Special color mixer for color weaving and special mixing method thereof

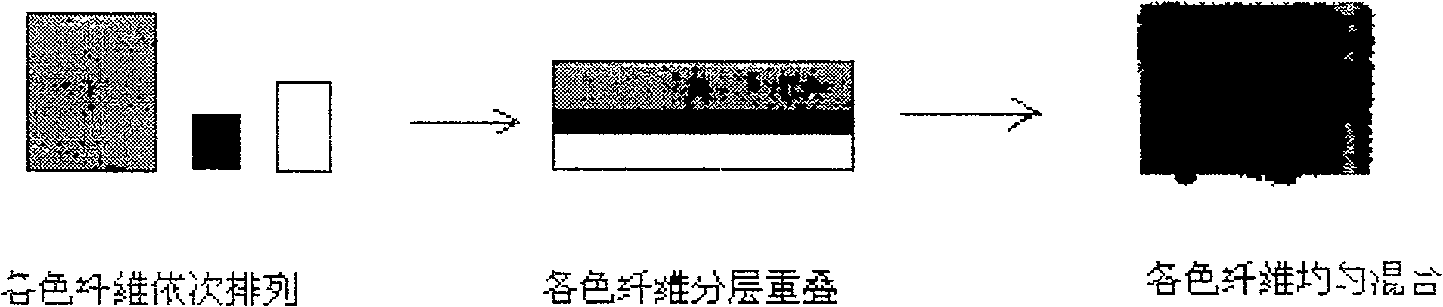

A technology of color mixing machine and color spinning, which is applied in the direction of fiber mixing, textile and paper making, fiber processing, etc. It can solve the problems of wasting manpower, increasing the operating cost of enterprises, and lagging behind the development speed, so as to improve the mixing quality and have a good development prospect. , to achieve a continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific embodiment of the present utility model is described in detail below in conjunction with accompanying drawing:

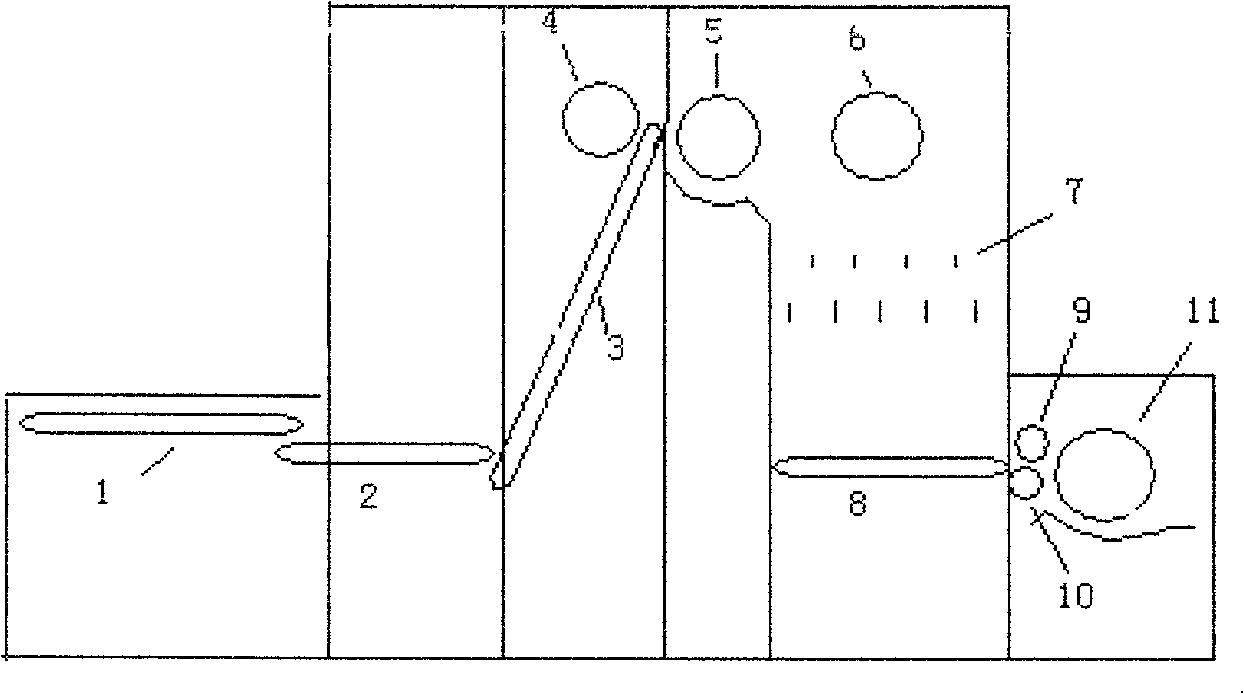

[0024] A special color mixing machine for color spinning, mainly including a feeding device, a grabbing device, an opening beater 5, a cotton mixing curtain 8 and a cotton mixing beater 11, wherein the feeding device, the grabbing device and the opening beater 5 are arranged in sequence, The grabbing device is obliquely higher than the feeding device at one end of the feeding device, the opening beater 5 is connected to the other end of the grabbing device, the cotton mixing curtain 8 is located below the opening beater 5, the cotton mixing beater 11 and the cotton mixing curtain 8 connected. The above-mentioned feeding device, grabbing device, opening beater 5, cotton mixing curtain 8 and cotton mixing beater 11 are separately provided with driving devices, and the working parameters can be set respectively according to the needs of the work.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com