Red copper tube bending method

A copper tube and bending technology, applied in the field of copper tube bending, can solve the problems of unreachable users and uneven wall thickness of the tube, and achieve the effect of bending and smoothing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] A copper tube bending method:

[0015] 1. Put the dry foundry scrubbing sand with a particle size of 40-80 mesh in an open iron box.

[0016] 2. Select poplar and fruit trees as the cork material. The angle of the car is 30° conical cork, and the length of the cork is 150mm.

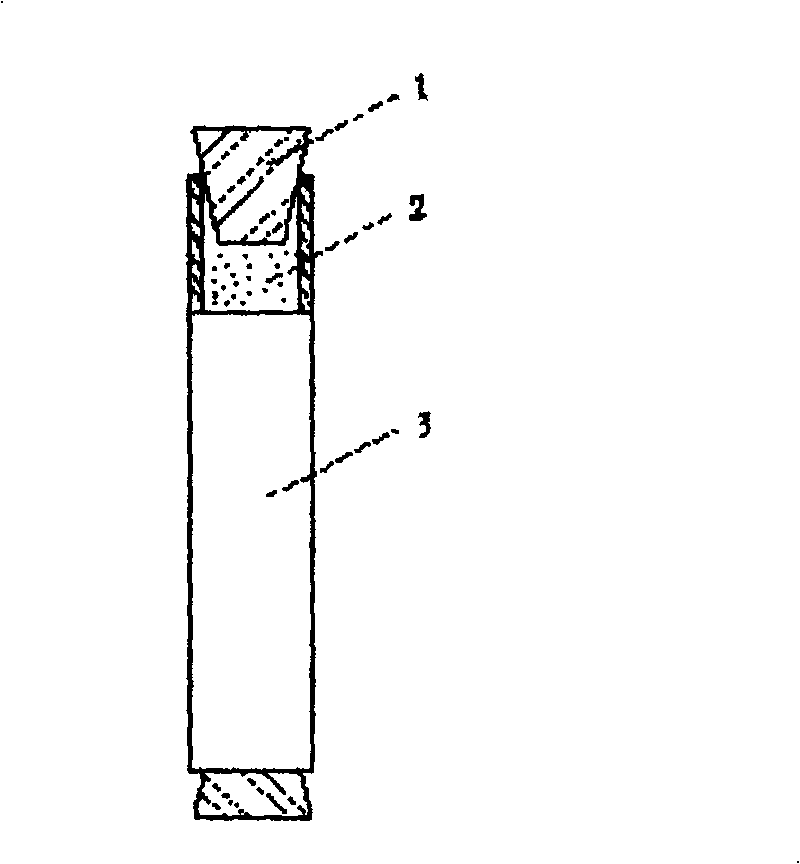

[0017] 3. Insert the lower end of the copper tube 3 with a diameter of 260 mm, a length of 5200 mm, and a wall thickness of 5 mm into the cork 1, place it upright on a multi-layer sand filling platform with a height of 6 meters, and pour it into the upper mouth of the copper tube 3 for scrubbing Sand 2, while filling, beat the copper pipe wall evenly with a wooden stick, so that the scrubbing sand 2 can be filled. When the scrubbing sand 2 is flush with the mouth of the copper tube 3, drive the cork 1 from the upper tube mouth and at the same time beat the copper tube wall evenly with a wooden stick to make the scrubbing sand 2 evenly filled. The depth of the cork 1 is about 100mm.

[0018] 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com