Process for preparing polymeric aluminium chloride through dimensionally stable anodes

A technology of polyaluminum chloride and aluminum trichloride, which is applied in the direction of electrolytic components and electrolytic processes, can solve the problems of aluminum material consumption and production costs, and cannot meet the needs of large-scale production, so as to save production costs, and the preparation process is easy to control. The effect of low process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

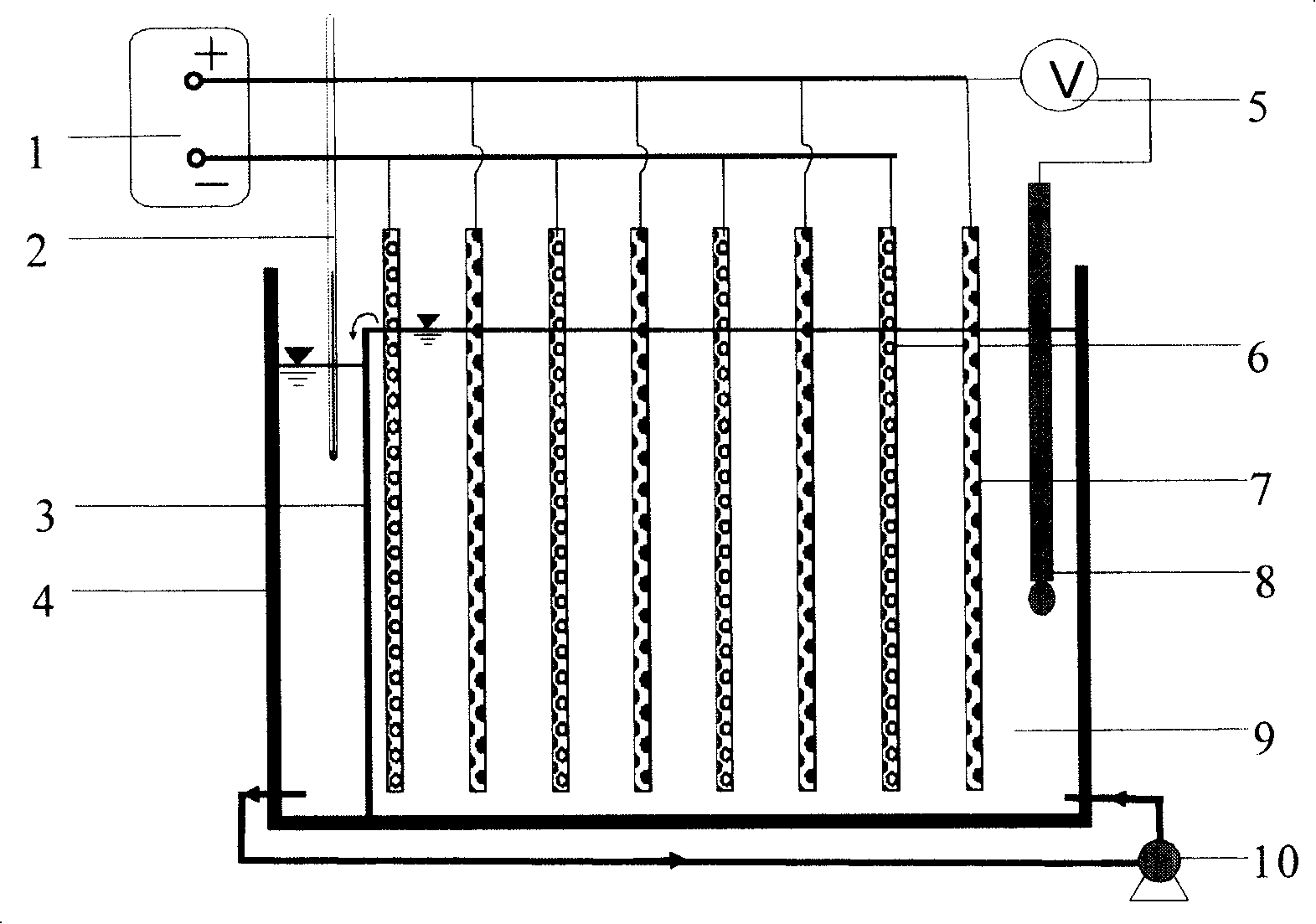

[0032] As shown in the accompanying drawing, in a plexiglass electrolytic cell with a volume of 1 L, 0.8 L of 0.5 mol / L aluminum trichloride electrolyte is added, and the electrolytic preparation is carried out under the following conditions.

[0033] Anode: ruthenium titanium mesh, the effective electrode area is 5.4dm 2 (60mm×90mm)

[0034] Cathode: Titanium mesh, the effective electrode area is 5.4dm 2(60mm×90mm)

[0035] Power supply: DC stabilized voltage stabilized current power supply

[0036] Voltage: 4.0~5.0V

[0037] Temperature: 15~40℃

[0038] Pole spacing: 15mm

[0039] Current density: 1.0A / dm 2

[0040] Electrolysis time: 8 hours

[0041] Electrode connection mode: 4 sets of electrodes connected in unipolar parallel

[0042] After electrolysis, the product is analyzed, the main indicators are as follows:

[0043] Total aluminum concentration: 0.56mol / L

[0044] Al 13 Content: 85.2%

[0045] Available chlorine content: 1720ppm

[0046] Alkalinity: 2...

Embodiment 2

[0049] As shown in the accompanying drawing, in a plexiglass electrolytic cell with a volume of 1 L, 0.8 L of 0.80 mol / L aluminum trichloride electrolyte is added, and the electrolytic preparation is carried out under the following conditions.

[0050] Anode: ruthenium titanium mesh, the effective electrode area is 5.4dm 2 (60mm×90mm)

[0051] Cathode: Titanium mesh, the effective electrode area is 5.4dm 2 (60mm×90mm)

[0052] Power supply: DC stabilized voltage stabilized current power supply

[0053] Voltage: 3.5~4.5V

[0054] Temperature: 15~45℃

[0055] Pole spacing: 10mm

[0056] Current density: 1.2A / dm 2

[0057] Electrolysis time: 15 hours

[0058] Electrode connection mode: 4 sets of electrodes connected in unipolar parallel

[0059] After electrolysis, the product is analyzed, the main indicators are as follows:

[0060] Total aluminum concentration: 1.06mol / L

[0061] Al 13 Content: 86.2%

[0062] Available chlorine content: 1510ppm

[0063] Alkalinity...

Embodiment 3

[0066] As shown in the accompanying drawing, in a plexiglass electrolytic cell with a volume of 1 L, add 0.8 L of 1.0 mol / L aluminum trichloride electrolyte, and perform electrolytic preparation under the following conditions.

[0067] Anode: ruthenium titanium mesh, the effective electrode area is 54dm 2 (60mm×90mm)

[0068] Cathode: Titanium mesh, the effective electrode area is 5.4dm 2 (60mm×90mm)

[0069] Power supply: DC stabilized voltage stabilized current power supply

[0070] Voltage: 3.0~4.0V

[0071] Temperature: 15~45℃

[0072] Pole spacing: 15mm

[0073] Current density: 1.5A / dm 2

[0074] Electrolysis time: 20 hours

[0075] Electrode connection mode: 4 sets of electrodes connected in unipolar parallel

[0076] After electrolysis, the product is analyzed, the main indicators are as follows:

[0077] Total aluminum concentration: 1.27mol / L

[0078] Al 13 Content: 72.3%

[0079] Available chlorine content: 1100ppm

[0080] Alkalinity: 1.84

[0081] p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com