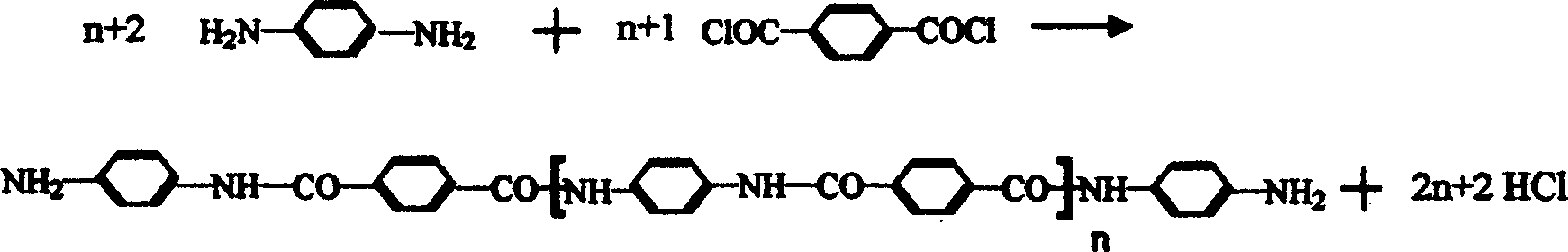

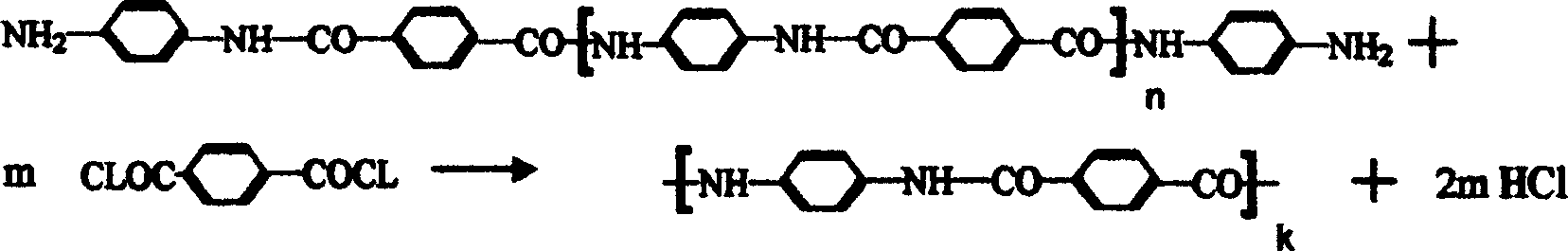

Synthetic method for poly terephthalyl terephaldiamine polymer

A technology of poly(p-phenylene terephthalamide) and its synthesis method, which is applied in the field of synthesis of poly(p-phenylene terephthalamide) polymers, and can solve the problem of large amount of solvent recovery, large resin ash content, and complex production equipment and other problems, to achieve the effects of reducing investment cost and production cost, smooth polymerization reaction, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 0.20 kg of p-phenylenediamine and 0.23 kg of lithium chloride in 5.30 kg of dimethylacetamide with a water content below 100ppm, and prepare the weight of p-phenylenediamine in a reactor with a double-helix belt stirrer. The percentage concentration is 3.5%, and the lithium chloride weight percentage concentration is a solution of 4%. Cool the solution to -10°C, add 0.1 kg of terephthaloyl chloride to the reactor for the first time, and after 15 minutes of reaction, pass 0.016 kg of pure ammonia into the reactor to neutralize the hydrogen chloride produced by the reaction to obtain polycondensation intermediate The pH of the product solution is 6. For the second time, 0.1 kg of terephthaloyl chloride is added to the reactor. After 20 minutes of reaction, 0.016 kg of pure ammonia is passed into the reactor to neutralize the hydrogen chloride produced by the reaction, and the polycondensation intermediate product solution pH is obtained. 0.1 kilogram of terephtha...

Embodiment 2

[0028] Dissolve 0.30 kg of p-phenylenediamine and 0.30 kg of lithium chloride in 5.00 kg of N-methylpyrrolidone with a water content below 100ppm, and prepare the weight of p-phenylenediamine in a reactor with a double-helix belt stirrer. The percentage concentration is 6%, and the lithium chloride weight percentage concentration is a solution of 6%. Cool the solution to -10°C, add 0.2 kg of terephthaloyl chloride to the reactor for the first time, and after 15 minutes of reaction, pass 0.031 kg of pure ammonia into the reactor to neutralize the hydrogen chloride produced by the reaction to obtain polycondensation intermediate The pH of the product solution is 5. For the second time, 0.1 kg of terephthaloyl chloride is added to the reactor, and after 20 minutes of reaction, 0.017 kg of pure ammonia is passed into the reactor to neutralize the hydrogen chloride produced by the reaction to obtain the polycondensation intermediate product solution pH 0.1 kg of terephthaloyl chlor...

Embodiment 3

[0030]Dissolve 0.25 kg of p-phenylenediamine with a purity of more than 99.9% and 0.35 kg of calcium chloride with a purity of more than 99.9% in 5.00 kg of dimethylacetamide with a water content of less than 100ppm in a double-helix belt stirrer In the reactor, it is prepared as a solution containing 5% by weight of p-phenylenediamine and 7% by weight of calcium chloride. Cool the solution to -10°C, add 0.18 kg of terephthaloyl chloride to the reactor for the first time, and after 20 minutes of reaction, pass 0.029 kg of pure ammonia into the reactor to neutralize the hydrogen chloride produced by the reaction to obtain polycondensation intermediate The pH of the product solution is 6. For the second time, 0.15 kg of terephthaloyl chloride is added to the reactor, and after 25 minutes of reaction, 0.025 kg of pure ammonia is passed into the reactor to neutralize the hydrogen chloride produced by the reaction to obtain the polycondensation intermediate product solution pH 6.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com