Method for making decoration lamp with glass handicraft in it

A manufacturing method and handicraft technology, which is applied to glass manufacturing equipment, glass molding, manufacturing of ships or leading wires, etc., to achieve the effects of good viewing, broad market prospects, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

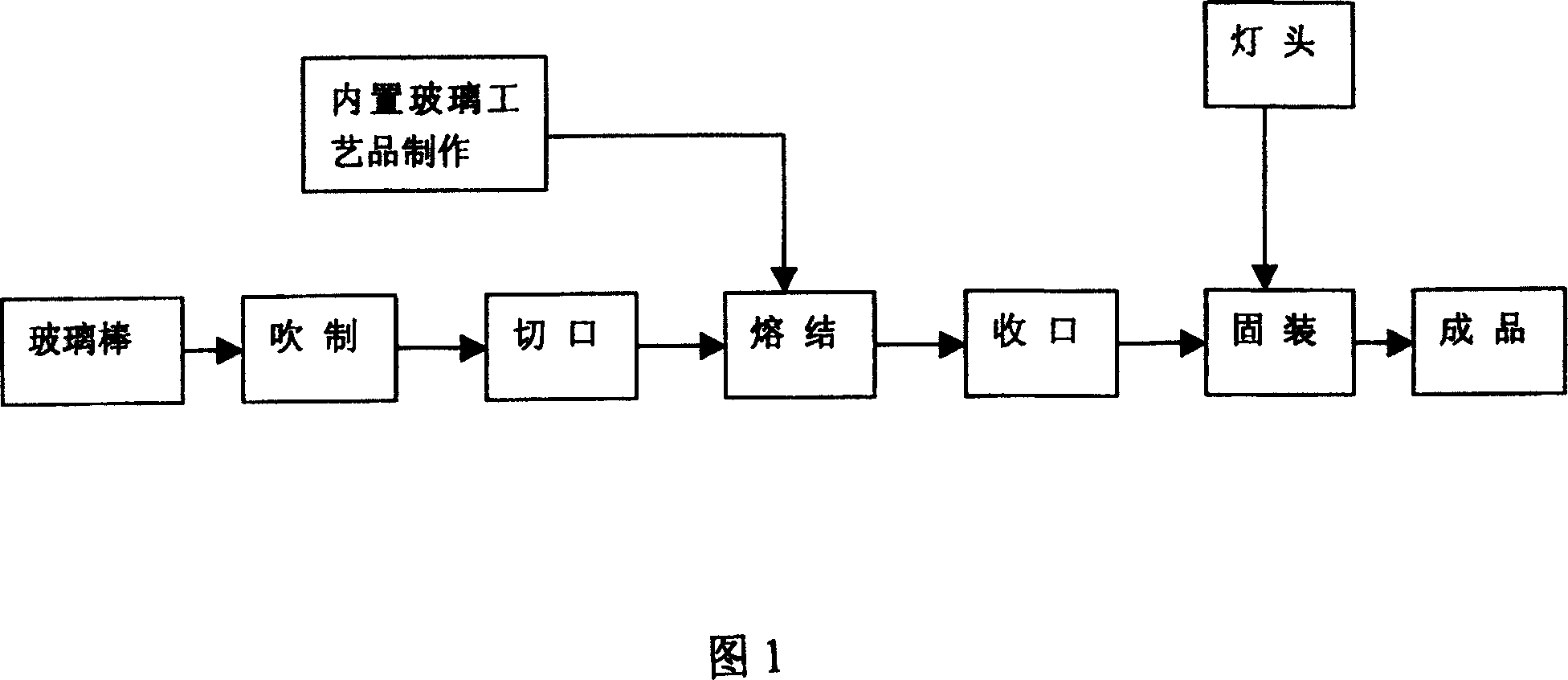

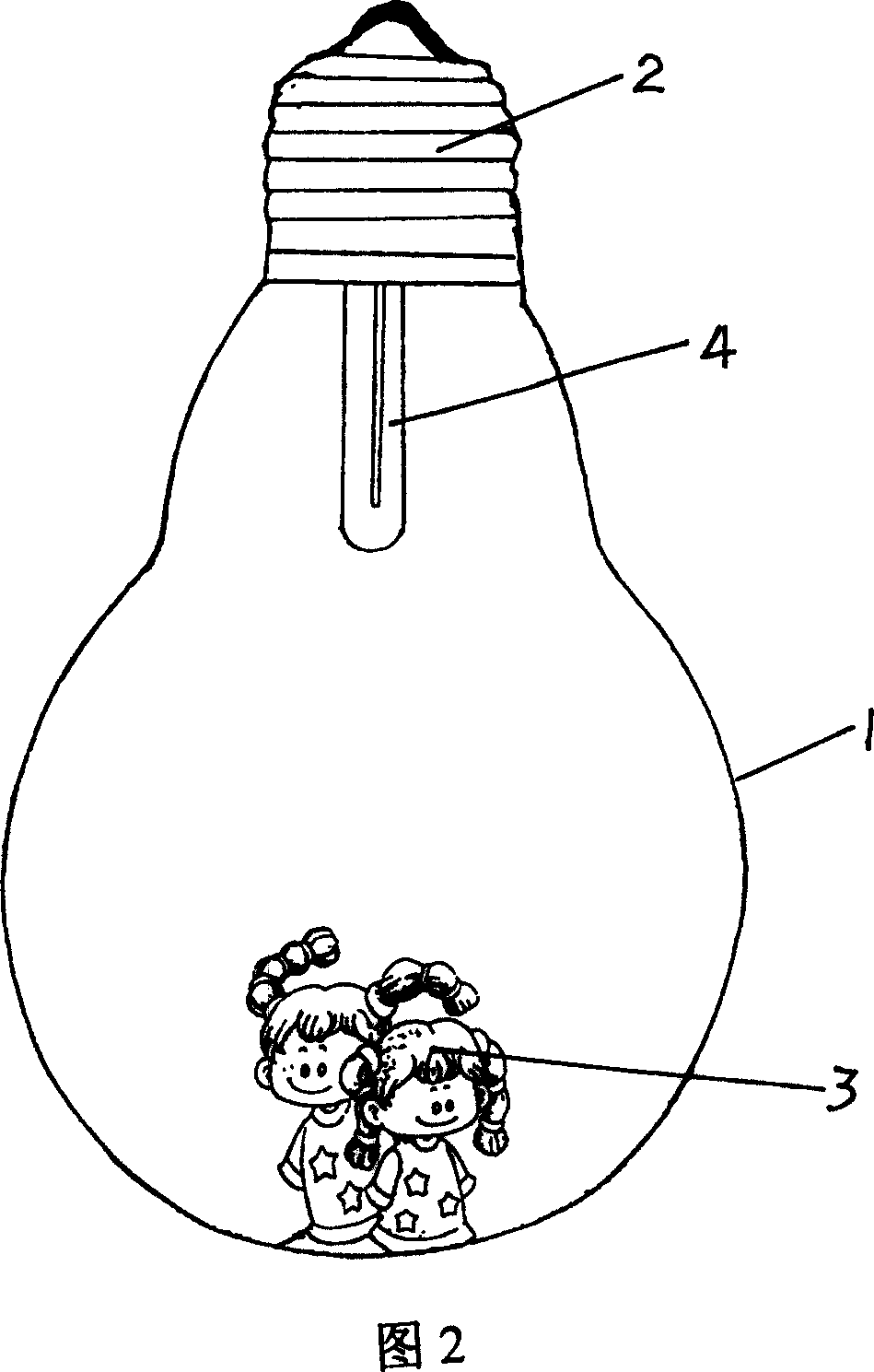

[0031] As shown in Figure 1 and 2.

[0032] Take the LN3.3 high borosilicate glass tube raw material produced by Puyang Company of Wuhan Linuo Industrial Co., Ltd. and blow it manually or by machine at a temperature of 650°C to form a glass shell embryo 1 with the shape (cucurbit shape) shown in Figure 2. use.

[0033] Cut the above-mentioned glass shell body 1 at a temperature of 750°C with a glass cutting machine or a conventional thermal explosion process to cut off the end facing the lamp cap 2 to form a cut that is larger than the outer diameter of the outline of the glass craft 3 to be built in , after cooling down naturally.

[0034] Using the above-mentioned high borosilicate glass as a raw material, the built-in glass handicraft 3 shown in FIG. 2 and having a size suitable for being built into the aforementioned glass shell body 1 is manufactured by conventional sintering process.

[0035] Put the built-in glass handicraft 3 prepared above into the glass shell body ...

Embodiment 2

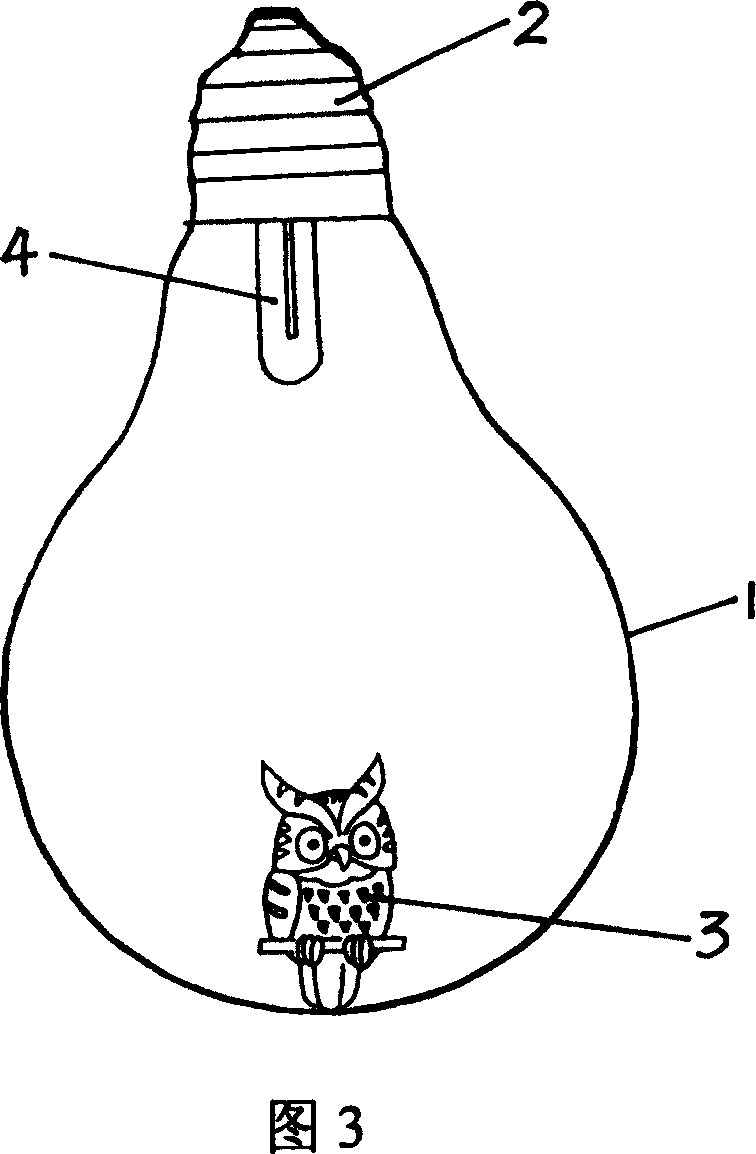

[0039] As shown in Figures 1 and 3.

[0040] Take the LN3.3 high borosilicate glass tube raw material produced by Wuhan Linuo Industrial Co., Ltd. Puyang Company and blow it manually or by machine at a temperature of 850°C to form a glass shell embryo 1 with a shape (spherical) as shown in Figure 3 for use .

[0041] Cut the above-mentioned glass shell body 1 at a temperature of 900°C at the end facing the lamp cap 2 with a glass cutting machine or a conventional thermal explosion process to form a cut that is larger than the outer diameter of the outline of the glass craft 3 to be built in , after cooling down naturally.

[0042] Using the above-mentioned high borosilicate glass as a raw material, a built-in glass handicraft 3 as shown in FIG. 3 is manufactured by conventional sintering process, and its size is suitable for being built into the aforementioned glass shell blank body 1 .

[0043] Put the built-in glass handicraft 3 prepared above into the glass shell body 1 f...

Embodiment 3

[0047] As shown in Figure 1 and 4.

[0048] Take the LN3.3 high borosilicate glass tube raw material produced by Wuhan Linuo Industrial Co., Ltd. Puyang Company and blow it manually or by machine at a temperature of 900°C to form a glass shell embryo 1 with a shape (ellipsoid) as shown in Figure 4. use.

[0049] Cut the above-mentioned glass shell body 1 at a temperature of 1000°C with a glass cutting machine or a conventional thermal explosion process to cut the end facing the lamp cap 2 to form a cut that is larger than the outer diameter of the outline of the glass handicraft 3 to be built in , after cooling down naturally.

[0050] Using the above-mentioned high borosilicate glass as a raw material, a built-in glass handicraft 3 as shown in FIG. 4 is manufactured by a conventional sintering process, and its size is suitable for being built into the aforementioned glass shell blank body 1 .

[0051] Put the built-in glass handicraft 3 prepared above into the glass shell bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com