Method for twining VPI corona-prevention layer between stator coil main insulating layer and corona-prevention layer

A technology of stator coil and main insulating layer, applied in the shape/style/structure of winding insulation, manufacturing stator/rotor body, etc., can solve the problem of reducing the corona and withstand voltage performance of anti-corona layer, withstand voltage and creeping flashover voltage drop, the corona onset voltage of the end anti-corona layer is reduced, etc., to achieve the effect of uniform electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

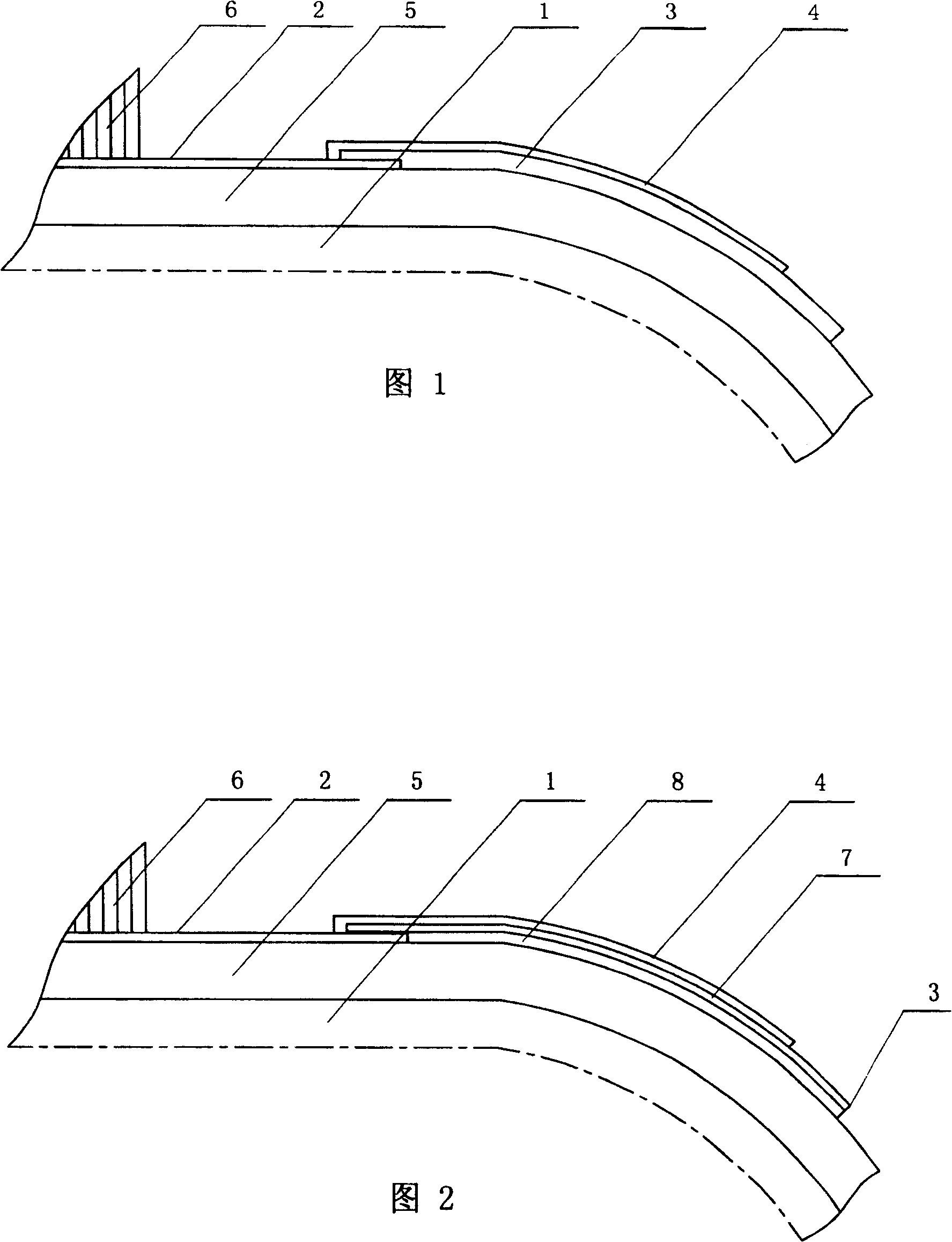

[0013] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . The steps of this embodiment are as follows:

[0014] Step 1. Wrap several layers of the stator coil copper core guide rod 1 with less glue mica tape, with a thickness of 2.5-7.5mm;

[0015] Step 2, wrapping a layer of low-resistance band 2 made of semiconductor material in the slot of the stator coil;

[0016] Step 3. Vacuum pressure impregnating resin glue on the stator coil groove part wrapped with a layer of semiconductor material low-resistance tape (2) in step 2, and dripping dry;

[0017] Step 4. Wrap the outer surface of the end of the main insulating layer 5 impregnated with resin glue around the VPI anti-corona barrier layer 3. The anti-corona barrier layer 3 is made of multi-glue mica tape, the thickness of which is 0.1mm, and its glue content It is 35~45% of the mica tape, and the winding thickness of the anti-corona barrier layer 3 is 0.3~1mm; Bread PTF...

specific Embodiment approach 2

[0021] Specific Embodiment 2: This embodiment will be described in conjunction with FIG. 2 . The difference between this embodiment and the first embodiment is that the anti-halation barrier layer 3 in step four is composed of a polymica tape 8 and an alkali-free glass tape 7 . The upper and lower positions of the multi-glue mica tape 8 and the non-alkali glass tape 7 are interchangeable. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the winding thickness of the anti-corona barrier layer 3 in step four of this embodiment is 0.4 mm; in step five, the temperature in the hot-press curing furnace is raised to 130 ° C, kept for 4 hours, and then heated to 160 ° C, kept for 12 Hour. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com