Composite fiber and its mfg. method

A composite fiber and manufacturing method technology, which is applied in the field of speech, can solve the problems of polyester stretchable composite fiber tensile strength and stretchability reduction, and achieve excellent chlorine resistance and shape stability, excellent stretchability, and reduced retention the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

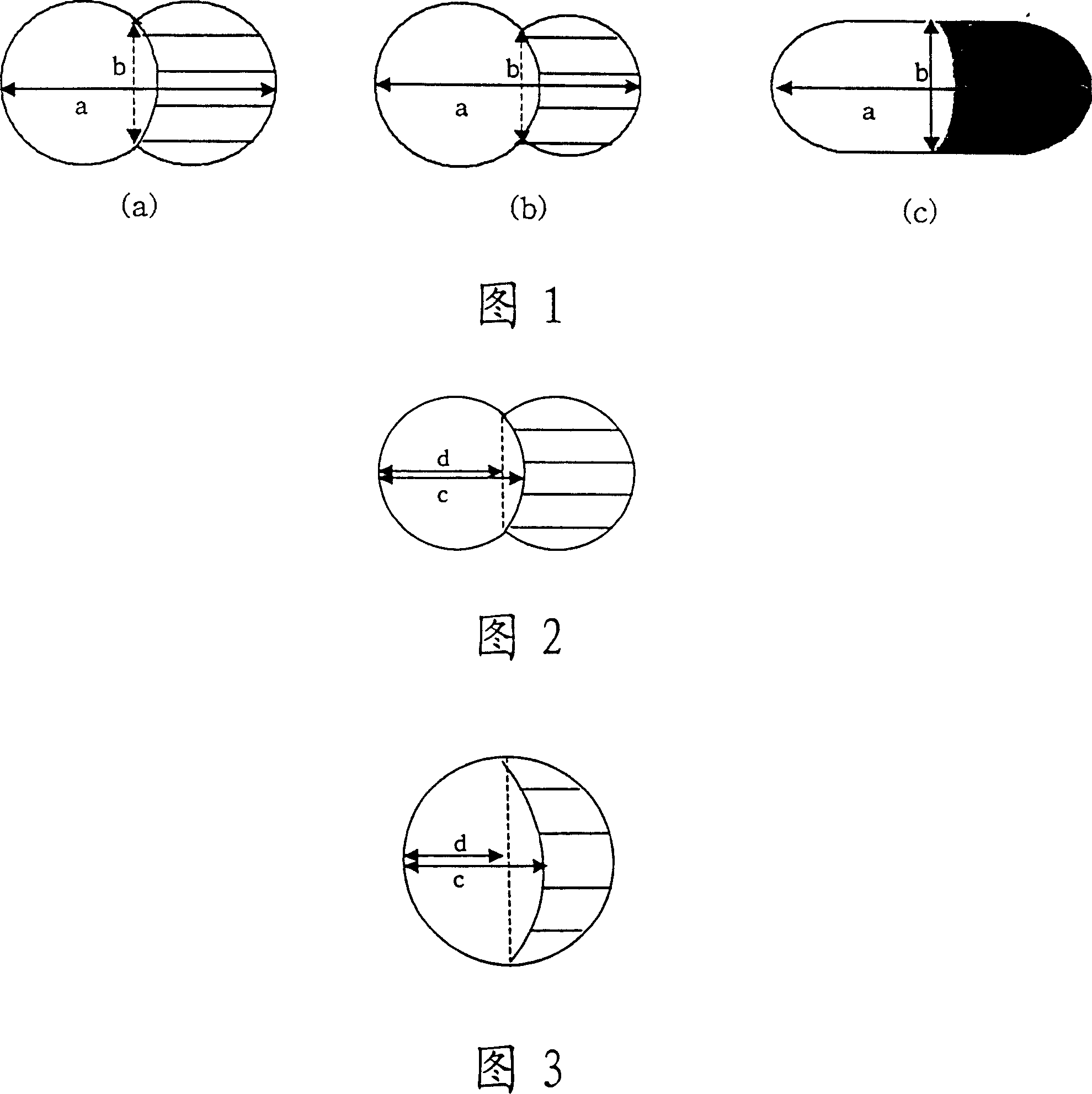

[0086] In the process of manufacturing stretchable composite fibers, the spinning temperature is set at 275°C, the spinning speed is 2800 m / min, the crimping tension is 0.09g / d, and the residence time in the module is 3 minutes, using the existing melt composite spinning Equipment, with the ratio of weight ratio 5:5, the number average molecular weight (Mn) is 14632, the molecular weight distribution index (PDI) is the polyethylene terephthalate of 2.2 and the number average molecular weight (Mn) is 32149, molecular weight distribution Polytrimethylene terephthalate with a coefficient (PDI) of 2.4 is used to produce polyester composite fibers in the side-by-side cross section of Fig. 1-(a). The conjugated fiber obtained through the above-mentioned spinning / coiling was drawn by another drawing device to produce a stretchable conjugated fiber having a single filament fineness of 2.1 denier. When stretching was performed, the stretching ratio was 1.60, the stretching temperature ...

Embodiment 2

[0088] In the process of manufacturing stretchable composite fibers, the spinning temperature is set at 280°C, the spinning speed is 2600 m / min, the crimping tension is 0.07g / d, and the residence time in the module is 4 minutes. Equipment, in the ratio of 5:5 by weight, polyethylene terephthalate with a number average molecular weight (Mn) of 14632 and a molecular weight distribution index (PDI) of 2.2 and a number average molecular weight (Mn) of 39334, molecular distribution Polytrimethylene terephthalate with a coefficient (PDI of) 2.2 is used to produce polyester composite fibers in the side-by-side cross section of Fig. 1-(a). The conjugated fiber obtained through the above-mentioned spinning / coiling was drawn by another drawing device to produce a stretchable conjugated fiber having a single filament fineness of 2.1 denier. When stretching was carried out, the stretching ratio was 1.70, the stretching temperature was 90°C, and the heat setting temperature was 160°C. Tabl...

Embodiment 3

[0090] In the process of manufacturing stretchable composite fibers, the spinning temperature is set at 283°C, the spinning speed is 2400 m / min, the crimping tension is 0.08g / d, and the residence time in the module is 4 minutes. Equipment, with the ratio of weight ratio 5:5, the number average molecular weight (Mn) is 16422, the molecular weight distribution index (PDI) is the polyethylene terephthalate of 2.1 and the number average molecular weight (Mn) is 45752, molecular weight distribution Polytrimethylene terephthalate with a coefficient (PDI) of 2.0 is used to produce polyester composite fibers in the parallel cross section of Fig. 1-(a). The conjugated fiber obtained through the above-mentioned spinning / coiling was drawn by another drawing device to produce a stretchable conjugated fiber having a single filament fineness of 2.1 denier. When stretching was carried out, the stretching ratio was 1.70, the stretching temperature was 90°C, and the heat setting temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com