Method for preparing solid self-lubricating material

A solid self-lubricating, raw material technology, applied in the direction of coating, etc., can solve the problems of limiting the strength and service life of self-lubricating parts, process equipment, process parameters, uneven particle size of metal powder, etc., to ensure compatibility and Compactness, simple preparation process, and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

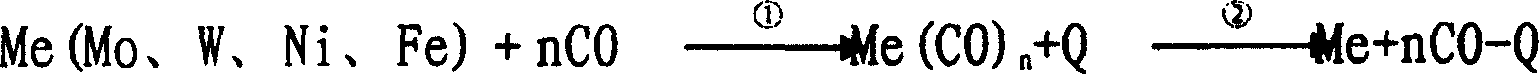

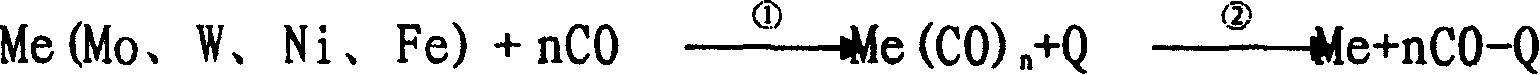

Method used

Image

Examples

Embodiment Construction

[0029] According to the chemical composition and preparation method of the raw materials used in the present invention, 6 batches of solid self-lubricating materials were prepared. According to different chemical components, they were fully mixed, and 6 batches of self-lubricating materials with different properties were prepared by using different carbonyl pyrolysis, forming and sintering process parameters. The chemical composition of the 6 batches is shown in Table 1, the process parameters of carbonyl thermal dissociation and forming sintering are shown in Table 2, and Table 3 lists the properties of the 6 batches of self-lubricating materials. The performance of the solid self-lubricating material obtained by the method is listed in Table 3, the serial number is 7#, and the embodiments of the present invention are 1-6#.

[0030]The chemical composition (weight %) of raw material used in table 1 embodiment of the present invention

[0031] batch number

Cu

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com