Method for adjusting dissolved liquid by spieces mother liquid

A technology of separating mother liquor and adjusting height, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of high supersaturation, muddy settling tank, decreased recovery rate of hydrolysis loss, etc., to increase stability, increase output, and improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

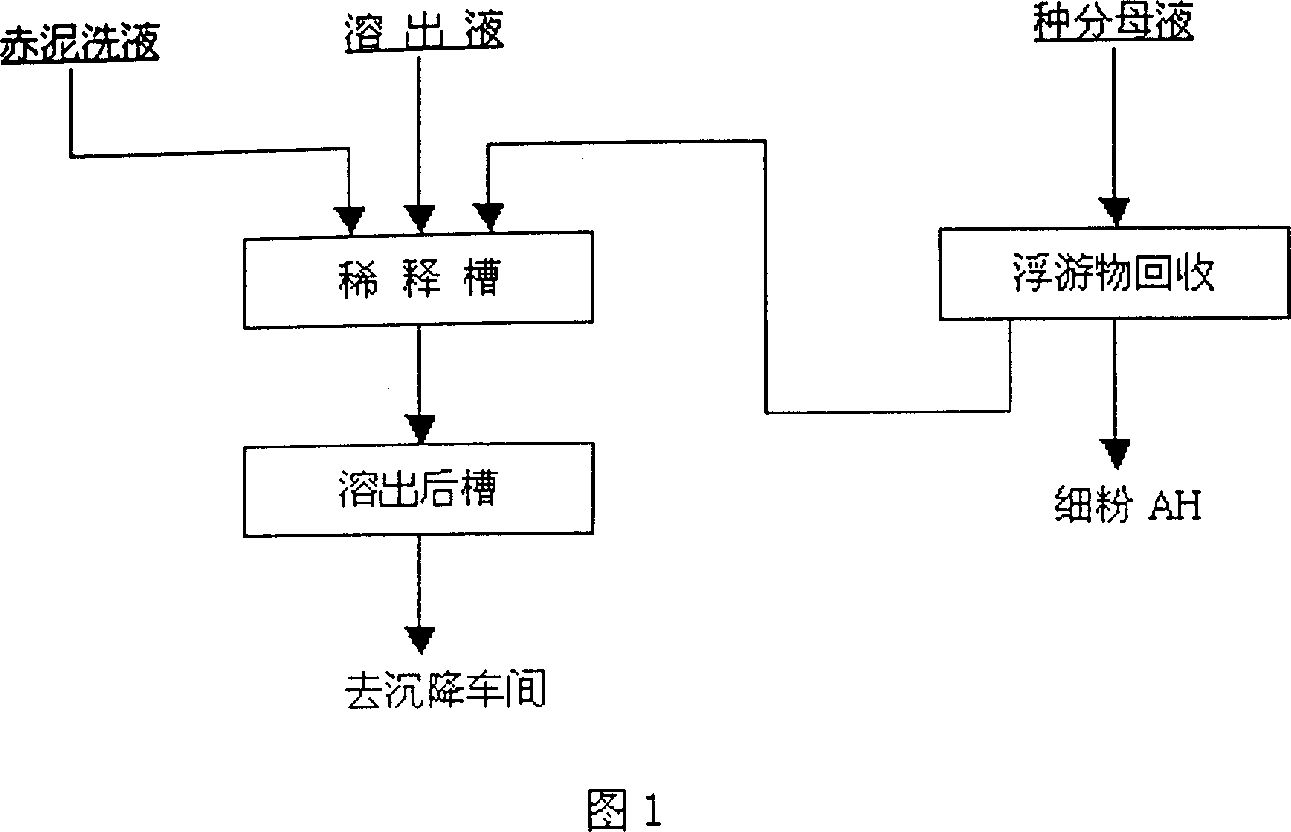

[0017] Embodiments of the present invention: first set up a float recovery process in the alumina plant, and set up float recovery facilities and install related equipment, and send the seed separation mother liquor into the float recovery process for float recovery, so as to avoid the seed separation mother liquor The hydrolysis loss of the dilution liquid increases due to the high content of floating matter; then the mother liquor recovered from the floating matter, the stripping slurry from the evaporator of the final ore pulp and the red mud washing liquid are added to the dilution tank together, the original Alkali Alkali α k The value is 1.30~1.35, and the dissolution liquid α is adjusted from the mother liquor k The role of the value, α k Adjust the value to 1.44~1.52; Alkali α of raw ore pulp k Value 1.30~1.35; diluent α of small alumina plant k The optimum value is 1.48~1.52, the diluent α of the large alumina plant k The value is 1.44 to 1.48. After adjustment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com