Collection and utilization system for waste alkaline water

A technology for recycling waste lye water and lye, which is applied in the direction of processing textile materials, equipment configuration, etc., can solve the problems of restricting enterprise development, high cost of sewage treatment and sewage discharge, and large water volume, and achieves the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples facilitate a better understanding of the present invention, but do not limit the present invention.

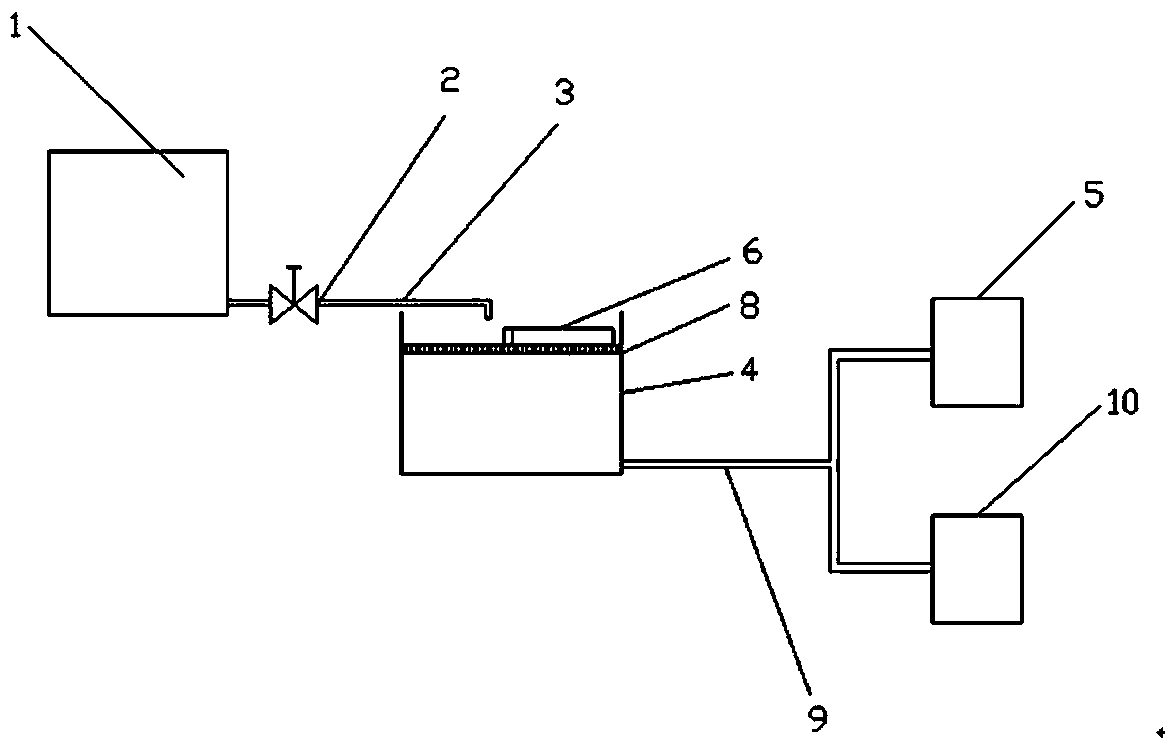

[0017] Such as figure 1 As shown, the waste alkaline water collection and utilization system in the light alkali pool of the mercerizing machine of the present invention comprises a light alkali pool 1 and an alkali recovery pool 4, and the lower end of the light alkali pool 1 is provided with an introduction pipe 3, and the alkali in the light alkali pool 1 Liquor enters lye recovery tank 4 through lead-in pipe 3, is provided with filter screen 8 in lye recovery tank 4, and filter screen 8 is the mesh structure of plane, is connected with outlet pipe 9 at the lower end of lye recovery tank 4, and the outlet tube The other end of 9 is connected with scouring machine 5 and dyeing machine 10 respectively.

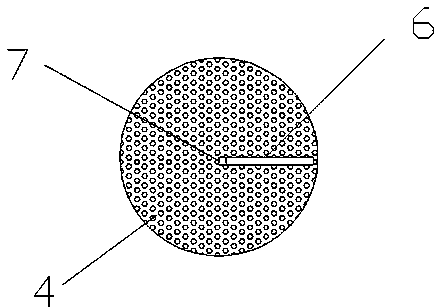

[0018] Such as figure 2 Shown, the lye recovery pool 4 of the present invention is a cylinder, and the central part of the lye recovery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com