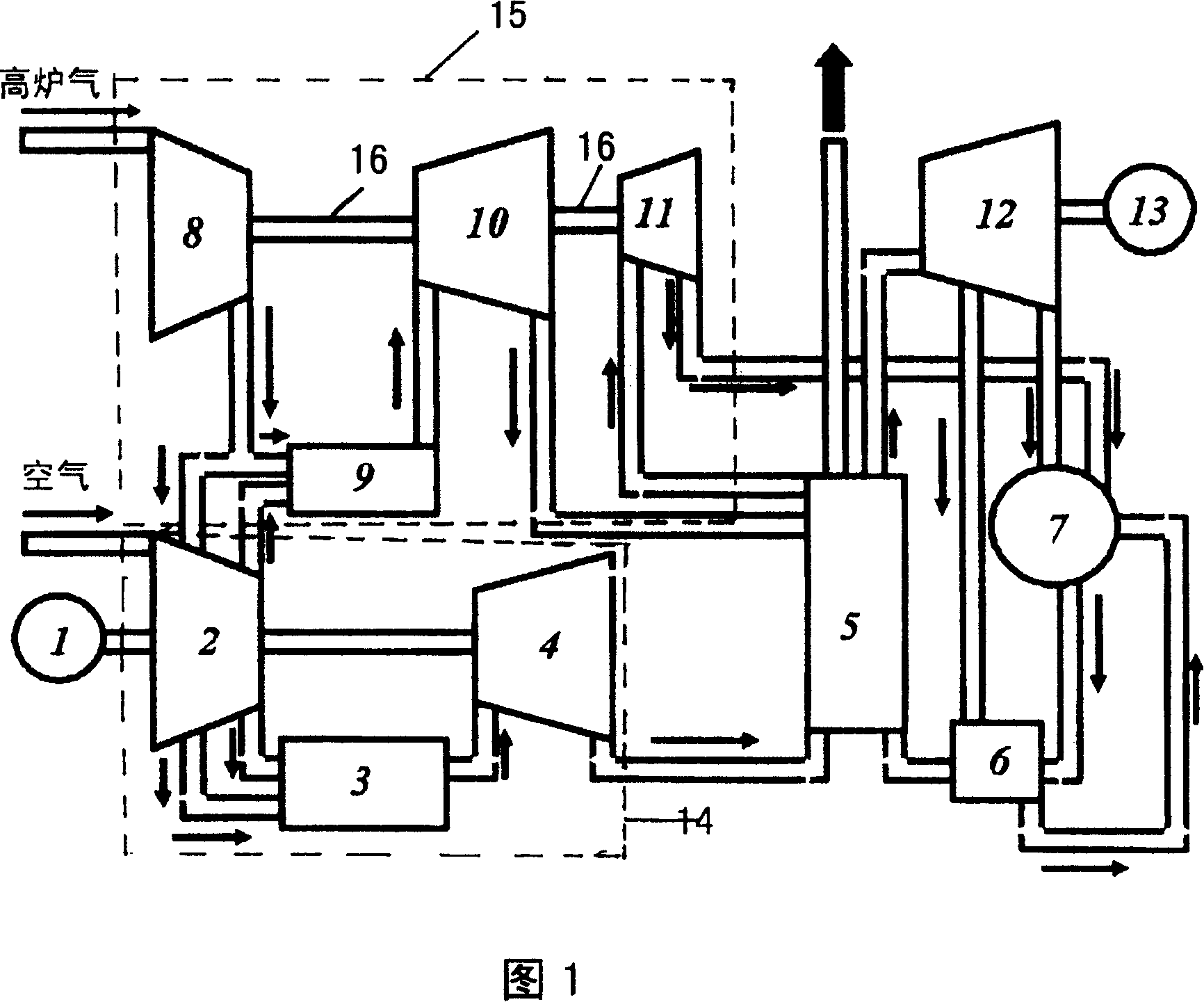

Combined cycle method and installation of combustion turbine of burning blast furnace gas

A gas turbine and combined cycle technology, which is used in the fuel delivery and charging systems of gas turbine units and turbine/propulsion units to widen the stable operation area, improve the operating efficiency of variable working conditions, and save auxiliary systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Using the low calorific value combustor technology of the gas turbine combustor of the Institute of Engineering Thermophysics, Chinese Academy of Sciences, the lower limit of the calorific value of the combustor is locked at 800Kcal / Nm 3 , using the nozzle burning coke oven gas [accounting for 1% of the fuel gas flow] as the on-duty flame, it greatly expands the flameout limit at low load and increases the temperature of the adiabatic flame, so that the combustion efficiency of low calorific value fuel can reach 98% at high load, and at the same time Considering the compressor surge and the passing capacity of the turbine, on the basis of the original number of combustion chambers [main combustion chambers], several combustion chambers [auxiliary combustion chambers] are added, and the gas burned in the auxiliary combustion chambers is led to the low-flow area. The centripetal turbine is connected in series with the first steam turbine formed by the dual-pressure waste h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com