Treatment method of lime kiln smoke dust pollution

A lime kiln and smoke dust technology, which is applied in the field of smoke pollution control, can solve the problems that cannot be used in practice, smoke overflow, and the sealing of the separation device cannot be guaranteed, so as to realize automatic adjustment, improve operation intensity, and prevent smoke overflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

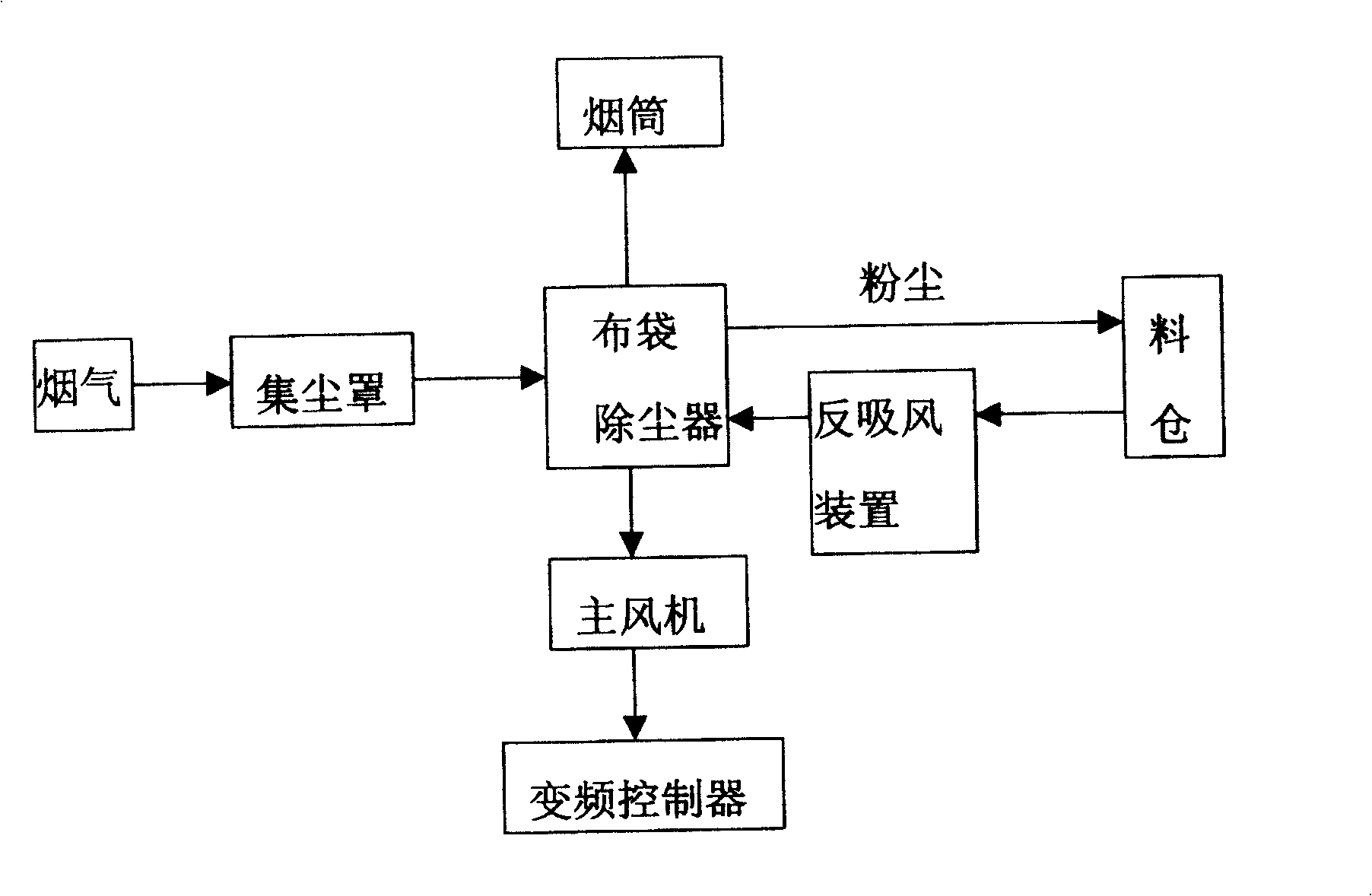

[0012] Change adjustment range: 7200m 3 / h~36000m 3 The flue gas per hour enters the bag filter through the dust collection hood, the dust and gas are separated, and the emission concentration up to the standard is ≤100mg / Nm 3 The flue gas is evacuated through the chimney. The collected dust enters the silo for recycling, and the main fan is controlled by adjusting the frequency converter to adapt to the technological operating conditions of the lime kiln. The induced air volume of the main fan is 20,000m 3 / h, by controlling the anti-suction device to ensure the pressure state of the silo, the negative pressure of the silo is 150Pa, and the smoke does not diffuse, which is compatible with the process operation, and the process operation is consistent with that when the device is not installed.

Embodiment 2

[0014] Change adjustment range: 7200m 3 / h~36000m 3 The flue gas per hour enters the bag filter through the dust collection hood, the dust and gas are separated, and the emission concentration up to the standard is ≤100mg / Nm 3 The flue gas is evacuated through the chimney. The collected dust enters the silo for recycling, and the main fan is controlled by adjusting the frequency converter to adapt to the process and operating conditions of the lime kiln. The induced air volume of the main fan is 27500m 3 / h, the pressure state of the silo is guaranteed by controlling the anti-suction device. The negative pressure of the silo is 200Pa, and the smoke does not diffuse, which is compatible with the process operation, and the process operation is consistent with that when the device is not installed.

Embodiment 3

[0016] Change adjustment range: 7200m 3 / h~36000m 3 The flue gas per hour enters the bag filter through the dust collection hood, the dust and gas are separated, and the emission concentration up to the standard is ≤100mg / Nm 3 The flue gas is evacuated through the chimney. The collected dust enters the silo for recycling, and the main fan is controlled by adjusting the frequency converter to adapt to the process and operating conditions of the lime kiln. The induced air volume of the main fan is 35000m 3 / h, the pressure state of the silo is guaranteed by controlling the anti-suction device. The negative pressure of the silo is 300Pa, and the smoke does not diffuse, which is compatible with the process operation, and the process operation is consistent with that when the device is not installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com