Vortex compressor with oil adjusting function

A scroll compressor and functional technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problem of difficulty in forming an oil film with sufficient thickness, the oil pressure cannot be increased to a certain extent, and the compressor can be reduced. performance and other issues to reduce friction and heat generation, promote cooling and lubrication, and increase oil film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0023] In the following description, the same parts as those of the aforementioned existing scroll compressor are described with the same serial numbers.

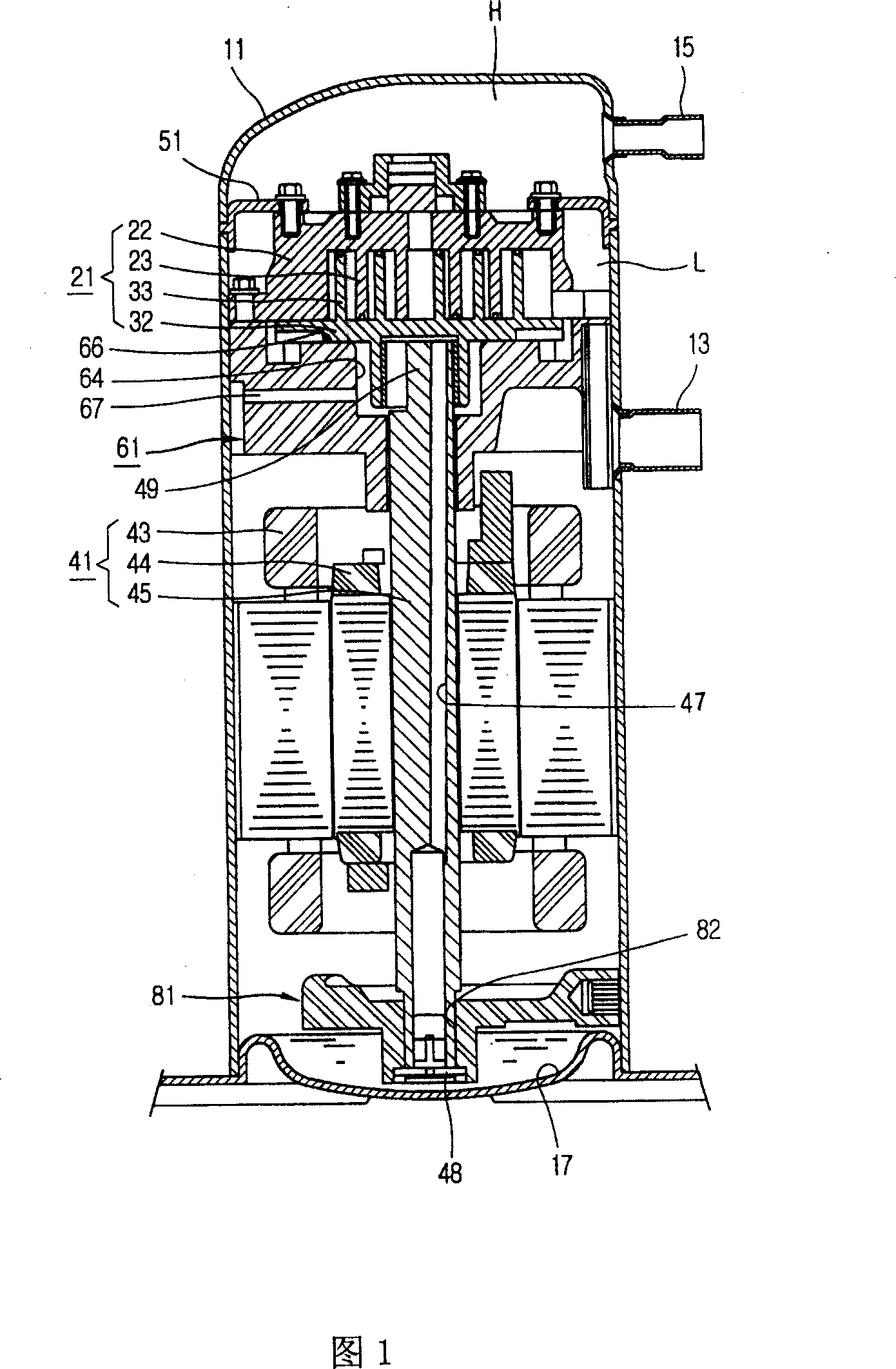

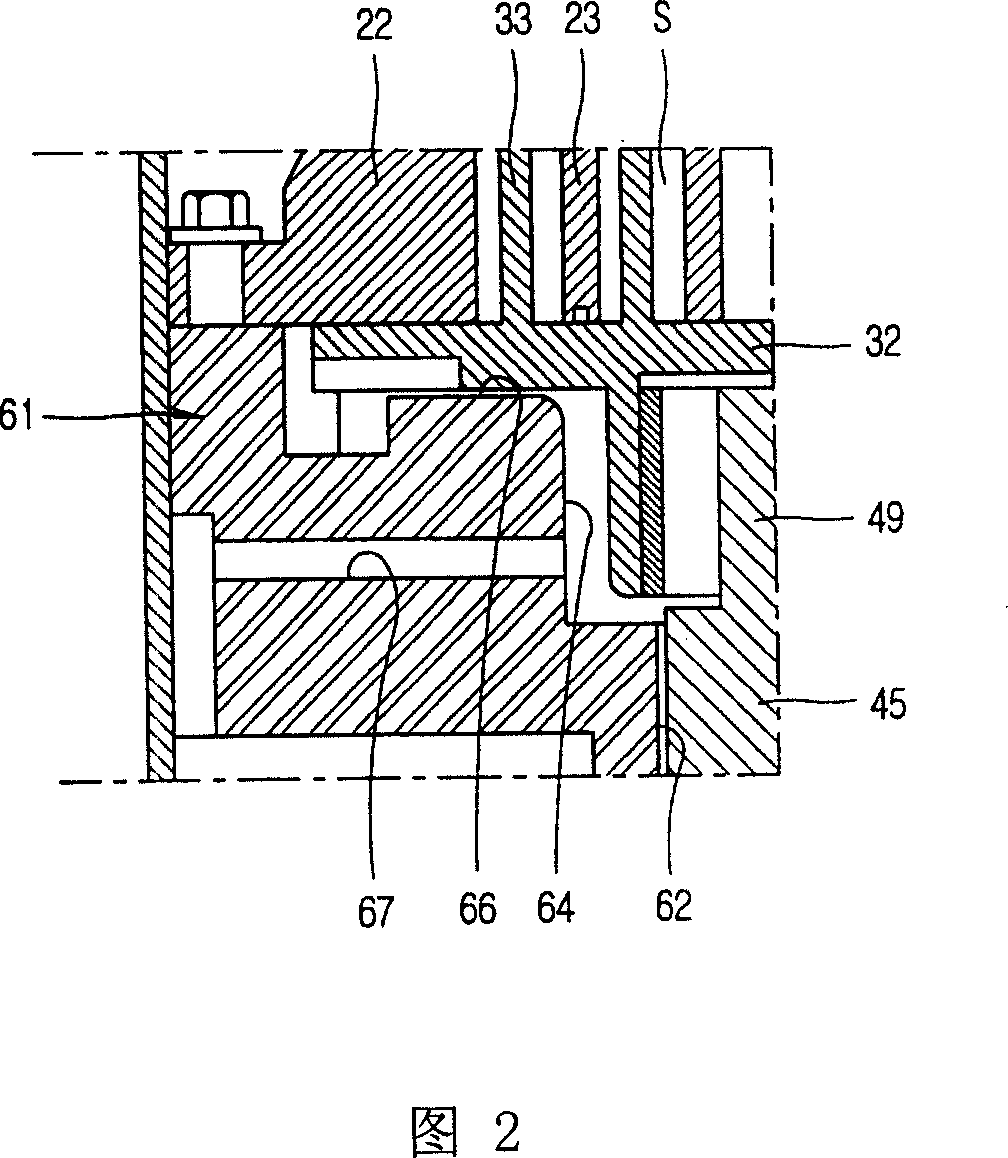

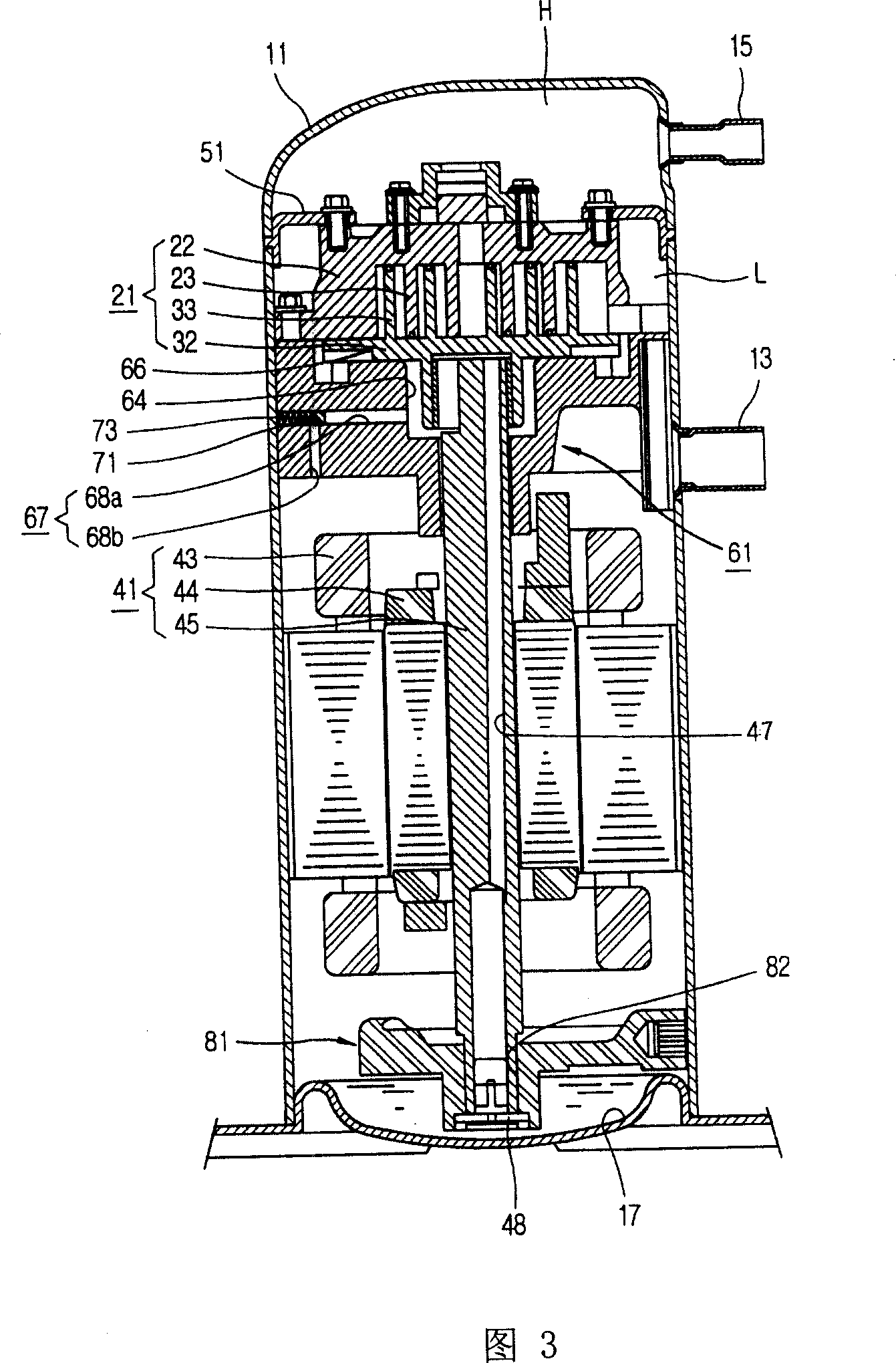

[0024] As shown in Figures 3 to 5, the present invention is a scroll compressor with an oil regulating function, and its structure includes a shell 11 with a sealed space formed inside; a fixed scroll 22 fixed inside the shell 11; Relatively moving relative to the fixed scroll and combined to form the movable scroll 32 that compresses the refrigerant; the movable scroll is arranged along the up and down direction of the casing 11 to make the movable scroll move eccentrically, and there is an oil supply passage 47 inside to supply the oil in the lower part of the casing to the upper oil supply passage 47 The rotating shaft 45; the surface in contact with the movable scroll 32 is the bearing surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com