Aluminum alloy for plastic working and manufacturing method thereof

A technology of plastic working and aluminum alloy, applied in metal processing equipment and other directions, can solve problems such as foaming, and achieve the effect of inhibiting re-adsorption, excellent ductility, and proper plastic workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

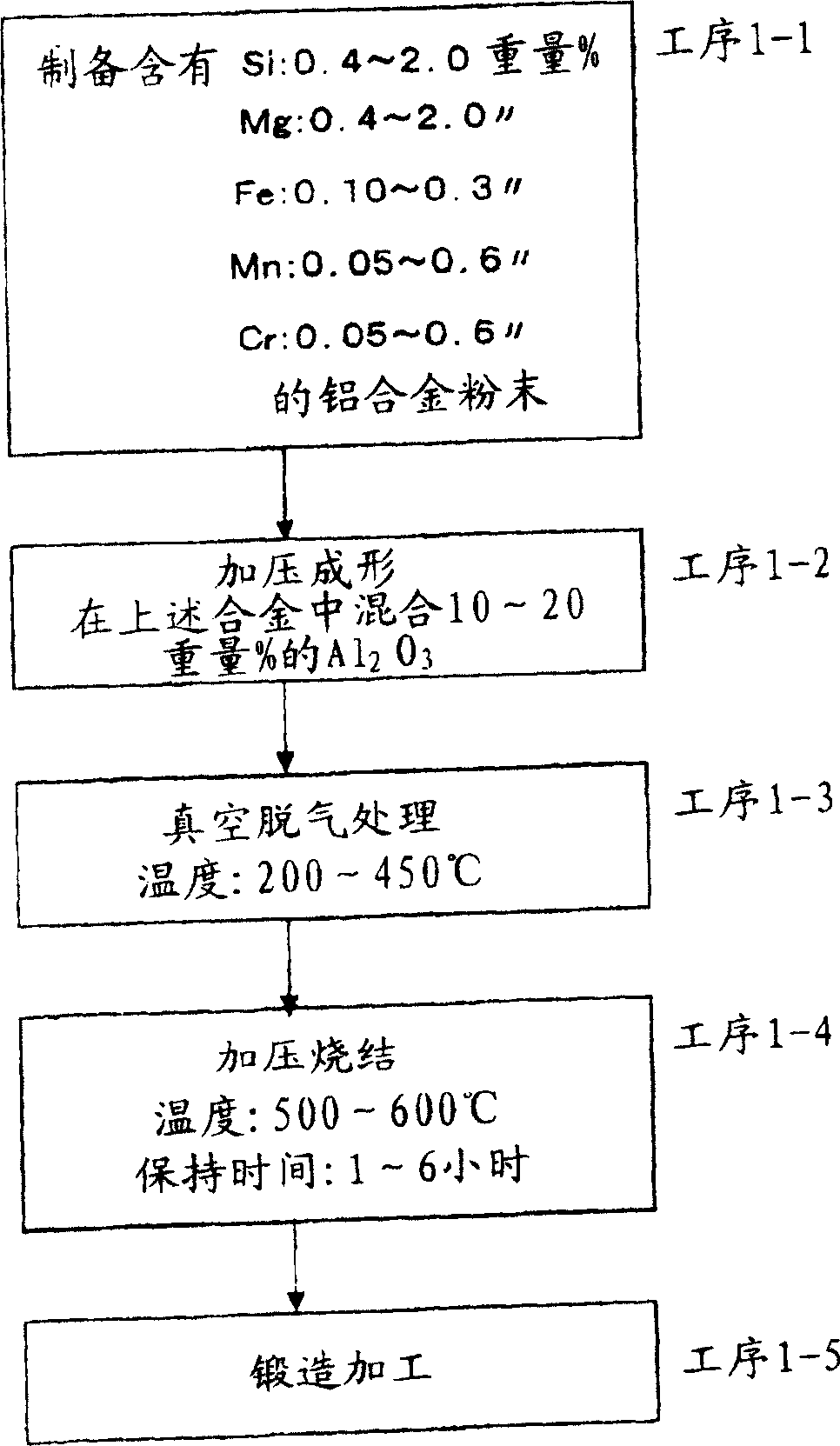

[0019] Hereinafter, the best embodiment of the method for producing an aluminum alloy for plastic working according to the present invention will be described in detail with reference to FIG. 1 .

[0020] First, by weight % (hereinafter only expressed in %), prepare Si: 0.4 to 2.0% (for example, 0.8%), Mg: 0.4 to 2.0% (for example, 1.0%) and a total of 0.5 to 2.0% selected from Fe, Mn , one or more than one of Cr (eg Fe: 0.15%, Mn: 0.05%, Cr: 0.3%), and the balance is an aluminum alloy rapidly solidified powder composed of Al containing unavoidable impurities (process 1-1 , aluminum alloy powder preparation process). As the method for preparing the rapidly solidified powder, it can be carried out according to well-known manufacturing methods such as the spray method, the ultra-rapid solidification method (Meltspinning method), the rotating disk method, and the rotating electrode method. From the viewpoint of being suitable for industrial production, the spray method (especiall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com