Low-energy-consumption aluminum alloy out-opening window

A technology of aluminum alloy and outward opening windows, applied in the direction of windows/doors, door/window fittings, wing fan layout, etc., can solve the problems of increasing the length of the handle fork, unsmooth opening and closing, and affecting the service life of hardware , to improve the opening and closing control performance, reduce indoor and outdoor convection, and meet the requirements of hardware force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

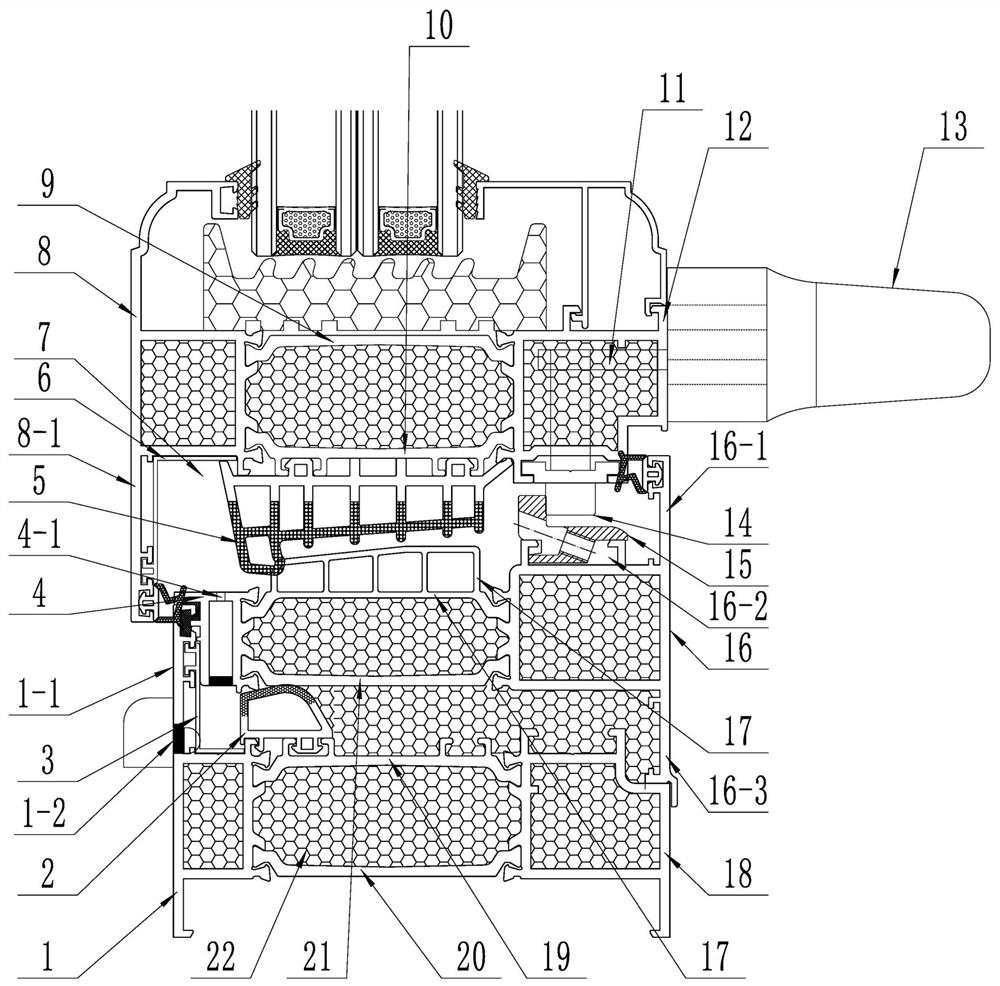

[0025] The present invention will be further described below in conjunction with the accompanying drawings and examples. The said left side of the present invention refers to the outside of the room, and the right side refers to the inside of the room.

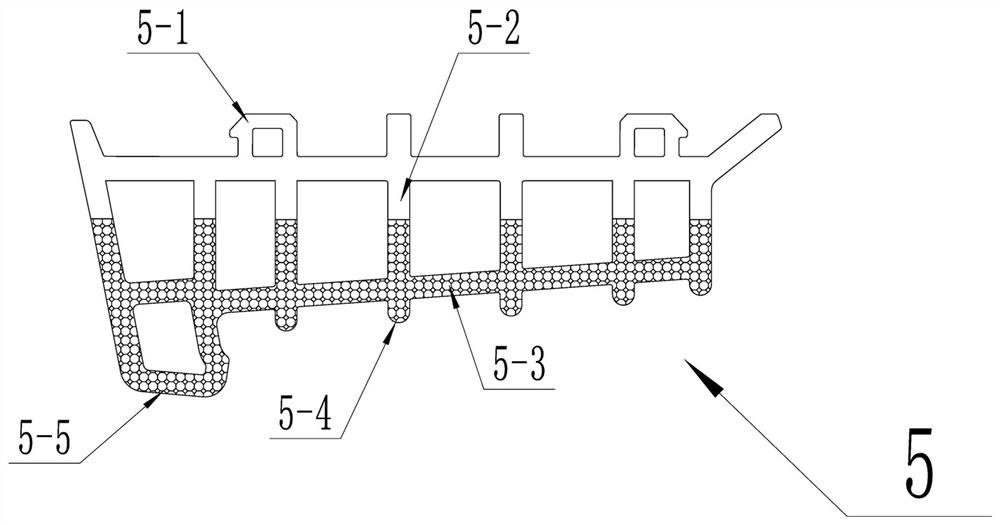

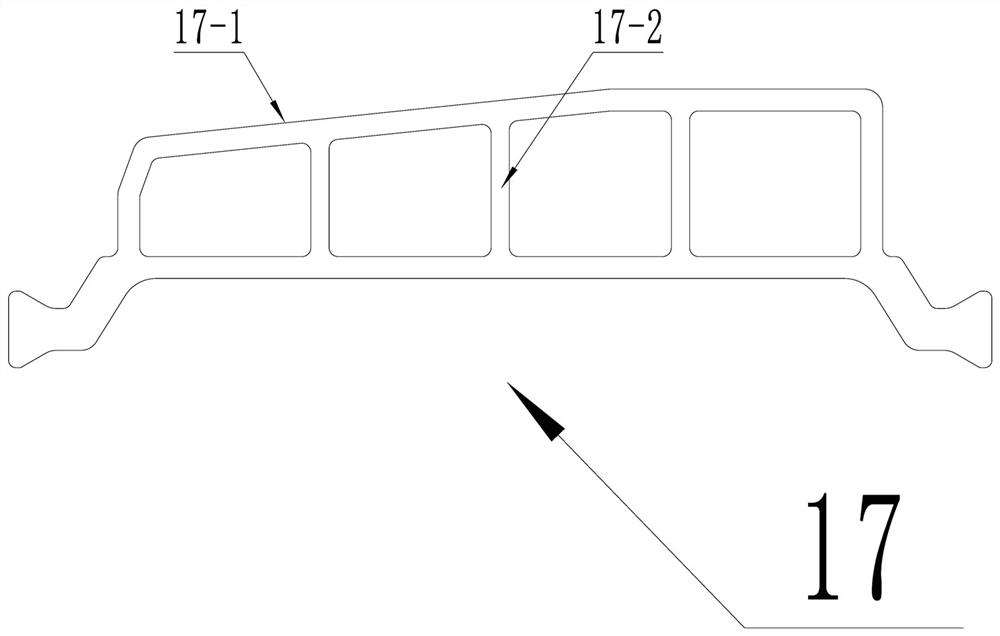

[0026] like figure 1 , the embodiment of the present invention includes the left side frame profile 1 and the right side frame profile 18 connected to each other through the frame upper heat insulation strip 19 and the frame lower heat insulation strip 20, wherein the left side frame profile 1 has a left side frame profile Up to the extension board 1-1. The embodiment of the present invention also includes a stile left profile 8 and a stile right profile 12 connected to each other through a stile upper heat insulation strip 9 and a stile lower heat insulation strip 10, wherein the outside of the stile left profile 8 has a stile The left profile extends downward to the extension plate 8-1. The lower end of the downward exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com