Matrix material for making green by planting on housetop and preparation process thereof

A base material and roof greening technology, applied in the fields of botanical equipment and methods, soilless cultivation, cultivation, etc., can solve the problems of inability to resist natural disasters, high maintenance costs, complicated procedures, etc., and improve the urban landscape and environmental energy conditions. , the effect of low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

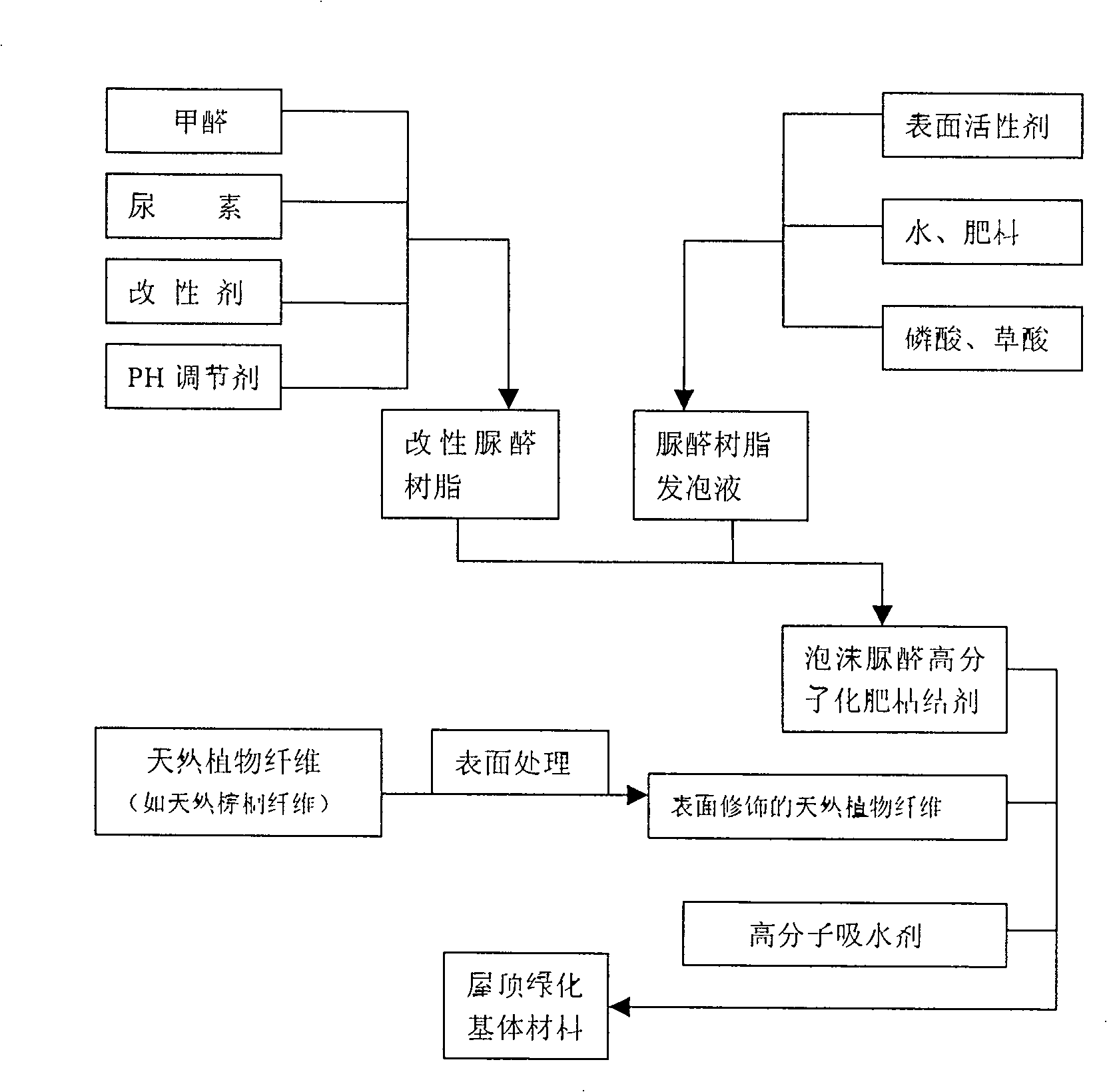

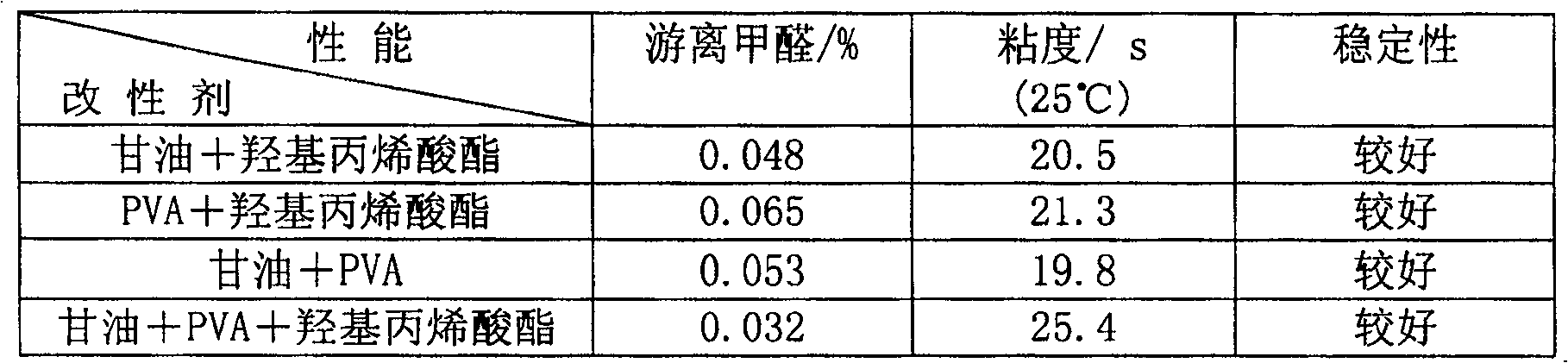

Embodiment 1

[0033] Such as figure 1 As shown, according to weak base (8.0)-weak acid (5.5)-weak base (8.0) traditional process modified synthetic urea-formaldehyde resin, wherein the weight ratio of raw material urea: formaldehyde: glycerol: hydroxy acrylate is 60: 120: 20: 15 ; In the weak base-weak acid-weak base process, the temperature is controlled at 40°C, 90°C, and 60°C respectively, and the time is controlled at 30-60min, 50-70min, and 30-45min; among them, formaldehyde is put in at one time, and urea is added in 3 times ( The mass ratio is 6:3:1), glycerin and hydroxyacrylate are added while adding the second batch of urea; the acid-base adjustment (PH regulator) in the synthesis process is formic acid and a weight concentration of 10% sodium hydroxide solution; Modified urea-formaldehyde resin was obtained.

[0034] The urea-formaldehyde resin foaming solution is composed of water, sodium dodecylbenzenesulfonate, alkyl alcohol polyoxyethylene (1-4) ammonium sulfate, potassium ...

Embodiment 2

[0041] According to weak base (7.5)-weak acid (4.5)-weak base (8.5) traditional process modified synthetic urea-formaldehyde resin, wherein the weight ratio of raw material urea: formaldehyde: polyvinyl alcohol: hydroxy acrylate is 60: 120: 3: 15; In the weak base-weak acid-weak base process, the temperature is controlled at 50°C, 85°C, and 65°C respectively, and the time is controlled at 30-60min, 50-70min, and 30-45min; among them, formaldehyde is added at one time, and urea is added in three times (mass Ratio is 4:5:1), polyvinyl alcohol and hydroxyacrylate are dropped into while adding the second batch of urea; acid-base adjustment (PH regulator) is formic acid and weight concentration is 10% sodium hydroxide solution; obtains modified Urea-formaldehyde resin.

[0042] The urea-formaldehyde resin foaming liquid is composed of water, sodium dodecylbenzenesulfonate, sodium nonylphenol polyoxyethylene (4) ether sulfate, potassium dihydrogen phosphate, potassium chloride, oxal...

Embodiment 3

[0049] According to the weak base (7.0)-weak acid (5.0)-weak base (8.5) process to modify and synthesize urea-formaldehyde resin, wherein the weight ratio of raw material urea: formaldehyde: glycerin: polyvinyl alcohol is 60: 100: 25: 4; weak base- In the weak acid-weak base process, the temperature is controlled at 60°C, 90°C, and 65°C respectively, and the time is controlled at 30-60min, 50-70min, and 30-45min; among them, formaldehyde is put in at one time, and urea is added in three times (mass ratio is 4 : 5: 1), glycerin and hydroxyacrylic acid ester are input while adding the second batch of urea; acid-base adjustment (PH regulator) is formic acid and weight concentration is 10% sodium hydroxide solution; Modified urea-formaldehyde resin is obtained.

[0050] The urea-formaldehyde resin foaming liquid is composed of water, alkyl alcohol polyoxyethylene (1-4) ammonium sulfate, nonylphenol polyoxyethylene (4) ether sodium sulfate, potassium dihydrogen phosphate, potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com