Torque impactor for lever reversing valve

The technology of reversing valve and impactor is applied in drilling tools, earth-moving drilling, driving device for drilling in wellbore, etc. Achieve the effect of improving rock breaking effect and work efficiency, reasonable structure design and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

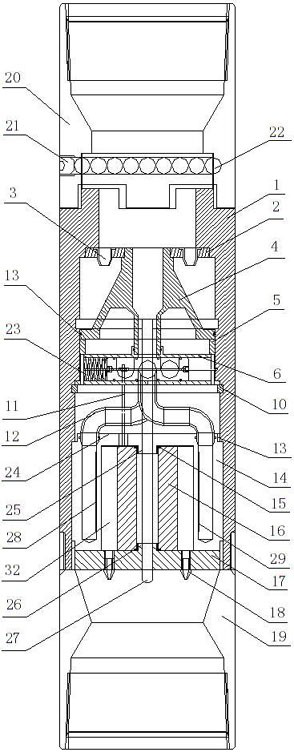

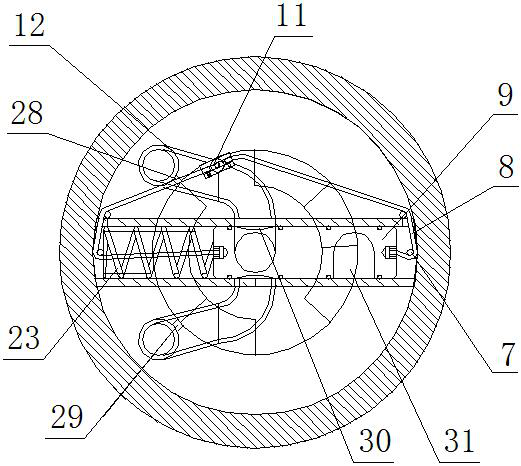

[0017] The torsion impactor of the lever reversing valve of the present invention is composed of an upper casing 1, a manifold body 19 and a lower connecting body 20, and the upper end of the upper casing 1 protrudes from a shoulder and is inserted into the groove end of the lower connecting body 20 The middle and lower ends of the hole are connected to the manifold body 19 , and the outer wall of the upper casing 1 is provided with more than one pressure relief groove 27 . The lower end of the lower connecting body 20 and the upper end of the upper housing 1 are provided with corresponding semicircular grooves, and more than one bearing steel ball 22 is arranged in the semicircular groove to play the role of bearing, and the outer part of the bearing steel ball 22 is provided with a plug 21 . The inner wall of the upper housing 1 is sequentially fixed with a diverter fixed plate 2, a reversing valve housing 6, a fixing plate 24 and a lower gland 17 from top to bottom, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com