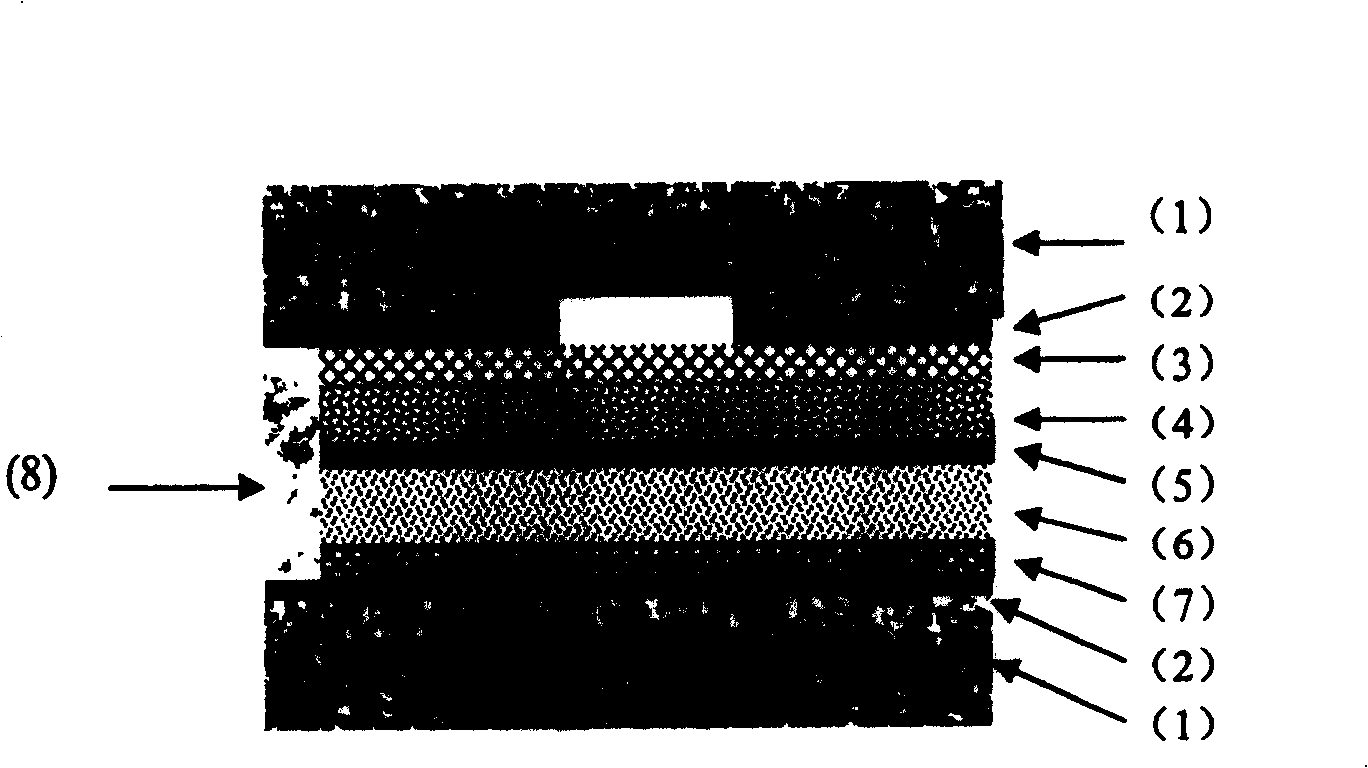

[0015] Embodiment 1: the composition is Mn 1.5 co 1.5 o 4 , a cloth with a thickness of 0.5cm, placed on the La of the plate-shaped SOFC cell stack 0.6 Sr 0.4 FeO 3 Between the cathode and the metal connection electrode, it is used as a flexible contact layer on the cathode side. The plate-type SOFC cell stack is composed of overlapping units consisting of stainless steel connecting pole, anode nickel foam contact layer, Ni-YSZ anode, YSZ electrolyte, cathode, flexible cathode contact layer, and stainless steel connecting pole. The measurement shows that the specific resistance of the contact layer in the battery stack at 750°C is ASR=0.01Ω·cm 2 .

Embodiment 2

[0016] Embodiment 2: the composition is La 0.5 Sr 0.5 MnO 3 , a cloth with a thickness of 0.5cm, placed on the La of the plate-shaped SOFC cell stack 0.6 Sr 0.4 MnO 3 Between the cathode and the metal connection electrode, it is used as a flexible contact layer on the cathode side. The plate-type SOFC cell stack is composed of overlapping units consisting of stainless steel connecting pole, anode nickel foam contact layer, Ni-YSZ anode, YSZ electrolyte, cathode, flexible cathode contact layer, and stainless steel connecting pole. The measurement shows that the specific resistance ASR of the contact layer in the battery stack at 800°C is 0.013Ω·cm 2 .

Embodiment 3

[0017] Embodiment 3: the composition is La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 , a cloth with a thickness of 0.4cm, placed on the La of the plate-shaped SOFC cell stack 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 Between the cathode and the metal connection electrode, it is used as a flexible contact layer on the cathode side. The plate-type SOFC cell stack is composed of overlapping units consisting of stainless steel connecting pole, anode nickel foam contact layer, Ni-YSZ anode, YSZ electrolyte, cathode, flexible cathode contact layer, and stainless steel connecting pole. The measurement shows that the specific resistance of the contact layer in the battery stack at 750°C is ASR=0.01Ω·cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com