Fixed tooth and movable tooth combined step-by-step peanut picking device

A step-by-step, peanut-based technology, which is applied to digging harvesters, agricultural machinery and tools, food processing, etc., can solve problems such as reduced picking stability, ineffective results, and cam disc fatigue damage, etc., to shorten the picking process, Improve the pick-up effect and avoid the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

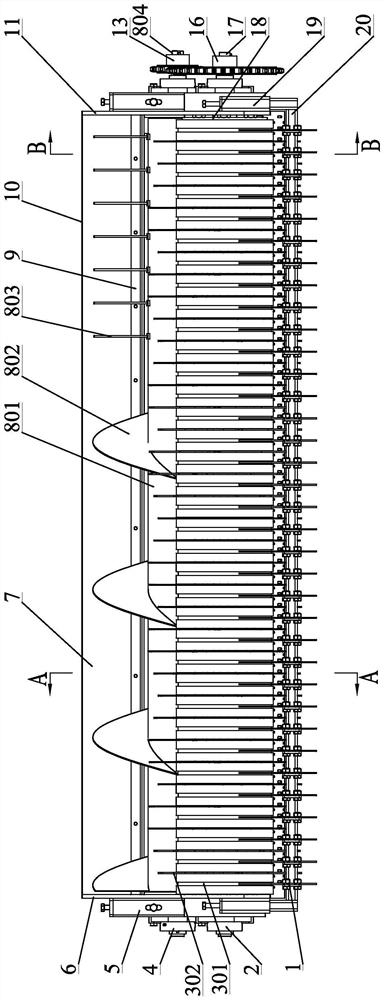

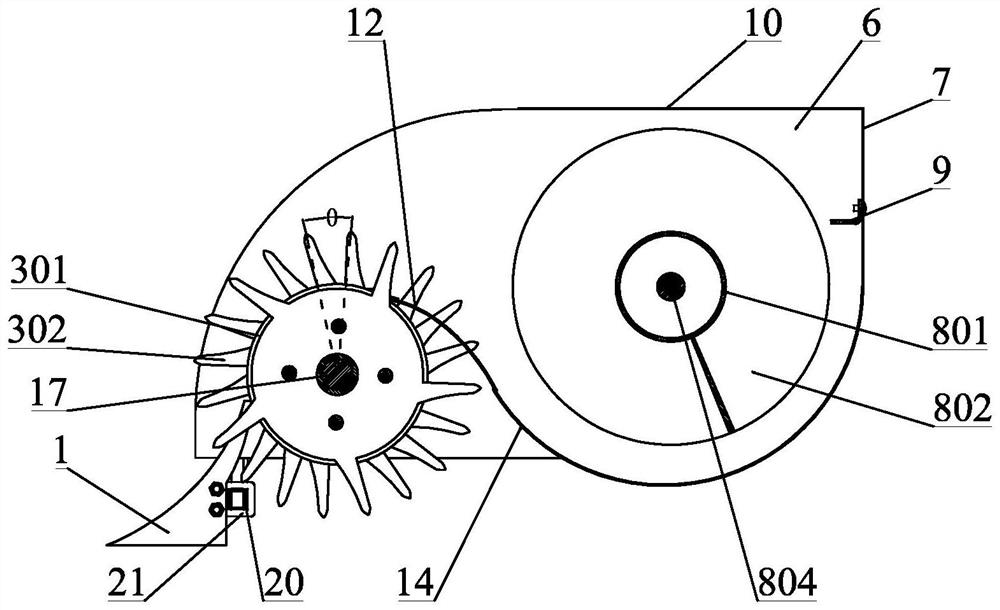

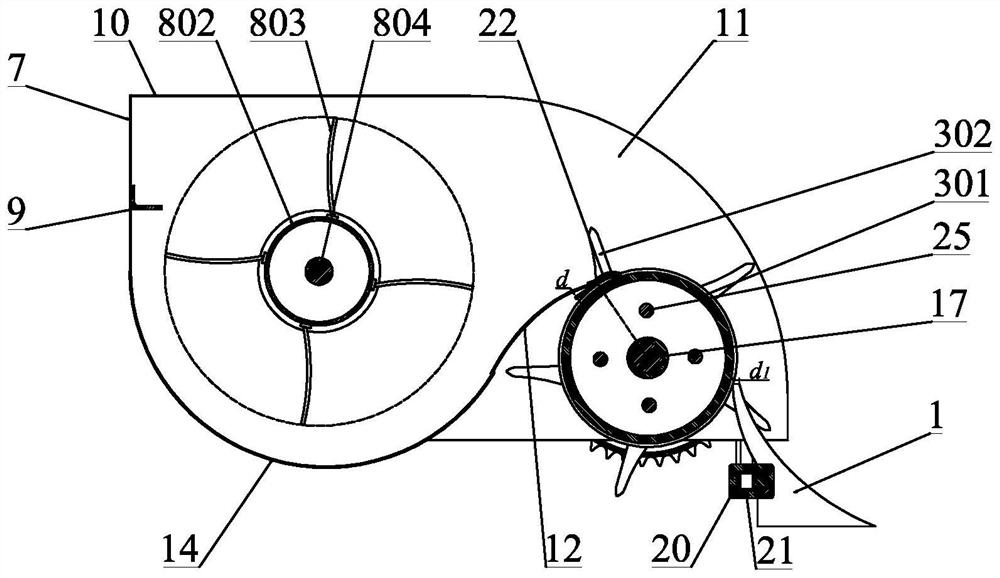

[0060] Embodiment 1: as Figure 1-3 As shown, a step-by-step peanut pick-up device without guard plate fixed and movable teeth of the present invention includes fixed teeth 1, pick-up roller 3, seedling unloading plate 12, sieve plate 14 and auger 8, and the pick-up roller 3 The two ends of the roller shaft are fixed on the left and right side plates 6, 11 of the shell through the pick-up roller bearing seat 2, and a row of fixed fixed teeth 1 is arranged at the front and bottom of the pick-up roller 3, and the fixed teeth 1 have an arc The front end of the auger 8 is installed behind the pick-up roller 3 through the auger bearing seat, and a sieve plate 14 is arranged under the auger 8, and the sieve plate 14 is connected to the pick-up roller 3 for transition. Connected seedling unloading plate 12; when working, the fixed teeth 1 are drawn into the ground to scoop up the peanut plants and move upwards to a certain height along the arc-shaped working surface under the action ...

Embodiment 2

[0076] Embodiment 2: The difference between this example and Embodiment 1 is that 6 pick-up teeth are used in this example, and the adjacent pick-up teeth are sequentially staggered by a phase angle θ of 15°, forming a "V"-shaped wave arrangement along the axial direction. The reclining angle of the picking teeth on the picking piece 302 is α=25°, and the length of the picking teeth is L 1 =100mm, height h between the tooth end of the pick-up piece 302 and the ground 1 = 30mm.

[0077] The side shape of the fixed tooth 1 is an involute curve, and the radius of the base circle is R 1 260mm, α 0 = 60°, α n = 108°.

[0078] The angle β between the picking teeth and the involute tangent of the seedling unloading plate 12 in the counterclockwise direction is always greater than the clamping angle of the peanut plant, 82°≤β≥115°.

[0079] Described seedling unloading plate 12 and sieve plate 14 are curve plate, respectively by curve and constitute, of which is based on R ...

Embodiment 3

[0081] Embodiment 3: The difference between this example and Embodiment 1 is that seven pick-up teeth are used in this example, and the adjacent pick-up teeth are sequentially staggered by a phase angle θ of 13°, forming a "V"-shaped wave arrangement along the axial direction. The reclining angle of the picking teeth on the picking piece 302 is α=20°, and the length of the picking teeth is L 1 =60mm, height h between the tooth end of the pick-up piece 302 and the ground 1 = 15mm.

[0082] The side shape of the fixed tooth 1 is an involute curve, and the radius of the base circle is R 1 is 150mm, starting angle α 0 =72°, end angle α n = 120°.

[0083] The angle β between the picking tooth and the involute tangent of the seedling unloading plate 12 in the counterclockwise direction is always greater than the clamping angle of the peanut plant, 75°≤β≥80°.

[0084] Described seedling unloading plate 12 and sieve plate 14 are curve plate, respectively by curve and constitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com