A kind of in-situ construction method of stepped concrete

A construction method and concrete technology, which are applied in the fields of stepped structure, formwork/formwork/work frame, and on-site preparation of building components, can solve problems such as the inability to guarantee the inherent and appearance quality of cast-in-place stepped concrete at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

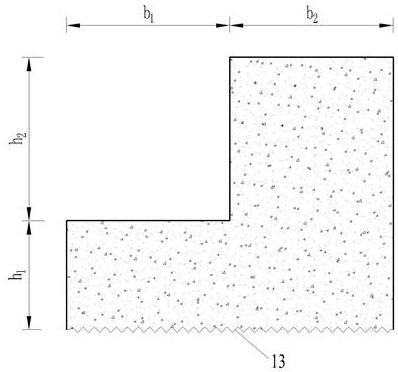

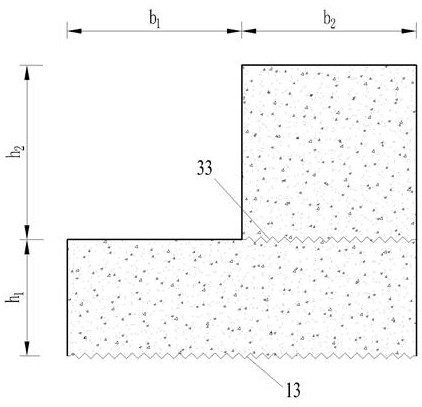

[0027] Such as Figure 5 As shown, the pouring mold assembly of stepped concrete of the present invention comprises an outer mold 2, an upper inner mold 3, a lower inner mold 1, a movable die 6, a prefabricated concrete spacer 4, a pull screw 5 and a weight block 8, and the prefabricated The concrete pad 4 is placed under the upper inner formwork 3, and the lower inner formwork 1 and the outer formwork 2, the upper inner formwork 3 and the outer formwork 2 are tensioned and fixed with the tension screw 5 respectively. The prefabricated concrete block 4 adopts small prefabricated concrete rods, and the distance between the small prefabricated concrete rods is 1-1.5m, and the pull screw 5 is covered with a hard plastic pipe and passes through the gap between the small prefabricated concrete rods. please also Figure 8 with Figure 9 As shown, after the lower concrete is put into the warehouse, vibrated and compacted, and the exposed surface is smoothed, the movable die 6 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com