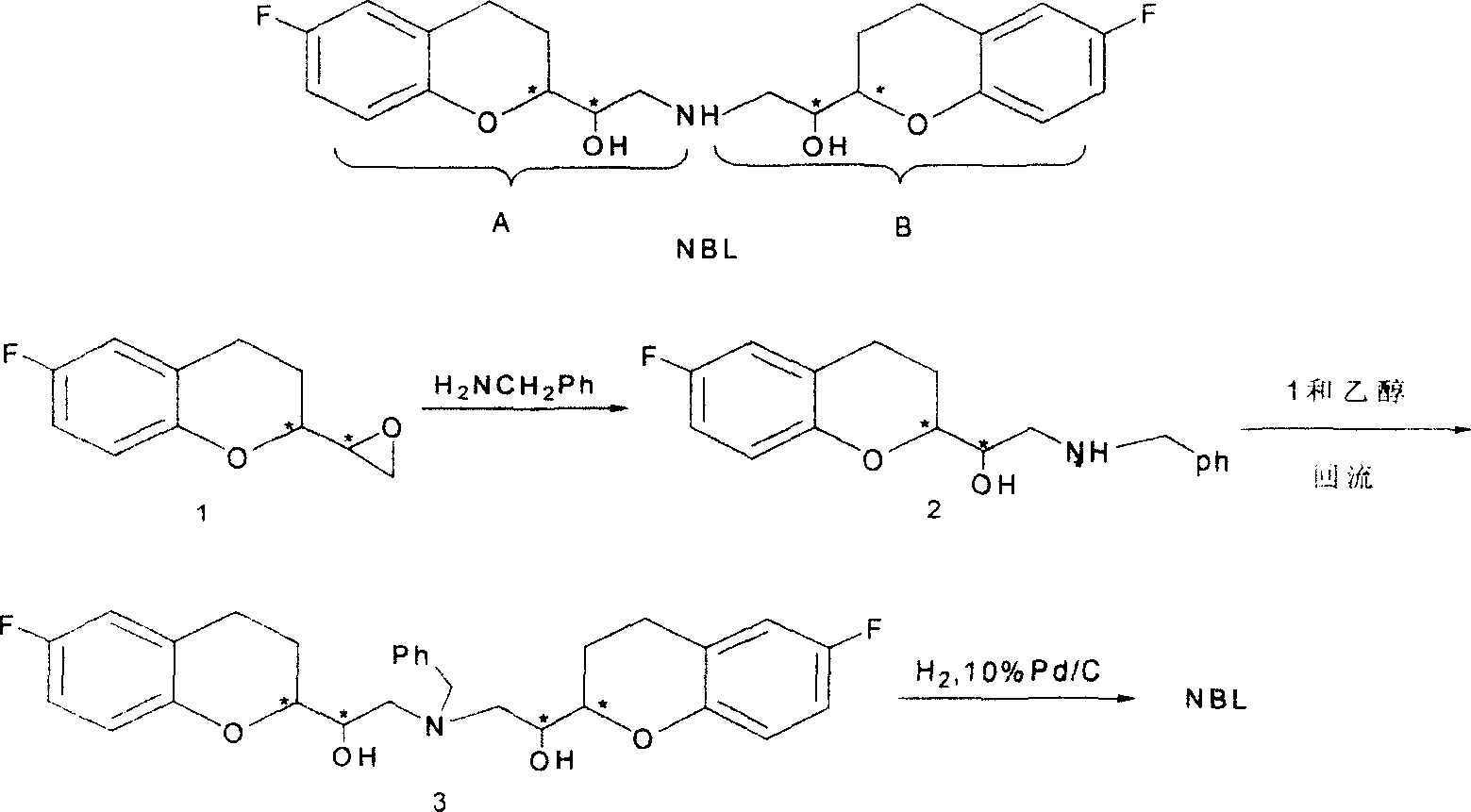

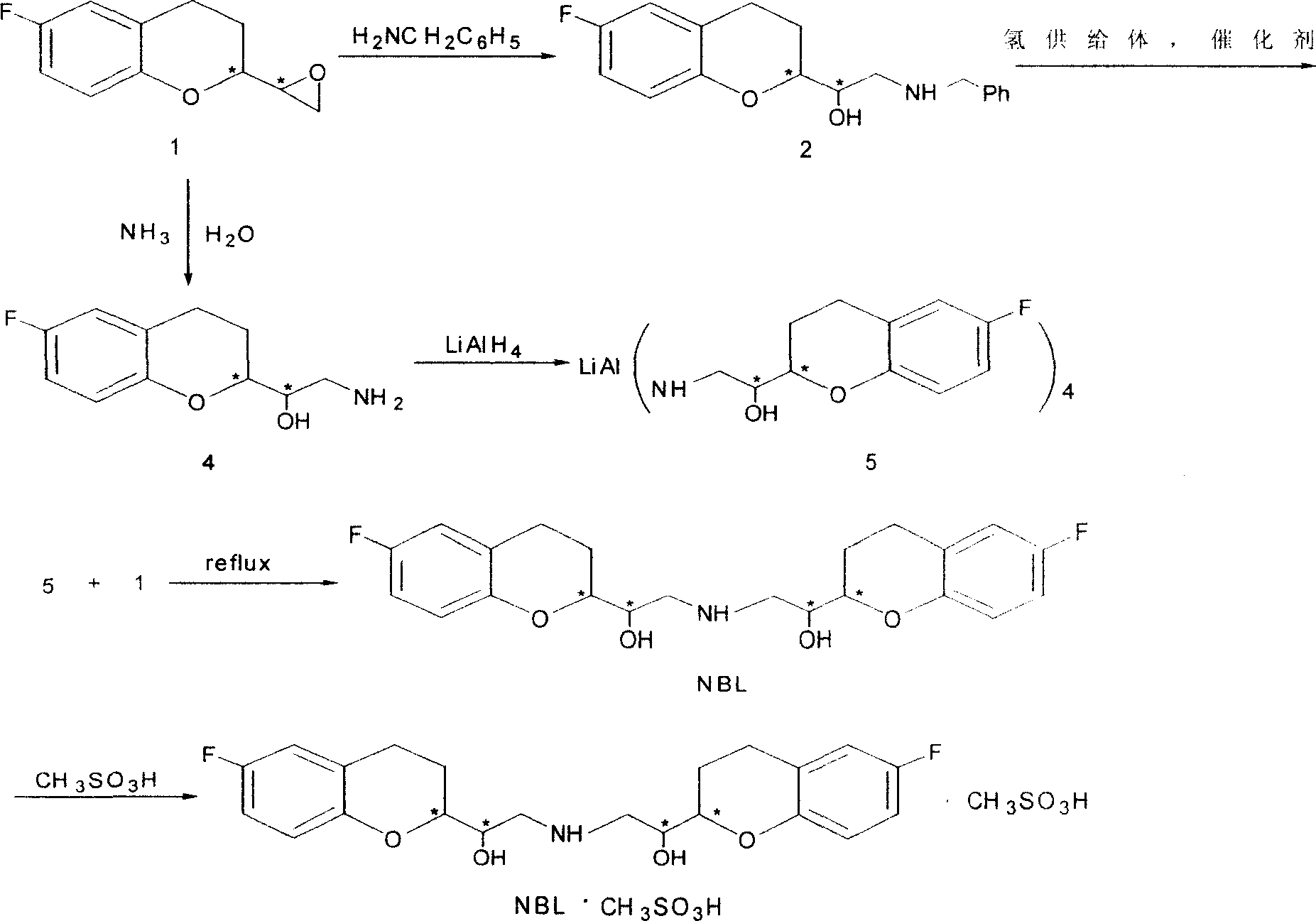

2,2'-[iminodi(methylene)di-(6-fluoro-3,4-dihydro-2H-1-benzenepyran-2- methanol) methane sulfosalt

A benzopyran, methylene technology, applied in the field of medicinal chemistry, can solve the problems of difficulty in mass production, expensive raw materials and reagents, complicated reaction operations and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1).6-fluoro-3,4-dihydro-2-oxiranyl-2H-1-benzopyran (1 shown in scheme 2) (3.0 grams, 0.016mol), benzylamine (8.3 gram, 0.08mol), isopropanol 100ml, add in the reaction vessel, reflux reaction 2 hours. After stopping the reaction, the solvent was distilled off to obtain a white solid. Recrystallization gave pure white solid 1-[6-fluoro-3,4-dihydro-2H-1-benzopyran-2-yl]-2-benzylamino-ethanol (shown in Scheme 2) ( Yield 85%), mp 117~118 ℃.

[0029] (2).6-fluoro-3,4-dihydro-2-oxirane group-2H-1-benzopyran (1 shown in scheme 2) (8.0 grams, 40mmol), the ammoniacal liquor of 25wt% ( 0.27 grams, 4.0mmol), methanol 800ml, after reflux reaction for 2 hours. The solvent was evaporated to obtain a yellow thick substance. Silica gel column purification, using dichloromethane and methanol as eluent. After evaporation of the solvent, white solid 1-[6-fluoro-3,4-dihydro-2H-1-benzopyran-2-yl]-2-amino-ethanol (4 shown in Scheme 2) was obtained (yield Rate 78%), mp 119 ~ 112 ℃.

...

Embodiment 2

[0035] (1).6-fluoro-3,4-dihydro-2-oxiranyl-2H-1-benzopyran (1 shown in scheme 2) (7.5 grams, 0.04mol), benzylamine (0.83 gram, 0.008mol), tetrahydrofuran 20ml, add in the reaction container, reflux reaction 2 hours. After stopping the reaction, the solvent was distilled off to obtain a white solid. Recrystallization gave pure white solid 1-[6-fluoro-3,4-dihydro-2H-1-benzopyran-2-yl]-2-benzylamino-ethanol (shown in Scheme 2) ( Yield 85%), mp 117~118 ℃.

[0036] (2).6-fluoro-3,4-dihydro-2-oxiranyl-2H-1-benzopyran (1 shown in Scheme 2) (1.6 g, 8.0 mmol), 25% ammonia (0.54 g, 8.0 mmol), butanol 70 ml, after reflux reaction for 2 hours. The solvent was evaporated to obtain a yellow thick substance. Silica gel column purification, using dichloromethane and methanol as eluent. After evaporation of the solvent, white solid 1-[6-fluoro-3,4-dihydro-2H-1-benzopyran-2-yl]-2-amino-ethanol (4 shown in Scheme 2) was obtained (yield Rate 78%), mp 119 ~ 112 ℃.

[0037] or

[0038] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com