Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Meet fast feeding needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feeder with valves and automatic leaked material receiving device

InactiveCN108967305APrecise feedingFree from pollutionClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The application discloses a feeder with valves and an automatic leaked material receiving device. The feeder comprises a frame, a material bin, hoppers, material spray pipes, a material spray pipe transverse adjusting device, a leaked material receiving device, a weighing system and an air pressure tank. The frame comprises an air pressure column connected with the material bin which is connectedat the upper part of the frame. The hoppers are connected below the material bin and equipped with material discharge pipes which are connected with the material spray pipes. Valves are arranged in the interiors of the material spray pipes. The material spray pipes are connected with the material discharge pipes through the material spray pipe transverse adjusting device. The leaked material receiving device is connected below the frame. The weighing system can weigh and calculate fodders. The air pressure tank is connected besides the frame and comprises a steel tank body and an air bag. Theair bag is arranged in the steel tank body and can store high-pressure water. The feeder takes high-pressure water as a power so that metered fodders in the material spray pipes are delivered out.

Owner:张达英

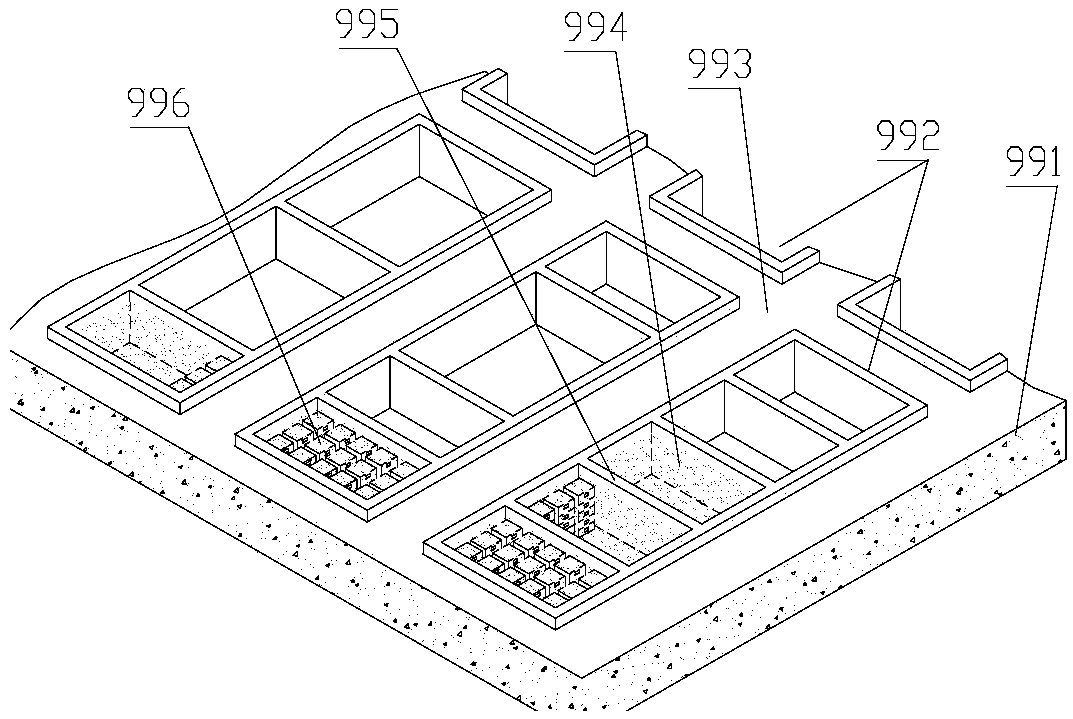

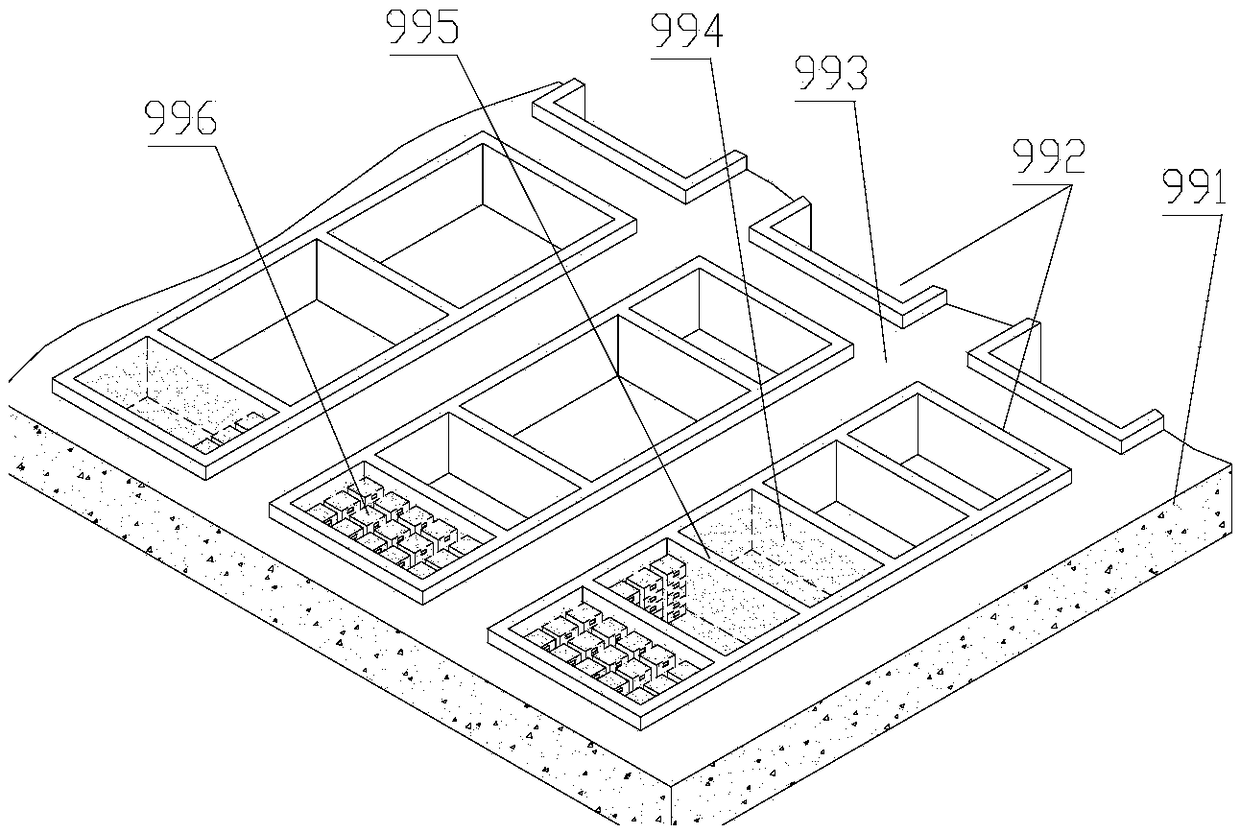

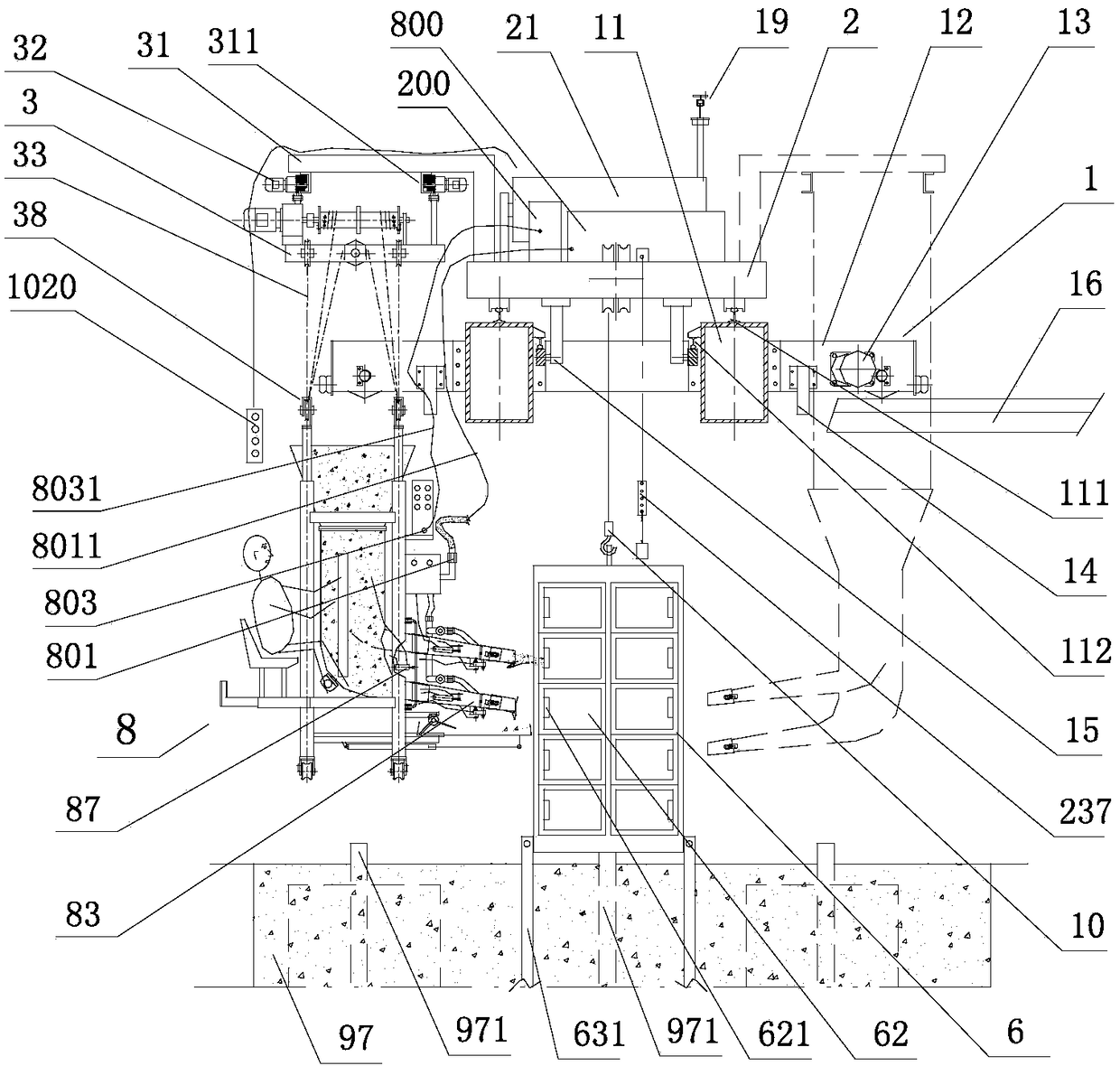

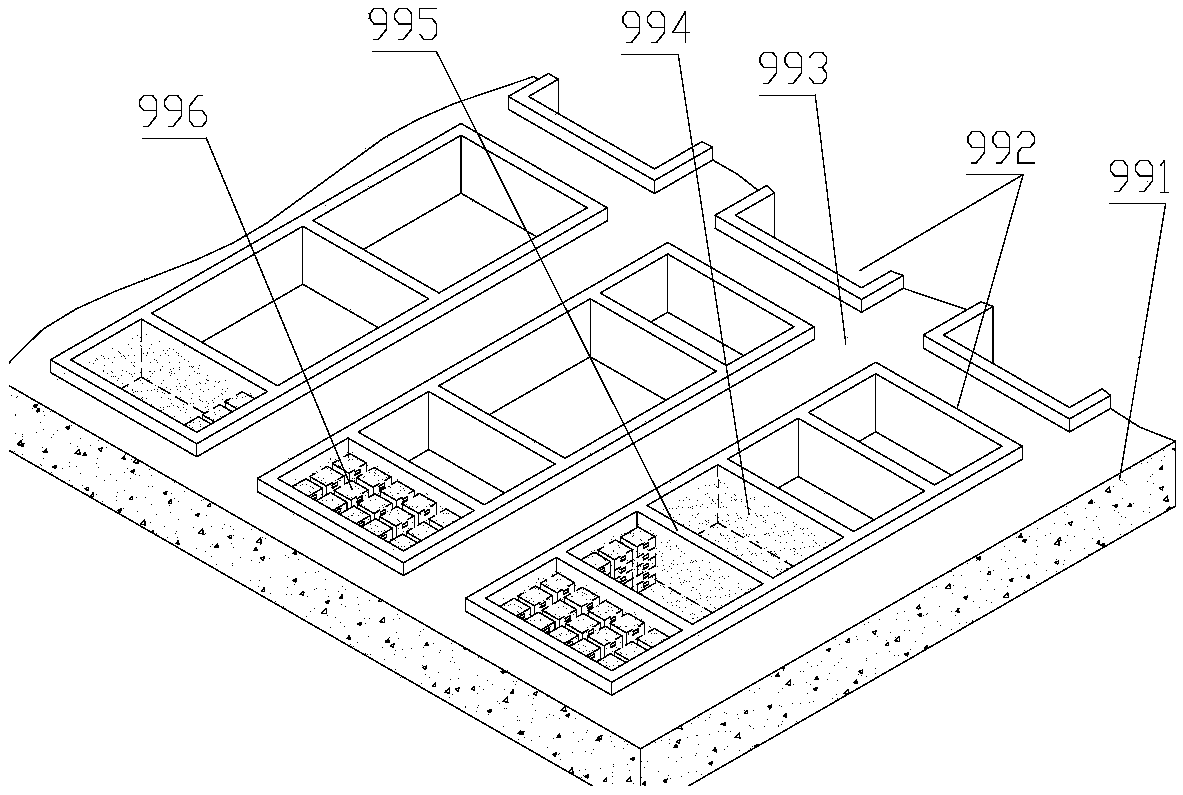

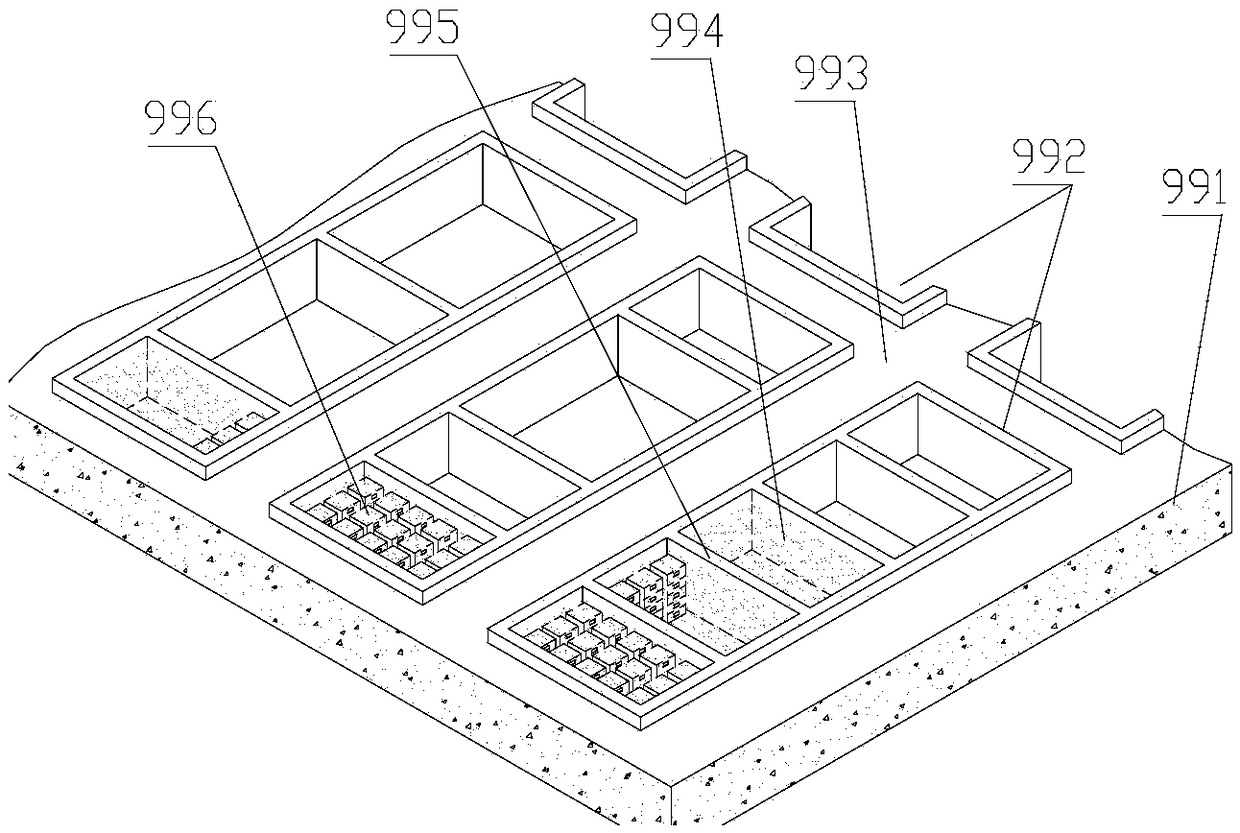

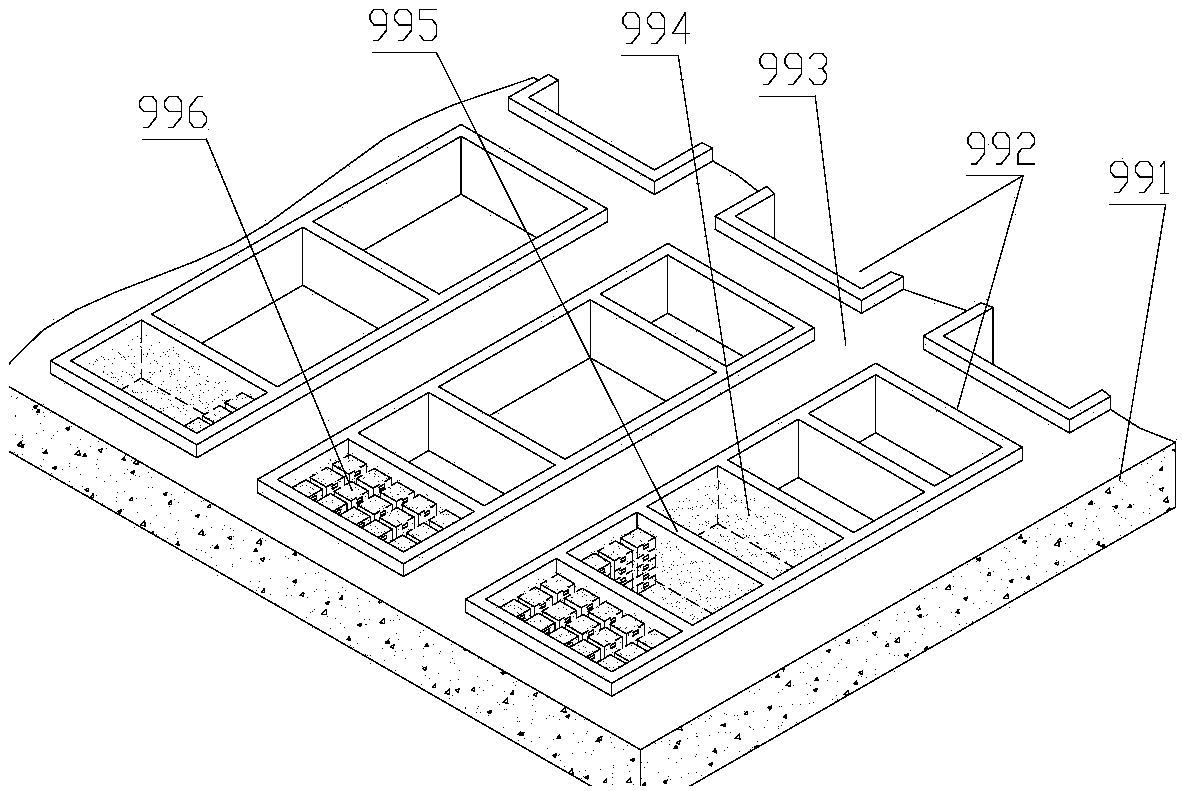

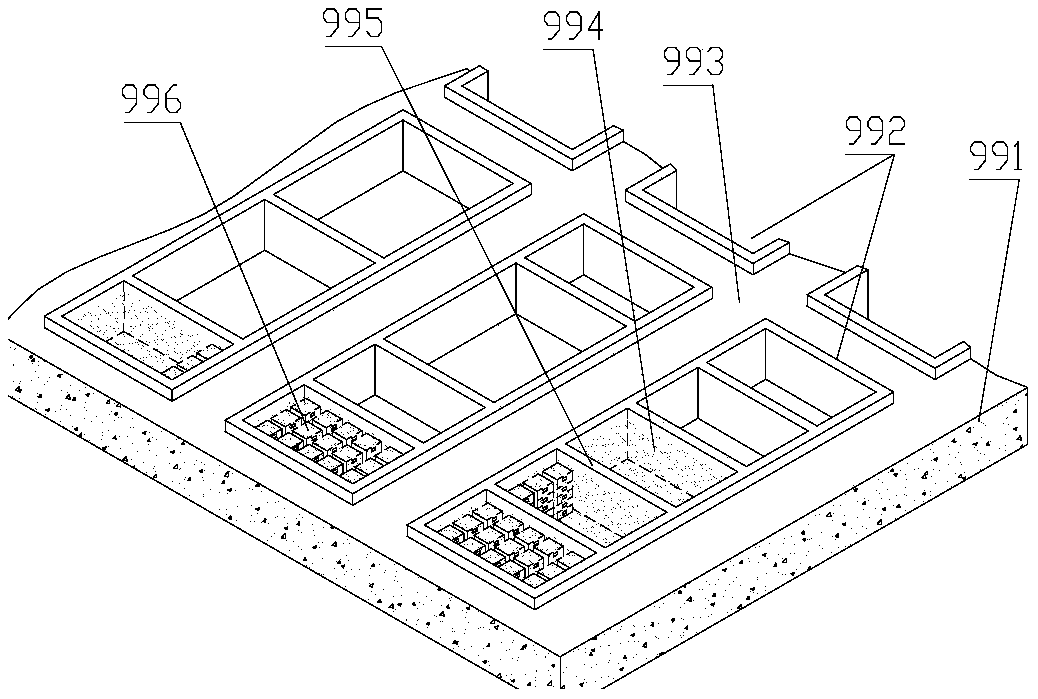

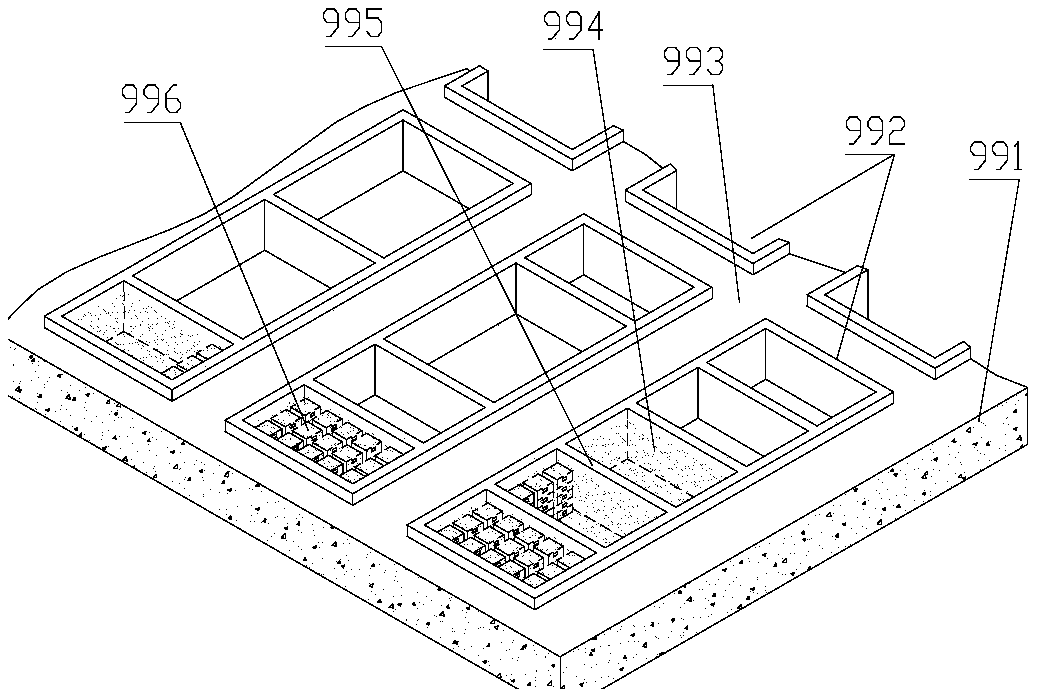

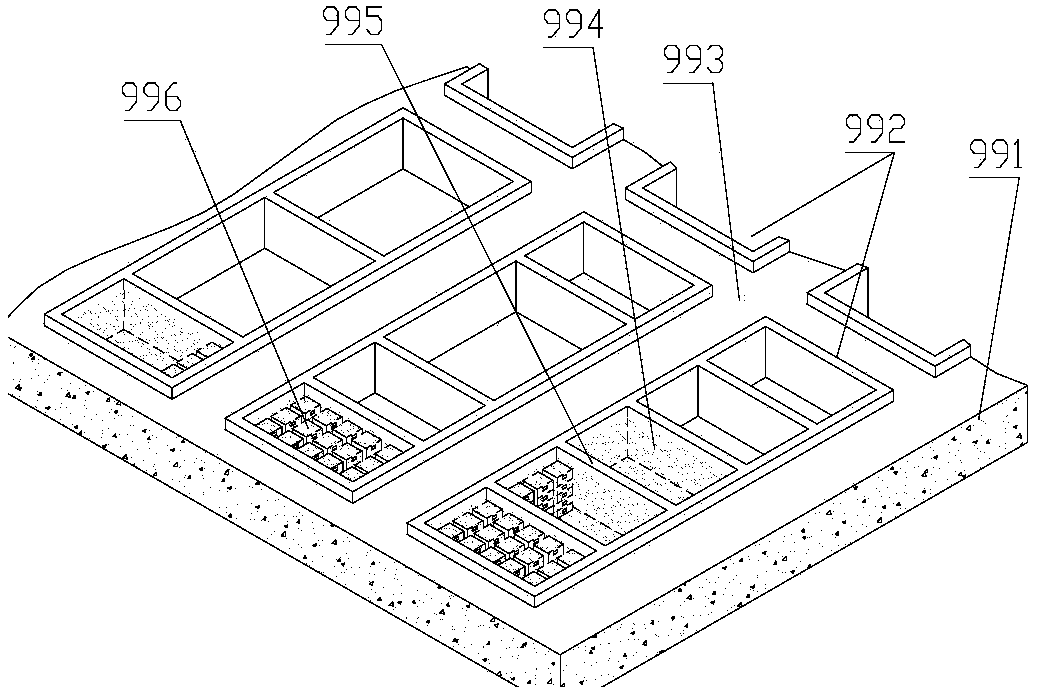

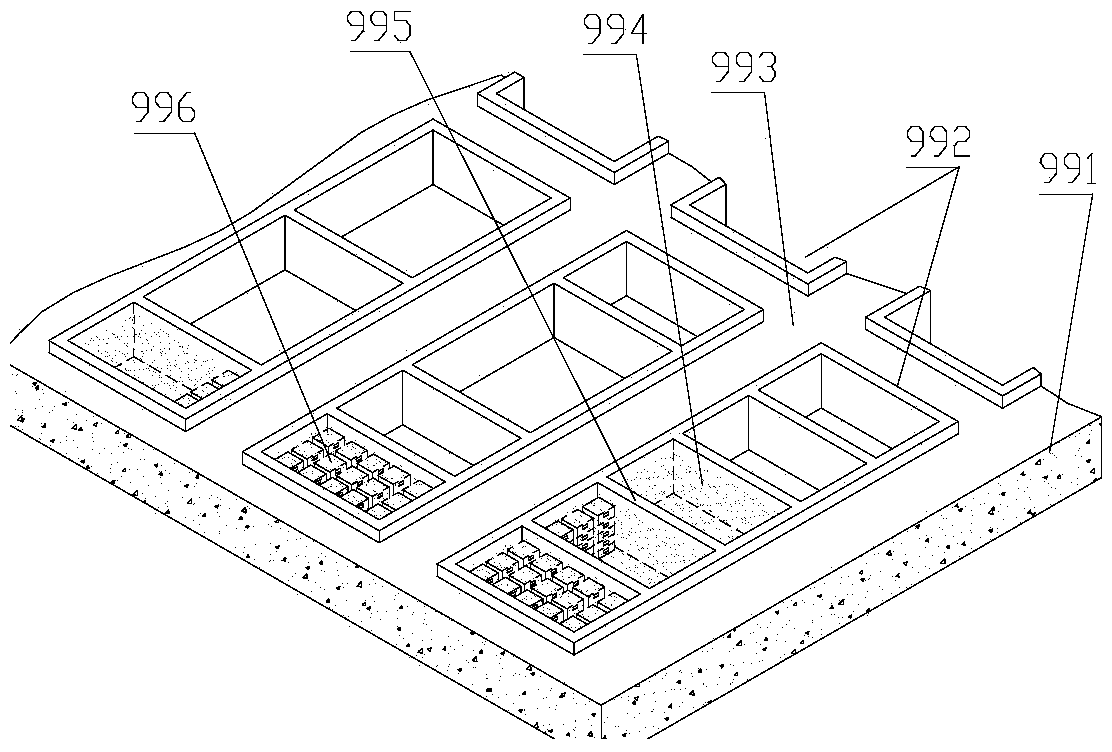

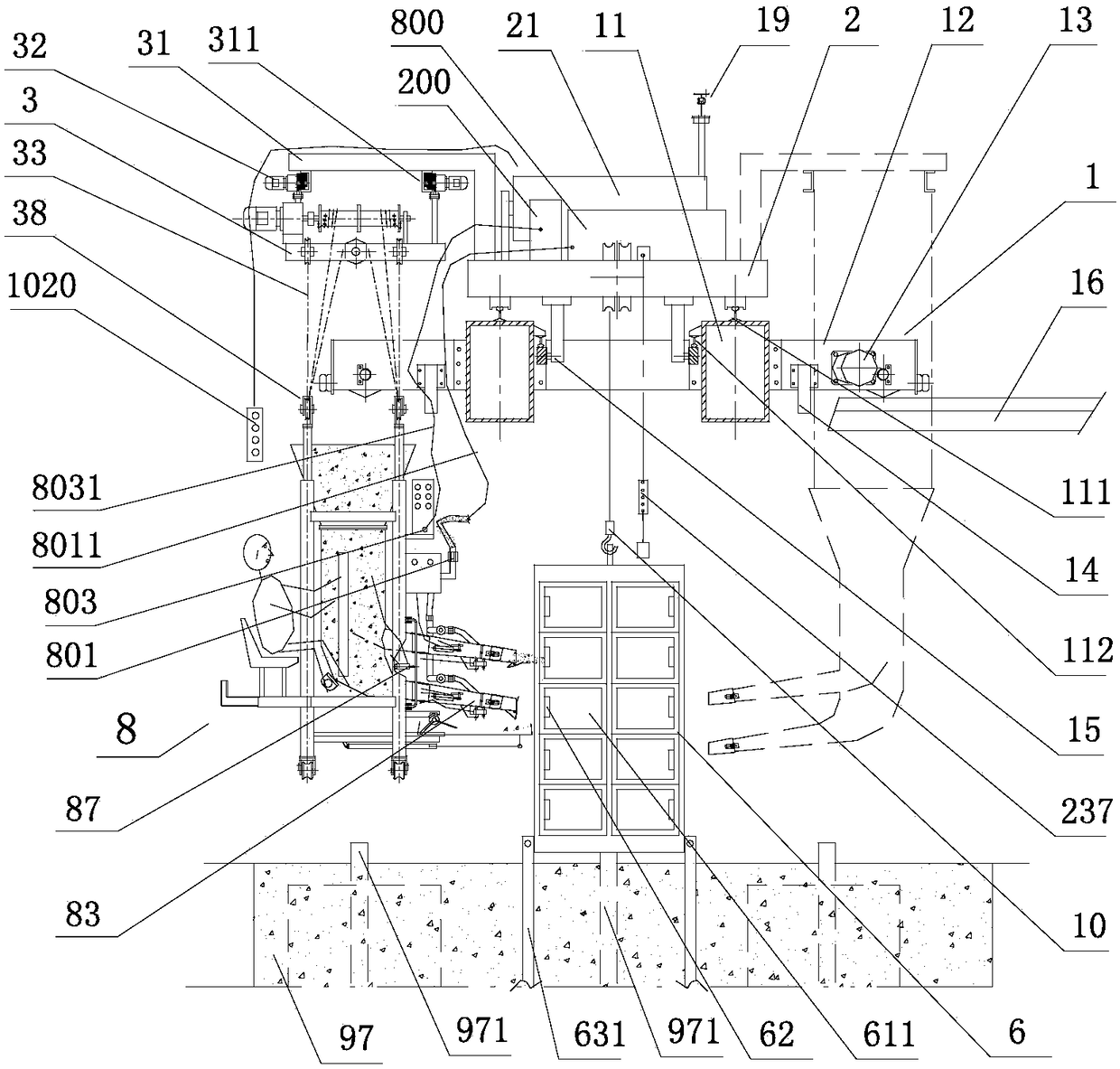

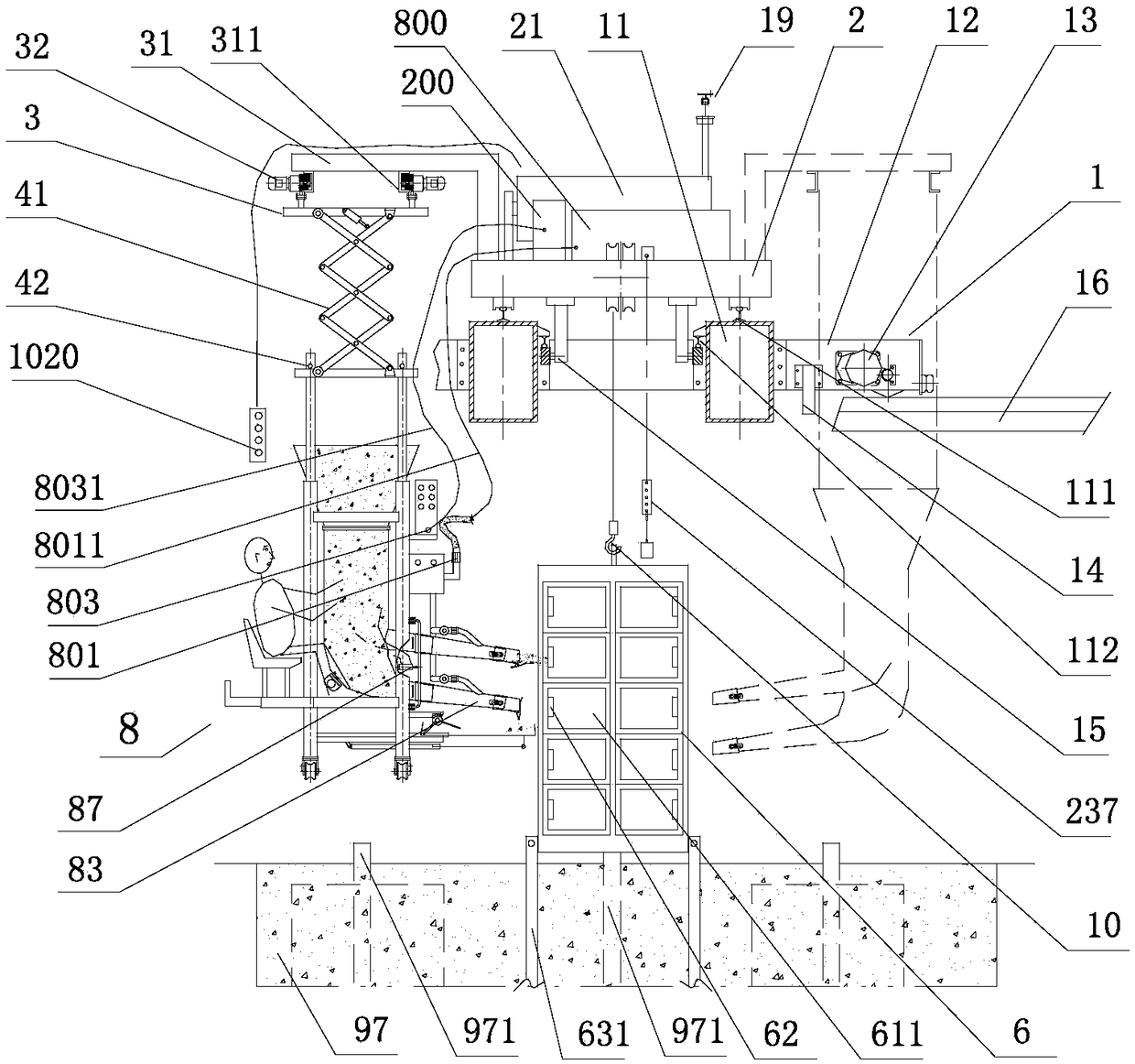

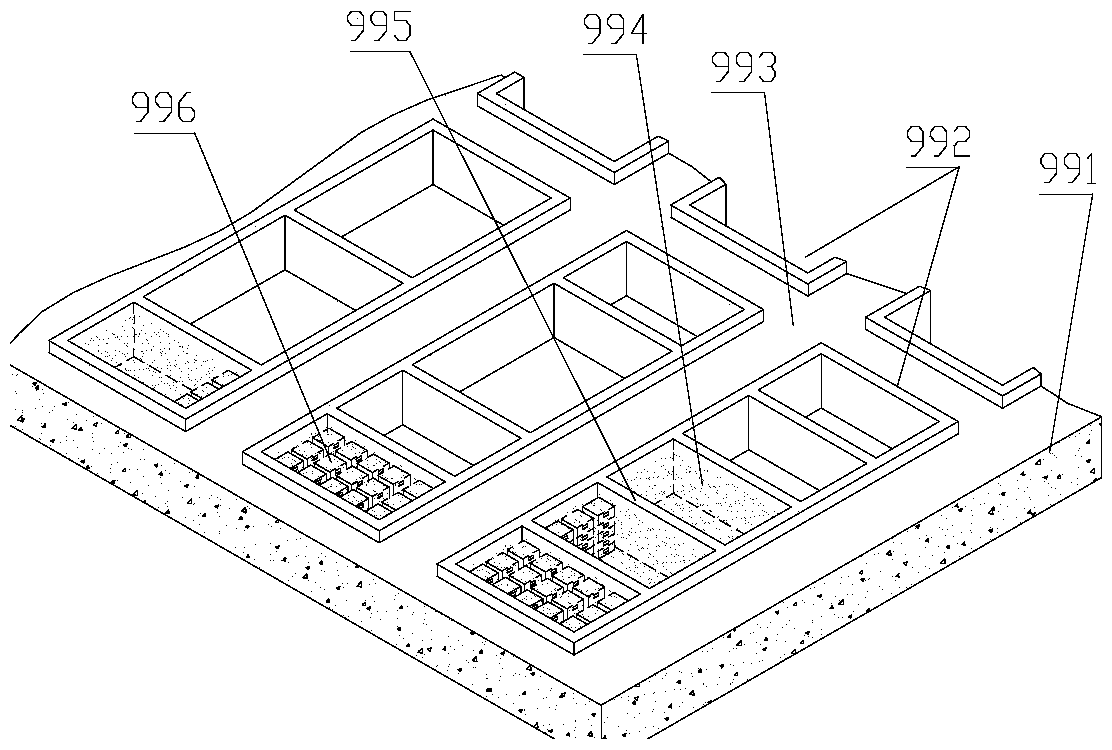

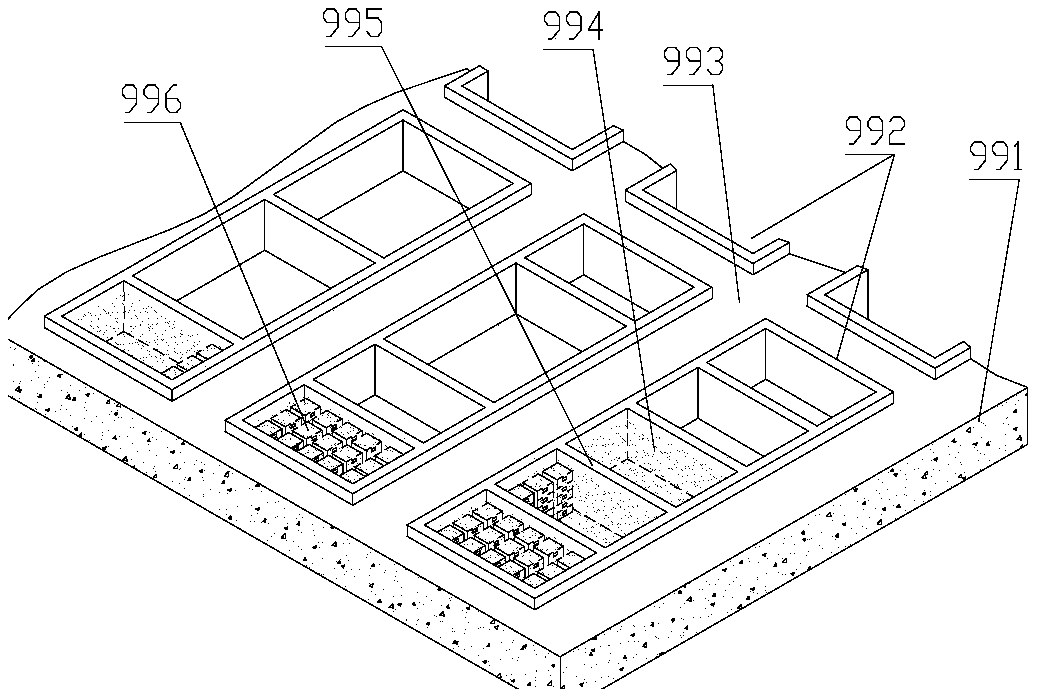

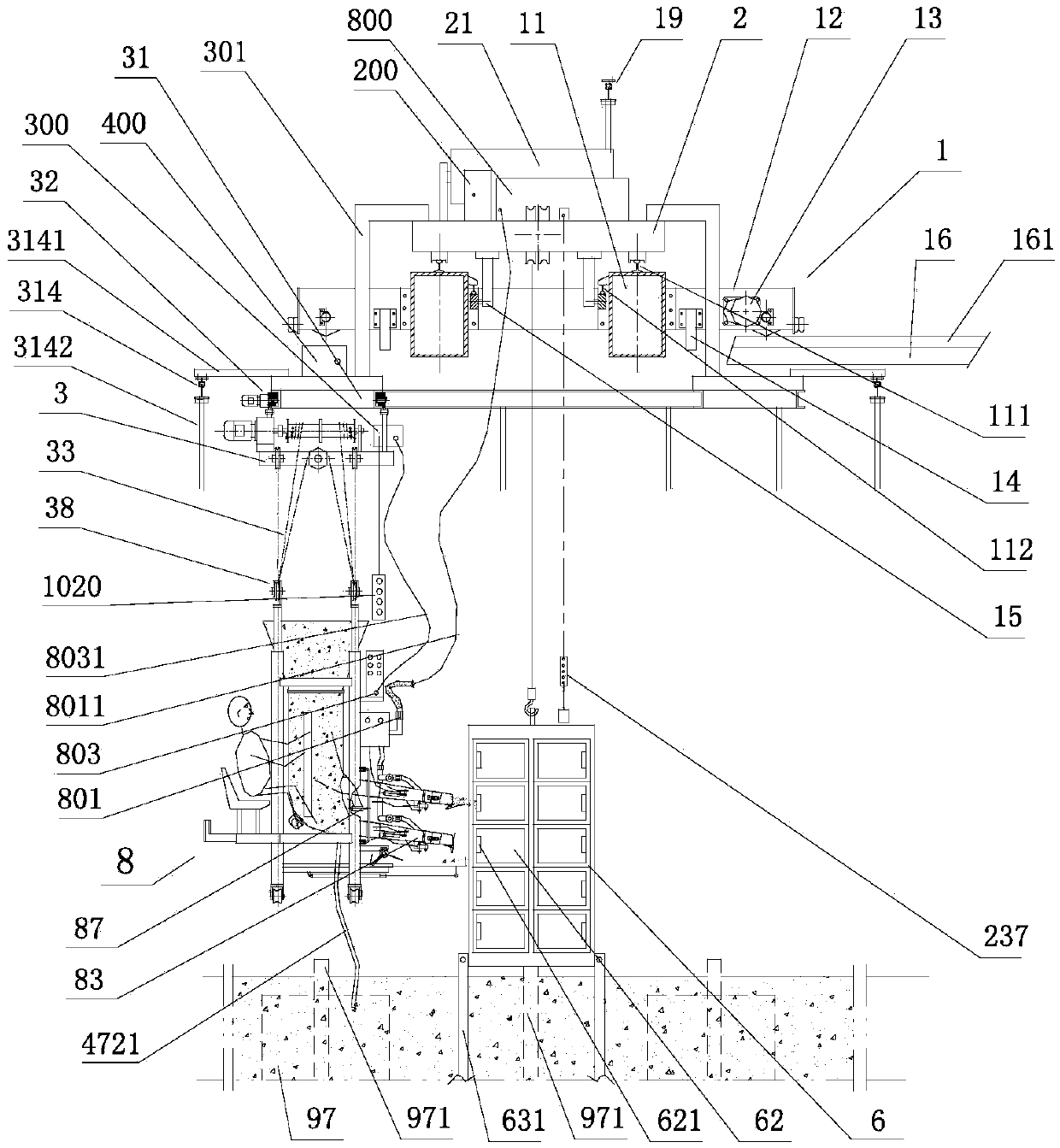

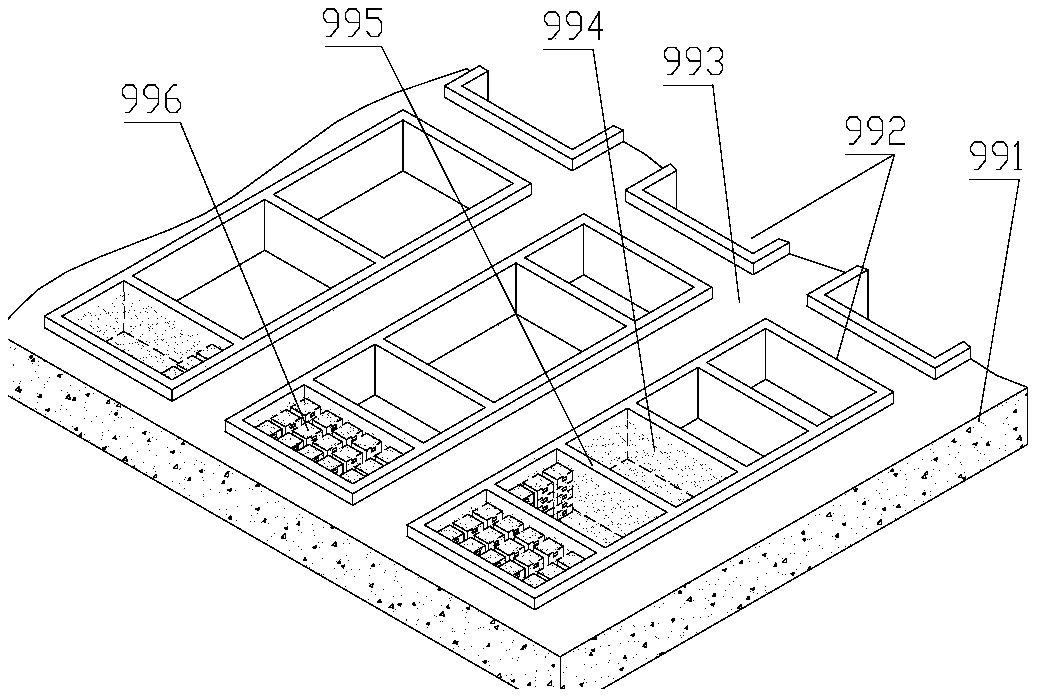

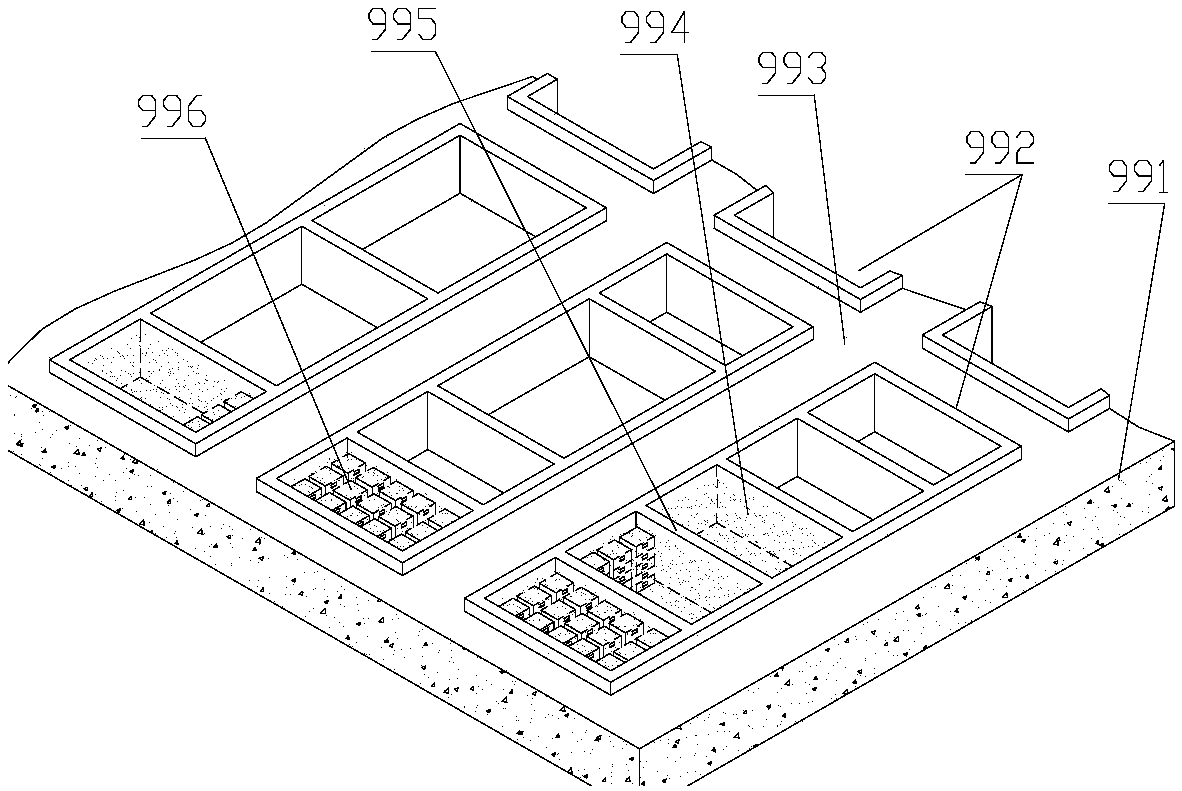

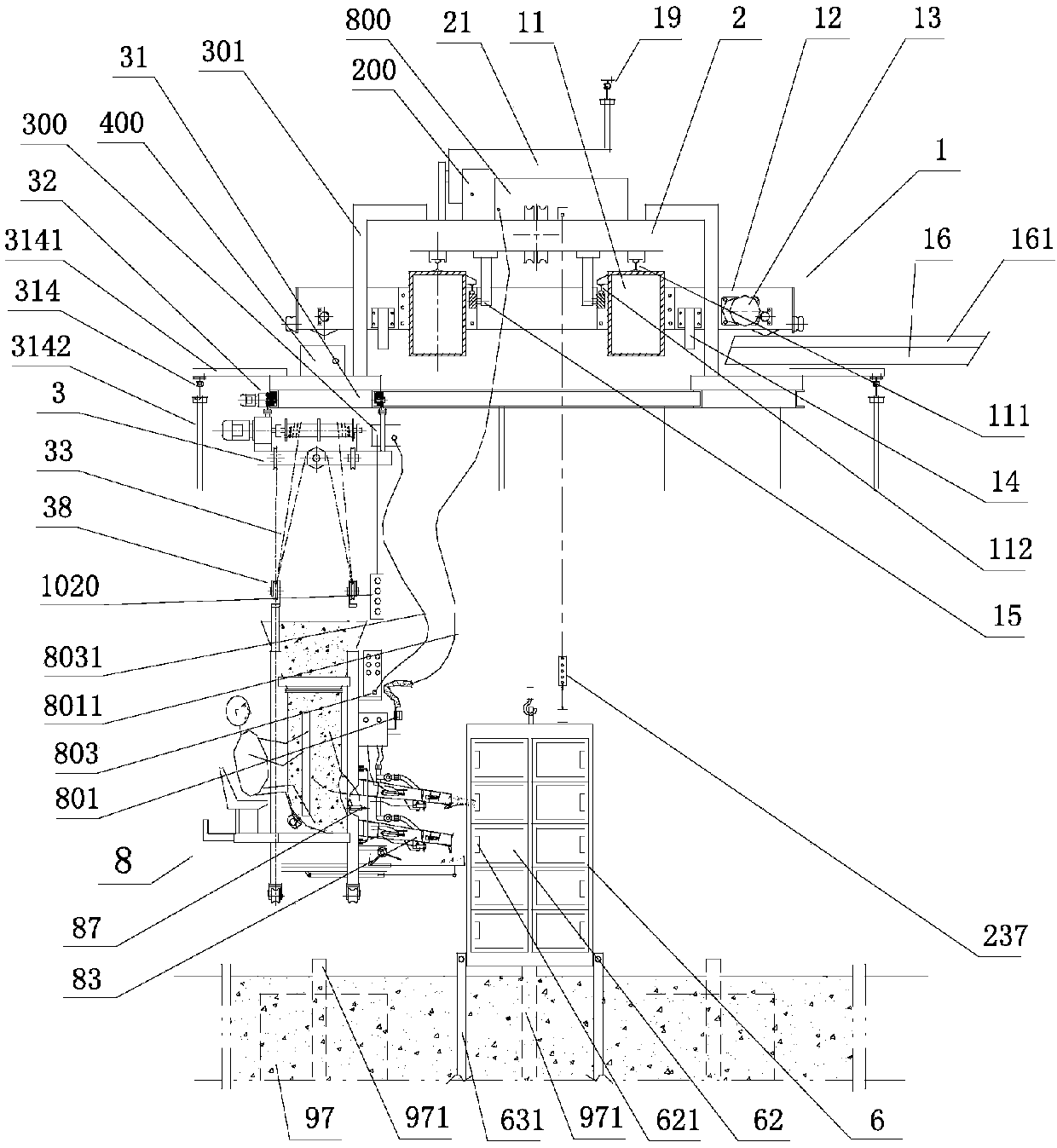

Aquaculture feeding system with bridge crane and weighing feeder

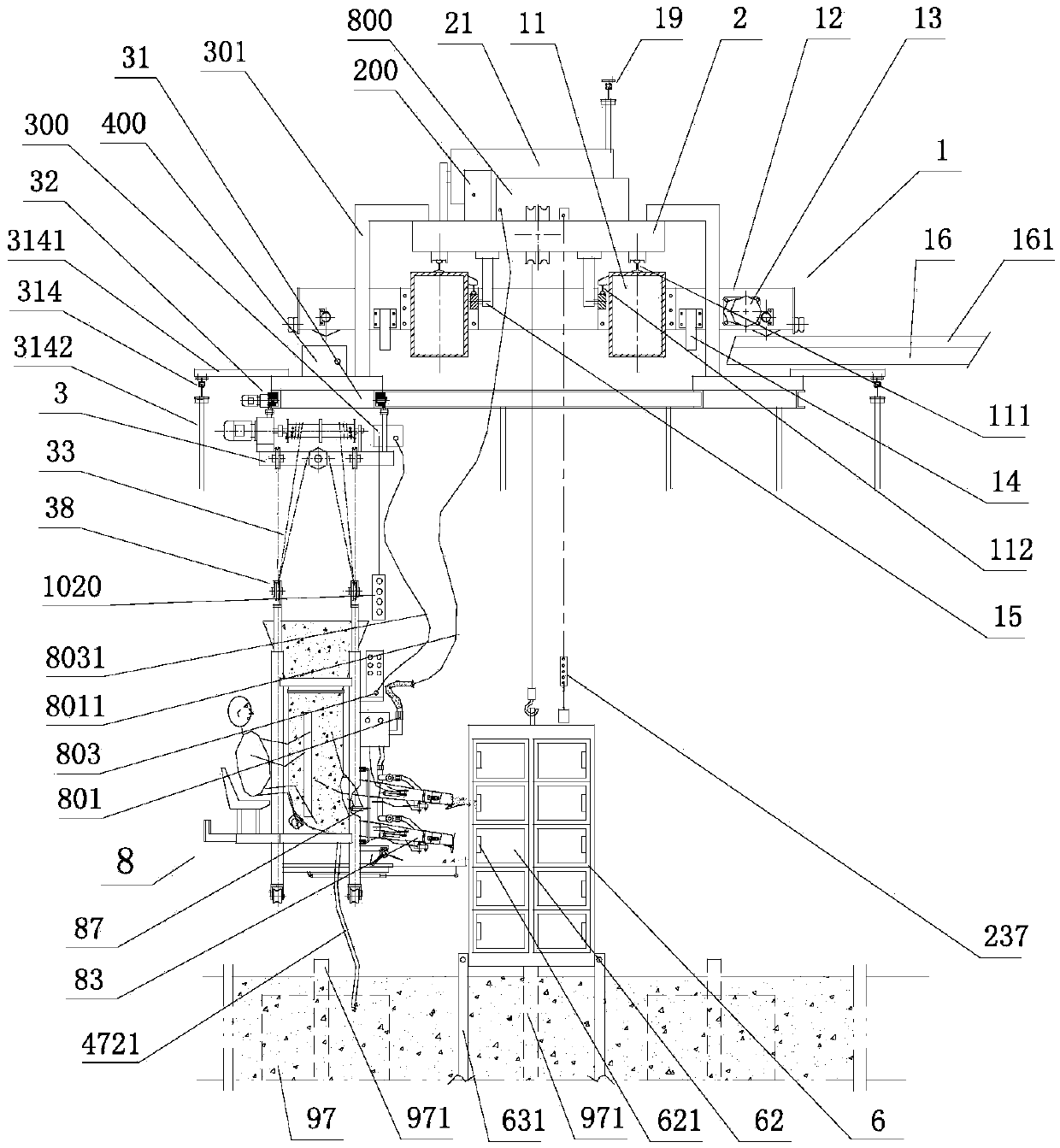

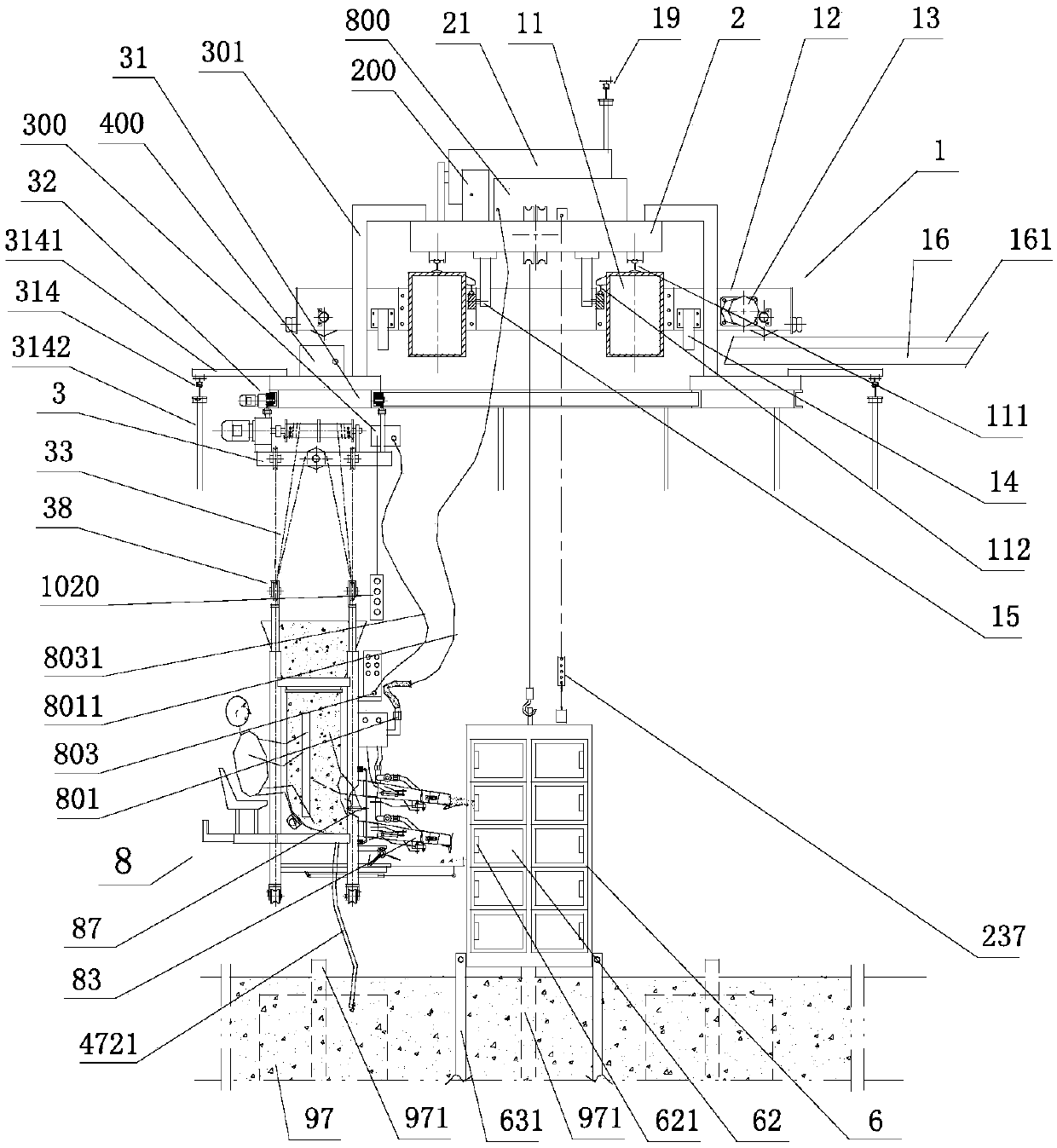

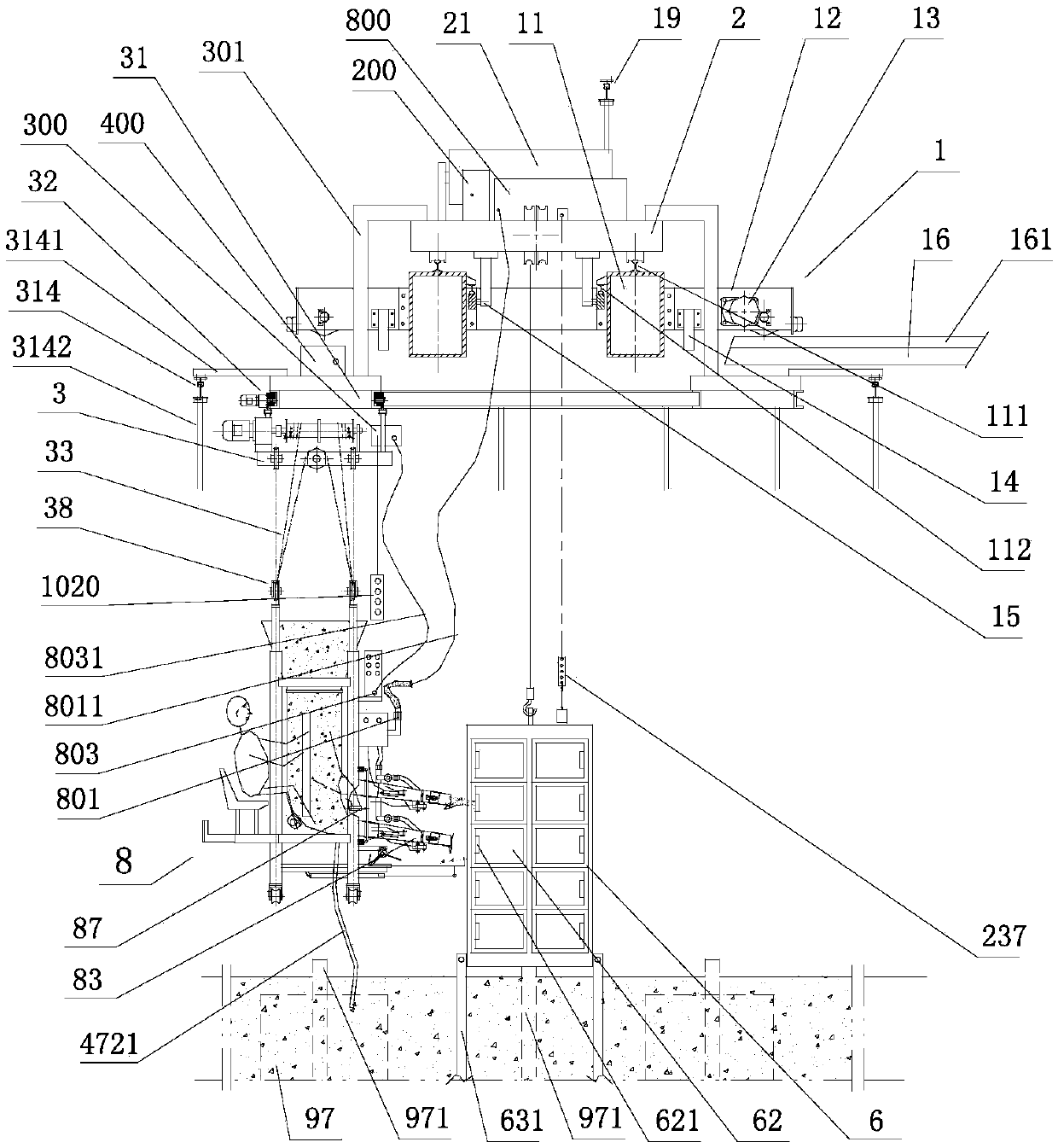

InactiveCN109418206AAccurate positioning and quantitative feedingReduce workshop aislesClimate change adaptationPisciculture and aquariaEngineeringOverhead crane

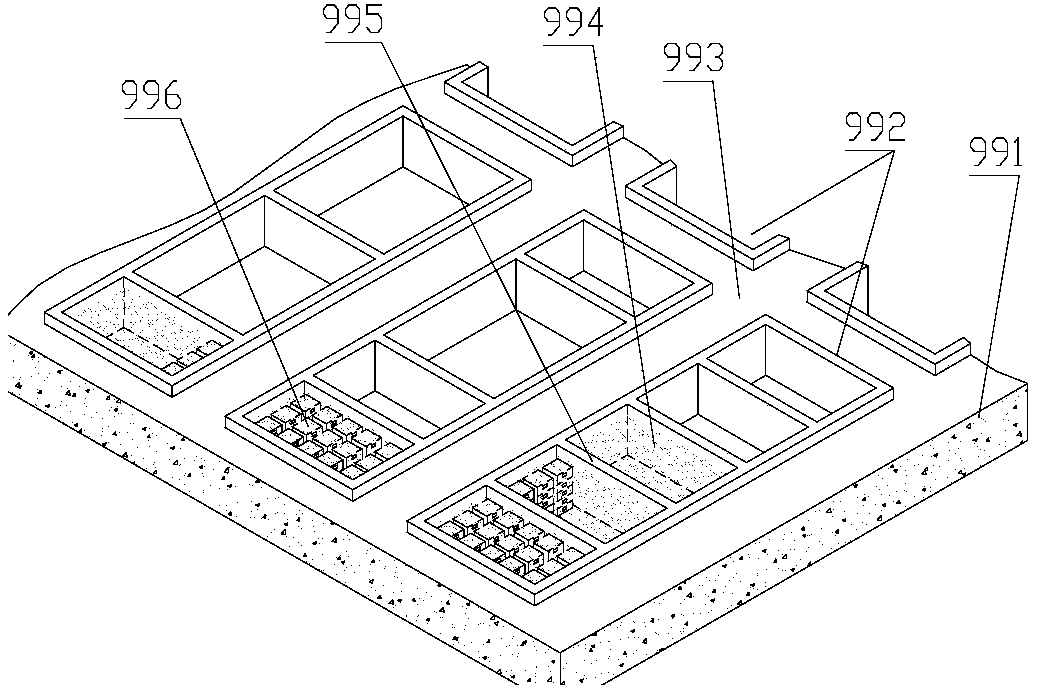

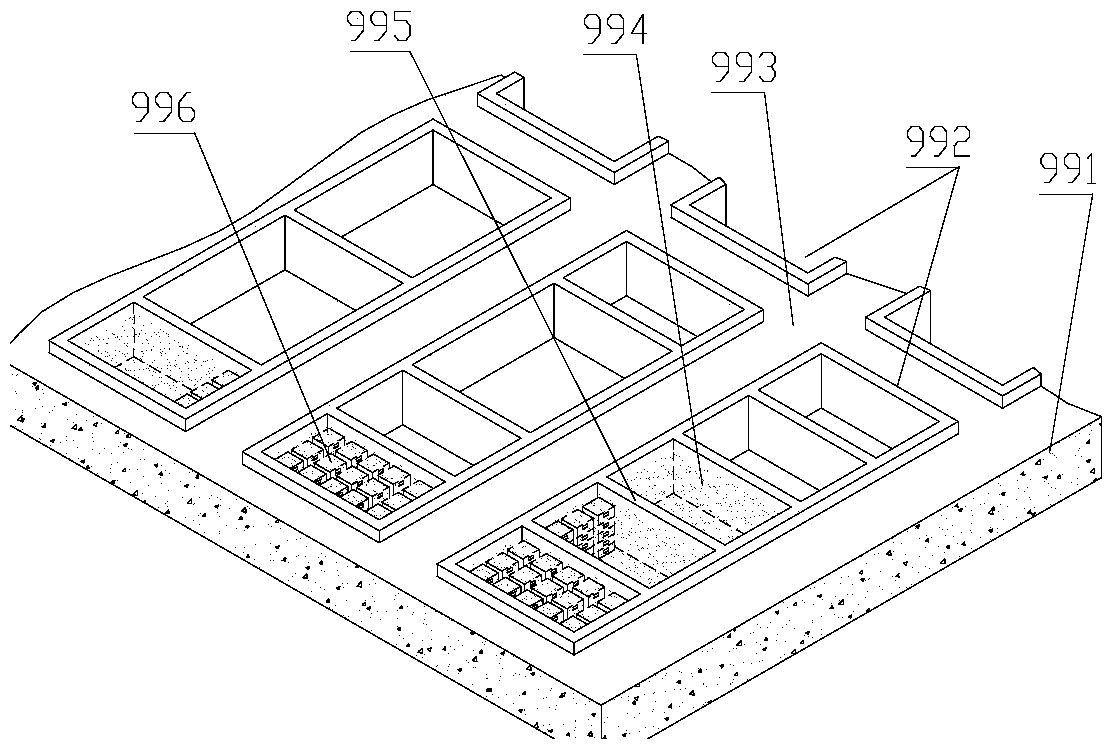

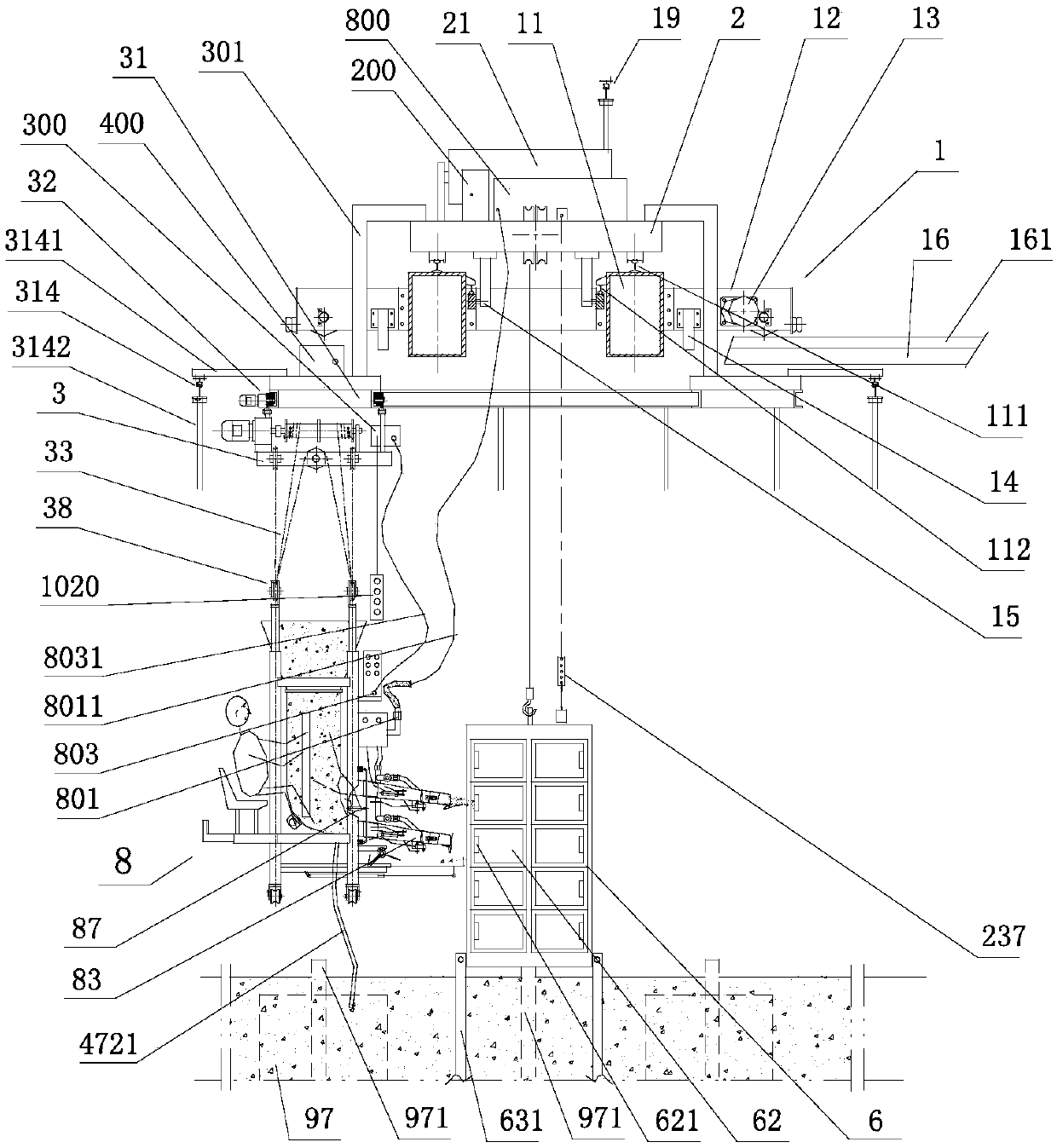

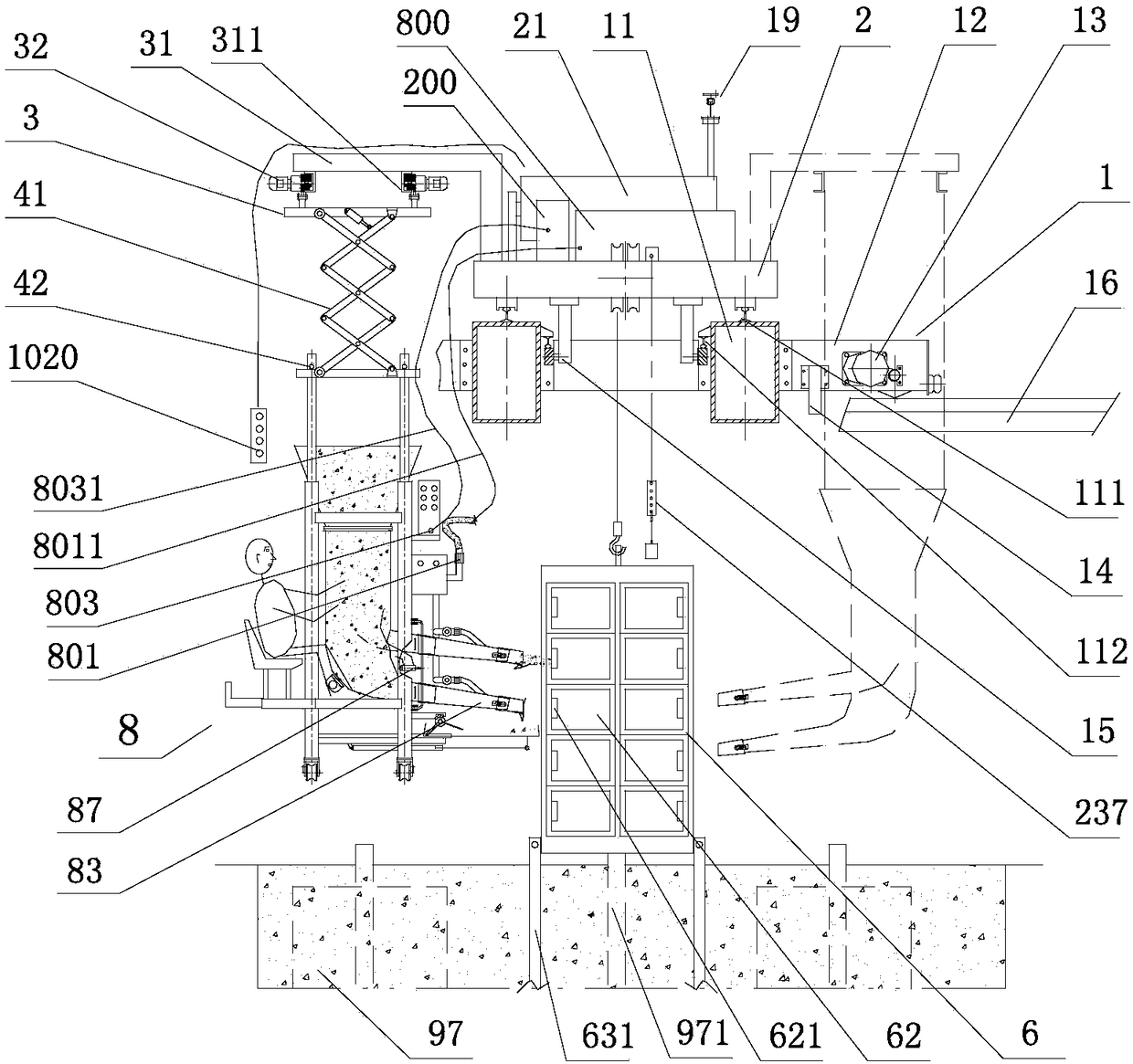

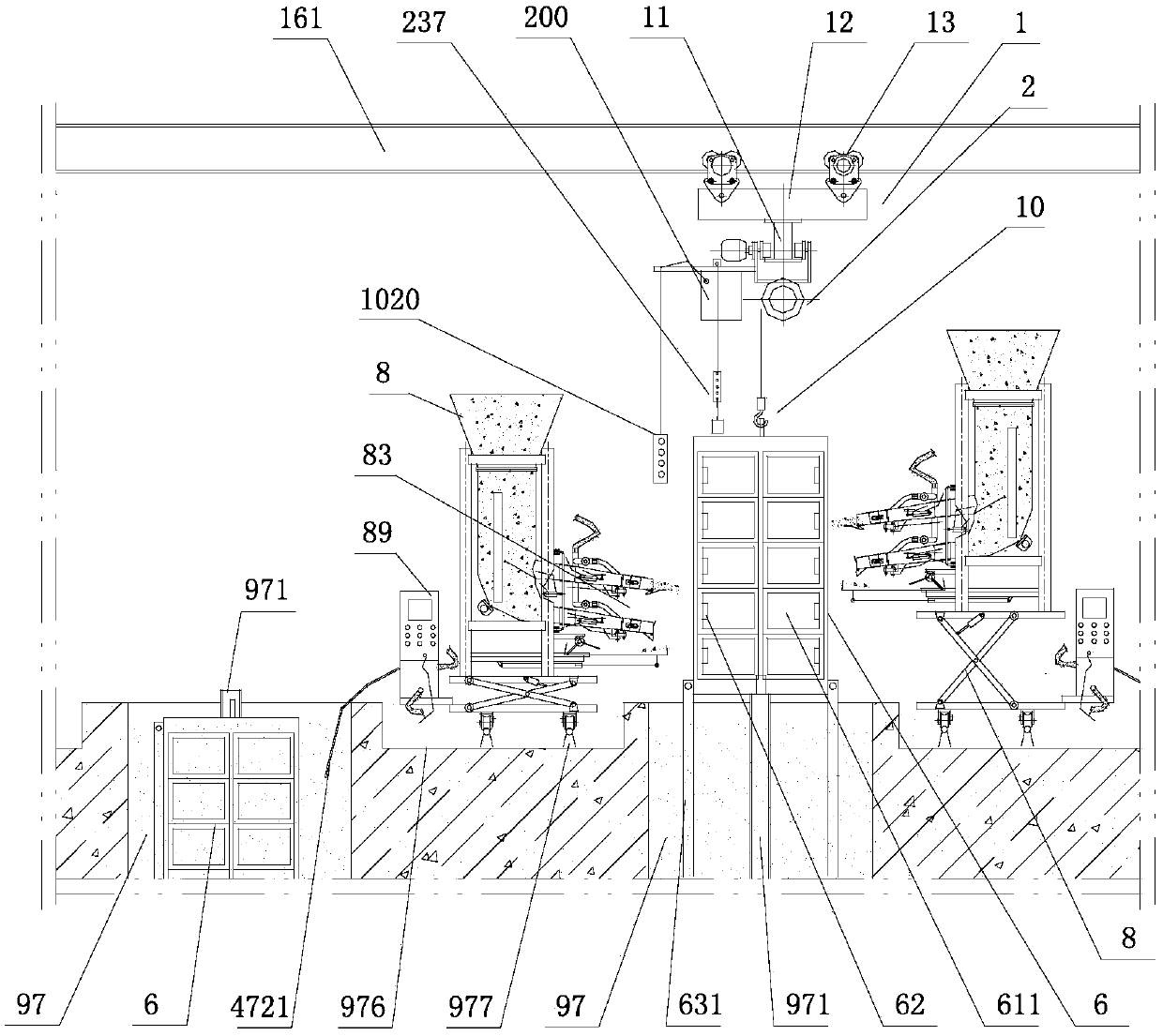

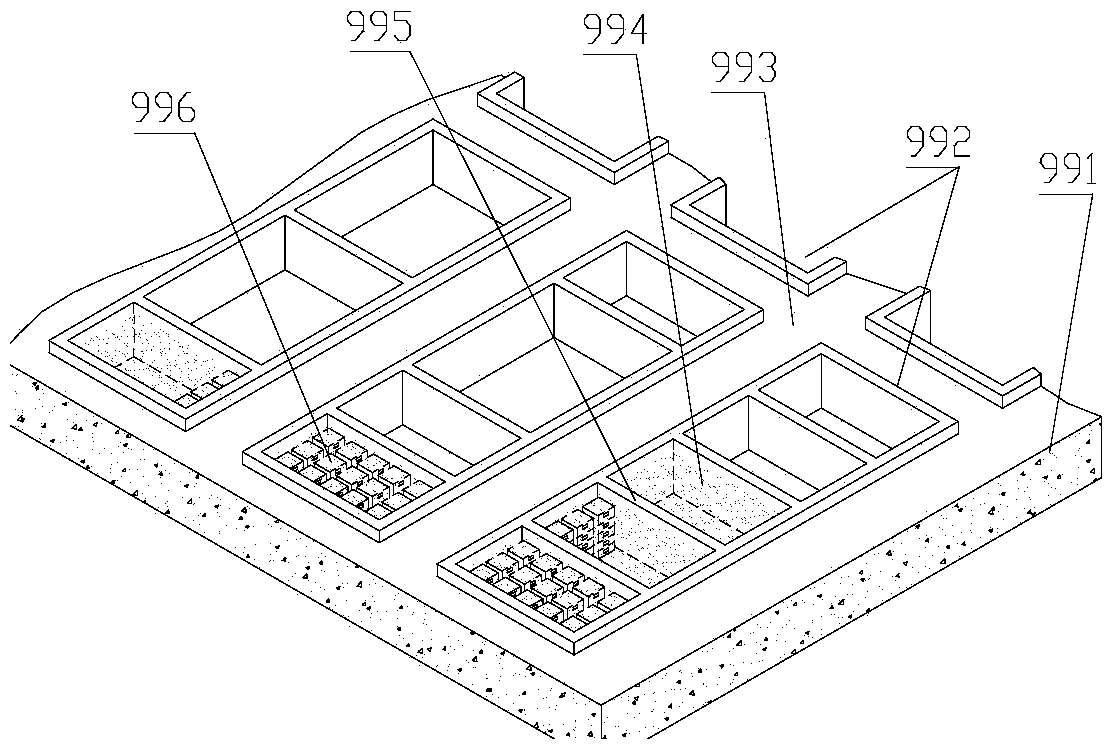

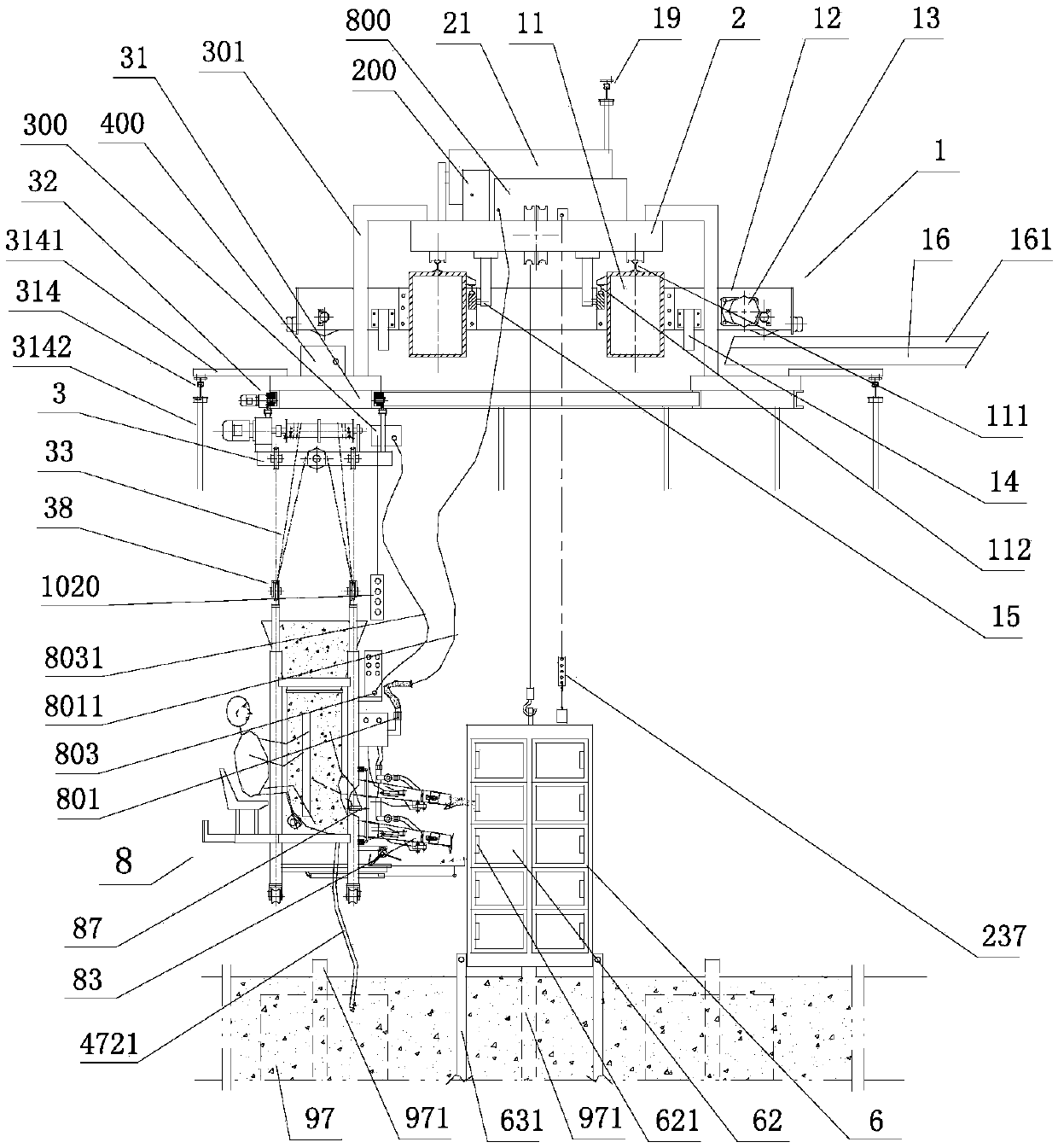

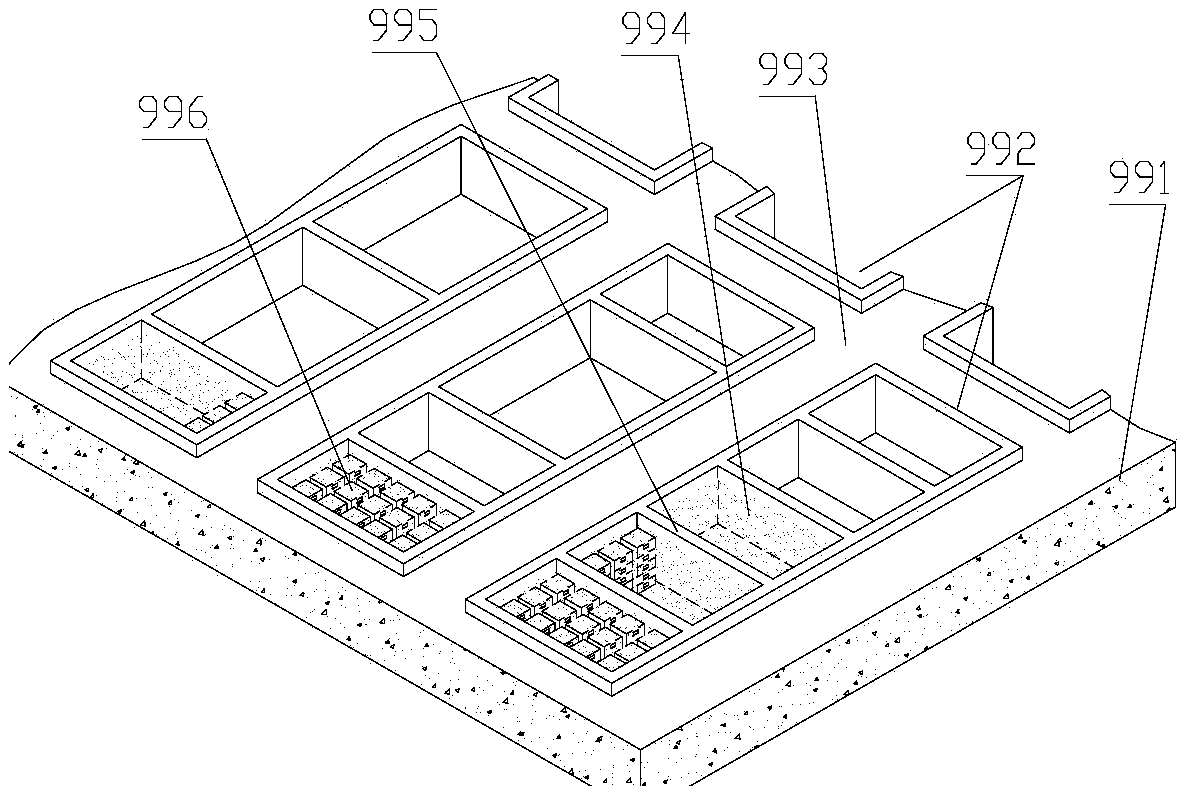

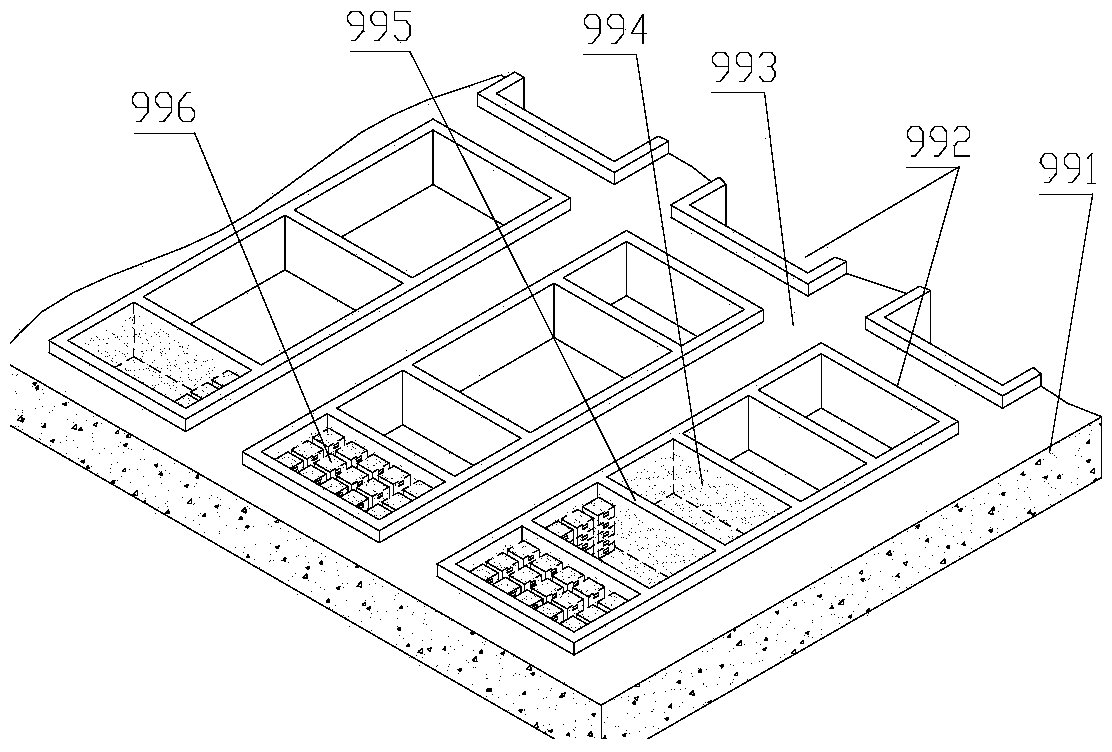

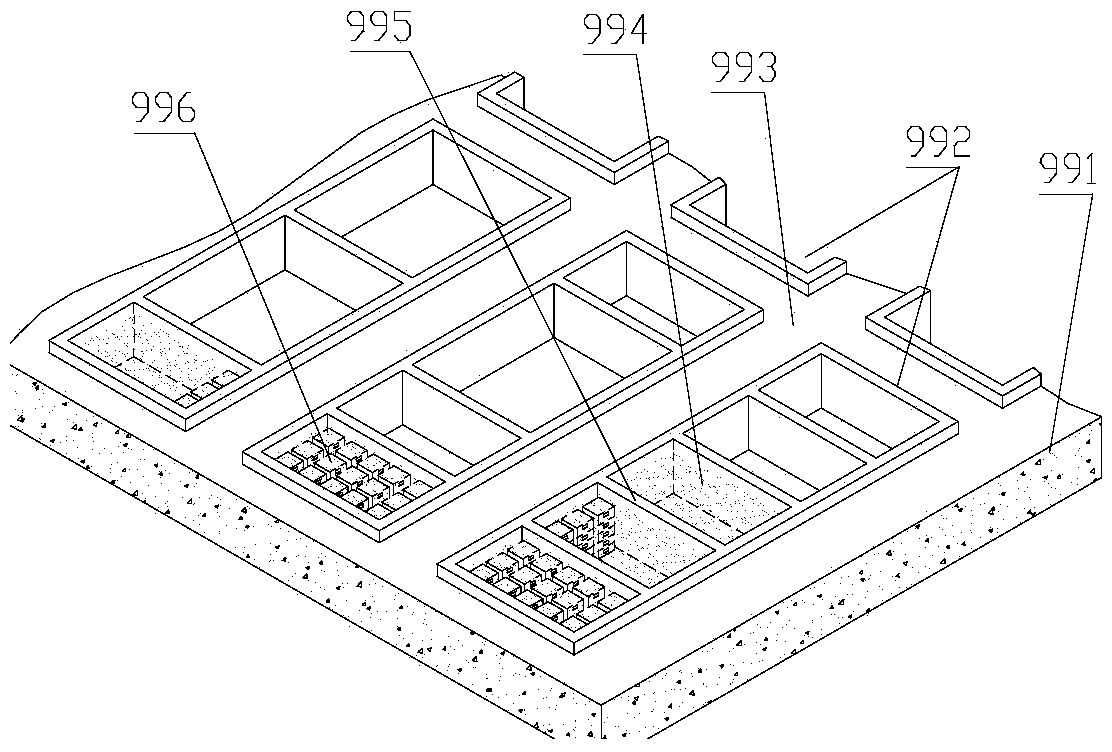

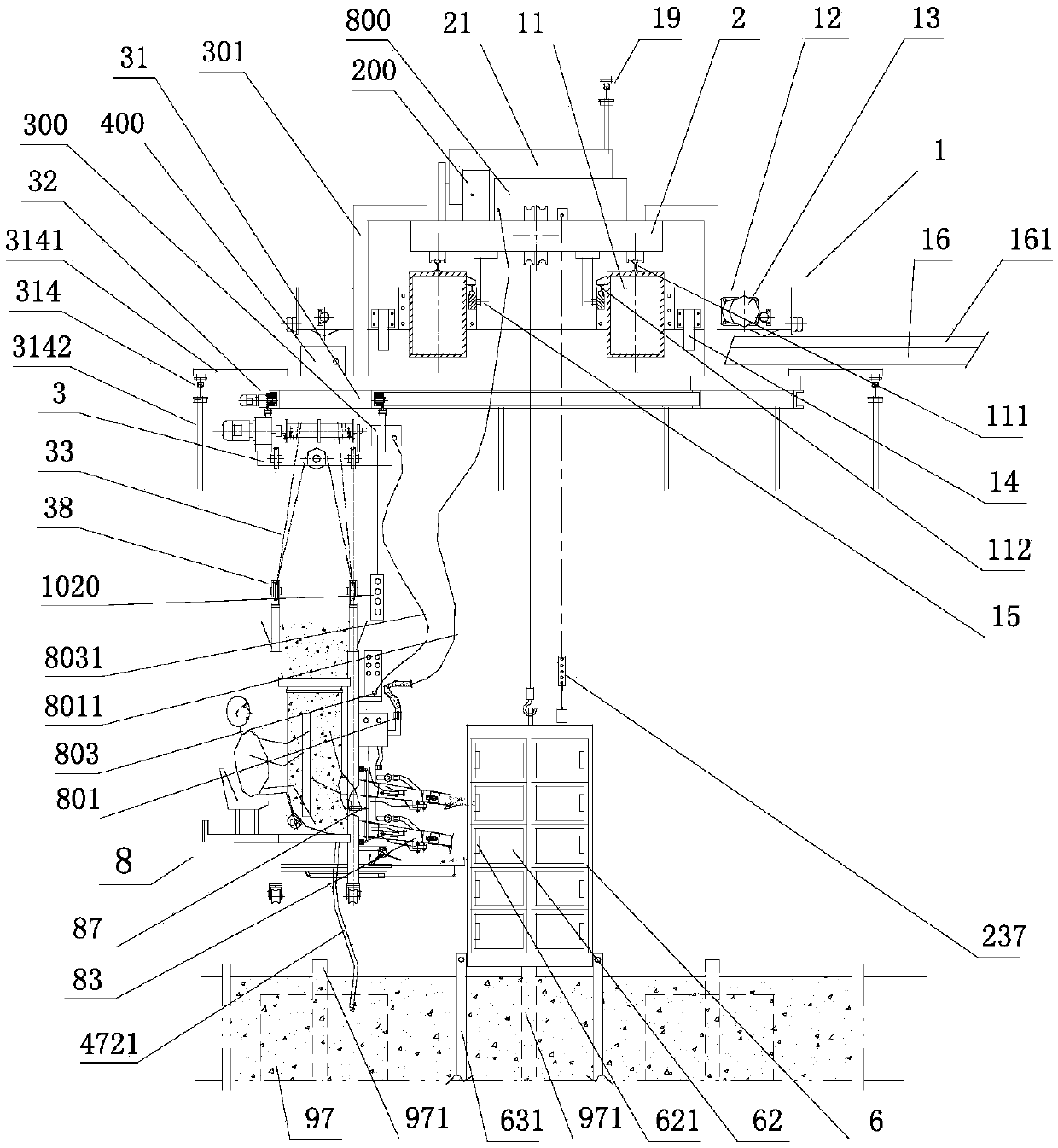

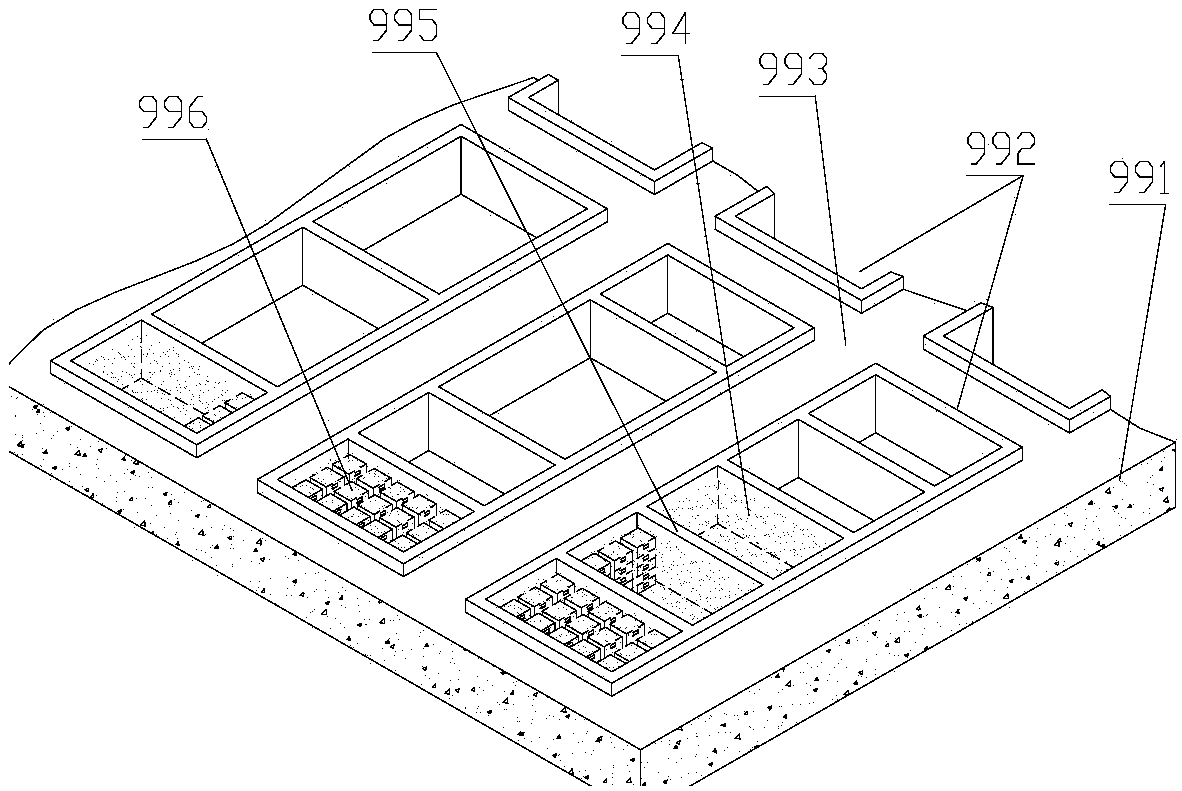

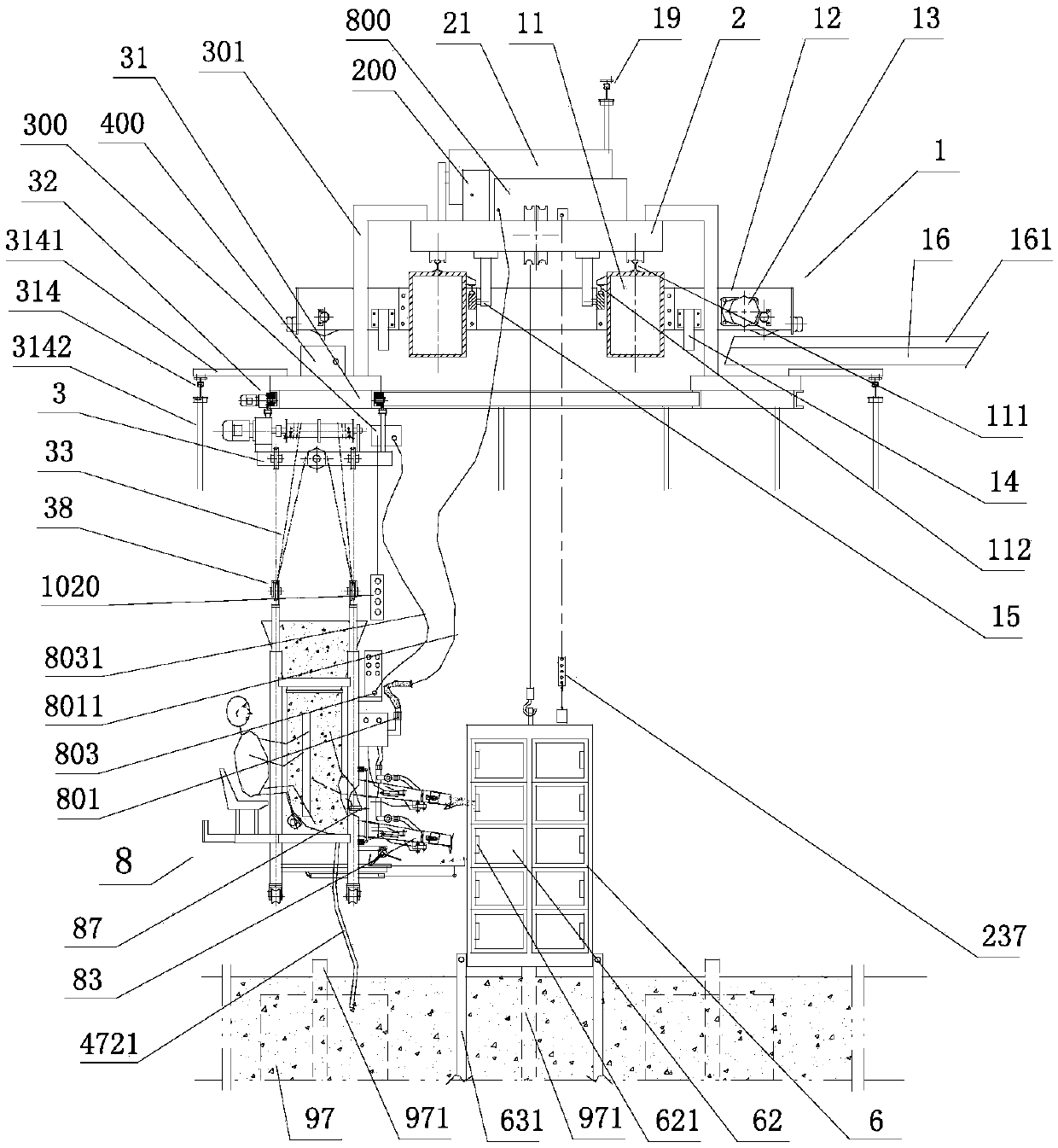

The invention discloses an aquaculture feeding system with a bridge crane and a weighing feeder. The aquaculture feeding system includes an aquaculture pond, at least one aquaculture cabinet, a craneand a feeder; a wheel tread of a cart running device of the crane runs, pressing on workshop tracks above rail-bearing beams, and the two rail-bearing beams are separately connected to brackets of workshop upright columns at both sides of the aquaculture pond; the at least one aquaculture cabinet is placed in the aquaculture pond; the crane comprises one or more trolley devices, and each trolley device is connected with one or two feeders and operates with the crane; the feeder is equipped with a weighing system, and the weighing system can weigh and measure the feed in a metering mouth of thefeeder; and hooks on the crane lift the at least one aquaculture cabinet to the pond surface of the aquaculture pond, and the feeder feeds the at least one aquaculture cabinet quantitatively throughhigh pressure gas.

Owner:黄滨

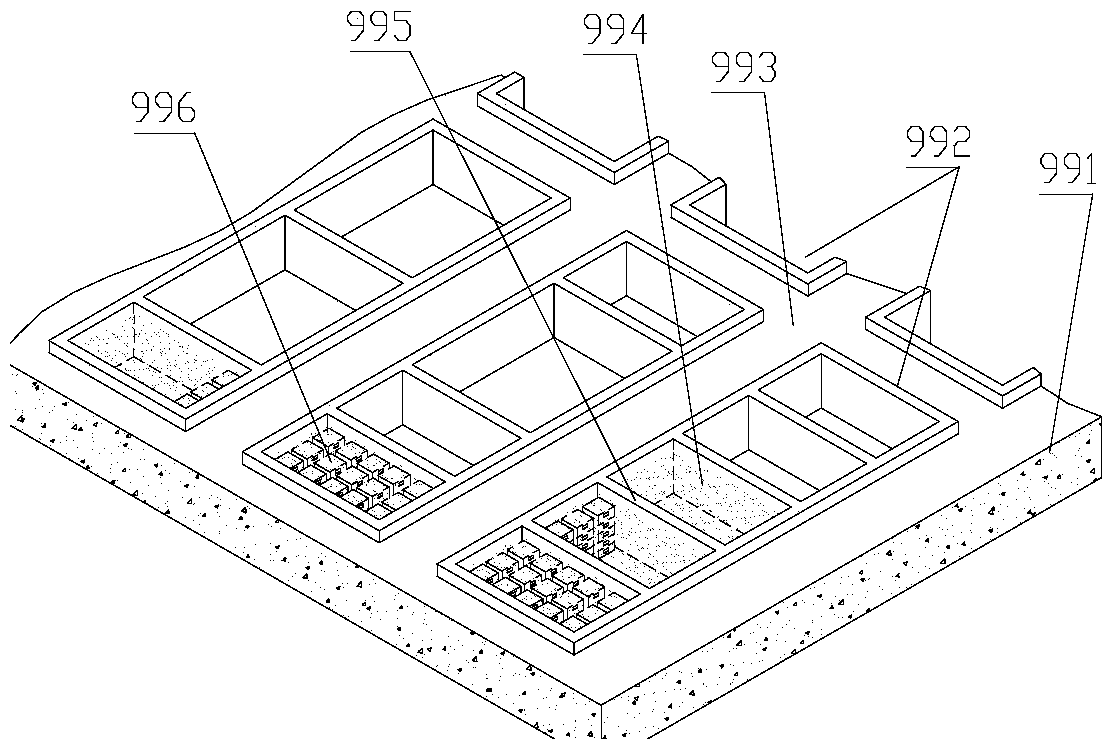

Overwater aquaculture feeding system with annular track and weighing feeder

InactiveCN111096269AAccurate positioning and quantitative feedingLabor savingClimate change adaptationPisciculture and aquariaCartEngineering

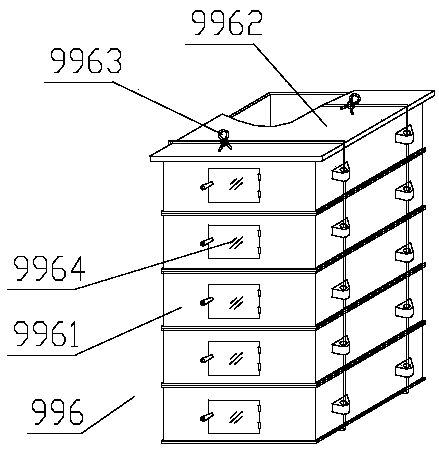

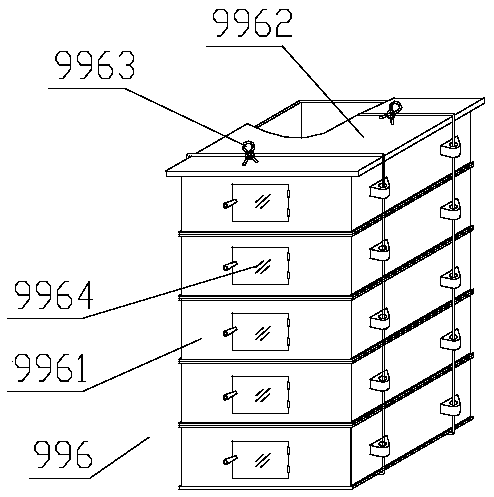

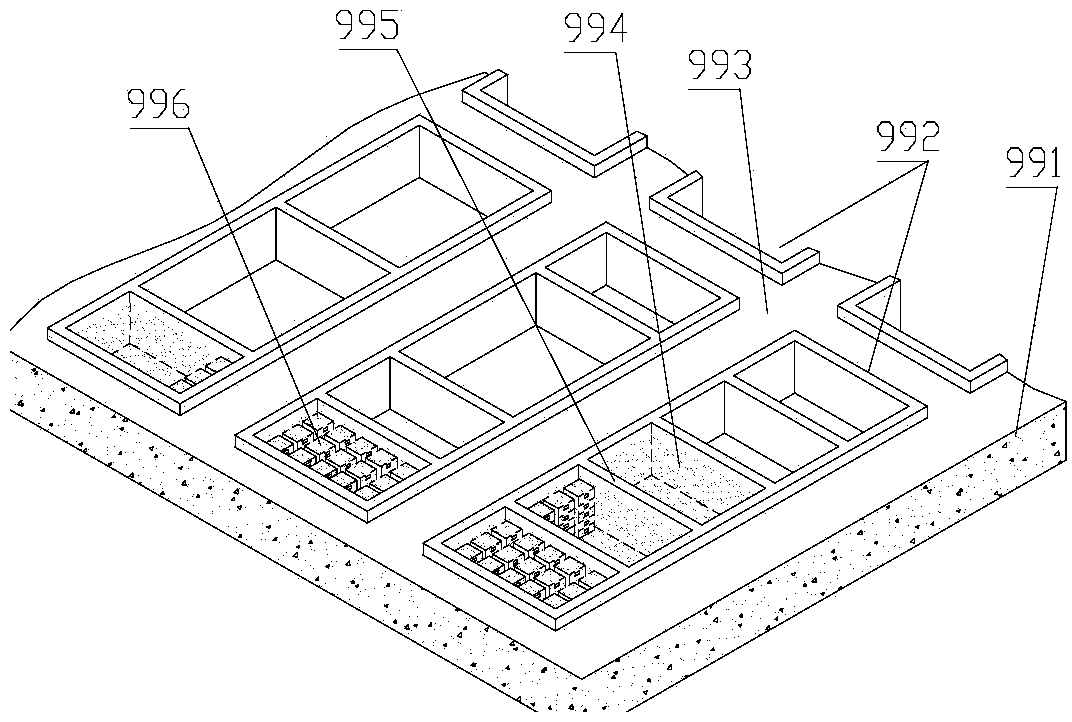

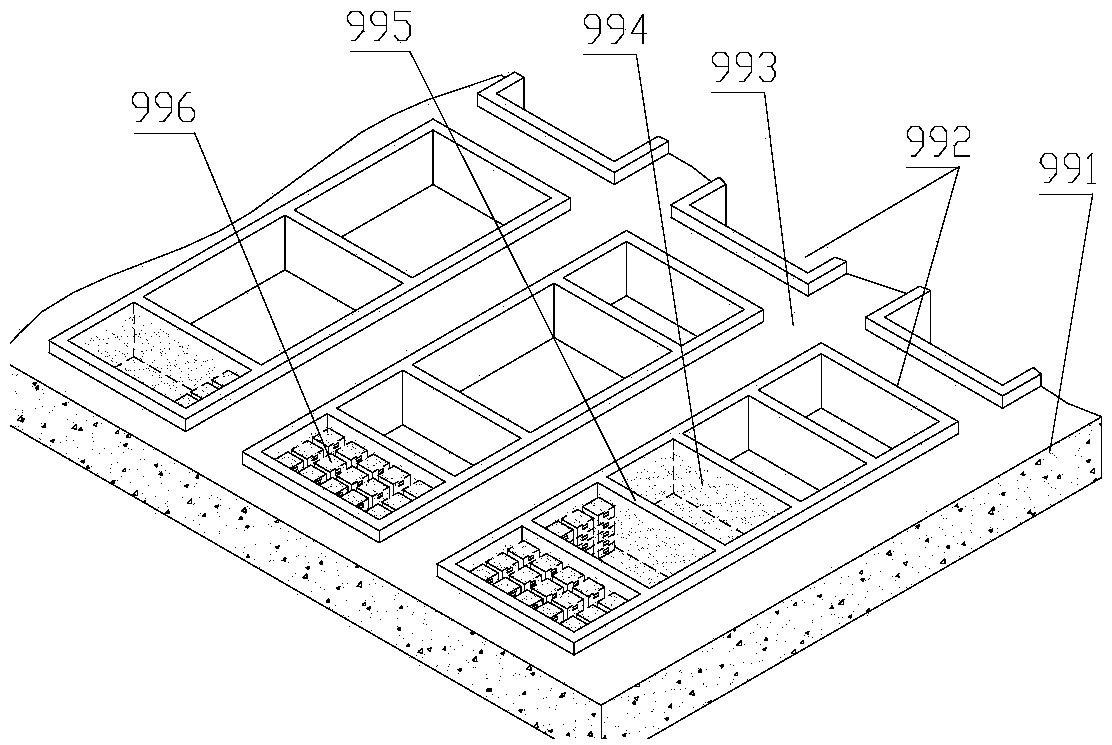

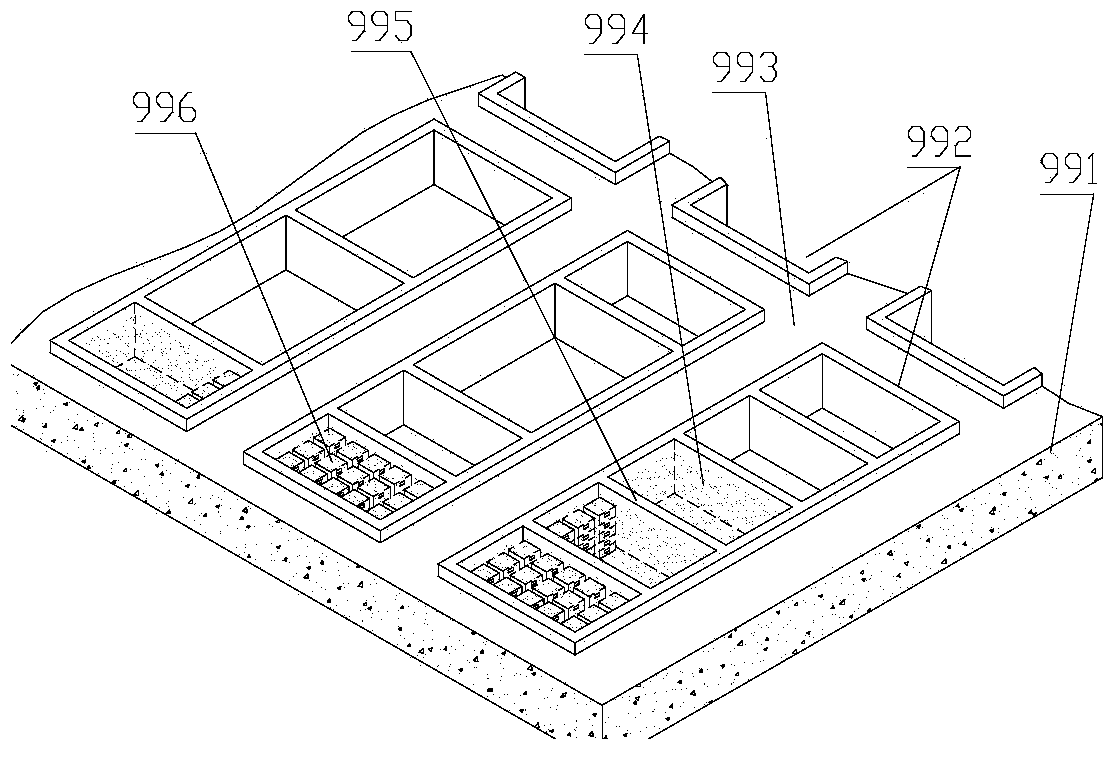

The invention discloses an overwater aquaculture feeding system with an annular track and a weighing feeder. The overwater aquaculture feeding system comprises an aquaculture pond, an aquaculture cabinet, a crane and the feeder. Wheel treads of a cart running device in the crane are pressed on workshop rails on rail bearing beams during running, and the two rail bearing beams are connected to brackets of workshop stand columns respectively. Limiting guide columns are arranged in the aquaculture pond, the aquaculture cabinet is placed in the aquaculture pond and arranged on the limiting guide columns in a sleeving mode and can move up and down; multiple aquaculture boxes are installed on the front side face and the rear side face of the aquaculture cabinet; feeding openings are formed in the aquaculture boxes; and one-way thorns are arranged around the feeding openings. The crane is provided with a plurality of trolley devices, each trolley device is connected with an annular rail, anda feeding machine is hung on the annular rail; the feeding machine is provided with a water flushing system and a weighing system; the crane lifts the aquaculture cabinet to the pond surface of the aquaculture pond; and the feeding machine quantitatively feeds a feed into the aquaculture boxes on the front side face and the rear side face of the lifted aquaculture cabinet with high-pressure wateras power.

Owner:林庆云

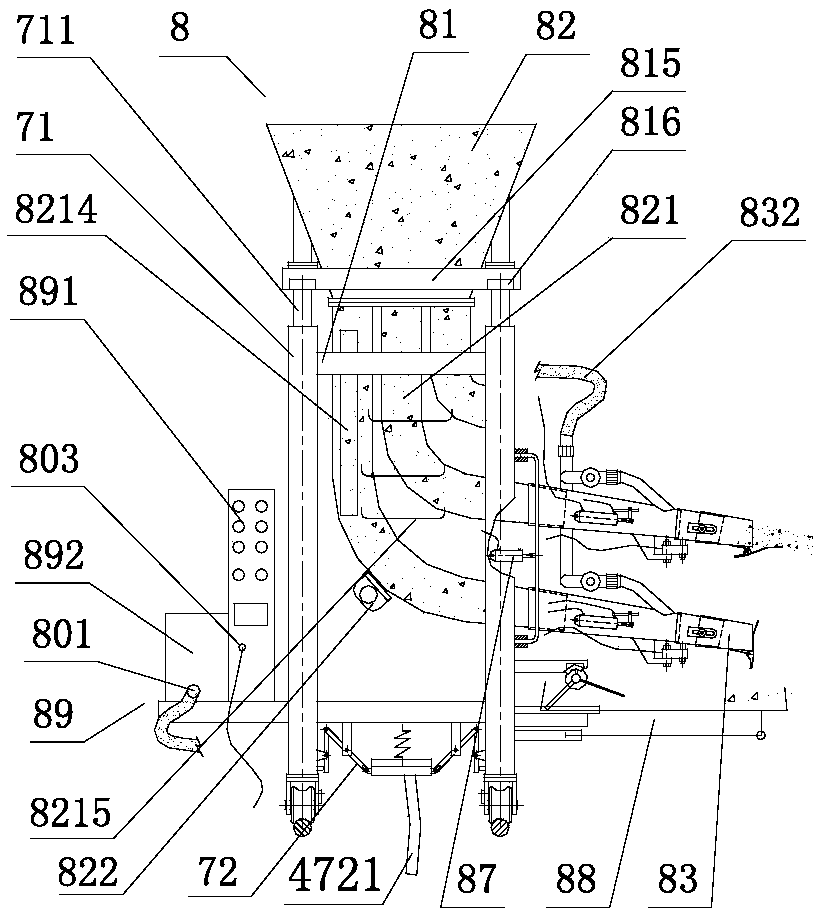

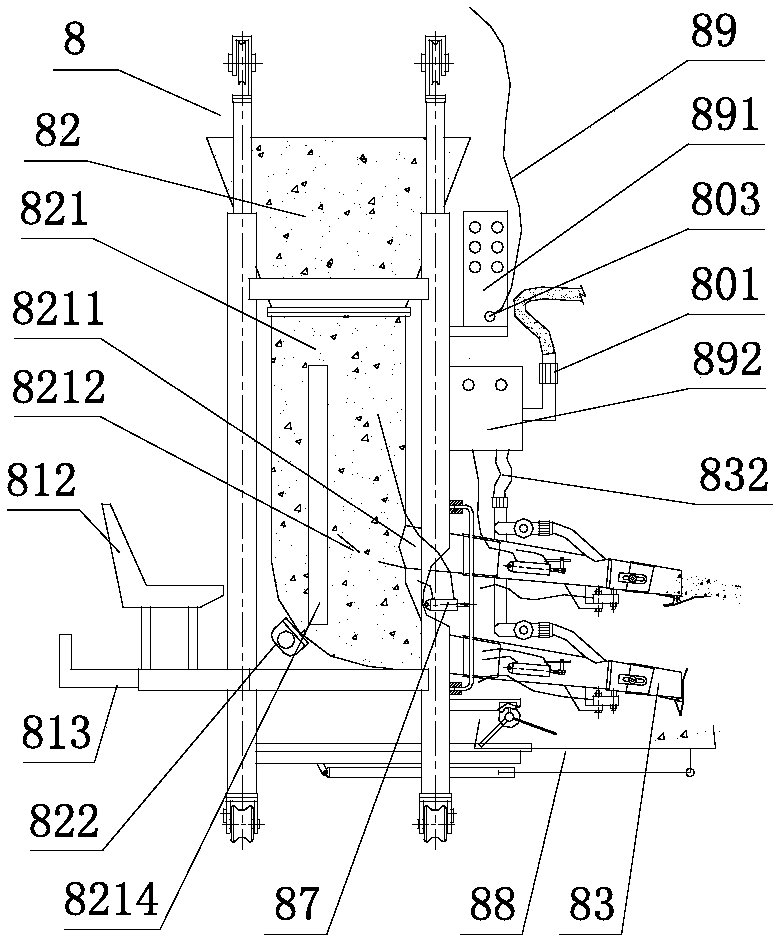

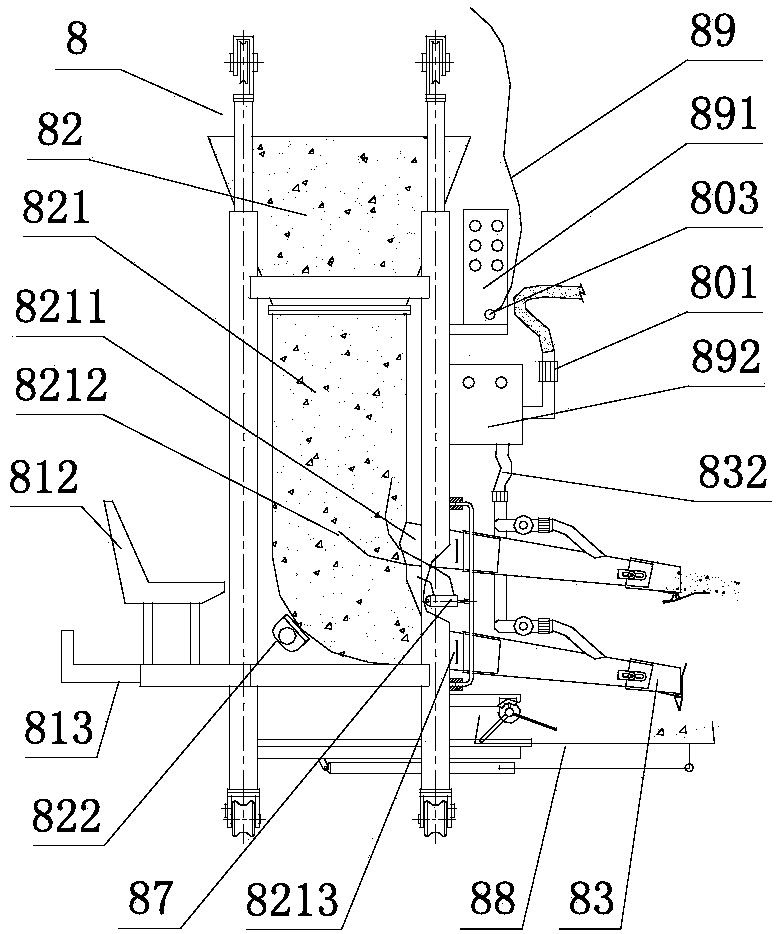

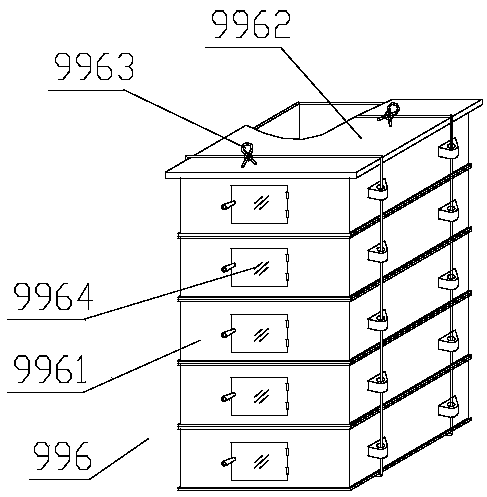

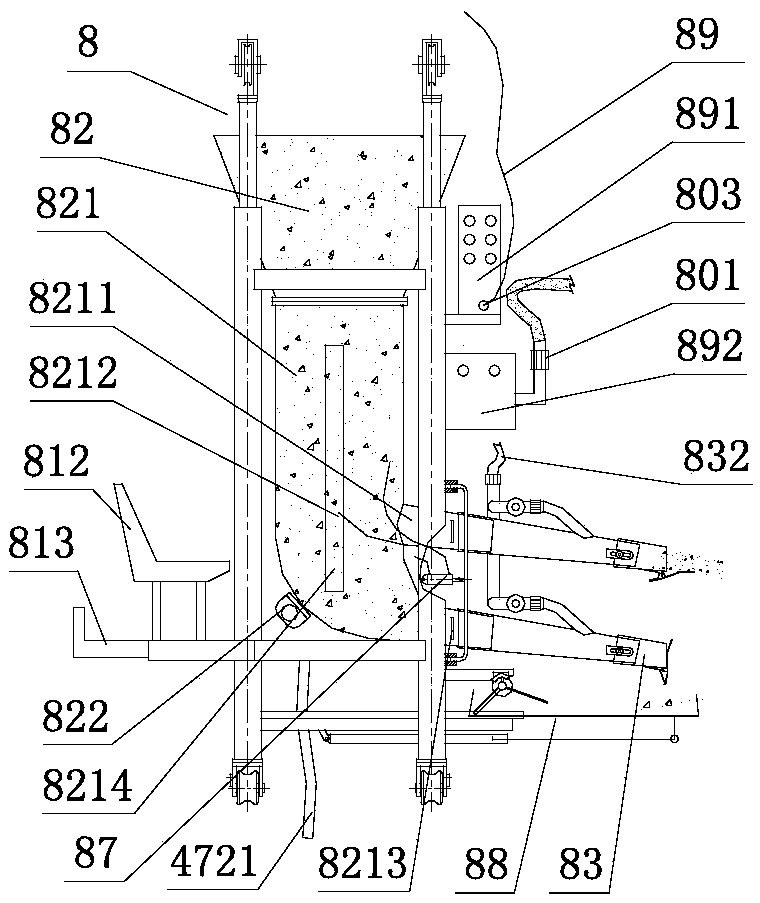

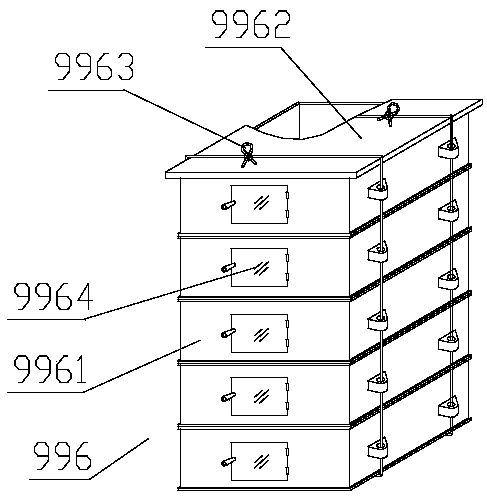

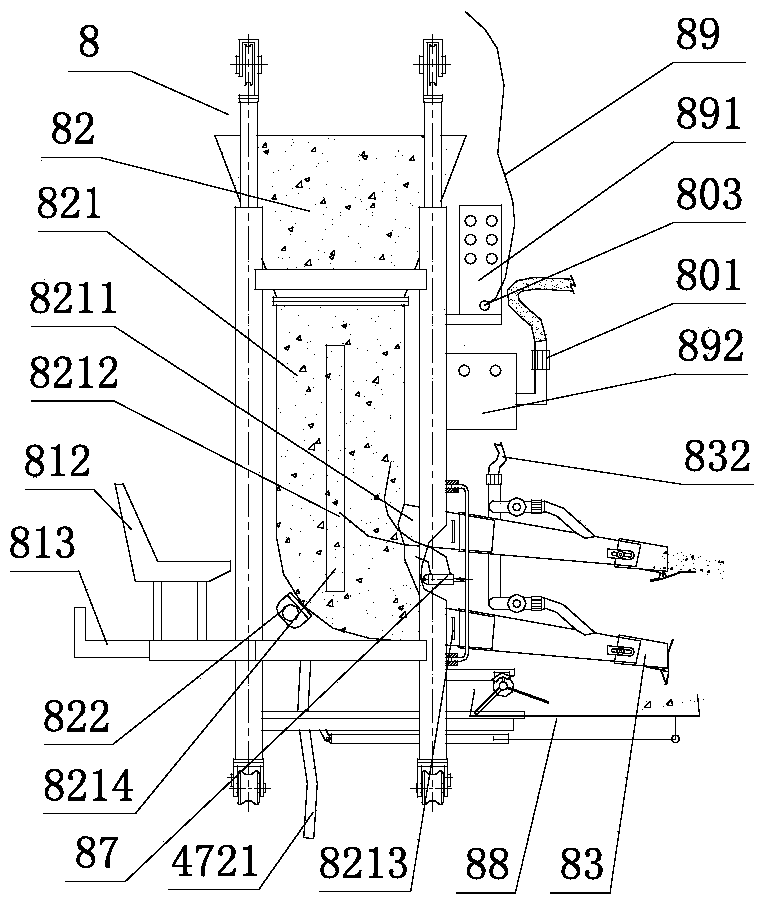

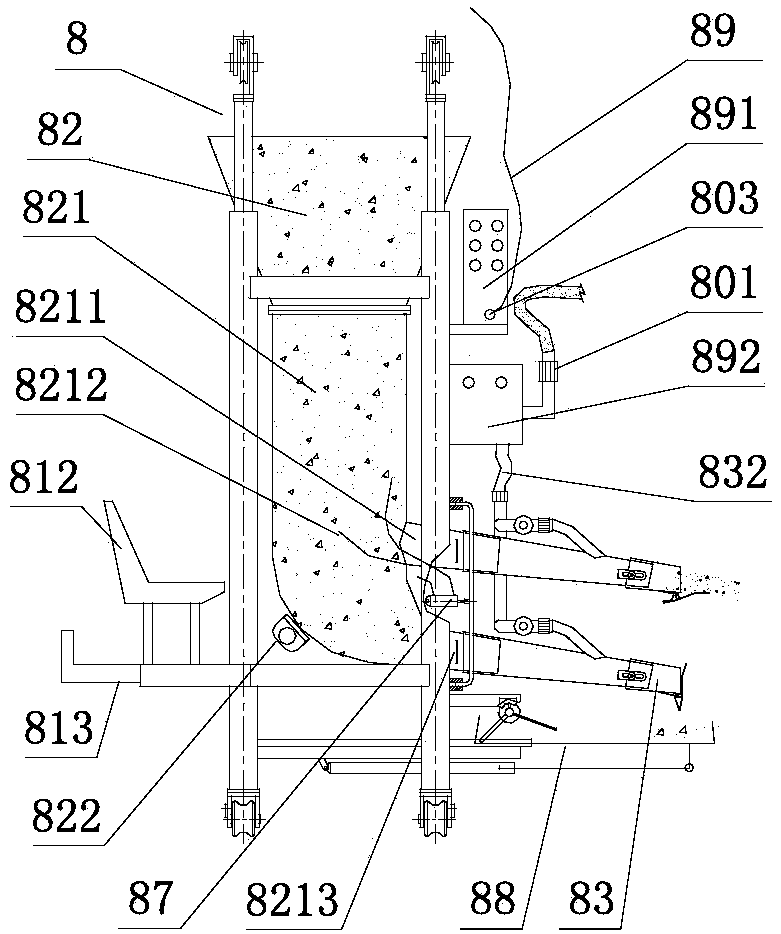

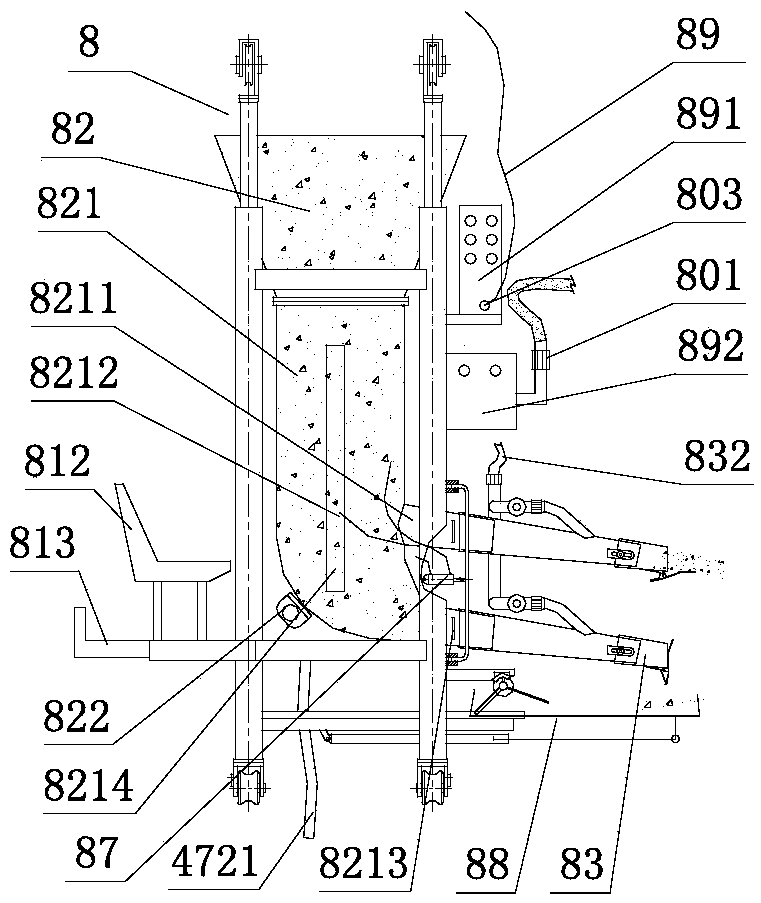

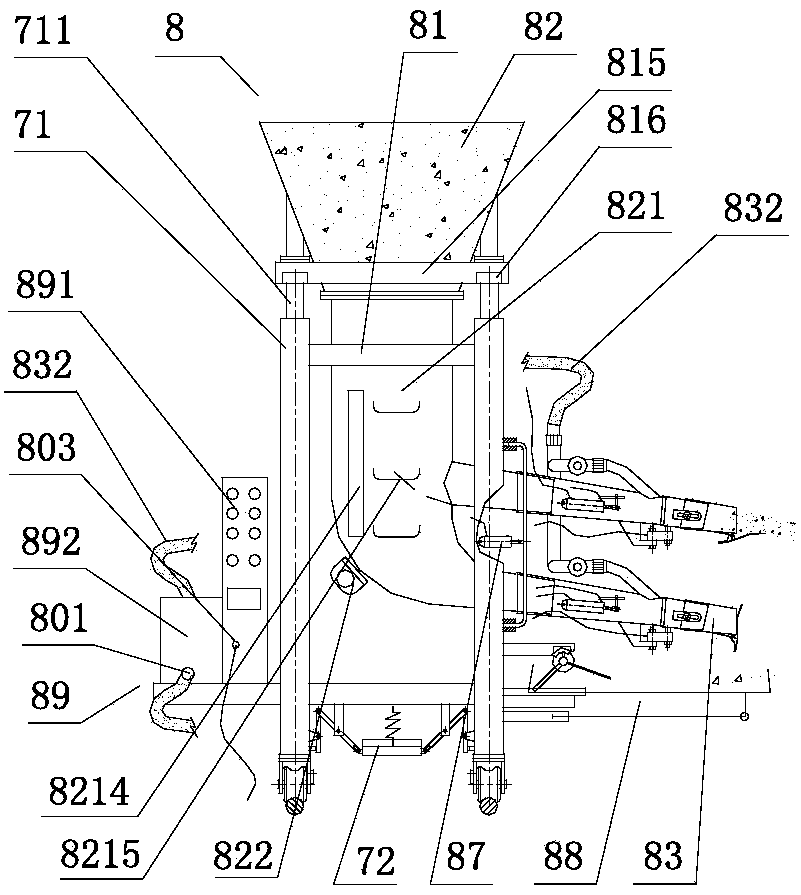

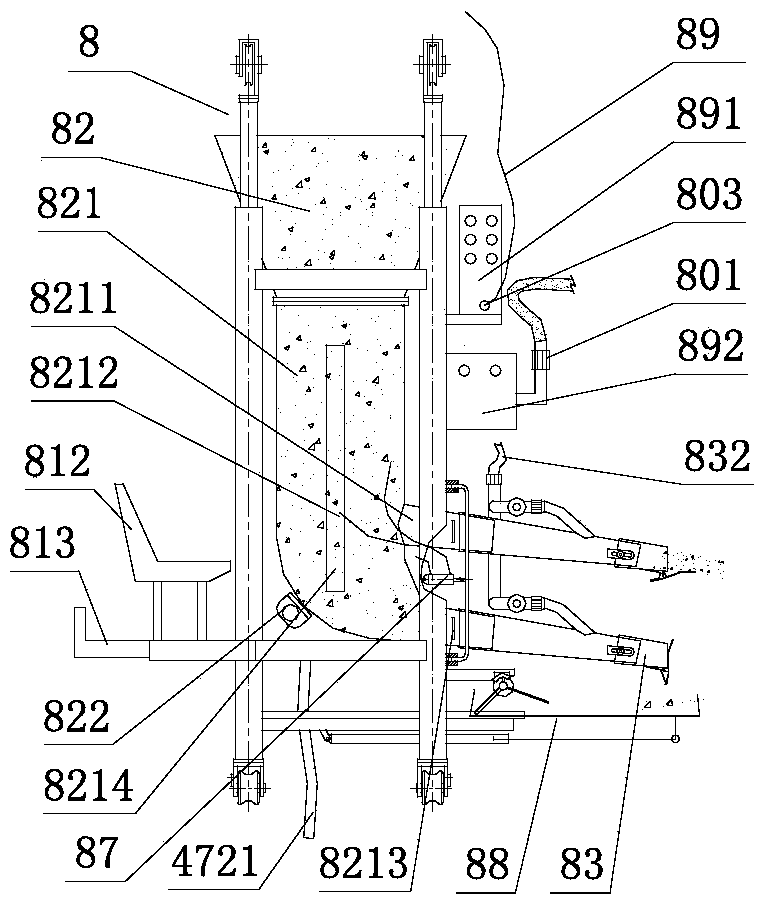

Feeding machine with weighing systems and leaked feed receiving device

InactiveCN109418195AEffective control of feed sizeEffective speed controlClimate change adaptationPisciculture and aquariaEngineeringElectromagnetic valve

The invention discloses a feeding machine with weighing systems and a leaked feed receiving device. The feeding machine comprises a frame, a feed bin, feed hoppers, feed spraying pipes, electromagnetic valves, a vibrator, the leaked feed receiving device and the weighing systems, wherein the upper part of the frame is connected with the feed bin; one or more feed hoppers are connected with and arranged below the feed bin in a vertical direction; one or more feed spraying pipes are connected with and arranged on each feed hopper; a plurality of the feed spraying pipes are in connected arrangement from bottom to top along the vertical direction of the feed hoppers; the plurality of the feed spraying pipes are arranged into one or more rows; the outlet direction of the plurality of the feed spraying pipes is horizontally and slightly inclined downward; the vibrator is connected with and arranged on the outer wall of a feed hopper, or connected with and arranged on a connecting body of theplurality of the feed hoppers, or connected with and arranged on the outer wall of the feed bin; each feed spraying pipe is provided with an air blowing pipe; each air blowing pipe is connected withan electromagnetic valve; the leaked feed receiving device is connected with and arranged below the frame, can collect a feed scattered in the process of feeding and can automatically scrape a scattered feed into a collection box; and the weighing systems can weigh and measure a feed sprayed from the feed spraying pipes.

Owner:陈云燕

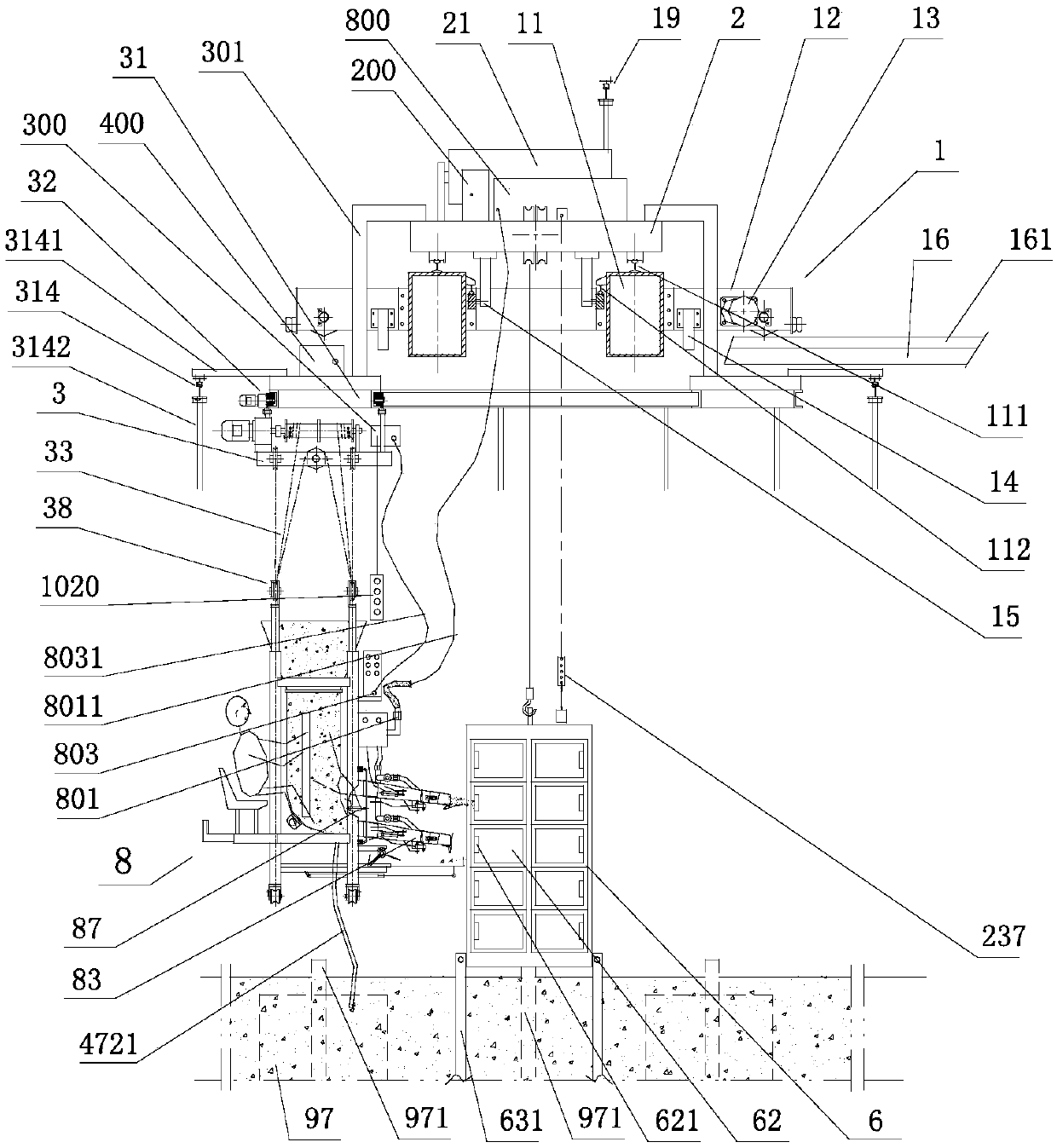

Culture feeding system with annular track and hanging operation mechanism

InactiveCN111096267AAccurate positioning and quantitative feedingLabor savingClimate change adaptationPisciculture and aquariaMarine engineeringFishery

The invention discloses a culture feeding system with an annular track and a hanging operation mechanism. The culture feeding system comprises a culture pond, culture cabinets, a crane and a feeding machine, wherein wheel treads of cart running devices in the crane are pressed on workshop rails on rail bearing beams to run; two rail bearing beams are connected with and arranged on workshop stand column brackets at two sides of the culture pond respectively; the culture cabinets are placed in the culture pond; culture boxes are installed on each culture cabinet; a feeding inlet is formed in each culture box; the feeding machine is connected with and arranged below the lifting mechanism; a hanging operation mechanism above the lifting mechanism is hung on an annular track and can operate along the annular track; the annular track is connected with and arranged below a crane main beam; the feeding machine is provided with a water flushing system and a weighing system; the crane is provided with a weighing device; the crane lifts a culture cabinet to the pond surface; the weight of each culture cabinet is displayed through the weighing device; and the feeding machine is used for quantitative feeding for the culture cabinets by taking high-pressure water as power.

Owner:林庆云

Feeding machine with multiple spray pipes and leaked feed receiving device

InactiveCN108849683AControl feed sizeControl speedBase supporting structuresClimate change adaptationEngineeringHigh pressure water

The invention discloses a feeding machine with multiple spray pipes and a leaked feed receiving device. The feeding machine comprises a framework, a bin, a plurality of hoppers, the spray pipes, a water flushing system, vibrators and the leaked feed receiving device. The bin is fixedly connected to the upper portion of the framework, the hoppers are connected with the lower side of the bin in thevertical directions, a transverse discharge pipe is arranged at the bottom of each hopper; each spray pipe is connected with the corresponding discharge pipe, the multiple spray pipes are arranged toform an array or a plurality of arrays, and outlets of the multiple spray pipes are consistent with one another in orientation and horizontally face downwards with slight inclination; the vibrators are connected onto connectors of the multiple hoppers or are connected onto the outer wall of the bin; high-pressure water can be generated and stored by the water flushing system; the leaked feed receiving device is arranged below the framework, feed scattered in feeding procedures can be collected by the leaked feed receiving device and can be automatically scraped into a collecting box by the leaked feed receiving device; movable wheels are arranged at the bottom of the framework. The feeding machine has the advantages that the high-pressure water is used as power for the feeding machine, andaccordingly quantitative feed in the spray pipes can be outwardly delivered.

Owner:张达英

Abalone culture feeding equipment with lifter and movable wheel feeding machine

InactiveCN111096279ASimple structureSmooth liftClimate change adaptationPisciculture and aquariaCartAnimal science

The invention discloses abalone culture feeding equipment with a lifter and a movable wheel feeding machine. The abalone culture feeding equipment comprises a crane and a feeding machine, wherein wheel treads of a crane cart running device are suspended on workshop rails for running; the two workshop rails are suspended and fixed below workshop roof beams; the feeding machine is provided with a weighing system and a water flushing system; the water flushing system can generate and store high-pressure water; the feeding machine is provided with a plurality of material spraying pipes; the plurality of the material spraying pipes are connected through a material spraying pipe transverse adjusting device and can be controlled to transversely stretch out and draw back; moving wheels are arranged at the bottom part of the feeding machine; the crane is provided with an annular track; the feeding machine is connected to the annular track through a lifting mechanism to operate; the lifting mechanism comprises a folding type connecting rod lifter; the crane is provided with a hook; and the feeding machine can operate around the lifting hook and transversely and quantitatively feed a feed toone side of the lifting hook by taking high-pressure water as power.

Owner:林庆云

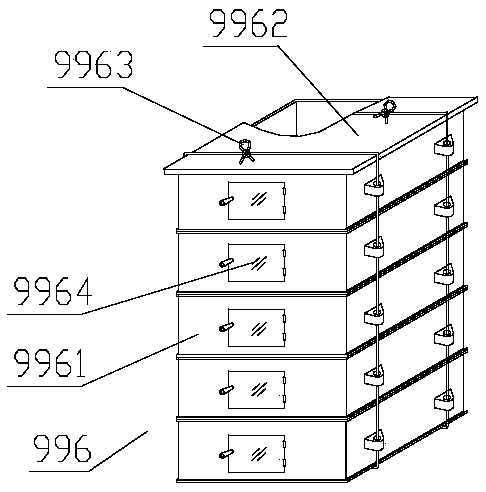

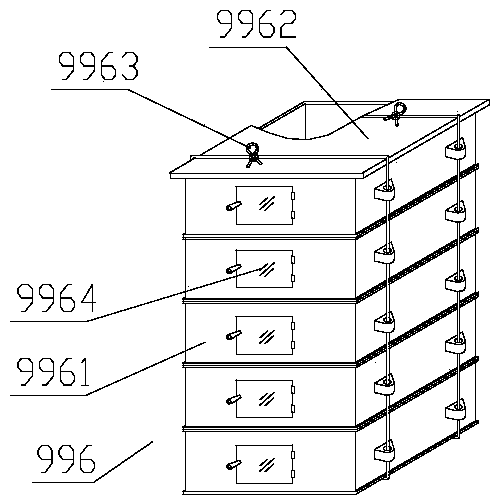

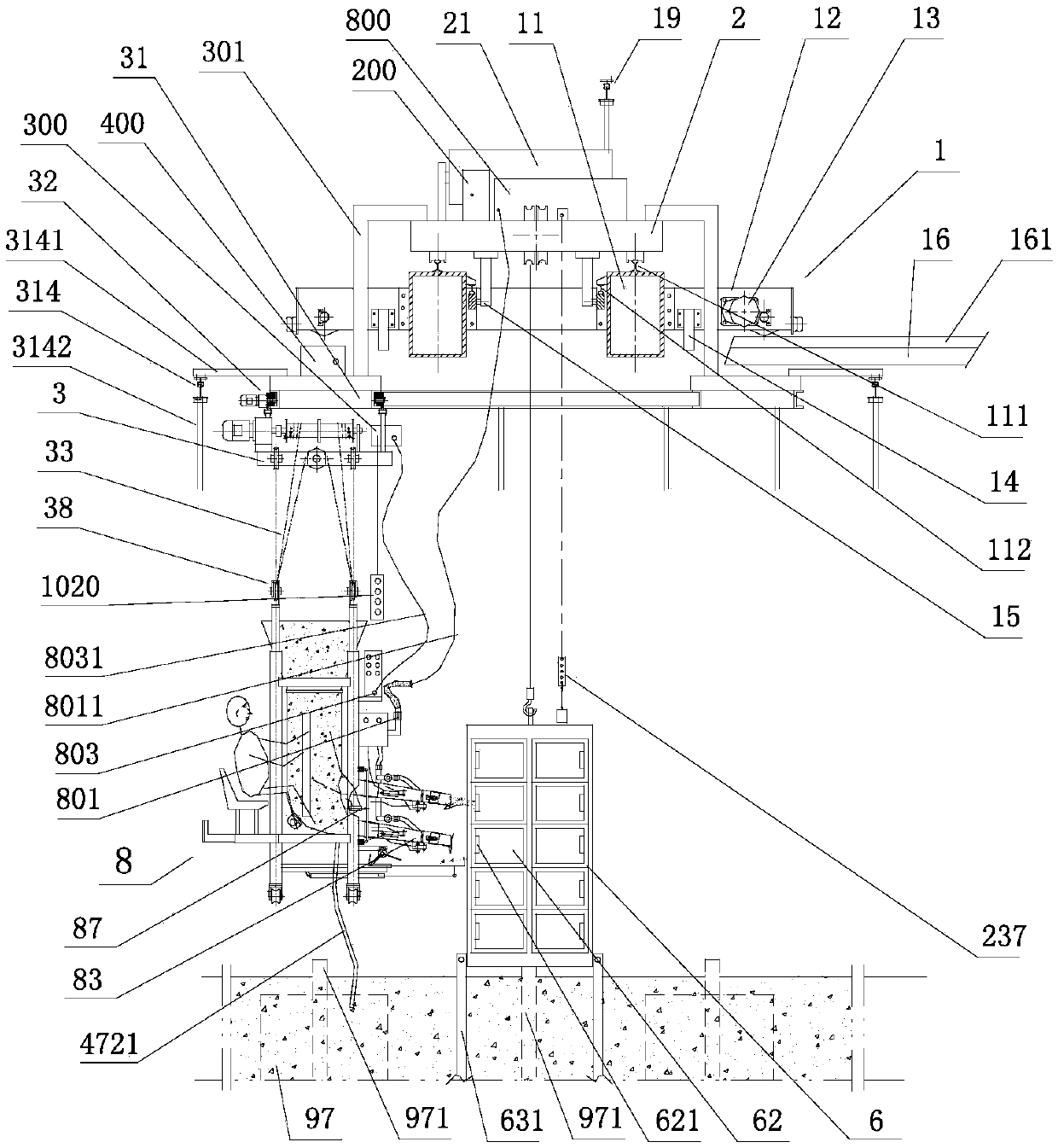

Breeding feeding system with elevator lifting mechanism and overturn-preventing device

InactiveCN109418185ASmooth liftIncrease stiffnessClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses a breeding feeding system with an elevator lifting mechanism and an overturn-preventing device. The system comprises a breeding pool, a culture cabinet, a crane and a feeding machine, wherein workshop tracks are pressed by wheel treads of a large vehicle running device of the crane so as to achieve running of the crane, the two workshop tracks are arranged on the floor of aworkshop in which the breeding pool is arranged, and the culture cabinet is arranged in the breeding pool; the feeding machine is provided with a leaked material receiving device for collecting feedscattered in the feeding process and automatically scraping the scattered feed into a collection box, the feeding machine is connected to a trolley device of the crane through the lifting mechanism, and runs with the crane, and the trolley device is provided with the overturn-preventing device; and the lifting mechanism includes a folding link elevator, the crane is used for lifting the culture cabinet to the pool surface of the breeding pool, and the feeding machine is used for performing quantitative feeding of the lifted culture cabinet through high-pressure gas.

Owner:福州市晋安区澳杰新自动化设备有限公司

Abalone culture feeding system with feed guiding tongues and lifting-mechanism feeders

InactiveCN111194712AIngenious designFree from pollutionClimate change adaptationPisciculture and aquariaFisheryEngineering

The application discloses an abalone culture feeding system with feed guiding tongues and lifting-mechanism feeders. The abalone culture feeding system comprises culture ponds, culture cabinets, the feeders and a hoist, wherein wheel treads of a cart of the hoist press and run on a workshop track on two support track beams, and the two support track beams are separately connected to upright columnbrackets at the two sides of a workshop; culture tanks on the culture cabinets are placed in the culture ponds in a manner of facing to workshop walkways; the feeders are arranged on the workshop walkways aside the culture ponds and can rise, fall and walk, downsides of bunkers of the feeders are connected with hoppers in vertical directions, a plurality of discharging pipes are arranged on the hoppers in lateral directions, and the feed guiding tongues which are located inside the hoppers are arranged at joints of the discharging pipes and the hoppers; leaking feed receiving devices of the feeders can collect scattered feed during feeding and can automatically scrape the scattered feed into a collection box; lifting mechanisms are arranged at bottoms of the feeders and can control risingand falling movement of the feeders; and the hoist is used for hoisting the culture cabinets to surfaces of the ponds, and the feeders perform feeding on the hoisted culture cabinets by taking high-pressure water as power.

Owner:黄君妍

Feeding machine with a plurality of feed spraying pipes

InactiveCN109418190AReduce sizeControl speedClimate change adaptationPisciculture and aquariaSolenoid valveEngineering

The invention discloses a feeding machine with a plurality of feed spraying pipes. The feeding machine comprises a rack, a feed bin, hoppers, the feed spraying pipes, solenoid valves and a vibrator, wherein the feed bin is fixedly connected to the upper part of the rack, the lower part of the feed bin is connected with one or more hoppers side by side in the vertical direction, and the feed spraying pipes are arranged and connected in the vertical direction of the hoppers from bottom to top; and the feed spraying pipes are arranged in one or more columns, and have a uniform outlet direction which is horizontal but slightly inclined downwards, the vibrator is connected to the outer wall of the hopper or a connecting body of the hoppers, and an air blowing pipe is disposed on each feed spraying pipe; and each solenoid valve is connected with the corresponding air blowing pipe.

Owner:陈云燕

Feeding machine with vibrator

InactiveCN108967299AControl feed sizeControl speedClimate change adaptationPisciculture and aquariaEngineeringHigh pressure water

The invention discloses a feeding machine with a vibrator, and the feeding machine comprises a frame, a stock bin, a hopper, a spraying pipe, the vibrator, an air compressor, and a material water flushing system. The stock bin is fixedly connected to the frame, and the hopper is connected below the stock bin. The vibrator is connected to the outer wall of the hopper, or the outer wall of the stockbin, or the frame or a connector body of the hoppers. The vibrator is driven electrically, or driven through high-pressure air or driven by high-pressure water to operate. The spraying pipe is provided with a water flushing pipe, and connected to the hopper. The outlet of the spraying pipe is horizontal, and is slightly inclined downwards. The air compressor is connected to the frame, and can generate high-pressure air which is used for controlling an air cylinder or the vibrator on the feeding machine. The material water flushing system can generate and store high-pressure water which is used for driving the fodder in the spraying pipe to be thrown outwards or driving the vibrator to operate.

Owner:张达英

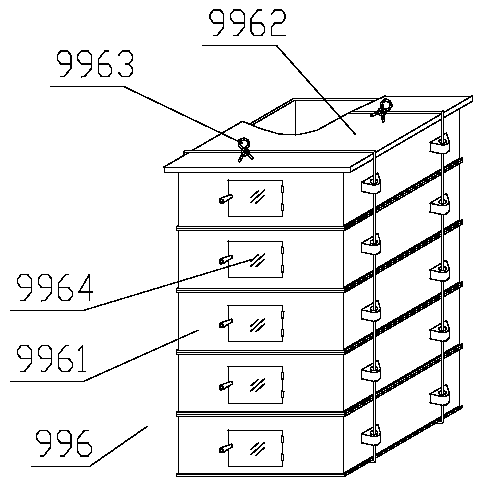

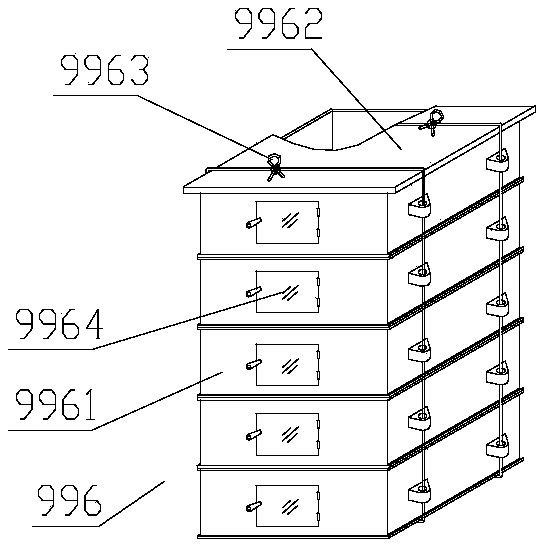

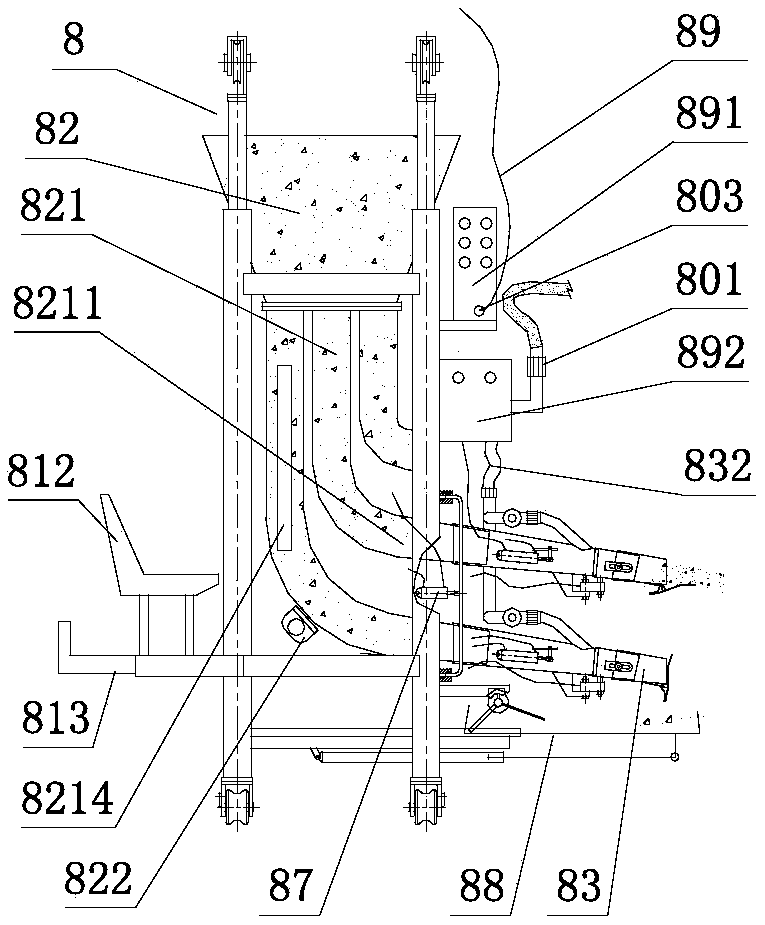

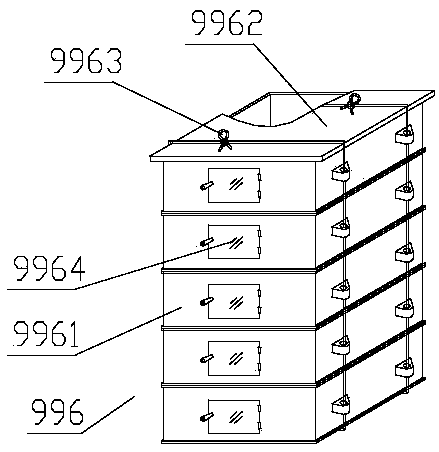

Feeding machine capable of automatically collecting leaked materials

InactiveCN108967295AEasy to disengageMeet fast feeding needsClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

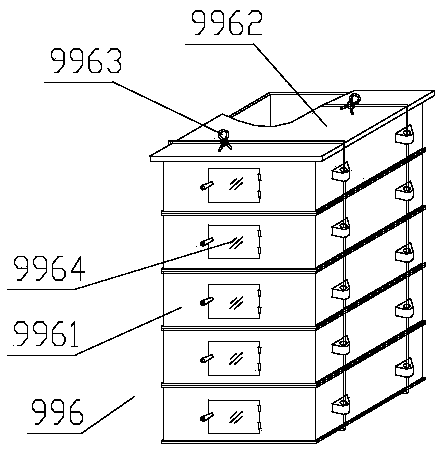

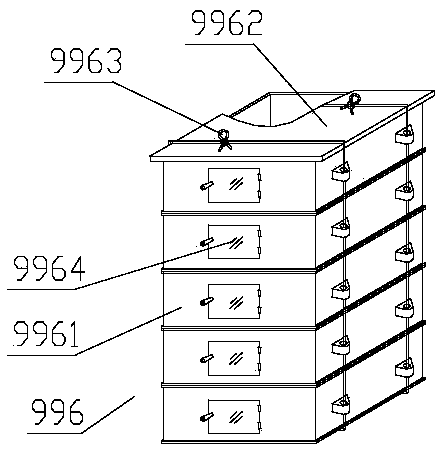

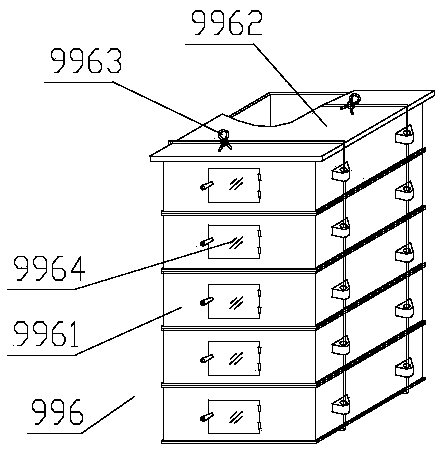

The invention discloses a feeding machine capable of automatically collecting leaked materials, and the feeding machine comprises a rack, a material cabin, a hopper, a material spraying pipe, and a leaked material receiving device. The material cabin is fixedly connected to the rack, and the lower part of the material cabin is connected with the hopper. The material spraying pipe is connected to the hopper, and the outlet of the material spraying pipe is slightly horizontal. The leaked material receiving device is connected below the rack, and capable of collecting the fodder in the fodder throwing and feeding process. The leaked material receiving device is provided with a material scraping device, and the material scraping device comprises a rotating shaft, a scraper plate, a resetting handle, an elastic limiting block, and a limiting clamping jaw. The material scraping device can automatically scrape the scattered fodder into a collection box. The feeding machine takes high-pressurewater as the power to throw the fixed quantity of fodder in the material spraying pipe to the outside.

Owner:张达英

Feeding machine with plurality of feed spraying pipes and weighing systems

InactiveCN109418191AAccurate external feeding amountEasy to handleWeighing apparatus using elastically-deformable membersClimate change adaptationEngineeringElectromagnetic valve

The invention discloses a feeding machine with a plurality of feed spraying pipes and weighing systems. The feeding machine comprises a frame, a feed bin, feed hoppers, the feed spraying pipes, electromagnetic valves, a vibrator and the weighing systems, wherein the upper part of the frame is connected with the feed bin; a plurality of the feed hoppers are connected with and arranged below the feed bin in a vertical direction; the bottom part of each feed hopper is provided with a discharging pipe; the plurality of the feed spraying pipes are correspondingly connected with a plurality of discharging pipes; the plurality of the feed spraying pipes are arranged into one or more rows; the outlets of the plurality of the feed spraying pipes are oriented in a uniform direction; the outlet direction of the plurality of the feed spraying pipes is horizontally and slightly inclined downward; each feed spraying pipe is provided with an air blowing pipe; each air blowing pipe is connected with an electromagnetic valve; the vibrator is connected with and arranged on a connecting body of the plurality of the feed hoppers or connected with and arranged on the outer wall of the feed bin; and theweighing systems can weigh and measure a feed sprayed from the feed spraying pipes.

Owner:陈云燕

Breeding feeding equipment with suspension crane and annular track

InactiveCN111096282ASimple structureFree from pollutionClimate change adaptationPisciculture and aquariaFisheryHigh pressure water

The invention discloses breeding feeding equipment with a suspension crane and an annular track. The breeding feeding equipment comprises the crane and a feeding machine, wherein wheel treads of cartrunning devices of the crane are suspended on workshop tracks for running, and the two workshop tracks are suspended and fixed below a workshop roof beam; the crane is connected with the annular track, the feeding machine is suspended on the annular track, the feeding machine is provided with a weighing system which can weigh and measure feed to be discharged from the feeding machine, and the feeding machine is provided with a water flushing system which can generate and store high-pressure water; the crane is provided with a lifting hook; and the feeding machine can run around the lifting hook, an outlet of a spraying pipe in the feeding machine always faces one side of the lifting hook, and the feeding machine can transversely and quantitatively provide the feed to one side of the lifting hook by taking the high-pressure water as power.

Owner:林庆云

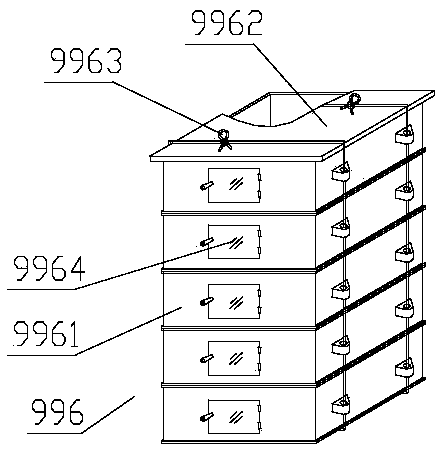

Abalone culture feeding system with leaked material receiving device

InactiveCN109418208ASimple structureAccurate positioning and quantitative feedingClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses an abalone culture feeding system with a leaked material receiving device. The abalone culture feeding system includes a culture pond, at least one culture cabinet, a crane anda feeder; a cart running device of the crane can run along workshop tracks above the culture pond, the wheel tread of the cart running device is suspended on the workshop tracks, and the two workshoptracks are suspended and fixed under a roof beam of a workshop; a plurality of culture boxes are arranged at the front side of each culture cabinet, a swing door is arranged on each culture box, andeach culture cabinet is provided with a gate device; when the at least one culture cabinet is put into the culture pond, the corresponding swing door is closed by a gate, and when the at least one culture cabinet is lifted to the pond surface of the culture pond, the swing doors opens automatically; the feeder is connected to the crane; the feeder is provided with a weighing system which can weighand measure the feed to be fed; the feeder is equipped with the leaked material receiving device which can automatically scrape the scattered feed into a collection box; and the crane lifts the at least one culture cabinet to the surface of the pond, and the feeder feeds the culture boxes quantitatively through high pressure gas.

Owner:黄滨

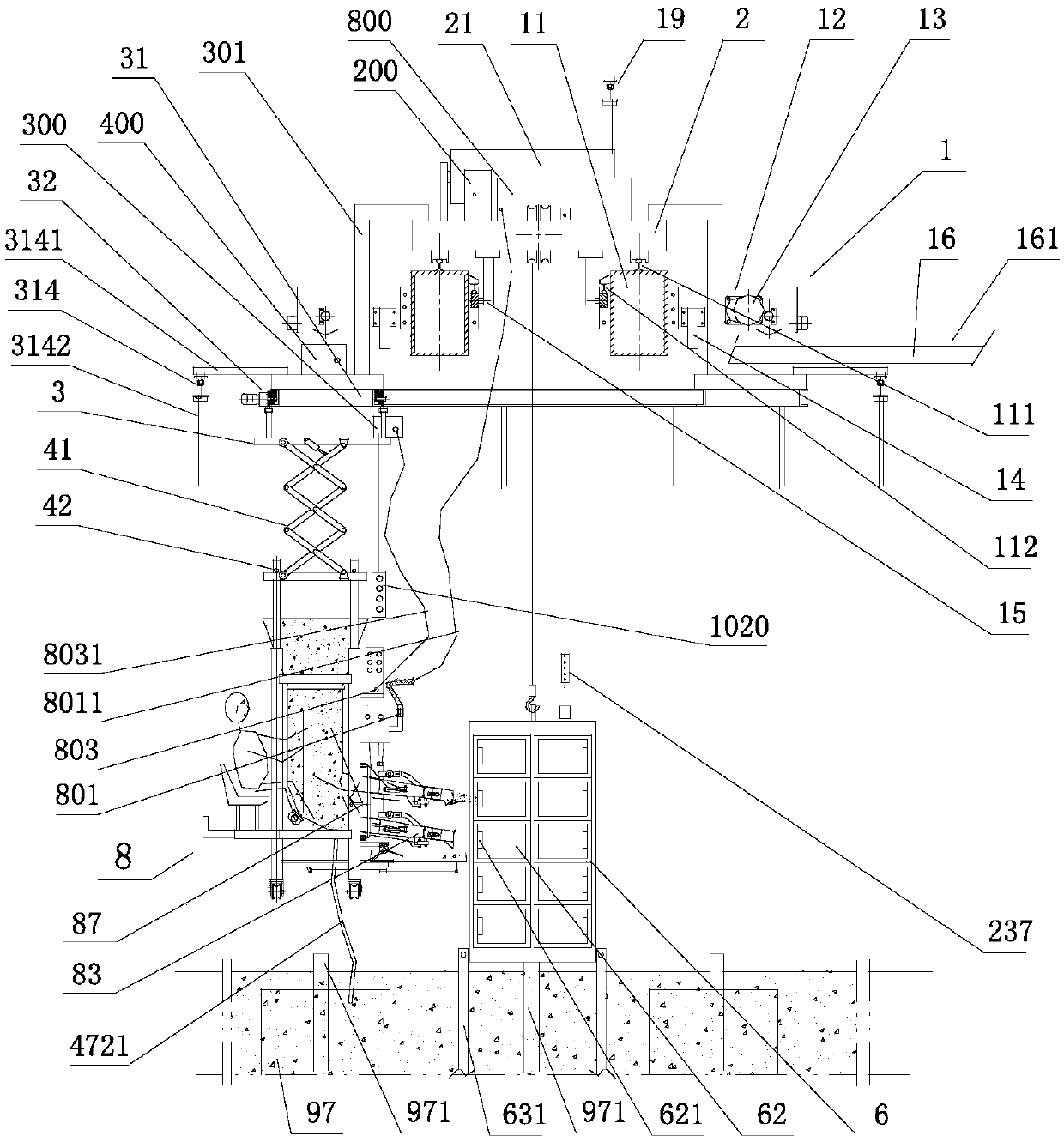

Abalone culture feeding system with operating platform and weighing device

InactiveCN109452209ASmooth liftIncrease stiffnessClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses an abalone culture feeding system with an operation platform and a weighing device, which comprises a culture pond, a culture cabinet, a crane and a feeding machine. The wheeltread of one large vehicle running device in the crane is pressed on a workshop track on the ground of the workshop where the culture pond is positioned to run, the wheel tread of the other large vehicle running device is pressed on the workshop track above a bearing rail beam to run, and the bearing rail beam is connected with a bracket of a workshop upright post; the culture cabinet is arrangedin the culture pond, the culture cabinet is provided with a plurality of culture boxes, and the culture boxes are provided with swing doors; the feeding machine is provided with an operation table; the feeding machine is connected on the crane through a lifting mechanism and runs along with the crane, and the lifting mechanism comprises a folding connecting rod elevator; the crane is provided withthe weighing device, the crane lifts the culture cabinet onto the pond surface of the culture pond and can display the weight of the culture cabinet on the weighing device, and the feeding machine quantitatively feeds the raised culture cabinet through high-pressure gas.

Owner:福州市晋安区澳杰新自动化设备有限公司

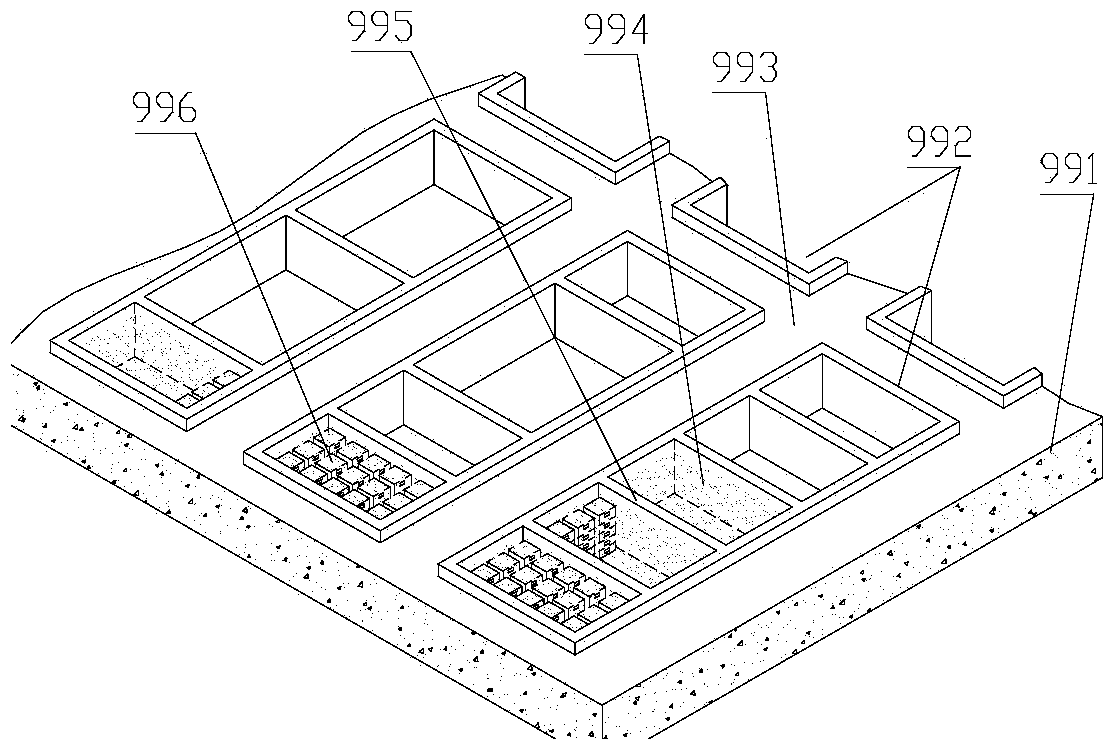

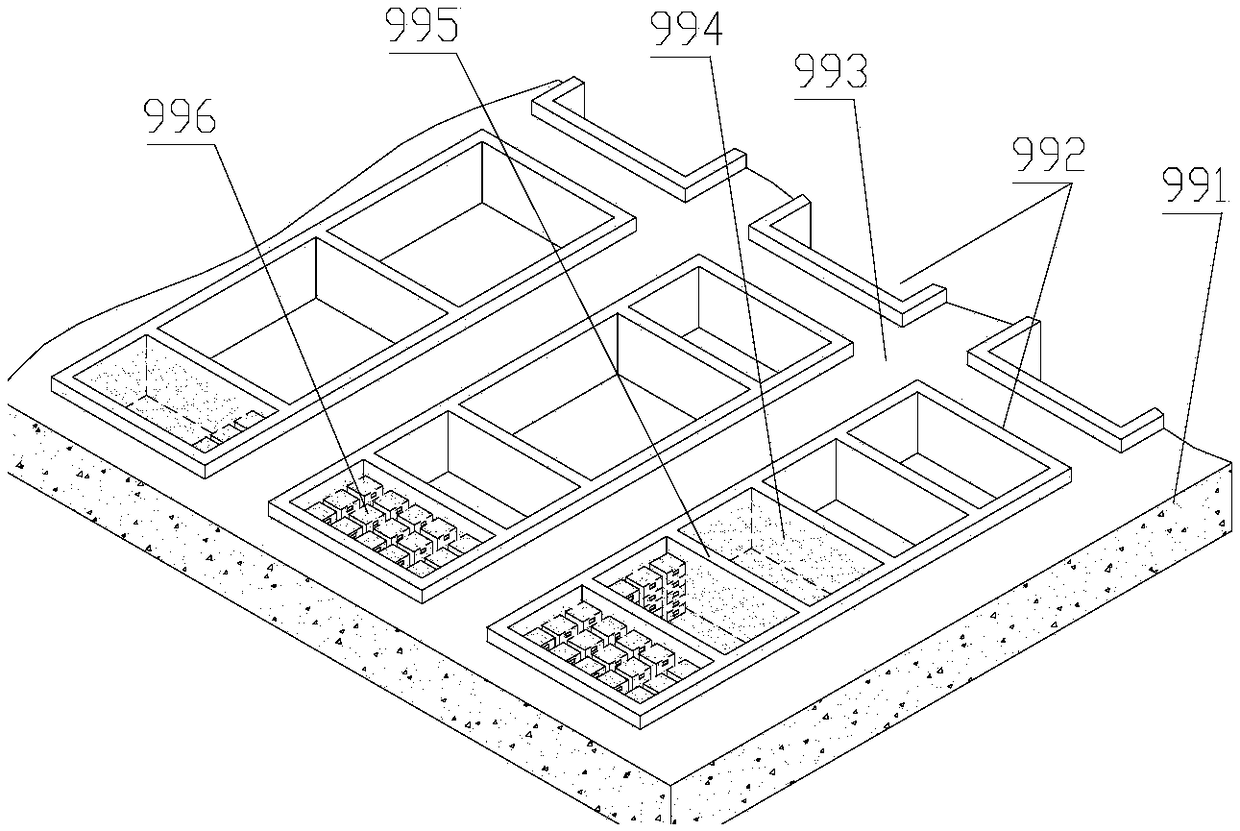

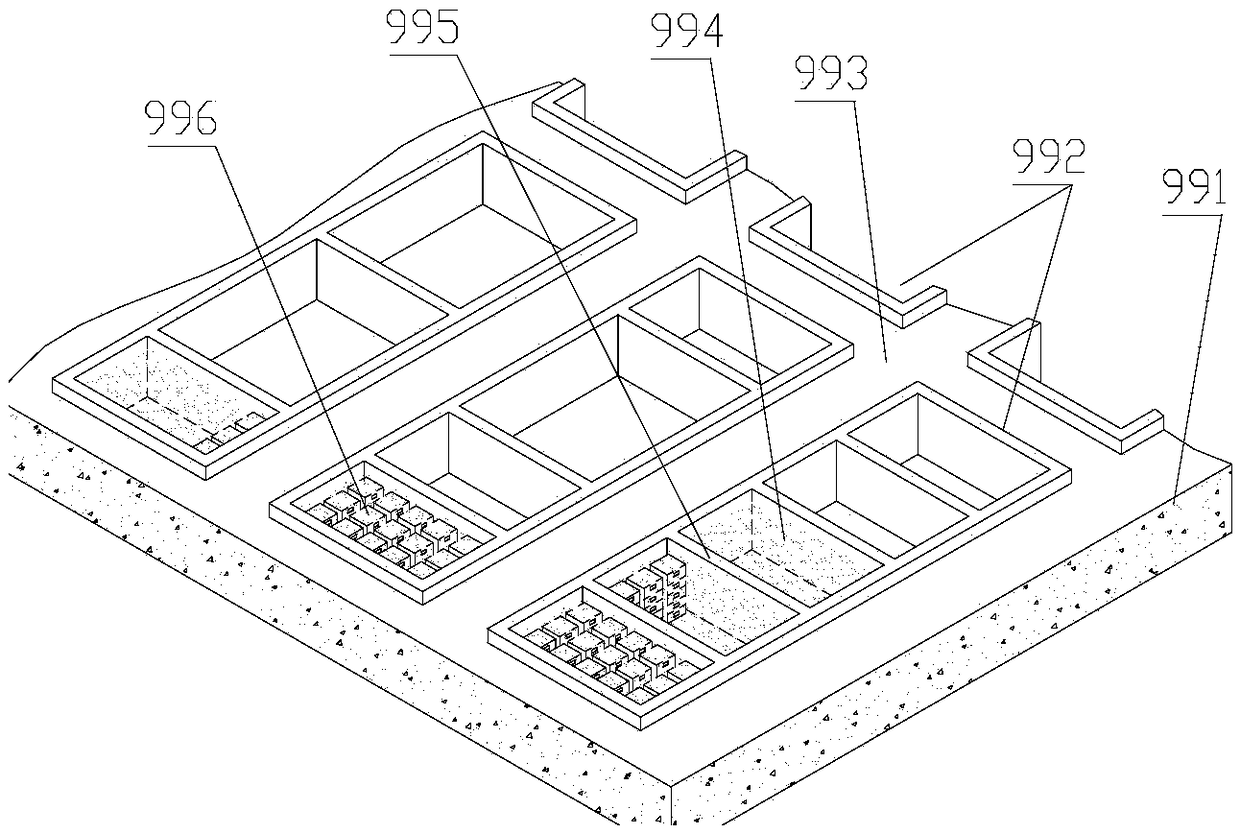

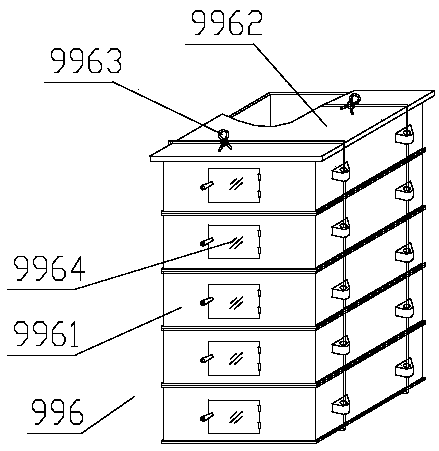

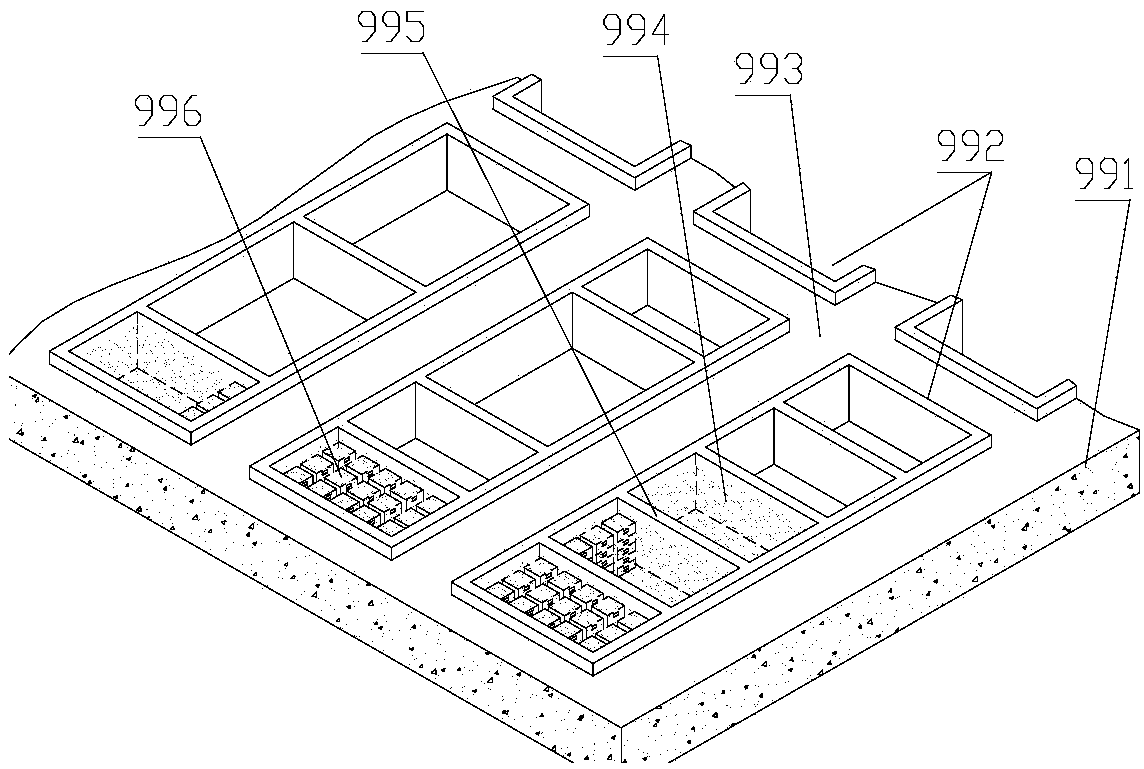

Culture feeding system with lifter and annular tracks

InactiveCN111096265AAccurate positioning and quantitative feedingLabor savingClimate change adaptationPisciculture and aquariaMarine engineeringFishery

The invention discloses a culture feeding system with a lifter and annular tracks. The culture feeding system comprises a culture pond, culture cabinets, a crane and a feeding machine, wherein wheel treads of cart running devices in the cranes are pressed on workshop rails on rail bearing beams to run; the two rail bearing beams are connected to workshop stand column brackets on the two sides of the culture pond respectively; the culture cabinets are placed in the culture pond; culture boxes are arranged on the culture cabinet; a feeding inlet is formed in each culture box; the annular track is arranged below each crane main beam; the feeding machine is connected to the annular tracks through a lifting mechanism; the lifting mechanism is hoisted by adopting a pulling rope; the pulling ropeis connected with the top part of the feeding machine to form a plurality of hoisting points which are not on the same line; the feeding machine is provided with a water flushing system and a weighing system; the crane lifts the culture cabinet to the surface of the culture pond; and the feeding machine quantitatively feeds the culture boxes in a lifted culture cabinet by using high-pressure water as power.

Owner:林庆云

Breeding feeding system with vibrator and feeding machine having feed guiding tongue

InactiveCN111096268AReduce workshop aislesLabor savingClimate change adaptationPisciculture and aquariaFisheryEngineering

The invention discloses a breeding feeding system with a vibrator and a feeding machine having a feed guiding tongue. The breeding feeding system comprises a breeding pond, a breeding cabinet, a craneand the feeding machine. The wheel treads of cart running devices in the crane are pressed on workshop tracks on track bearing beams to run, and the two track bearing beams are connected to workshopupright post brackets on the two sides of the breeding pond respectively. The breeding cabinet is placed in the breeding pond. A trolley device in the crane is connected with an annular track and an anti-tipping device, and the feeding machine is hung on the annular track. The feeding machine is provided with the feed guiding tongue and the vibrator which can control the feed flushing speed. The feeding machine is provided with a water flushing system and a weighing system, the weighing system can weigh and measure feed to be discharged from the feeding machine, and the water flushing system provides high-pressure water. The crane lifts the breeding cabinet to the pond surface of the breeding pond, and the feeding machine quantitatively provides feed for the front side face and the rear side face of the breeding cabinet with the high-pressure water as power.

Owner:林庆云

Feeding machine with adjustable metering nozzles

InactiveCN109418200AControl speedEasy to handleClimate change adaptationPisciculture and aquariaEngineeringElectromagnetic valve

The invention discloses a feeding machine with adjustable metering nozzles. The feeding machine comprises a frame, a feed bin, feed hoppers, feed spraying pipes and electromagnetic valves, wherein thefeed bin is fixedly connected with and arranged on the frame; the feed hoppers are connected with and arranged below the feed bin; one or more feed spraying pipes are connected with and arranged on each feed hopper; each feed spraying pipe is provided with an air blowing pipe; each air blowing pipe is connected with an electromagnetic valve; each feed spraying pipe is provided with an adjustablemetering nozzle which can adjust different metering capacities; the position of the outlet of each adjustable metering nozzle is provided with a feed sealing door; feed sealing doors are in a normallyclosed state when no air is blown; and the outlet direction of the adjustable metering nozzles is horizontally and slightly inclined downward.

Owner:陈云燕

Abalone cultivating and feeding system with annular rail and gate device cultivation cabinet

InactiveCN111096271AAccurate positioning and quantitative feedingLabor savingClimate change adaptationPisciculture and aquariaAgricultural scienceFishery

The invention discloses an abalone cultivating and feeding system with an annular rail and a gate device cultivation cabinet. The abalone cultivating and feeding system comprises a cultivation pond, cultivation cabinets, a crane and a feeding machine, wherein a wheel tread of a cart running device in the crane is pressed on workshop rails on rail bearing beams; two rail bearing beams are independently connected to workshop stand column brackets on two sides of the cultivation pond; the font side surface and the rear side surface of each cultivation cabinet are independently provided with a plurality of cultivation boxes; a feeding hole is arranged on each cultivation box; and each cultivation cabinet is provided with a gate device. When each cultivation cabinet is put in the cultivation pond, the feeding hole is blocked by a gate to be closed, and when the cultivation cabinet is lifted to the pond surface of the cultivation pond, the feeding hole is opened to be exposed; the feeding machine is connected to the annular rail of the crane and operates along with the crane; the feeding machine is provided with a water material flushing system and a weighing system; the crane is provided with an elevation restriction device, the crane elevates the cultivation cabinets to the pond surface, and the feeding machine carries out quantitative feeding on the cultivation boxes elevated to the front side surface and the rear side surface of the cultivation cabinets by taking high-pressure water as impulse force.

Owner:林庆云

Abalone culture feeding system with lifting mechanism and annular track

InactiveCN111096266AAccurate positioning and quantitative feedingLabor savingClimate change adaptationPisciculture and aquariaHigh pressure waterAir compressor

The invention discloses an abalone culture feeding system with a lifting mechanism and an annular track. The abalone culture feeding system comprises a culture pond, culture cabinets, a crane, a feeding machine and an air compressor, wherein wheel treads of cart running devices in the crane are pressed on workshop rails on rail bearing beams to run; the two rail bearing beams are connected to workshop stand column brackets respectively; limiting guide columns are arranged in the culture pond; the culture cabinets are placed in the culture pond and arranged on the limiting guide columns in a sleeved mode; a plurality of culture boxes are arranged on each culture cabinet; the feeding machine is connected to the annular track through the lifting mechanism and can operate along the annular track; the air compressor is connected to the feeding machine or the crane; the feeding machine is provided with a water flushing system and a weighing system; the crane is provided with a weighing device; the crane lifts a culture cabinet to the pond surface; the weight of a culture cabinet is displayed through the weighing device; and the feeding machine is used for quantitatively feeding a liftedculture cabinet through high-pressure water.

Owner:林庆云

Breeding and feeding system with bridge crane and circular rails

InactiveCN111096270AConstruction changeAccurate positioning and quantitative feedingClimate change adaptationPisciculture and aquariaFisheryOverhead crane

The present application discloses a breeding and feeding system with a bridge crane and circular rails. The breeding and feeding system with the bridge crane and the circular rails comprises a breeding pond, a breeding cabinet, a crane and a feeder; wheel treads of large vehicle running devices in the crane run on workshop rails on rail bearing beams in a pressing manner, and the two rail bearingbeams are respectively connected to brackets of workshop stand columns on both sides of the breeding pond; the breeding cabinet is placed in the breeding pond; the crane comprises one or more trolleydevices, each trolley device is connected with a circular rail, and the feeder is suspended above the circular rails; the feeder is provided with a weighing system capable of weighing and measuring feeds in a metering nozzle in the feeder; and the crane lifts the breeding cabinet to a pond surface of the breeding pond, the feeder is provided with a water flushing system, and the feeder feeds the lifted breeding cabinet quantitatively through high-pressure water.

Owner:林庆云

Feeding machine capable of automatically collecting leakage

InactiveCN109418192AConvenient choiceConsistent and accurate feedingClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention discloses a feeding machine capable of automatically collecting leakage. The feeding machine comprises a machine frame, a material bin, a hopper, material spraying pipes and a material leakage receiving device; the material bin is connected and fixed on the machine frame; the hopper is connected under the material bin; the material spraying pipes are connected to the hopper, and theoutlet direction of each spraying pipe is horizontally and slightly inclined downwards; the material leakage receiving device is connected under the machine frame and can collect feed scattered in a feeding process; and a material scraping device is arranged on the material leakage receiving device and can automatically scrape scattered feed into the collecting box.

Owner:陈云燕

Feeding machine with spraying pipe adjustment device

InactiveCN108967304AConvenient choiceConsistent and accurate feedingClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses a feeding machine with a spraying pipe adjustment device, and the feeding machine comprises a frame, a stock bin, hoppers, spraying pipes and a spraying pipe lateral adjustmentdevice. The upper part of the frame is connected with the stock bin, and the stock bin is connected with one or more hoppers. Each hopper is connected with more than one spraying pipes, and the spraying pipes are arranged and connected in the vertical direction of the hopper from the bottom to the top. The spraying pipes are arranged into one column or multiple columns, and the mouths of the spraying pipes are set to be in the same direction and are slightly horizontal. One or more spraying pipes are provided with the spraying pipe lateral adjustment device, and the spraying pipe lateral adjustment device is provided with a control mechanism which is driven by an air cylinder, an oil cylinder or a push rod to operate, and the control mechanism can control the connected spraying pipes to make lateral telescoping motion. The spraying pipes perform the quantitative putting of materials to the outside through taking the high-pressure water as the power.

Owner:张达英

Overwater culture feeding system with leaked material receiving device and annular track

InactiveCN111096275AReduce workshop aislesMake full use of the workshop areaClimate change adaptationPisciculture and aquariaFisheryEngineering

The invention discloses an overwater culture feeding system with a leaked material receiving device and an annular track. The overwater culture feeding system comprises a culture pond, culture cabinets, a crane and a feeding machine, wherein wheel treads of cart running devices in the crane are pressed on workshop rails on the rail bearing beams to run; the two rail bearing beams are connected toworkshop stand column brackets on the two sides of the culture pond respectively; each culture cabinet is provided with a plurality of culture boxes; a gate device is arranged in front of each culturebox; when a culture cabinet is placed in the culture pond, a feeding inlet is blocked and closed by a gate; when a culture cabinet is lifted to the pond surface of the culture pond, feeding inlets are opened and exposed; the feeding machine is connected to the annular track and a balance track of the crane; the leaked feed receiving device is arranged on the feeding machine and can automaticallyscrape a scattered feed into a collecting box; the feeding machine is provided with a water flushing system and a weighing system; the crane lifts a culture cabinet to the pond surface; and the feeding machine quantitatively feeds the culture boxes in the lifted culture cabinets with high-pressure water as impulsive force.

Owner:林庆云

Abalone culture feeding system with plurality of material spraying pipes and annular tracks

InactiveCN111096263AAccurate positioning and quantitative feedingLabor savingClimate change adaptationPisciculture and aquariaEngineeringHigh pressure water

The invention discloses an abalone culture feeding system with a plurality of material spraying pipes and annular tracks. The abalone culture feeding system comprises a culture pond, culture cabinets,a crane and feeding machines, wherein wheel treads of cart running devices in the crane are pressed on workshop rails on rail bearing beams to run; the two rail bearing beams are connected to workshop stand column brackets respectively; the culture cabinets are placed in the culture pond; the crane comprises one or more trolley devices; each trolley device is connected with an annular track; thefeeding machine is suspended on the annular tracks; a plurality of material spraying pipes are arranged on the feeding machine and are arranged from bottom to top along the vertical direction of a hopper of the feeding machine; the plurality of material spraying pipes are arranged in one or more rows; and outlets of the material spraying pipes face the same direction; the feeding machine is provided with a water flushing system and a weighing system; the weighing system can weigh and meter a feed in a metering nozzle in the feeding machine; the crane lifts a culture cabinet to the pond surface; and the feeding machine quantitatively feeds the lifted culture cabinet through high-pressure water.

Owner:林庆云

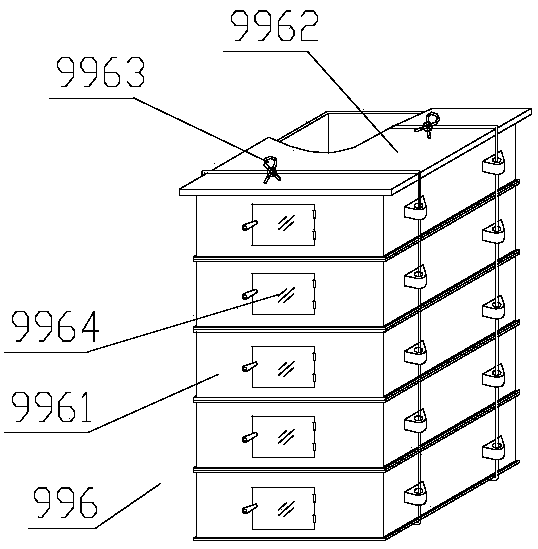

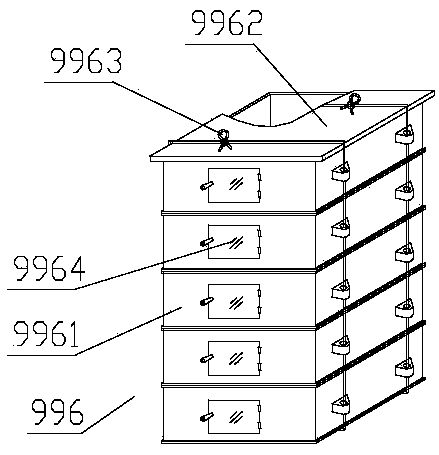

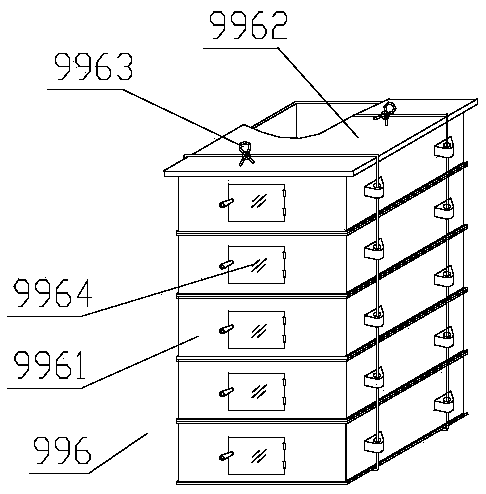

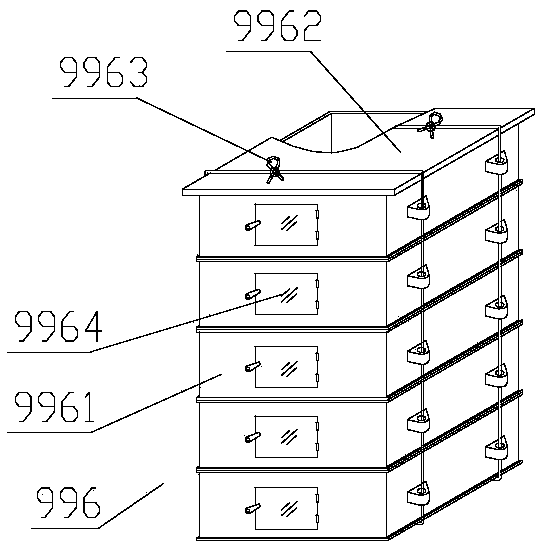

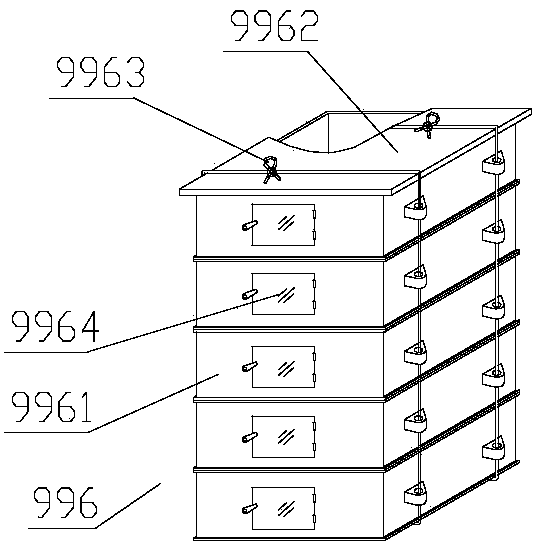

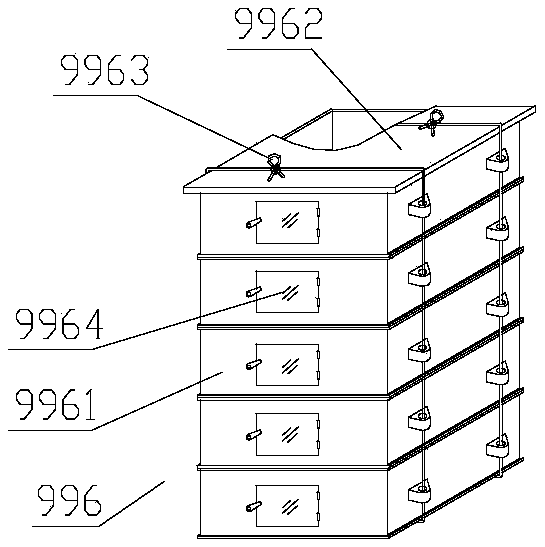

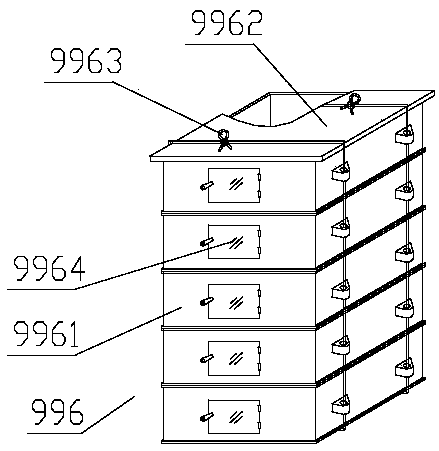

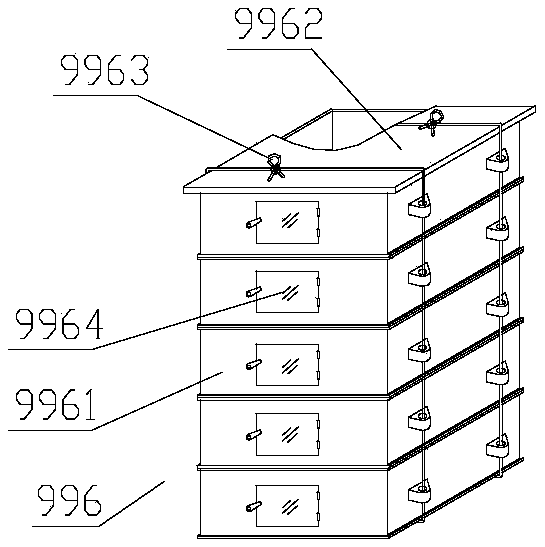

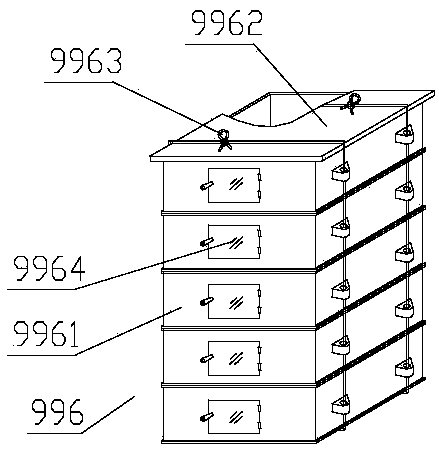

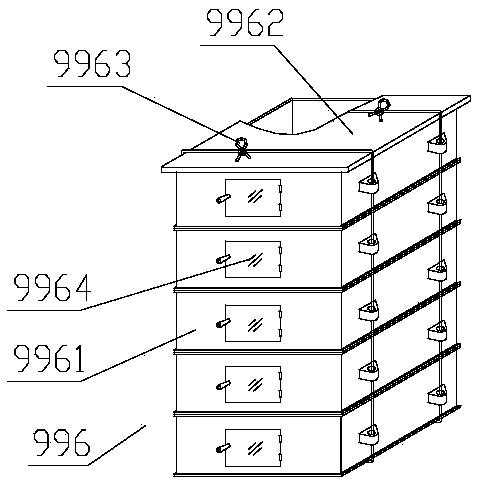

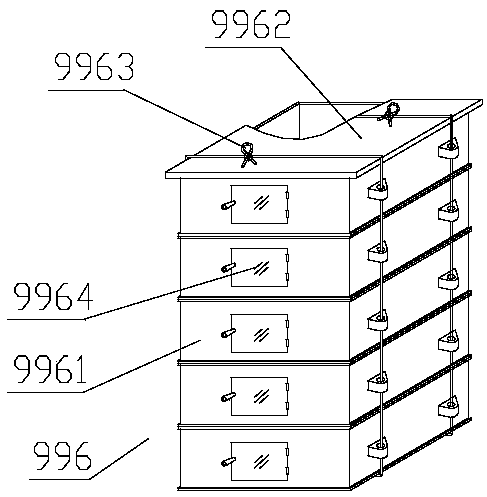

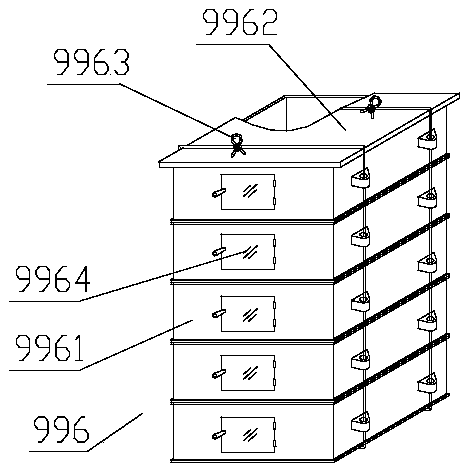

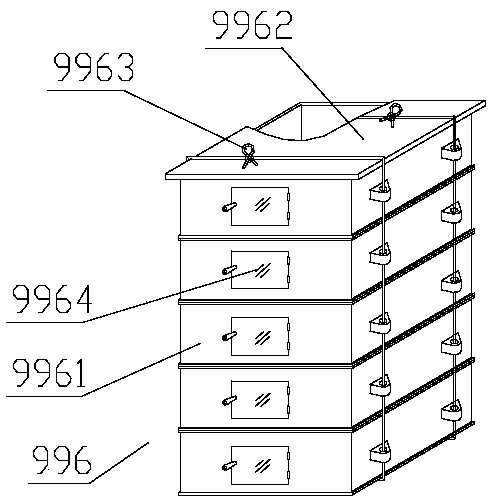

Feeding machine with barometric columns and lift-drop control mechanism

InactiveCN109418209AQuick cleaningClean and quick feed sizeClimate change adaptationPisciculture and aquariaEngineeringAtmospheric pressure

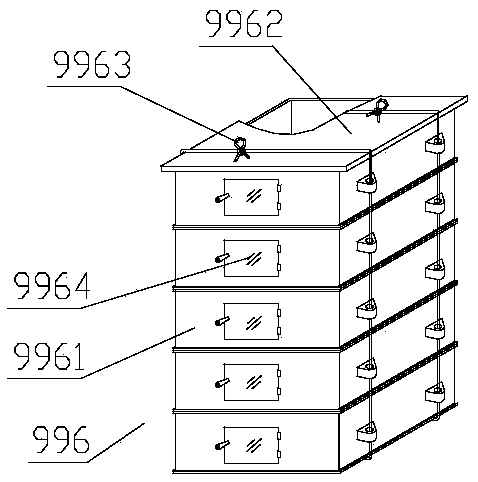

The invention discloses a feeding machine with barometric columns and a lift-drop control mechanism. The feeding machine comprises a frame, a feed bin, feed hoppers, feed spraying pipes, a leaked feedreceiving device and the lift-drop control mechanism, wherein the frame comprises a plurality of the barometric columns; each barometric column comprises a piston rod; the feed bin is connected withand arranged on piston rods located on the frame and can be moved to lift and drop; the feed hoppers are connected with and arranged below the feed bin; each feed hopper is provided with a transparentwindow and a pull handle; a plurality of the feed spraying pipes are connected with and arranged on each feed hopper; the outlet direction of the plurality of the feed spraying pipes is horizontallyand slightly inclined downward; the leaked feed receiving device is arranged below the frame and can collect a feed scattered in the process of feeding; the bottom part of the frame is provided with moving wheels which are universal casters or track wheels with a rim; and the lift-drop control mechanism is arranged below the frame and can control the lift-drop movement of the piston rods.

Owner:黄滨

Feeding machine with adjustable metering mouth

InactiveCN108967297AConvenient choiceConsistent and accurate feedingClimate change adaptationPisciculture and aquariaWater pipeEngineering

The invention discloses a feeding machine with an adjustable metering mouth, and the feeding machine comprises a frame, a stock bin, a hopper, a spraying pipe, and a material water flushing system. The stock bin is connected to the frame, and the hopper is connected below the stock bin. The spraying pipe is connected to the hopper, and is provided with a flushing pipe. The flushing pipe is connected with a control valve. The spraying pipe is provided with a metering mouth and the adjustable metering mouth, and the adjustable metering mouth is a casing pipe and sleeves the metering mouth and isconnected through a long hole rack. The metering mouth and the adjustable metering mouth are combined to adjust the metering capacity. The outlet of the adjustable metering mouth is provided with a sealing gate, and the sealing gate is opened during flushing, and is normally closed during no flushing operation. The outlet of the adjustable metering mouth is slightly horizontal. The material waterflushing system can generate and store high-pressure water. The spraying pipe takes the high-pressure water as the power to quantitatively throw materials to the outside.

Owner:张达英

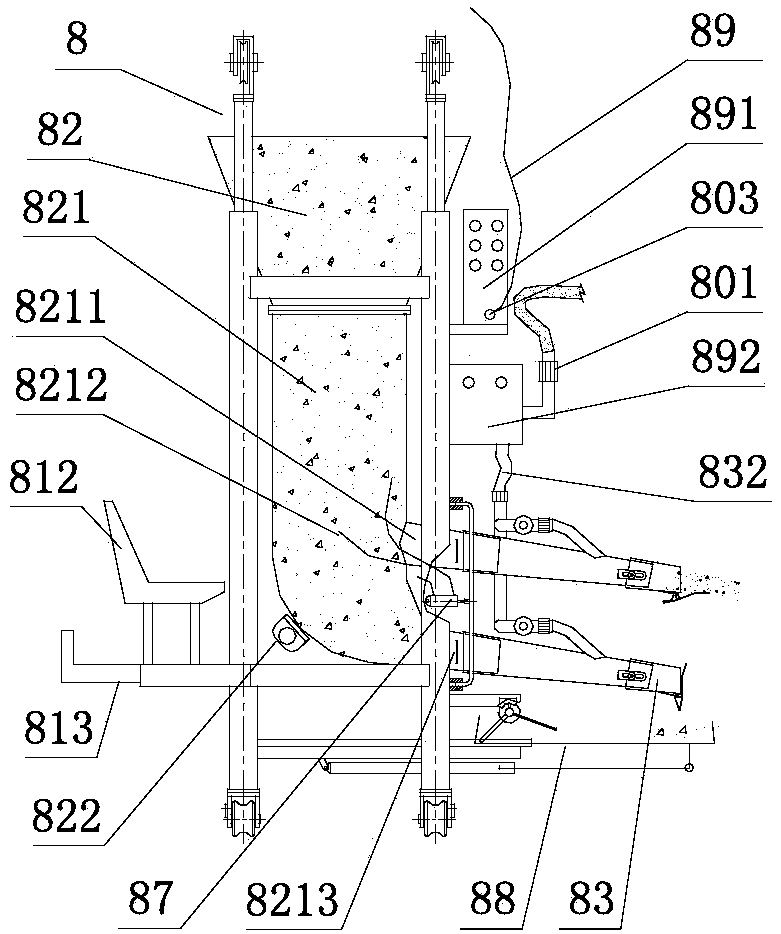

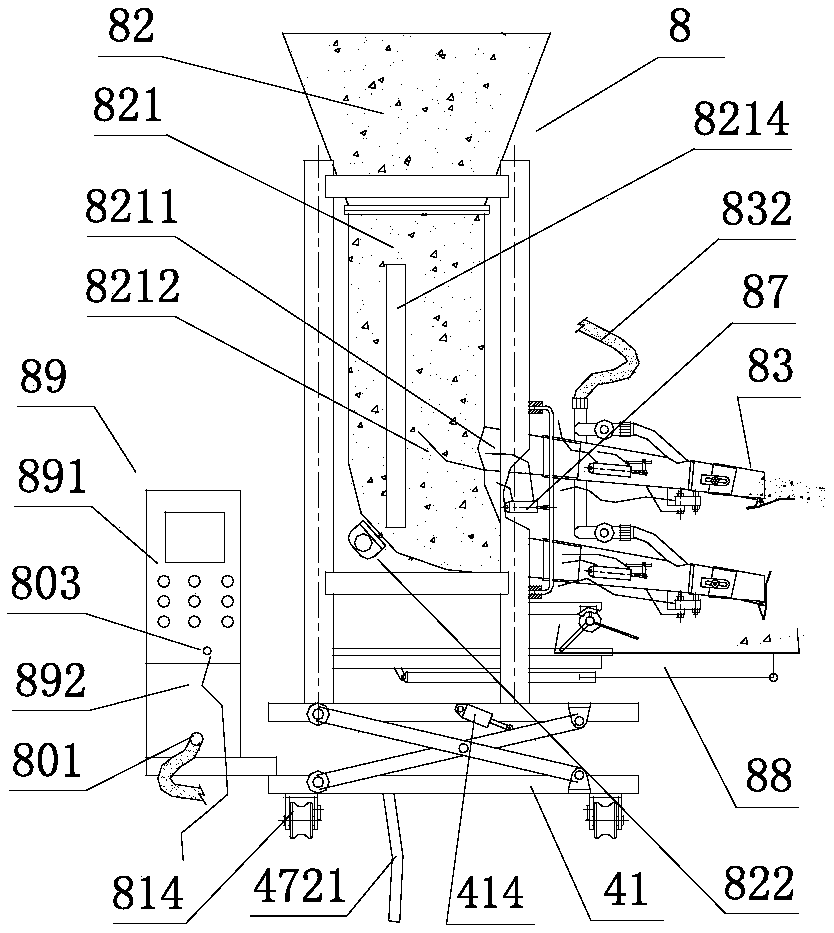

Feeder with vibrator and leaked material receiving device

InactiveCN108967313AEasy to observe the remaining amountControl feed sizeClimate change adaptationPisciculture and aquariaEngineeringHigh pressure water

The application discloses a feeder with a vibrator and a leaked material receiving device. The machine comprises a frame, a material bin, a hopper, material spray pipes, the vibrator, an elevating machine, the leaked material receiving device, an air pressure tank and a water pump. The material bin is connected on the material bin, below which the hopper is connected. The side surface of the hopper is equipped with multiple water discharge pipes connected with the water spray pipes. The bottom of the frame is connected on the elevating machine equipped with a telescopic cylinder. The vibratoris connected on the hopper or connected to the material bin. The leaked material receiving device is arranged below the material spray pipes and connected on the elevating machine. Water flushing pipes of the water spray pipes are connected with a pipeline of the air pressure tank. The air pressure tank and the water pump are connected to the elevating machine. The water pump supplies water to theair pressure tank which is capable of producing and storing high-pressure water. The high-pressure water is taken as a power used for driving the water spray pipes to deliver fodders outside or takenas a power driving the telescopic cylinder to work, or a power driving the vibrator to work, or a power used for driving the leaked material receiving device to automatically scrap material.

Owner:张达英

Breeding and feeding equipment provided with crane and annular tracks

InactiveCN110476859AReduce labor intensityAccurate positioning and quantitative feedingClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses breeding and feeding equipment provided with a crane and annular tracks. The feeding equipment comprises the crane and a feeding machine; the crane comprises one or more cart devices, each cart device is connected with the corresponding annular track, each annular track is connected with the feeding machine, and the feeding machine can run back and forth along the annular tracks; the feeding machine is provided with a weighing system, and the weighing system can weight and meter feed in metering nozzles of the feeding machine; the crane is provided with lifting hooks; the feeding machine can run around the lifting hooks in the direction of the horizontal plane, outlets of spraying pipes in the feeding machine always face one sides of the lifting hooks, and the feeding machine can conduct transverse and quantitative feed putting towards one sides of the lifting hooks through high-pressure gas.

Owner:黄滨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com