High frequency hydraulic power vibration tool

A hydraulic and high-frequency technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes, etc., can solve the problems of percussion tool parts that are prone to fatigue damage, unsatisfactory overall effect, and low service life. Remarkable speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

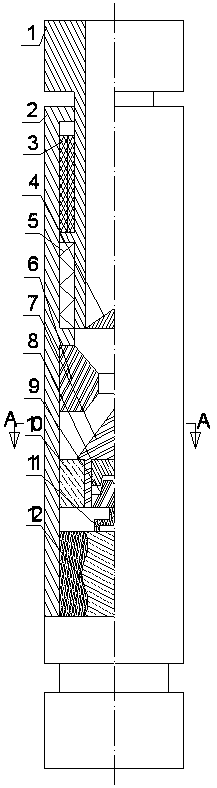

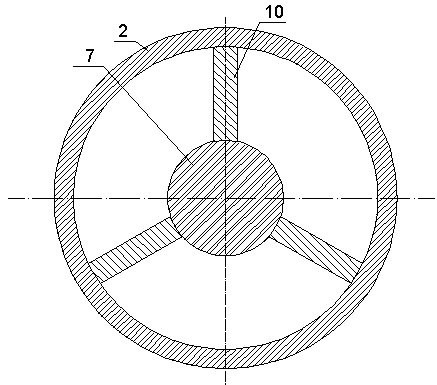

[0018] Refer to attached figure 1 and 2 , a high-frequency hydraulic vibration tool, including a central shaft 1, an outer shell 2, a spring 5, a screw motor assembly 12, a valve seat 6, a cone valve 7, an upper cam 8, a lower cam 9, ribs 10 and a connecting rod mechanism 11; wherein: a spline pair 3 is set between the central shaft 1 and the outer shell 2 to form an axial spline sliding fit; the spring 5 is installed between the central shaft 1 and the outer shell 2; the valve seat 6 is fixed on the outer shell 2 On the inner wall, and located at the lower part of the central axis 1, a rib 10 is installed between the cone valve 7 and the outer shell 2, the rib 10 and the outer shell 2 are fixedly installed, and the cone valve 7 can move axially along the rib 10; The upper cam 8 is fixedly installed inside the poppet valve 7, the lower cam 9 is installed below the upper cam 8 and is axially limited, the lower cam 9 and the upper cam 8 form a cam transmission cooperation; the ...

Embodiment 2

[0020] Such as figure 1 and 2 As shown, the high-frequency hydraulic vibration tool is mainly composed of a central shaft 1, an outer shell 2, a spline pair 3, a one-way valve 4, a spring 5, a valve seat 6, a cone valve 7, an upper cam 8, a lower cam 9, ribs Plate 10, link mechanism 11, screw motor assembly 12. The spline pair 3 is installed between the central shaft 1 and the outer casing 2, and forms a spline fit. A check valve 4 is installed on the bottom of the central shaft 1, a spring 5 is installed between the central shaft 1 and the outer casing 2, and a valve seat 6 is installed on the inner wall of the outer casing 2 and is located at the bottom of the central shaft 1. A rib 10 is installed between the poppet valve 7 and the outer casing 2 , the rib 10 and the outer casing 2 are fixedly installed, and the poppet valve 7 can move axially along the rib 10 . The upper cam 8 is fixedly installed inside the cone valve 7, the lower cam 9 is installed inside the cone val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com