Cooling system of apparatus for measuring thickness / convexity

A cooling system and measuring device technology, which is applied in the field of metal rolling processing, can solve problems such as drift, increase noise, and affect measurement accuracy, so as to achieve good cooling effect, keep the interior dry, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

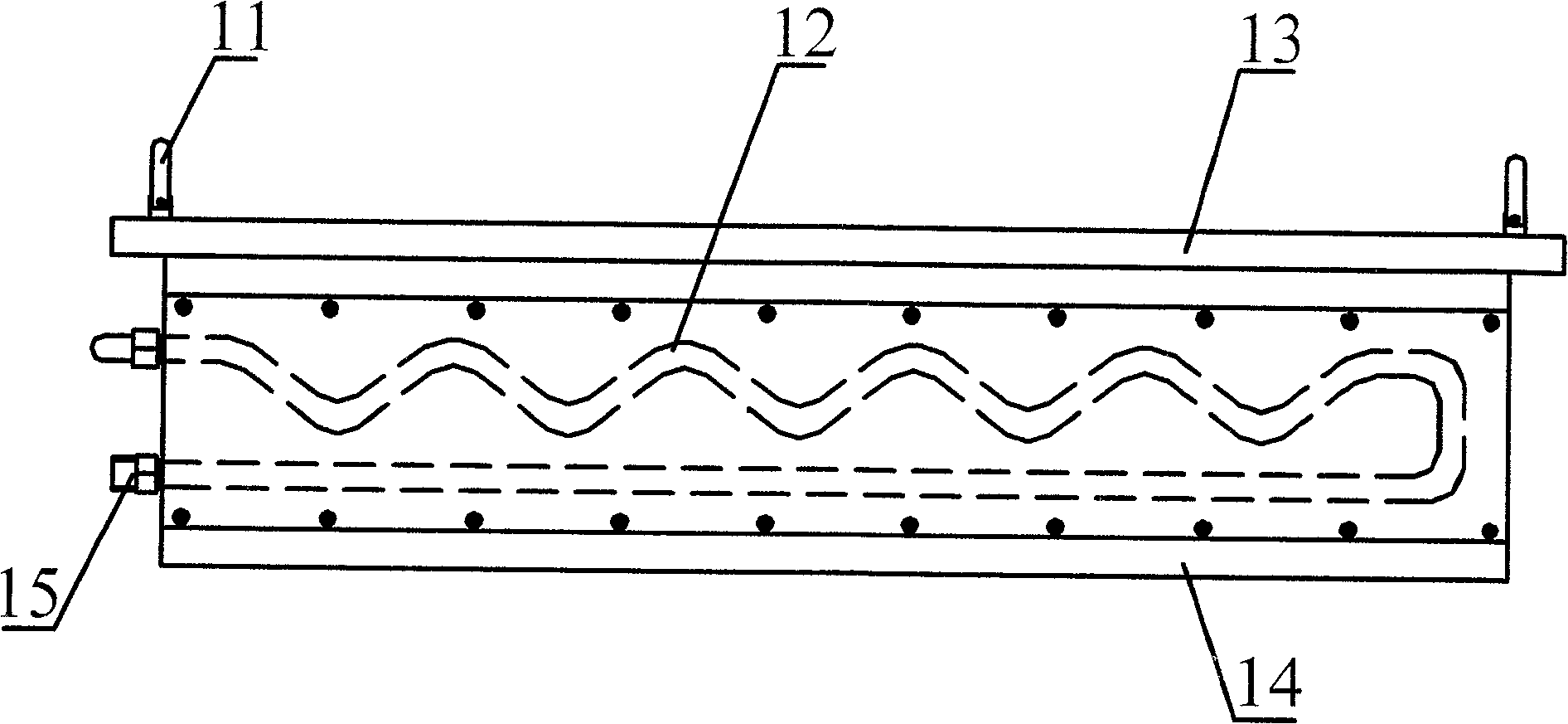

Embodiment Construction

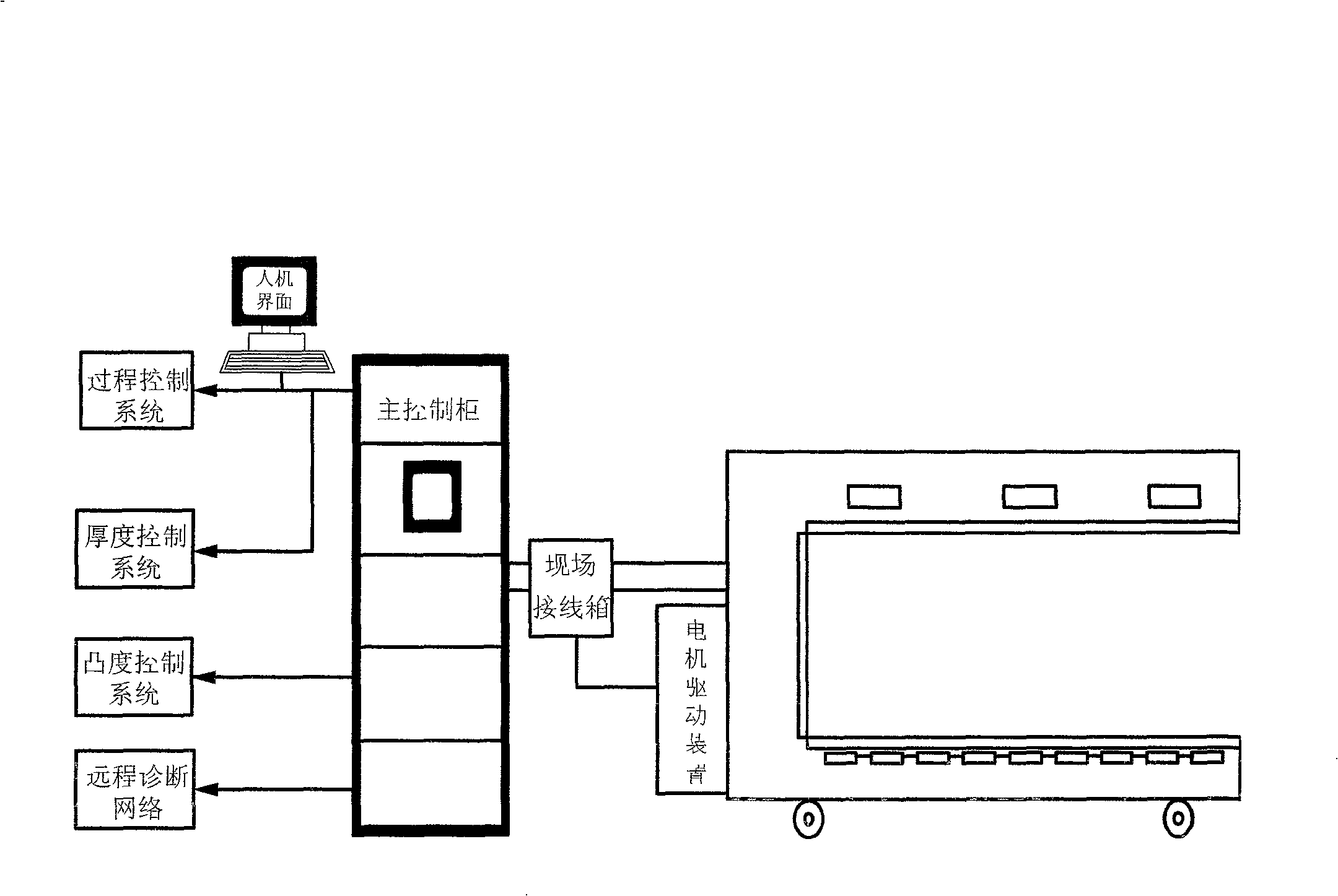

[0021] figure 1 As shown, the system configuration of the thickness / convexity measuring device mainly includes: X-ray source part, detector part, electrical control part, mechanical part, convexity detection signal processing unit, and man-machine interface part.

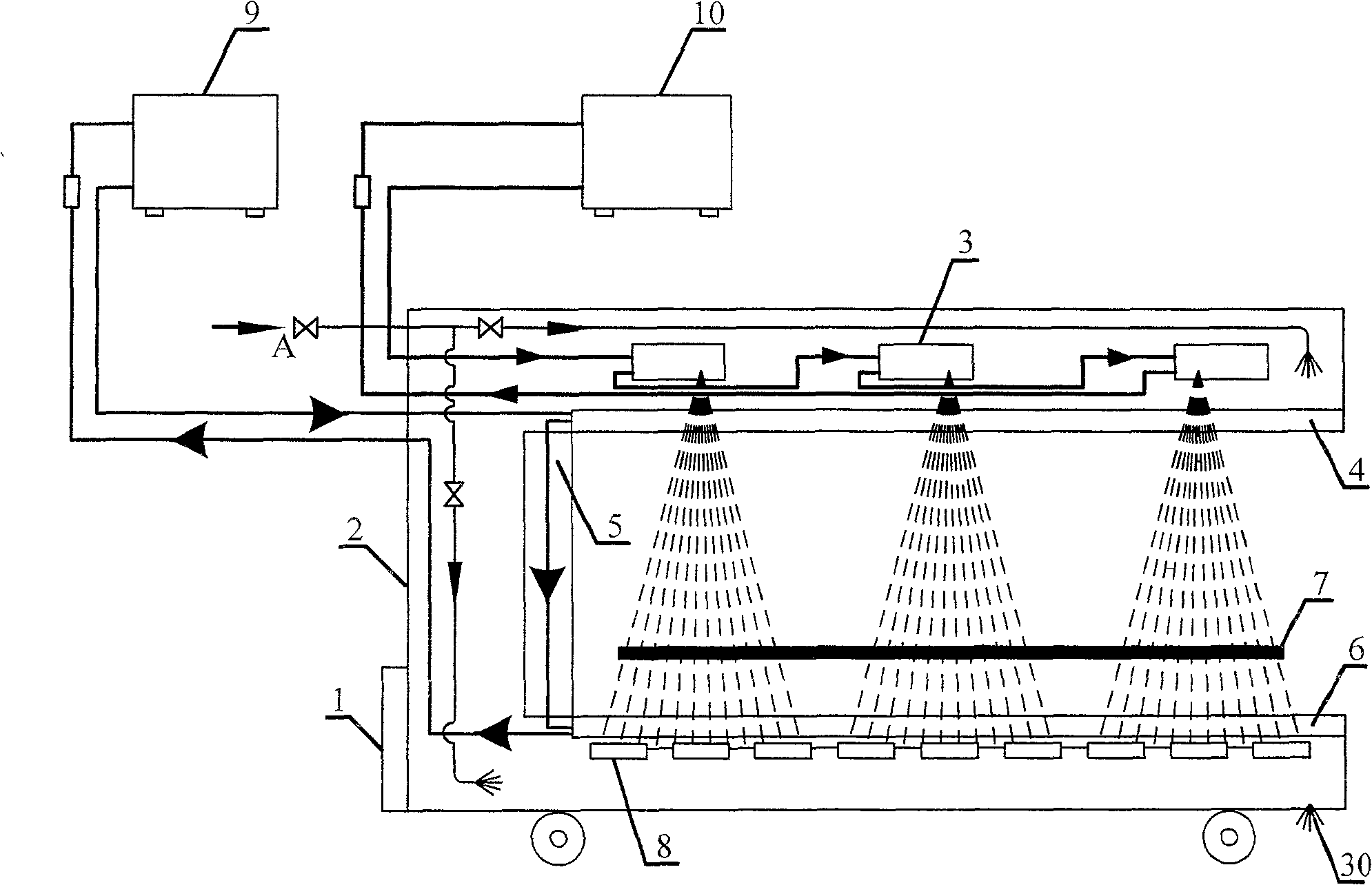

[0022] Radiometry works by using the attenuation (or absorption of radiation by the material) properties of radiation within the metal to measure the thickness of the strip. The X-ray or isotope radiation emitted by the radiation source penetrates the measured strip, and the radiation energy is partially absorbed, and the detector located on the other side of the strip measures the radiation intensity. The detector converts the detected radiation intensity signal into a current signal proportional to the thickness of the strip and outputs it to the signal processing computer, and the signal processing computer calculates the thickness of the strip to be measured.

[0023] X-ray source part: including the X-ray sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com