Method and device for shortening pidgeon method reduction cycle and extending reduction jug durability

A technology for reducing tanks and tank walls, which is applied in the field of shortening the Pidgeon method reduction cycle and prolonging the service life of reduction tanks and devices, and can solve problems such as the service life of reduction tanks being only 2-3 months, tank wall collapse, and failure. Achieve the effects of shortening the reduction cycle, long service life, and enhancing creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention overcomes the disadvantages of long reduction period and short service life of the traditional Pidgeon method by providing a reduction tank intensifier device for the horizontal reduction tank. However, the present invention does not change the existing technological process and equipment of the Pidgeon method, nor does it increase the difficulty of loading and unloading materials.

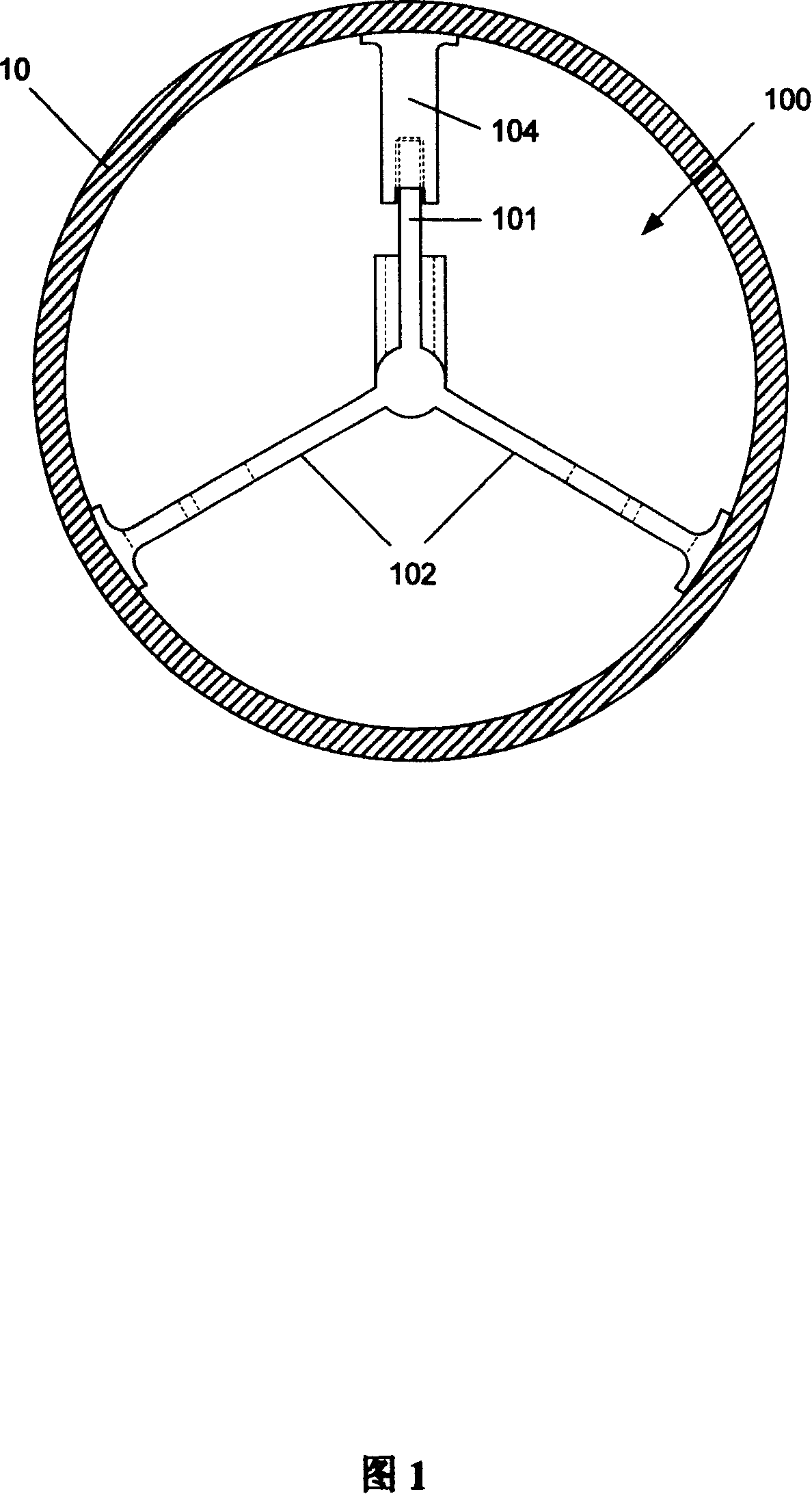

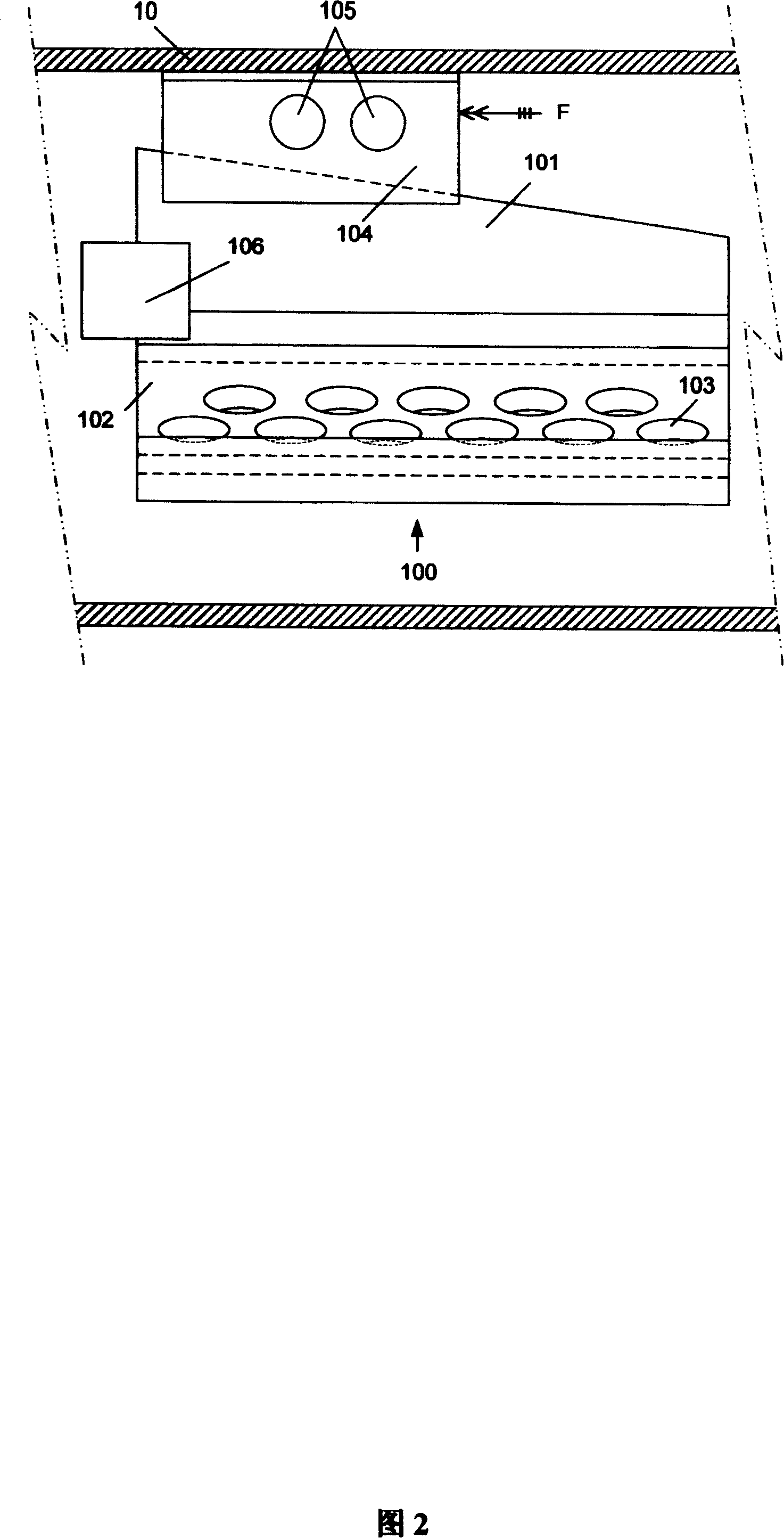

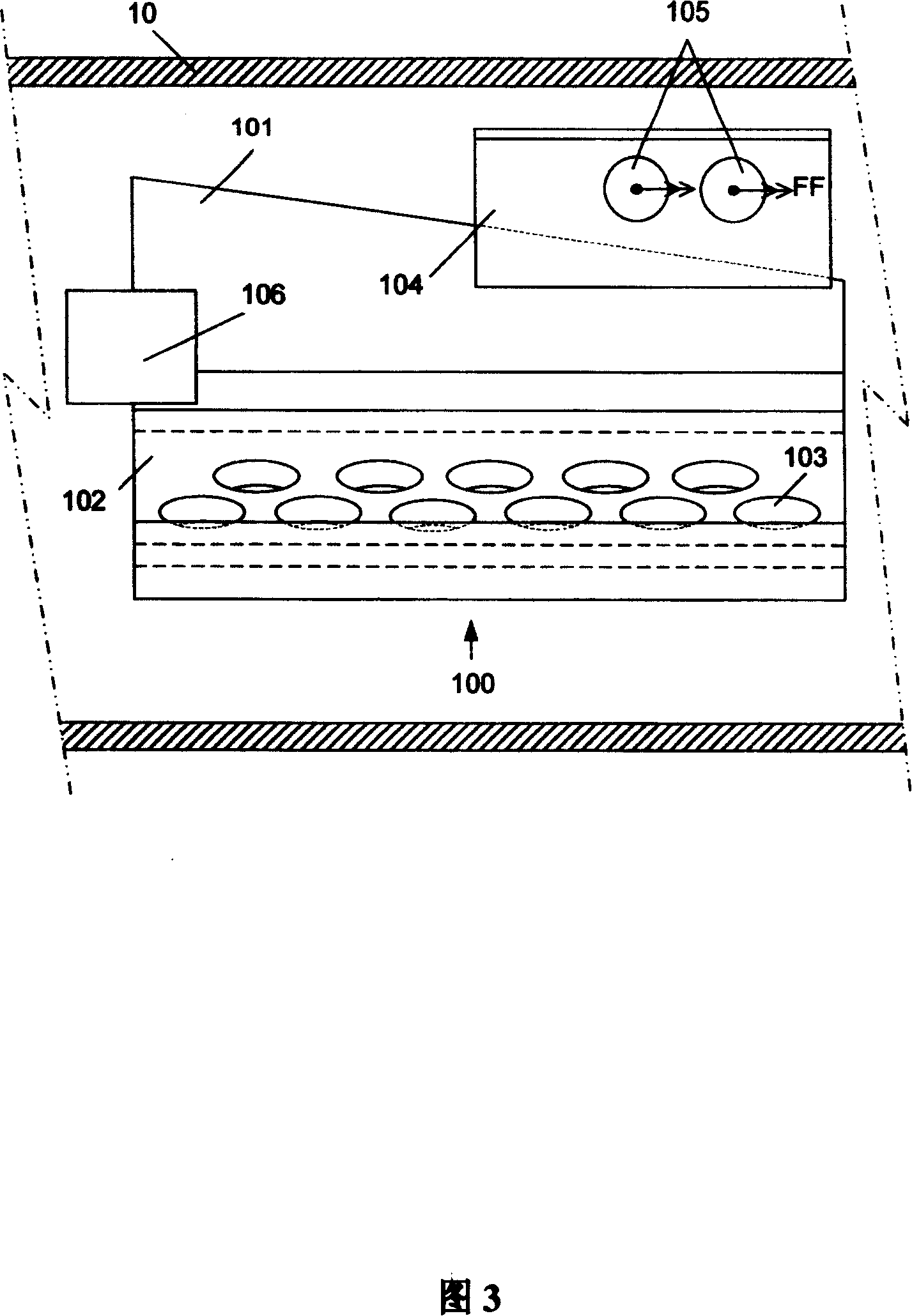

[0017] Fig. 1 and Fig. 2 are respectively the transverse and longitudinal sectional views of the reduction tank strengthener (one of the embodiments). The reduction tank strengthener (100) is composed of three reinforcing plates that are radially formed at an angle of 120 degrees to each other and made of heat-resistant good conductor and heat-resistant material. One of the reinforcement plates (101) has an inclined surface, and some slag leakage through holes (103) are prefabricated on the other two reinforcement plates (102). During installation, the inclined-plane reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com