Technology of preparing ammonium phosphide using solid liquid reextraction method

An ammonium phosphate and process technology, which is applied in the field of preparing solid ammonium phosphate compound fertilizer from wet-process phosphoric acid, can solve the problem of no fundamental change or improvement in technical and economic indicators, achieve comprehensive technical and economic indicators improvement, simplify process flow and shorten process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The wet-process phosphoric acid obtained by the sulfuric acid method is used as raw material, and the composition of the wet-process phosphoric acid:

[0038] P 2 o 5 18.9%, Fe 2 o 3 0.48%, Al 2 o 3 0.88%,

[0039] Mg 1.37%, F 1.31%, SO 3 1.8%,

[0040] Take 120g of the above-mentioned wet-process phosphoric acid, according to the volume ratio of tributyl phosphate and co-solvent 260# kerosene as 1:1, measure 400ml×2 composite extractant for three-stage countercurrent extraction, and the extraction temperature is controlled at 32-45°C. After the extraction, the terminal raffinate aqueous phase contains a small amount of white solid, after separation, the liquid phase removes the original acid system, and the solid phase mixture contains effective P 2 o 518.13% is used as agricultural fertilizer. After the extraction, the extracted oil phase enters the washing reactor and is washed with phosphoric acid with a weight concentration of 20%. The was...

Embodiment 2

[0042] Get the calcium chlorphosphate 140g (wherein P 2 o 5 Content is 27.07%, CaO 26.41%), industrial hydrochloric acid 100ml and the washing acid 28ml that last circulation returns enter acid hydrolysis tank together and make hydrochloric acid method wet-process phosphoric acid. Take 140ml of the filtered wet-process phosphoric acid, and use the compound extractant liquid-liquid three-stage extraction. The temperature of the extraction process was controlled at 32-45° C., and all subsequent steps after the extraction were completed were exactly the same as in Example 1, and finally 49 g of the ammonium phosphate product was obtained, of which effective P 2 o 5 43.61%, N content 13.18%, moisture 2.21%.

[0043] The material in the process is completely closed loop, and there are no emissions.

Embodiment 3

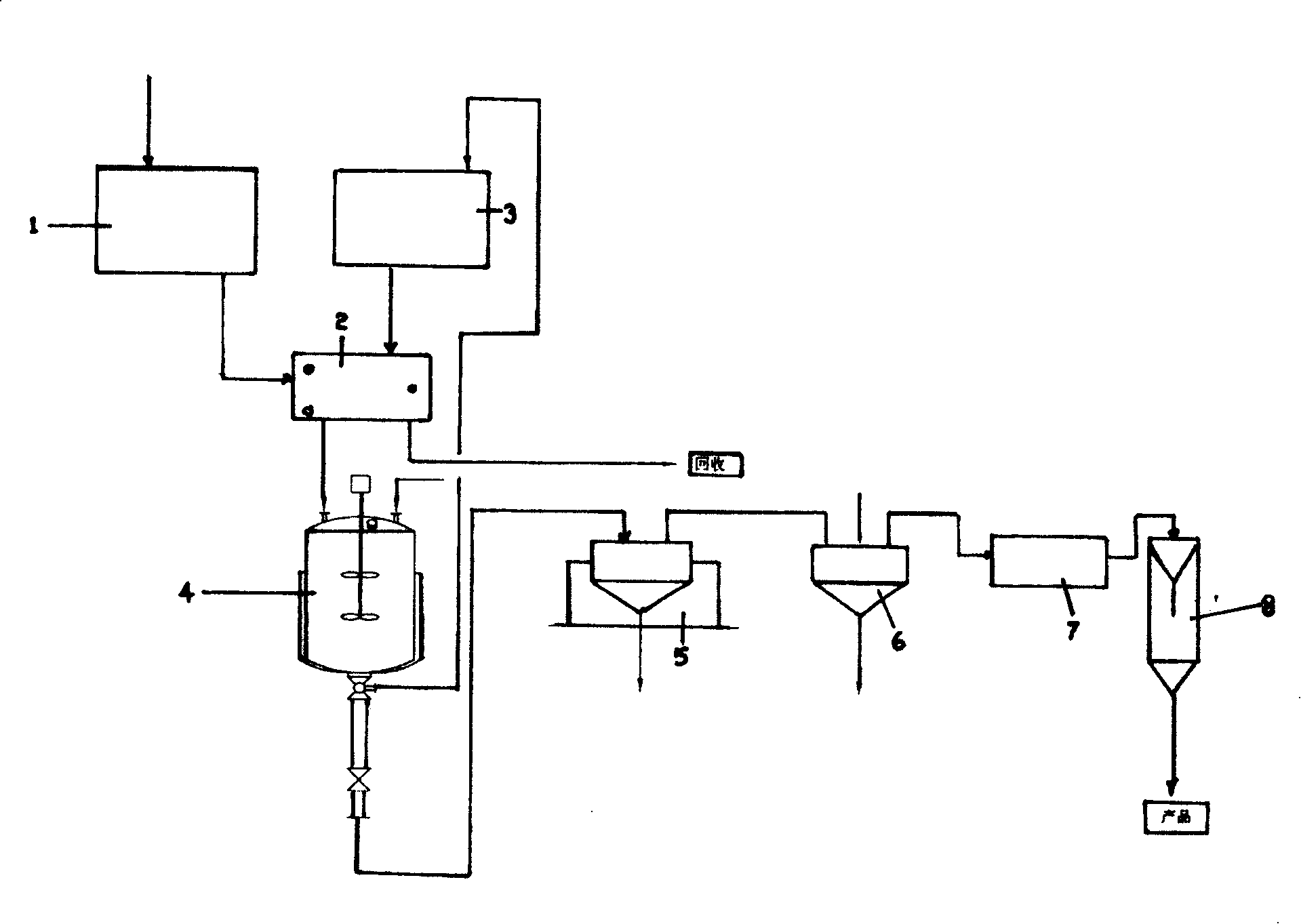

[0045] The process of preparing ammonium phosphate by solid-liquid back extraction method, such as figure 1 As shown, it includes the following steps:

[0046] 1), preparation of compound extractant:

[0047] The main material composition of the composite extractant is tributyl phosphate and co-solvent 260# kerosene. The volume ratio of tributyl phosphate and co-solvent 260# kerosene is 1:3.

[0048] 2), wet-process phosphoric acid concentration adjustment:

[0049] Wet-process phosphoric acid produced by hydrochloric acid method, the acid content in wet-process phosphoric acid is 15%, P 2 o 5 The content is 10%; the wet-process phosphoric acid is put into the head tank 1 of the wet-process phosphoric acid.

[0050] 3), liquid-liquid extraction:

[0051] The well-prepared composite extractant and the adjusted wet-process phosphoric acid enter from the light phase inlet and the heavy phase inlet of the three-stage countercurrent continuous sedimentation extractor 2 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com