Method for manufacturing semiconductor chip

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, manufacturing tools, etc., can solve problems such as semiconductor chip cracking and broken damage, semiconductor chip damage, and difficulty in re-attaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

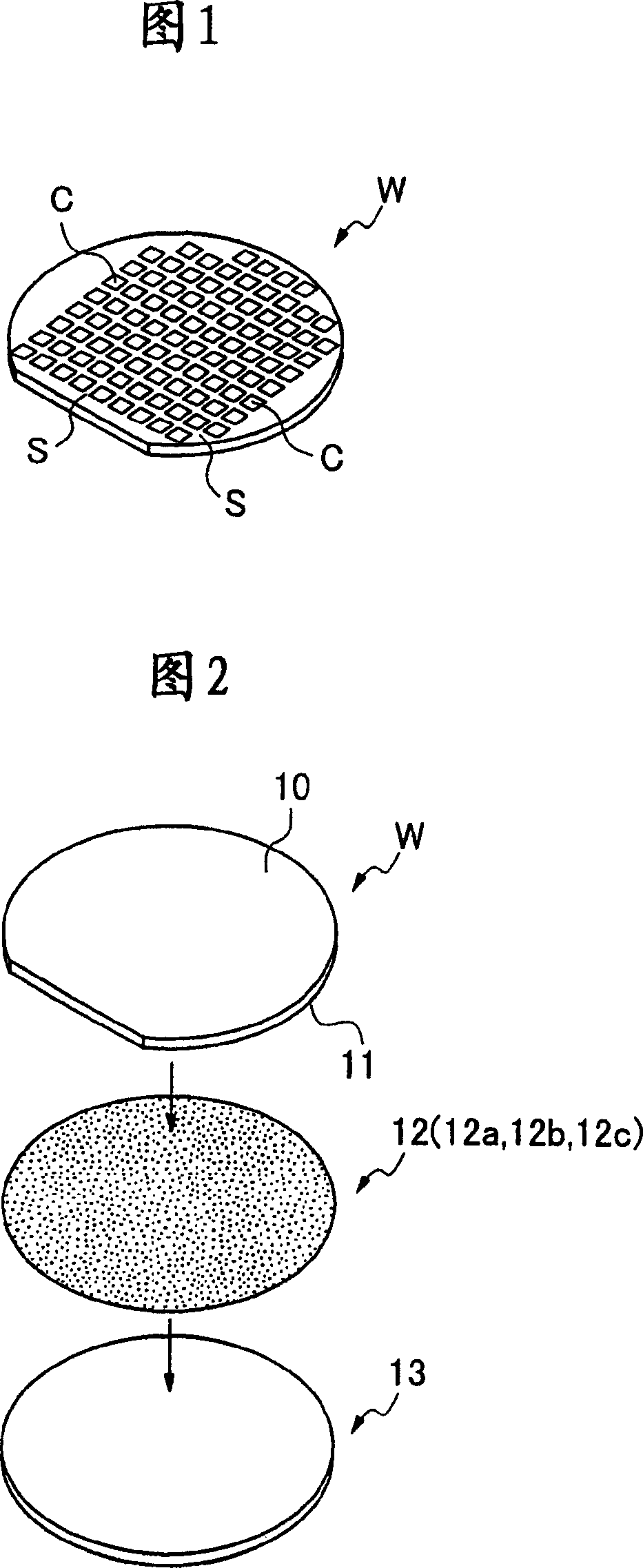

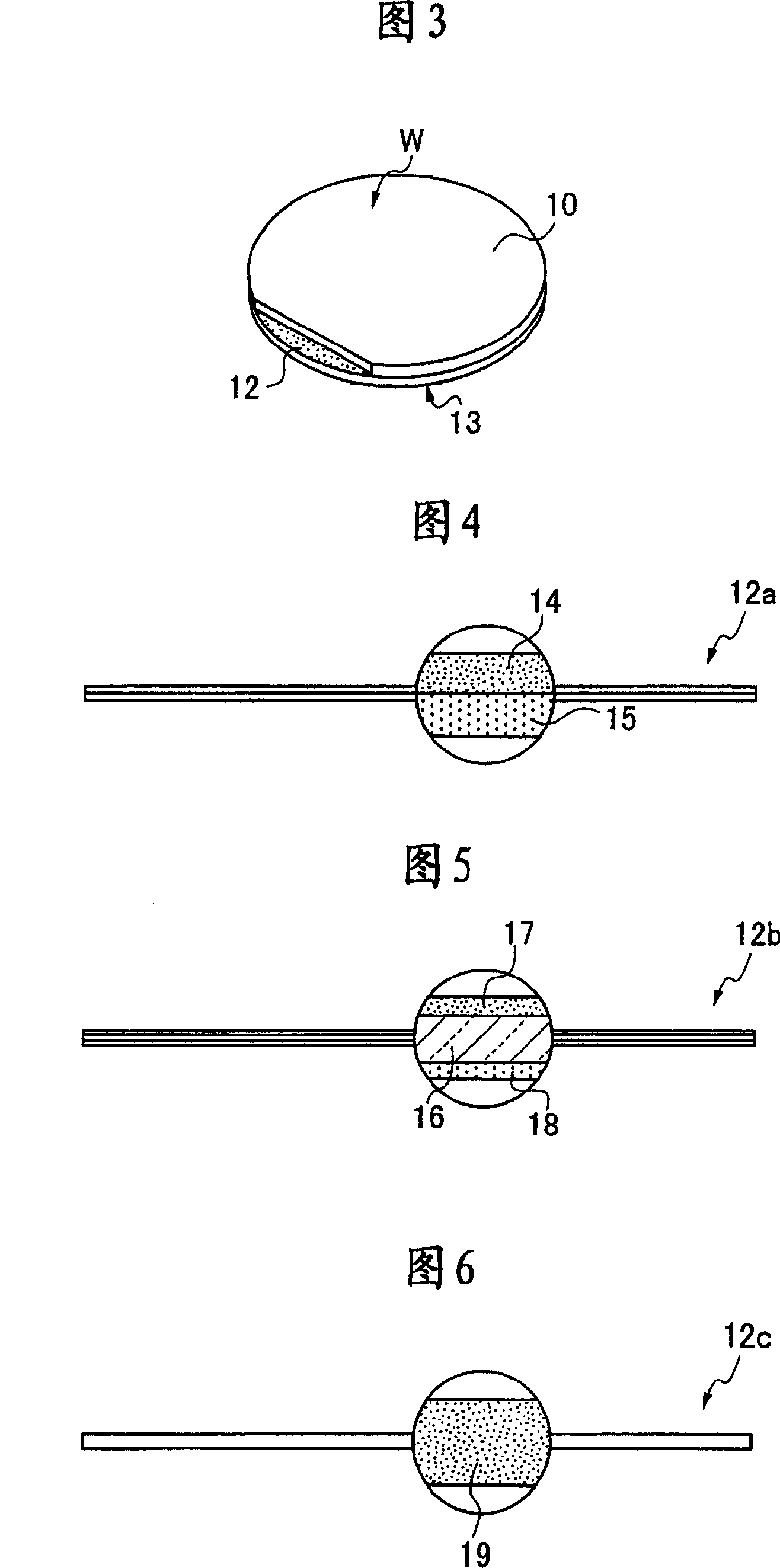

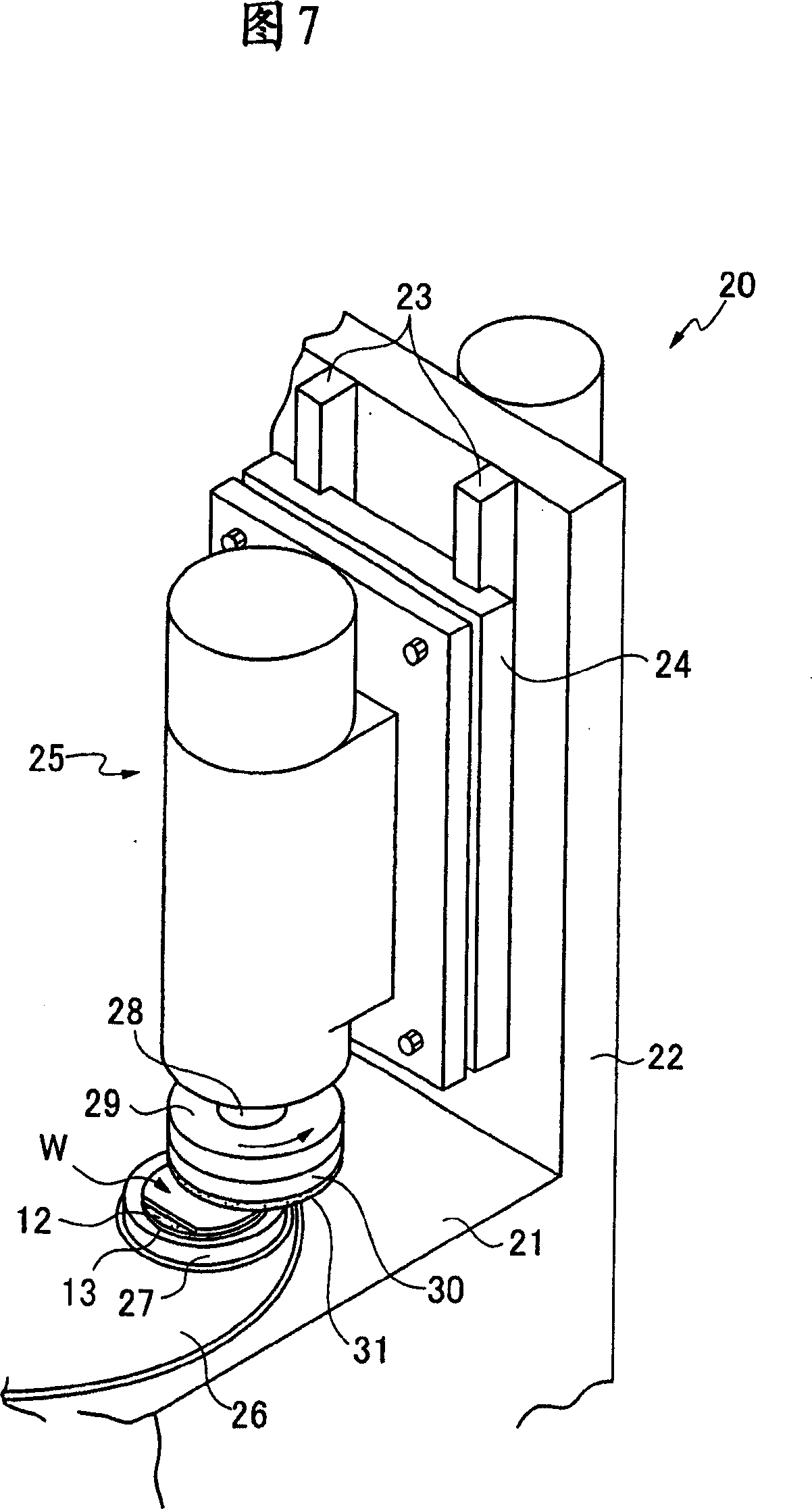

[0024] As a preferred mode for carrying out the present invention, a method for manufacturing individual semiconductor chips C by grinding the back surface of the semiconductor wafer W shown in FIG. 1 and cutting (dicing) the channels S vertically and horizontally will be described below.

[0025] In the semiconductor wafer W shown in FIG. 1 , circuits are formed on the surface of the regions divided by the channels S. As shown in FIG. As shown in FIG. 2, under the state that the semiconductor wafer W is turned over so that the back surface 10 faces upward, the surface of the semiconductor wafer W is pasted on the support plate 13 through the adhesive sheet 12, and it is integrated as shown in FIG. 3 ( support plate integration process). That is, the surface 11 of the semiconductor wafer W is pasted on the adhesive sheet 12 .

[0026] The adhesive sheet 12 has a property of reducing the adhesive force by excitation, and is, for example, an adhesive sheet containing a gas gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com