Shell and tube type heat exchanger having shell side multi path parallel flow inlet and outlet structure

A technology of shell-and-tube heat exchanger and side outlet, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., which can solve the problem of increased fluid baffle dead zone, good heat transfer performance, and heat exchanger Low operating energy consumption and other issues, to achieve the effect of reducing the flow dead zone, improving heat transfer performance, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

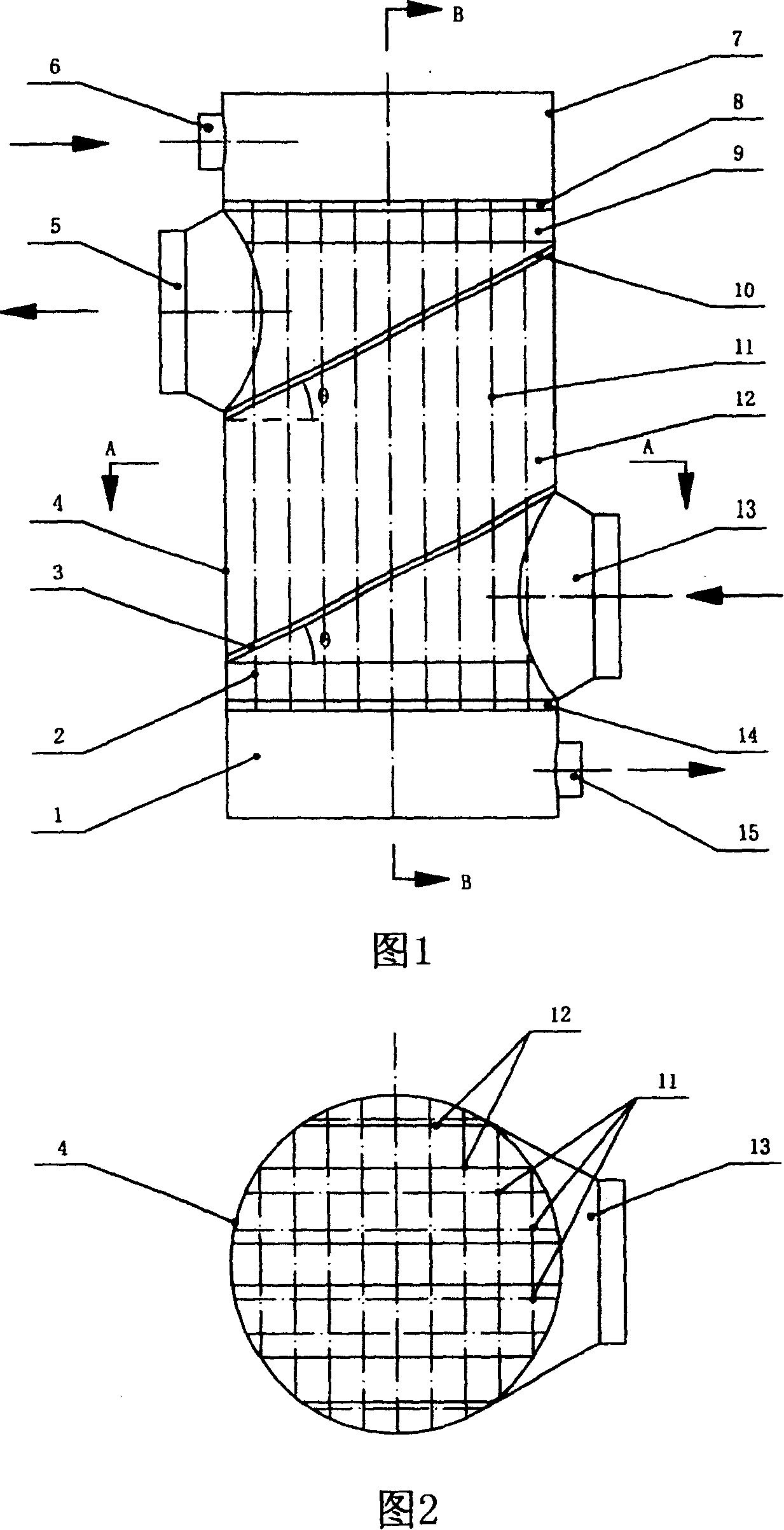

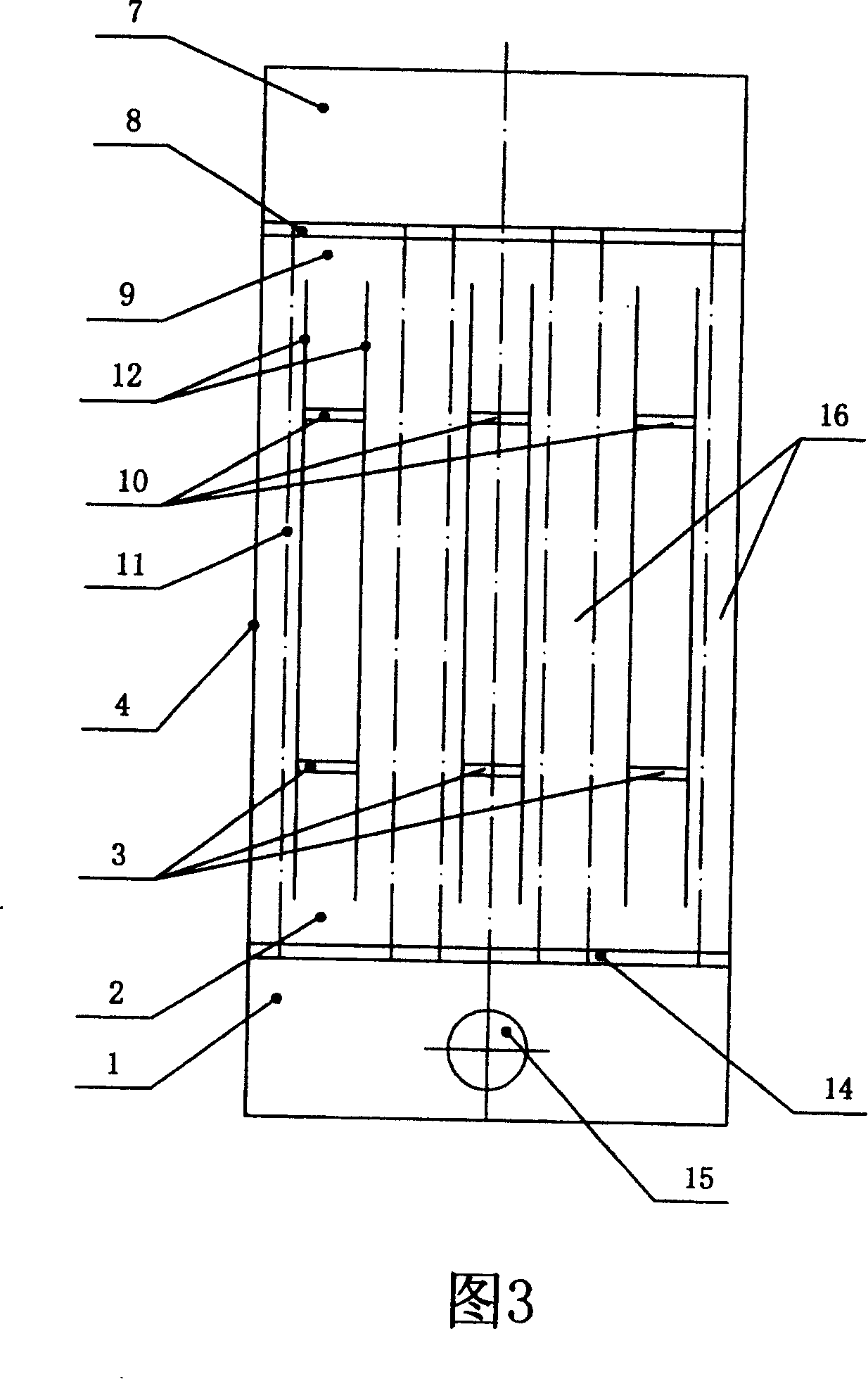

[0016] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0017] As shown in Figure 1, Figure 2 and Figure 3, the shell-and-tube heat exchanger with shell-side multi-channel parallel flow inlet and outlet structure of the present invention includes a lower head 1, a shell 4, a shell-side outlet 5, and a tube-side inlet 6 , upper head 7, upper tube sheet 8, heat transfer tube bundle 11, shell side inlet 13, lower tube sheet 14, tube side outlet 15, also includes shell side inlet notch 2, inlet baffle plate 3, shell side outlet notch 9, The outlet baffle 10 and the longitudinal baffle 12, the shell side inlet 13 are welded with the shell 4 and the lower tube plate 14 respectively, the lower tube plate 14 is welded with the lower head 1, and the lower head 1 is welded with the tube side outlet 15 The shell side outlet 5 is welded with the shell 4 and the upper tube plate 8 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com