Alloy-style temperature fuse

A thermal fuse, alloy type technology, used in emergency protection devices, structural parts, electrical components, etc., can solve the problems of poor oxidation resistance and flowability, and the alloy wire composition cannot work normally, so as to improve the overall performance and oxidation resistance. And the effect of excellent flowability and good temperature fusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

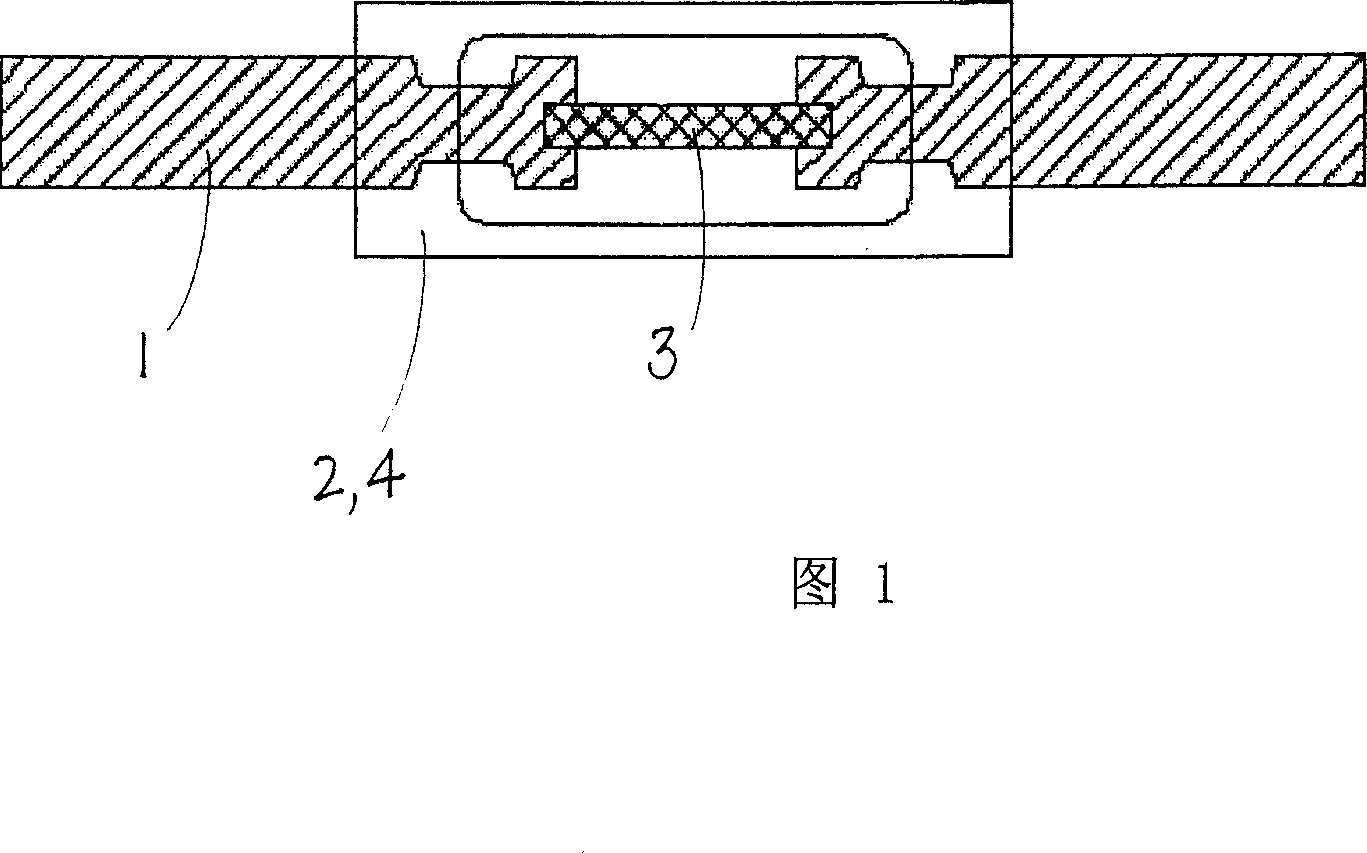

[0032] Referring to Fig. 1, the alloy type thermal cutoff of the present invention comprises electrode connecting piece 1, plastic base film 2 and alloy wire 3, is compounded with the plastics of bonding performance higher than and melting point lower than plastic base film on plastic base film 2 Membrane 4, wherein, the electrode connecting piece is made of nickel, copper, aluminum or the alloy that above-mentioned metal forms, and the thickness of electrode connecting piece is 100um in this example, and its surface with plastic base film 2 and plastic upper film 4 is provided with The copper metal layer can improve the welding performance of the electrode connecting piece and the low melting point alloy wire. The plastic bottom film 2 and the plastic upper film 4 are made of PET (polyethylene terephthalate), PBT (polybutylene terephthalate), PC (polycarbonate), ABS (acrylonitrile-butadiene- Styrene copolymer), PS (polystyrene) and other engineering plastic composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com