Processing method of mixed fiber extruded sectional materials for civil engineering

A hybrid fiber, pultruded profile technology, applied in the field of fiber pultruded profiles and processing, can solve the problems of limited wide application and research, poor interlayer anti-cutting ability, low stiffness, etc., to improve the interlayer shear resistance, The effect of saving engineering costs and reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

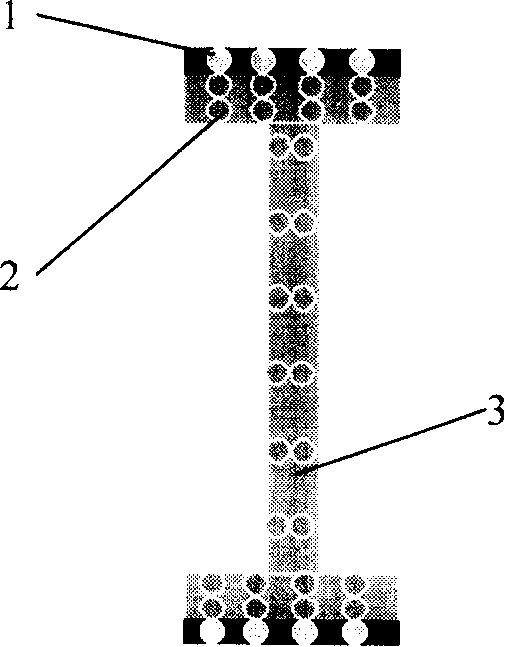

Image

Examples

Embodiment 1

[0012] Formula: 6% carbon fiber, 54% glass fiber, 30% epoxy vinyl modified resin, 10% fly ash; after mixing, pultrusion process is carried out, and the pultrusion temperature is controlled between 120-140°C, generally 130 °C is better, too low temperature will make the bonding performance between different fibers poor, seriously affecting the mechanical properties of the profile, and too high temperature will cause an initial temperature inside the profile due to the difference in expansion coefficient between carbon fiber and glass fiber The pressure seriously affects the mechanical properties of the profile, which must be paid attention to during processing; the pultrusion speed is controlled at 0.5-1.5 m / min, generally 1.0 m / min is better, if the speed is too fast, there is no gap between the fiber and the resin. Adequate bonding will seriously affect the mechanical properties of the profile. If the speed is too low, the production speed will be reduced and economic benefits...

Embodiment 2

[0015] Formula: 12% carbon fiber, 48% glass fiber, 30% epoxy vinyl modified resin, 10% fly ash. Others are the same as embodiment 1.

Embodiment 3

[0017] Formula: 20% carbon fiber, 50% glass fiber, 30% epoxy vinyl modified resin, 0% fly ash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com