Mechanical stepless speed gear with equal angular speed and shape-position and high gear ratio

A continuously variable transmission, constant angular velocity technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of large slip rate, high manufacturing cost, narrow speed change range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

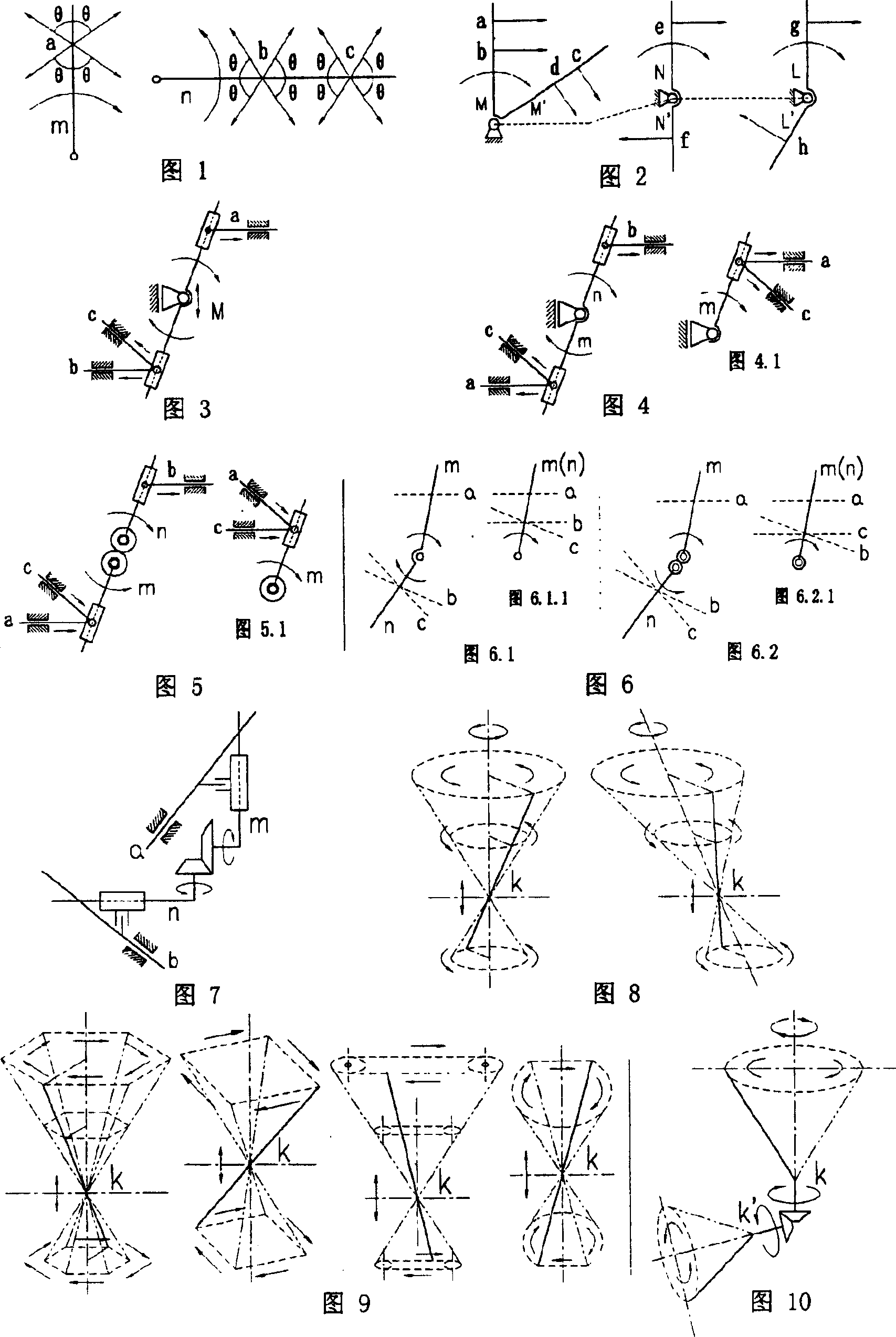

Method used

Image

Examples

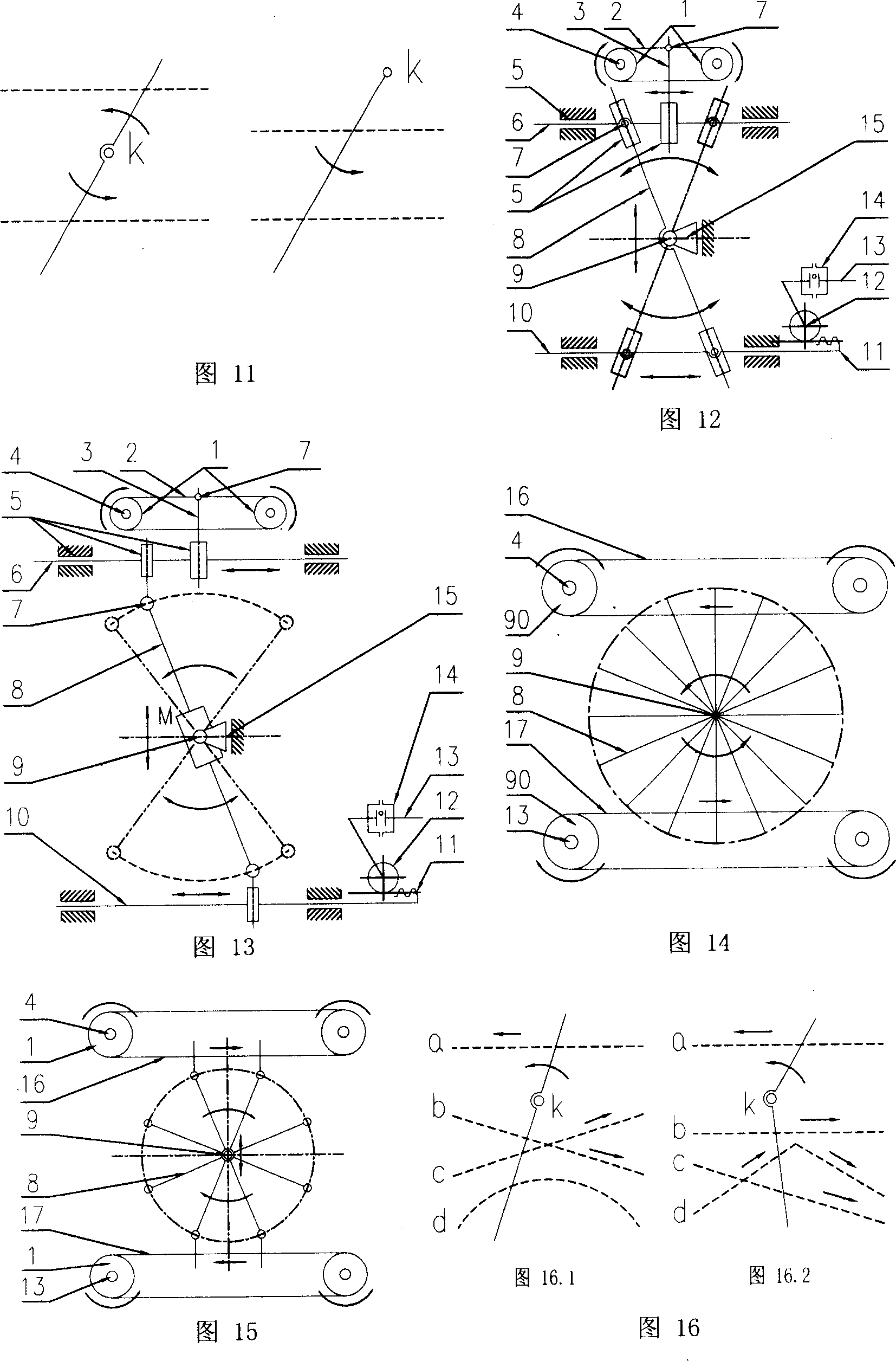

Embodiment Construction

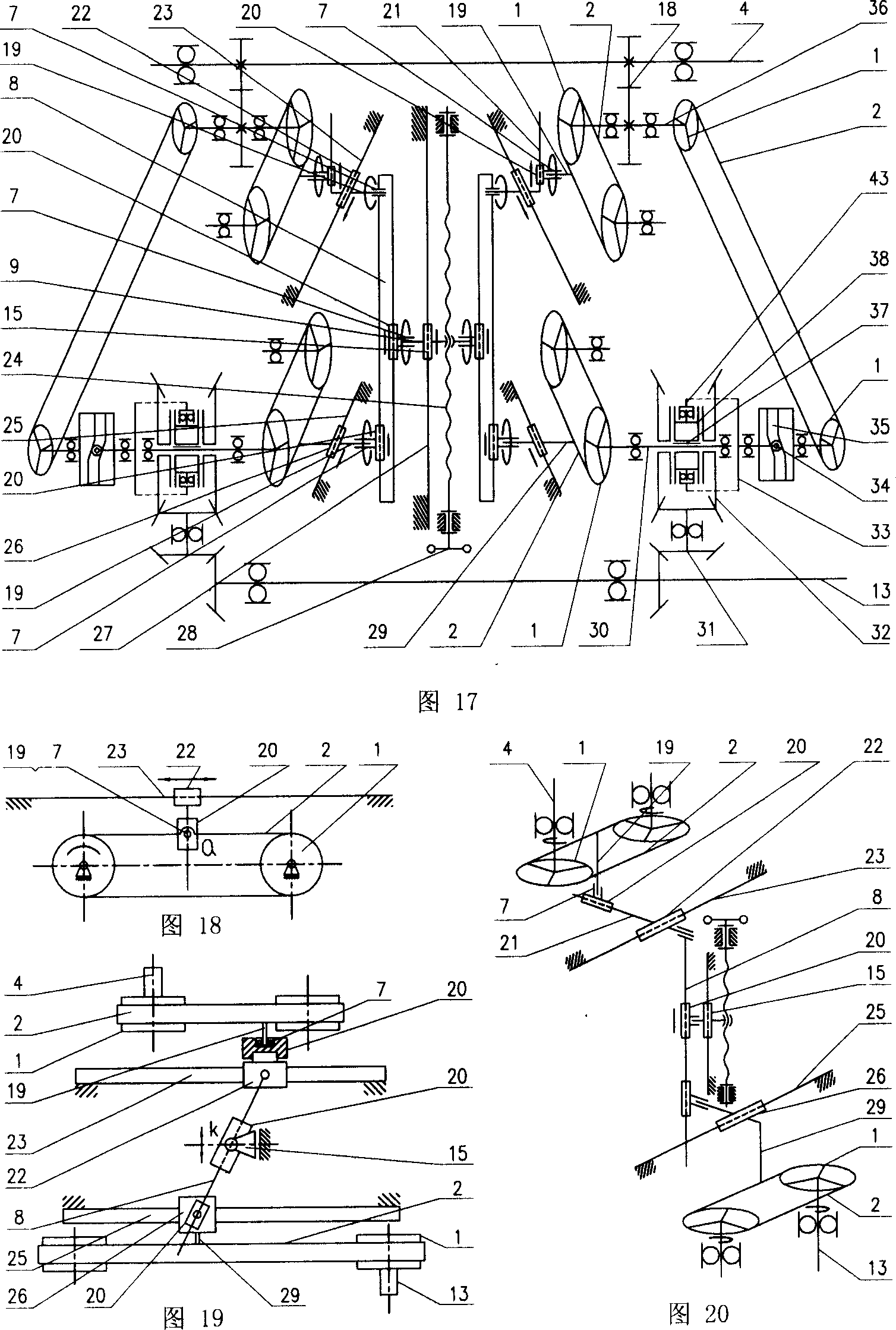

[0143]Figure 17 shows: the schematic diagram of the reciprocating zero-crossing continuously variable transmission with equal angular velocity and the same shape For direction drawing, please refer to detailed figure 21 for relevant details; Note 2: The direction of the arrow in the figure only represents the type of motion (the curved arrow represents rotation; the straight arrow represents translation), and does not represent the specific working motion direction). This type of transmission consists of: input shaft, output shaft, input and output rotary / reciprocating linear motion conversion mechanism, input and output speed lock pillow, input and output speed lock track, gear lever, speed control block, speed control track, screw nut It is composed of speed regulating device, selective flow clutch, roller, cam control device and other main components. The connection and transmission process of power flow is completed through a series of motion transmission parts. The auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com