Sticking device of substrates, judging method for substrates sticking, and method for substrates sticking

A technology for pasting devices and substrates, which is applied in the directions of optics, instruments, floors, etc., can solve the problems of longer sealants and unavoidable complex structures, etc., and achieve the effect of shortening the interval between production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

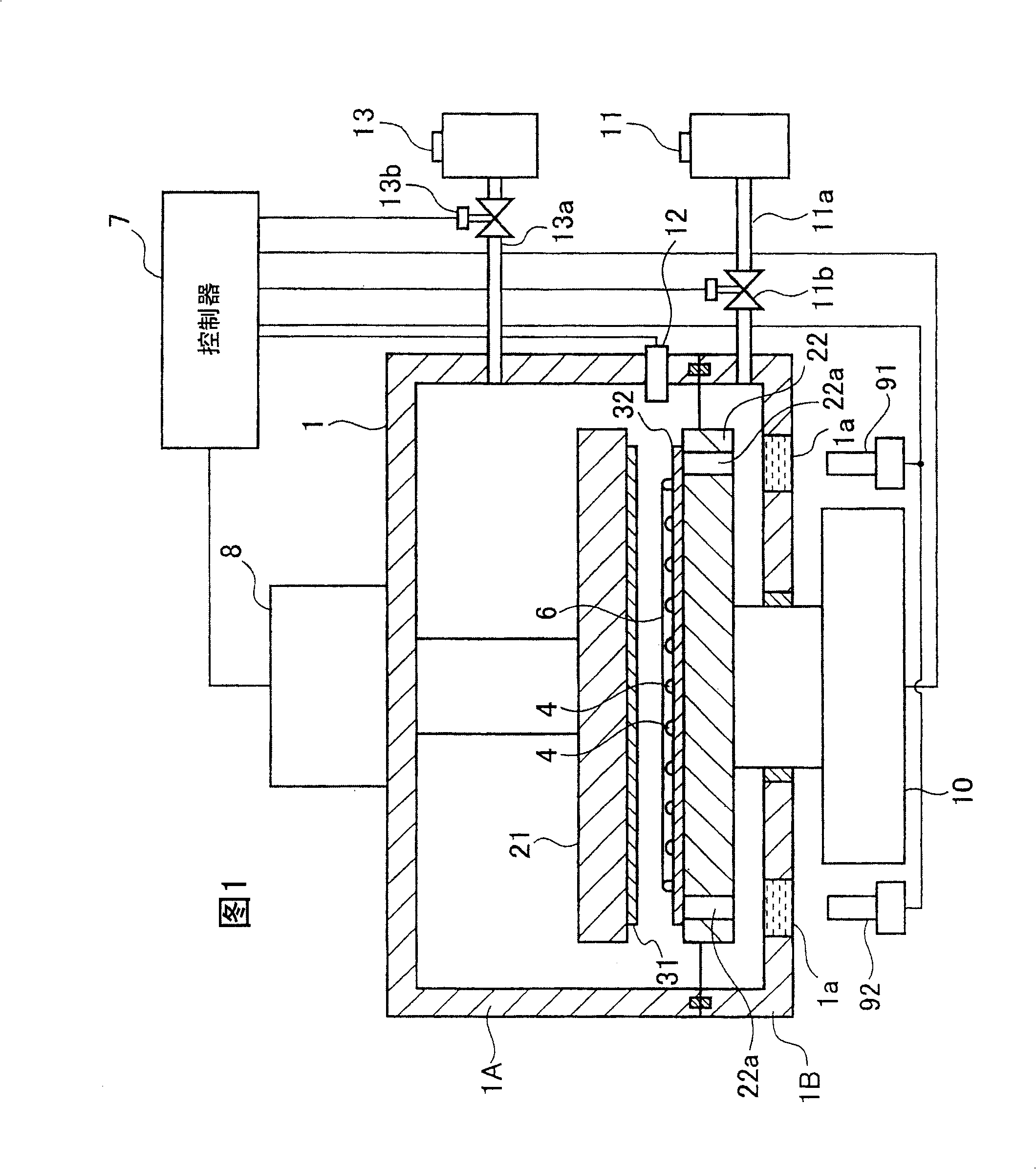

[0028] Below, refer to Figure 1 to Figure 4 An embodiment of the present invention will be described in detail.

[0029] That is, FIG. 1 is a configuration diagram showing an embodiment of a substrate bonding apparatus according to the present invention.

[0030] The substrate sticking device shown in FIG. 1 is a device used in the manufacture of liquid crystal display panels, and is configured such that an upper stage 21 and a lower stage 22 are arranged opposite to each other in a chamber 1 composed of an upper chamber 1A and a lower chamber 1B. , the glass-made upper substrate 31 and lower substrate 32 to be pasted are held on the upper stage 21 and the lower stage 22 by electrostatic chucks or the like, respectively. Here, the upper stage 21 constitutes the first holding means, and the lower object stage 22 constitutes the second holding means.

[0031] Among the two substrates 31 and 32 facing each other, a spacer (not shown) is provided on the display surface of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com