Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Flexible track output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

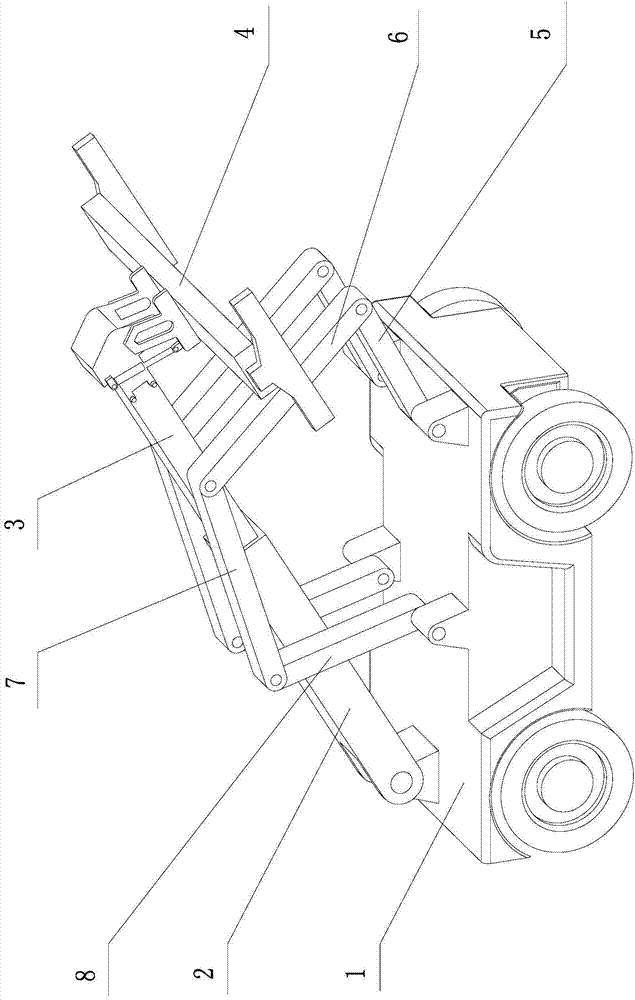

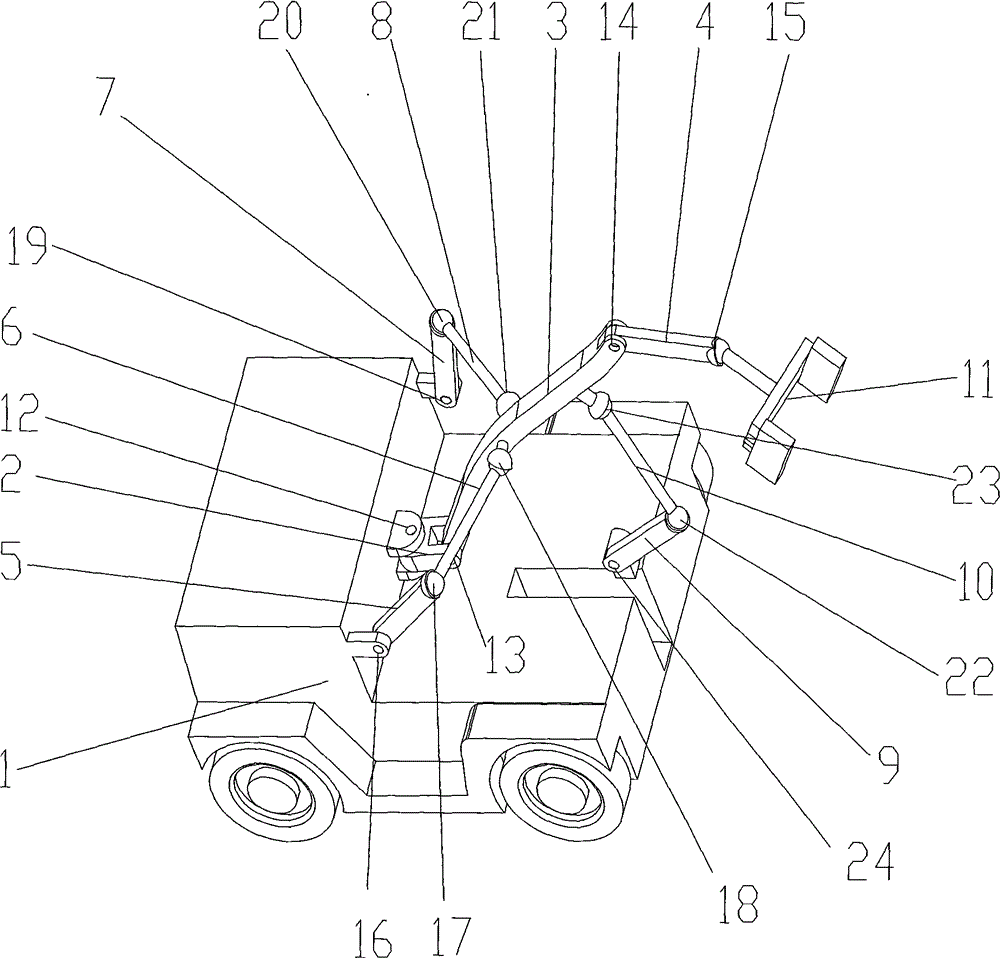

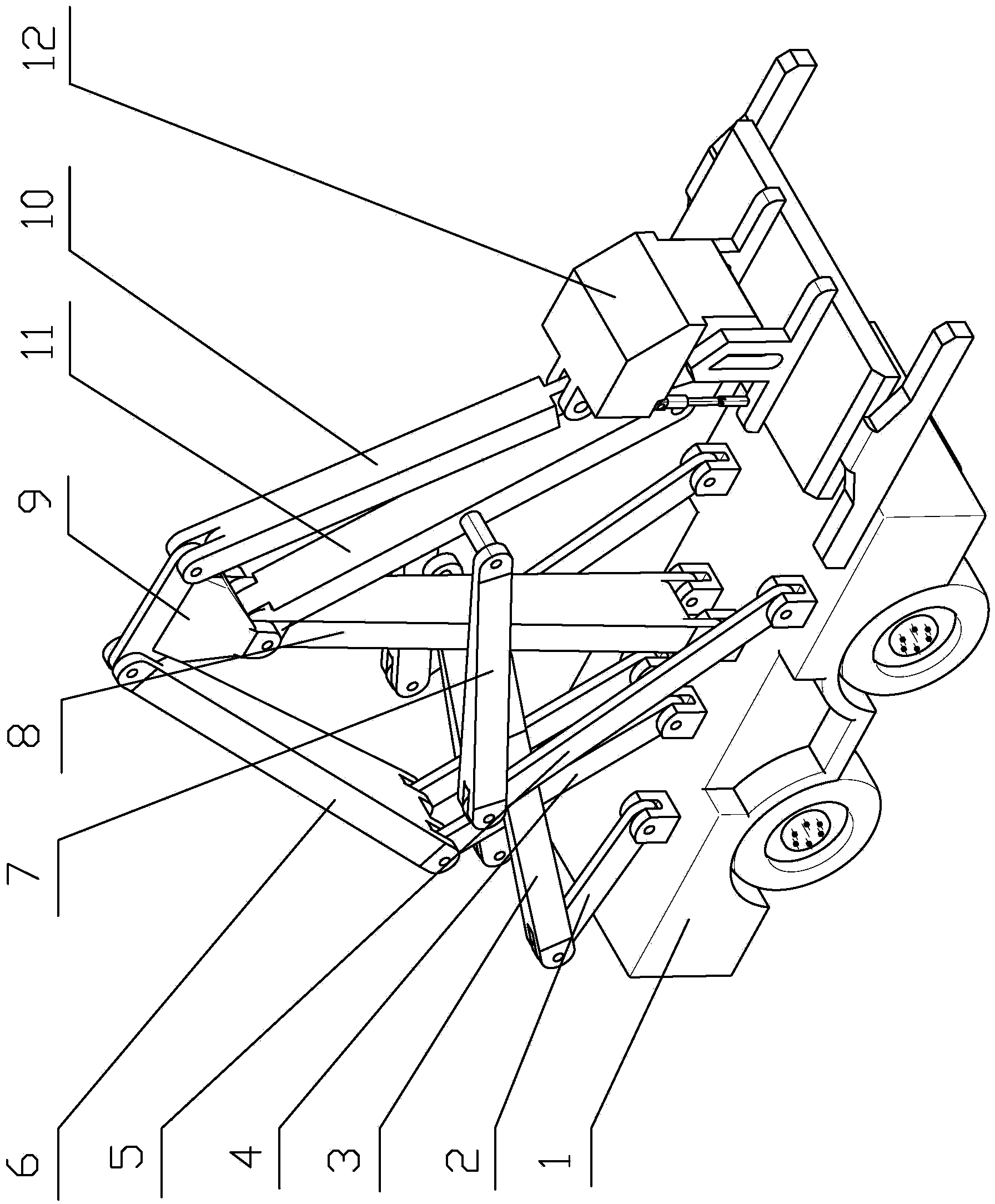

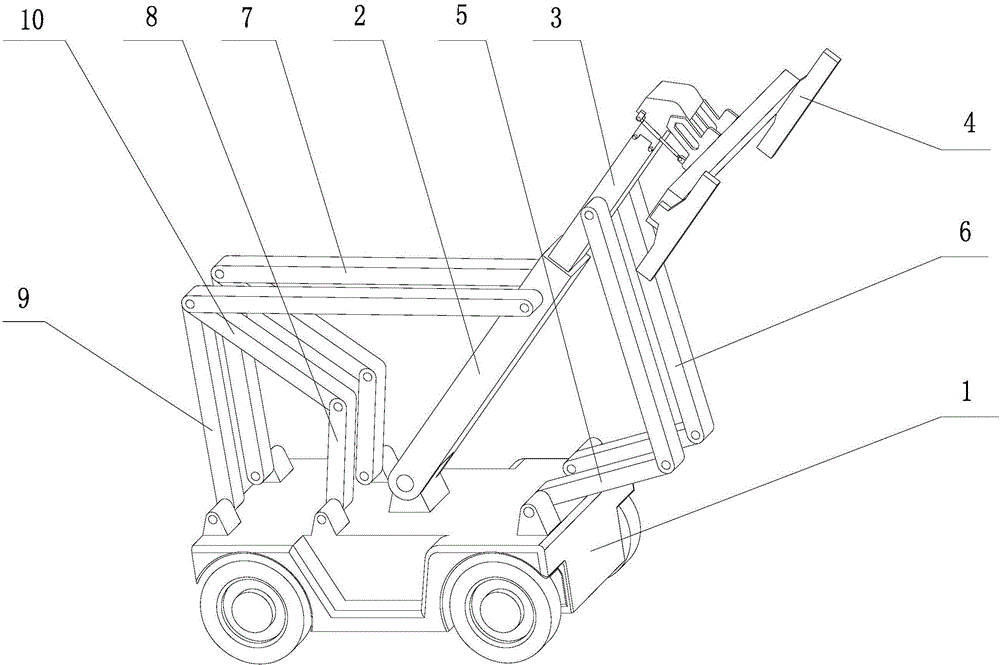

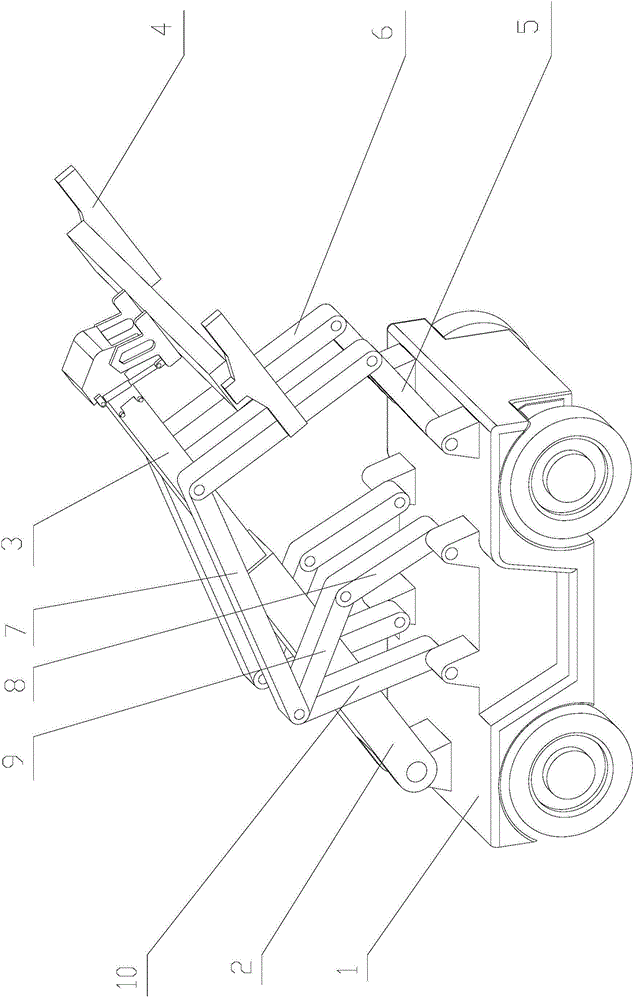

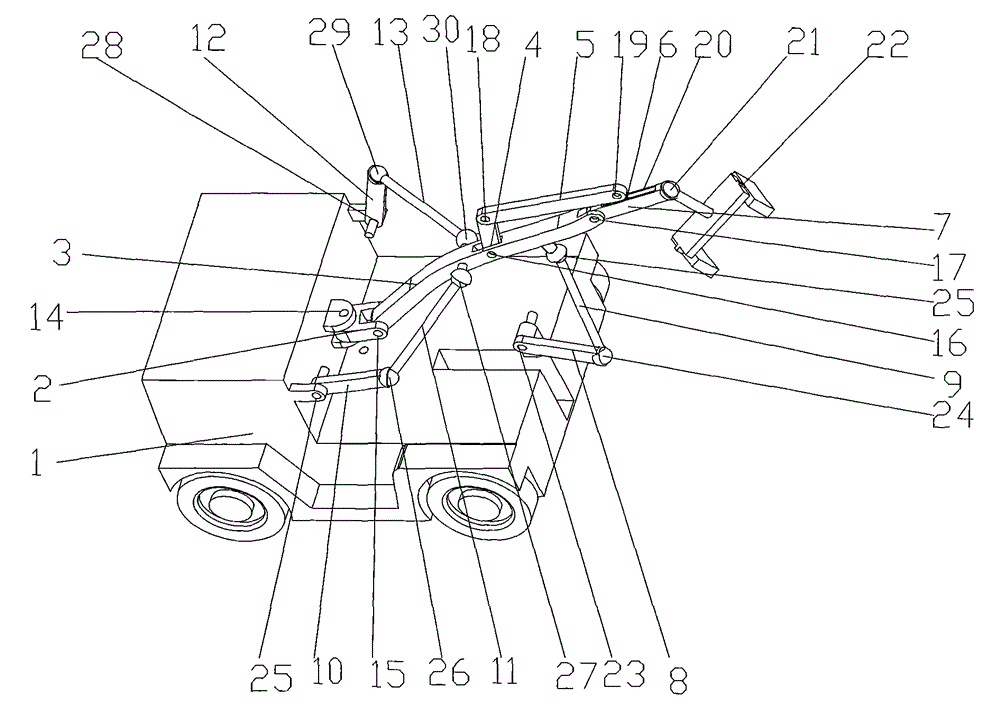

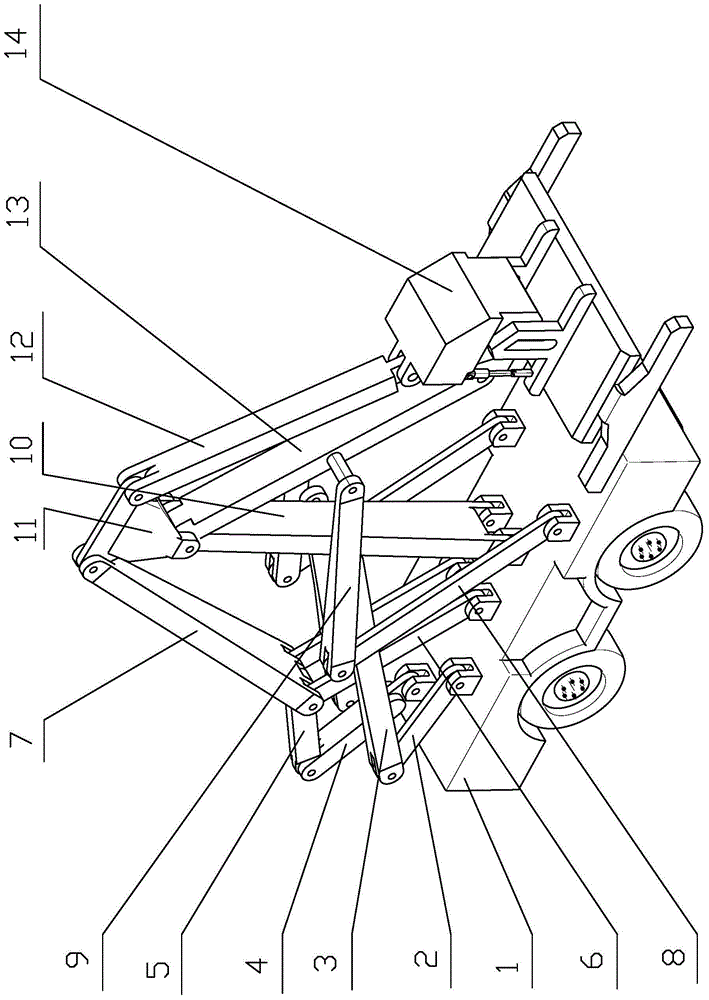

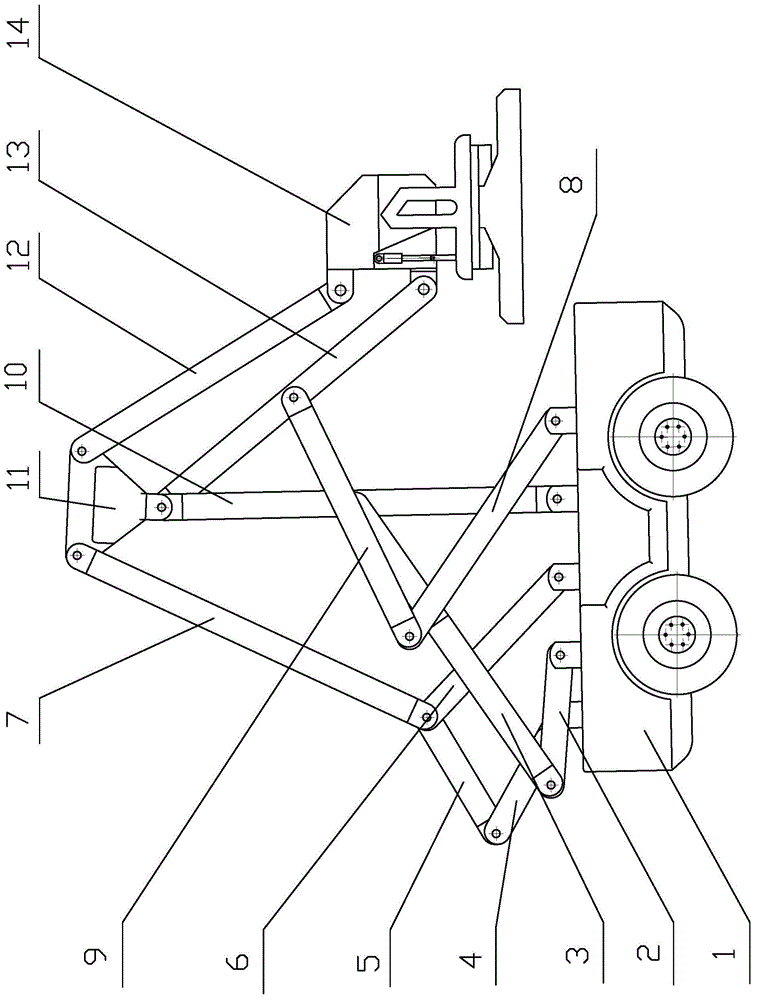

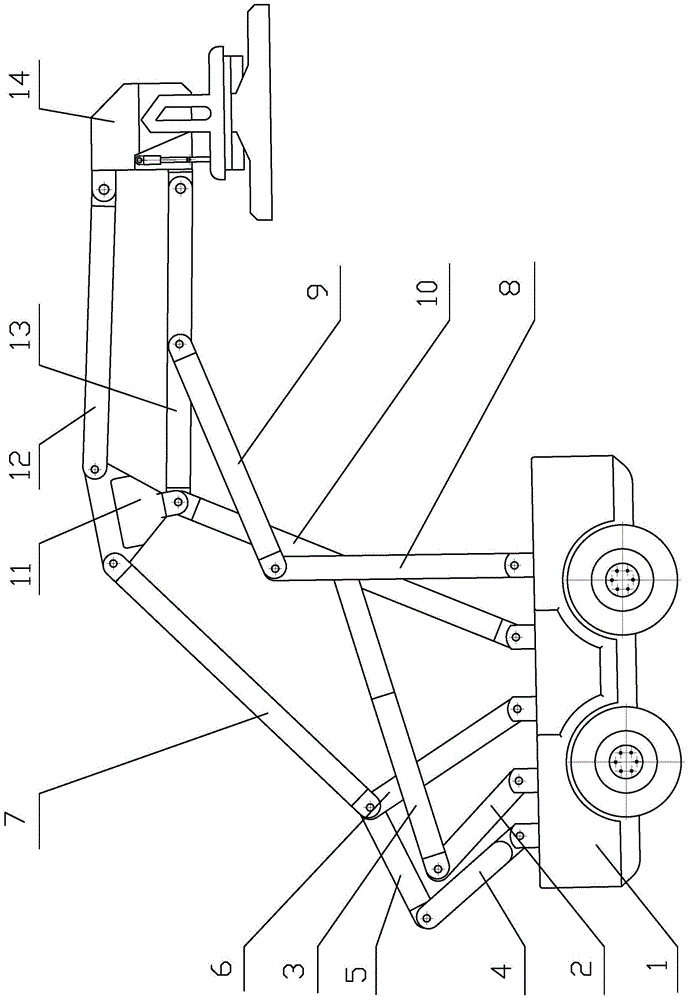

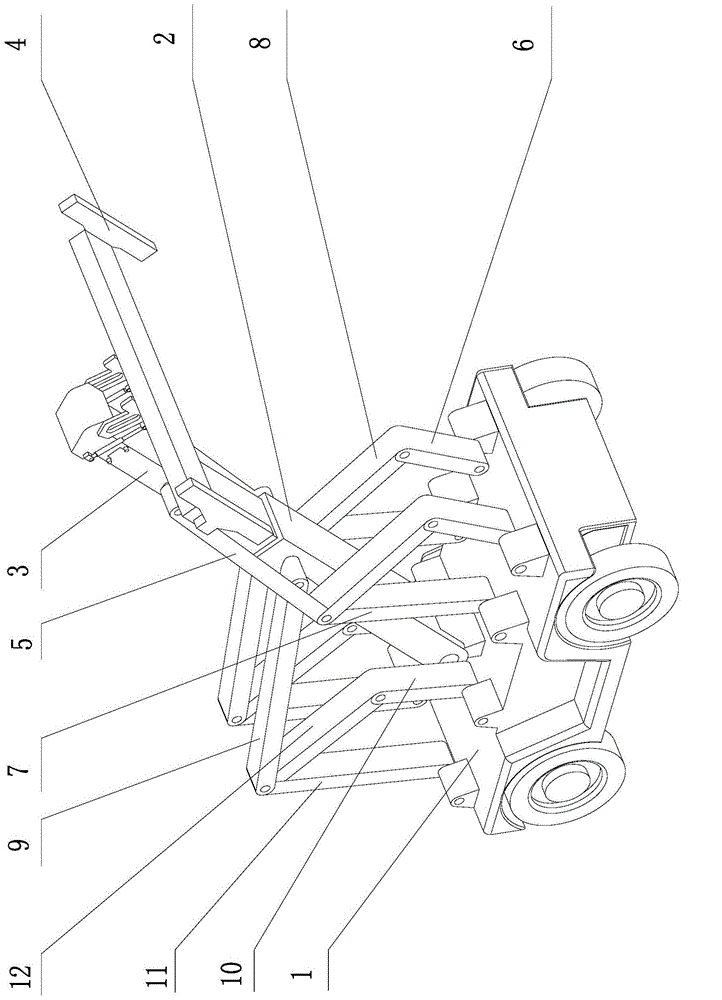

Plane two-degree-of-freedom seven-rod closed chain type reach stacker for containers

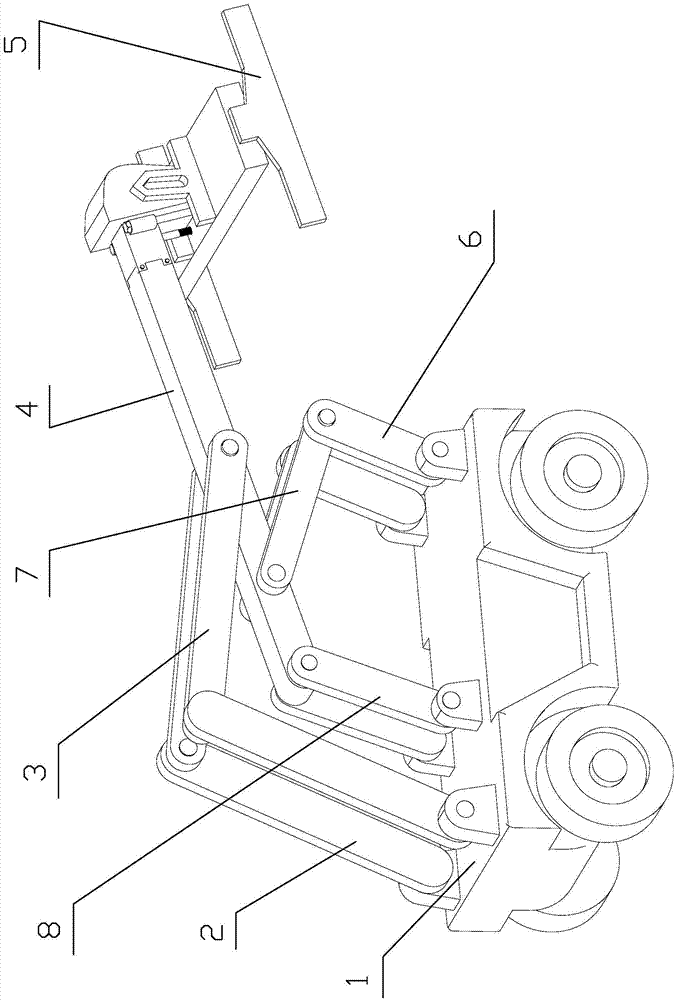

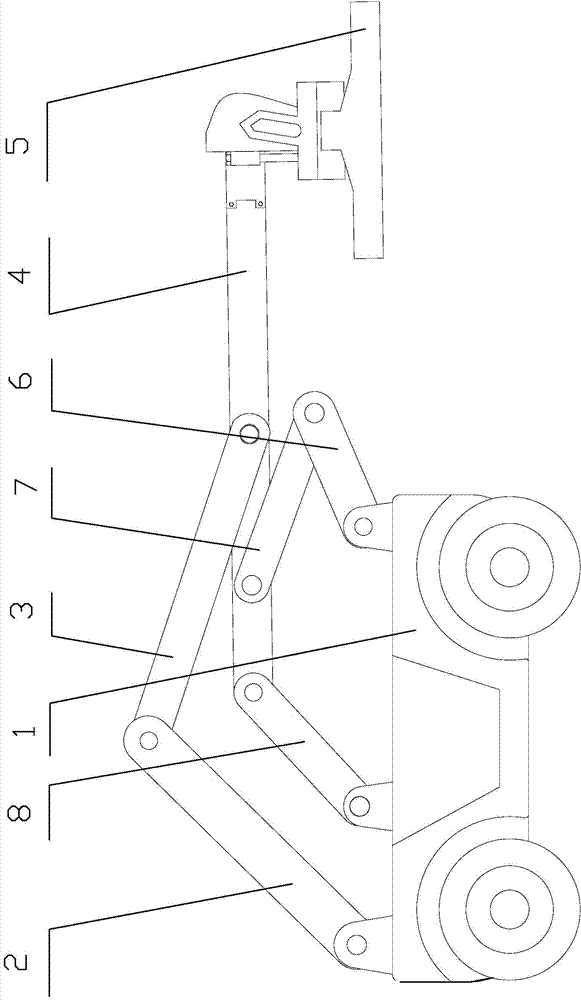

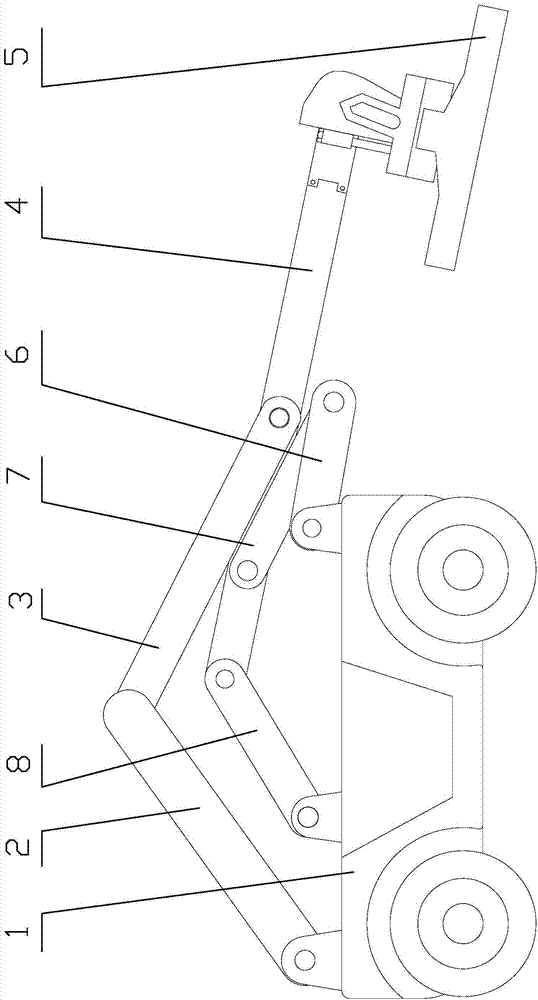

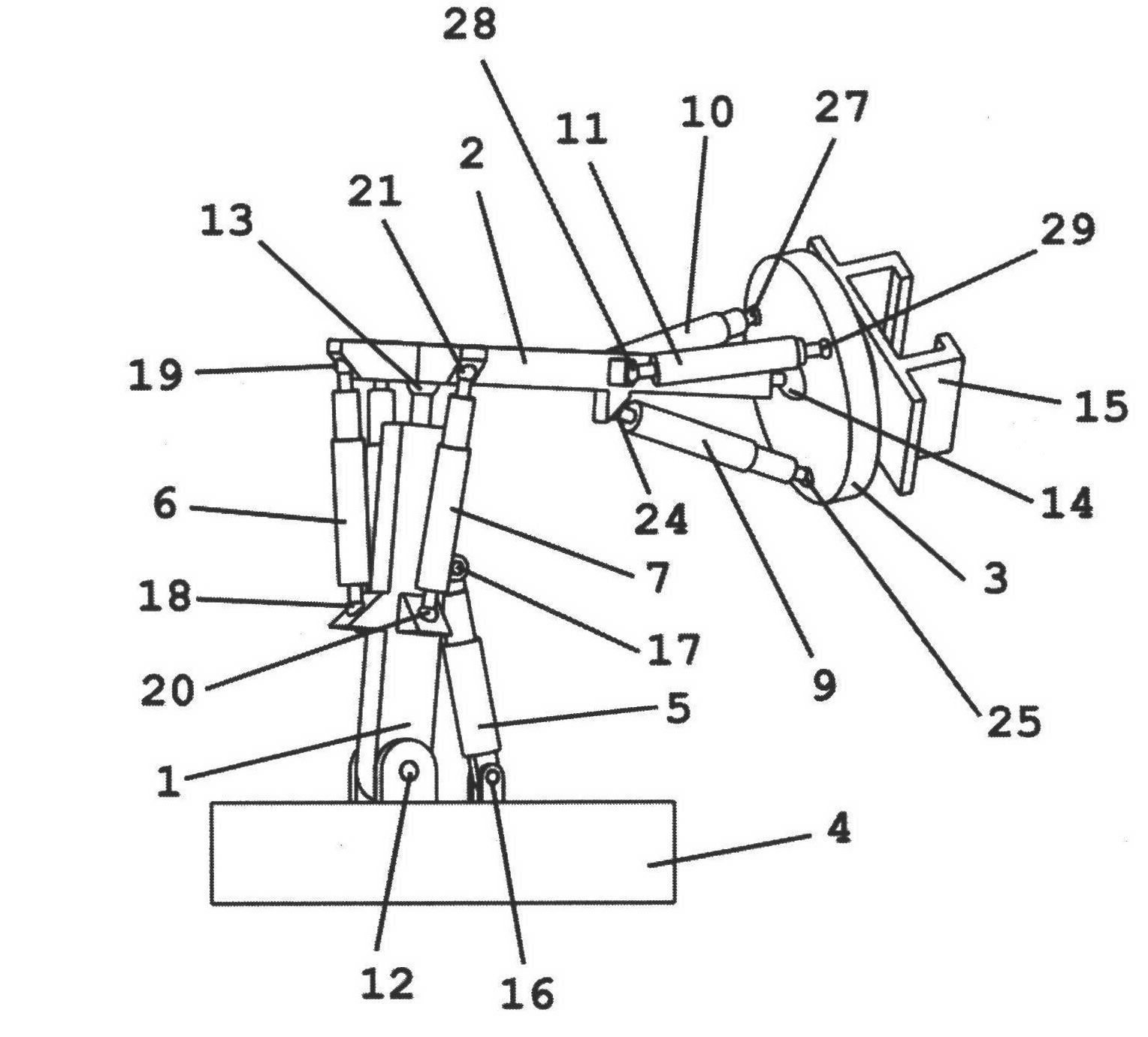

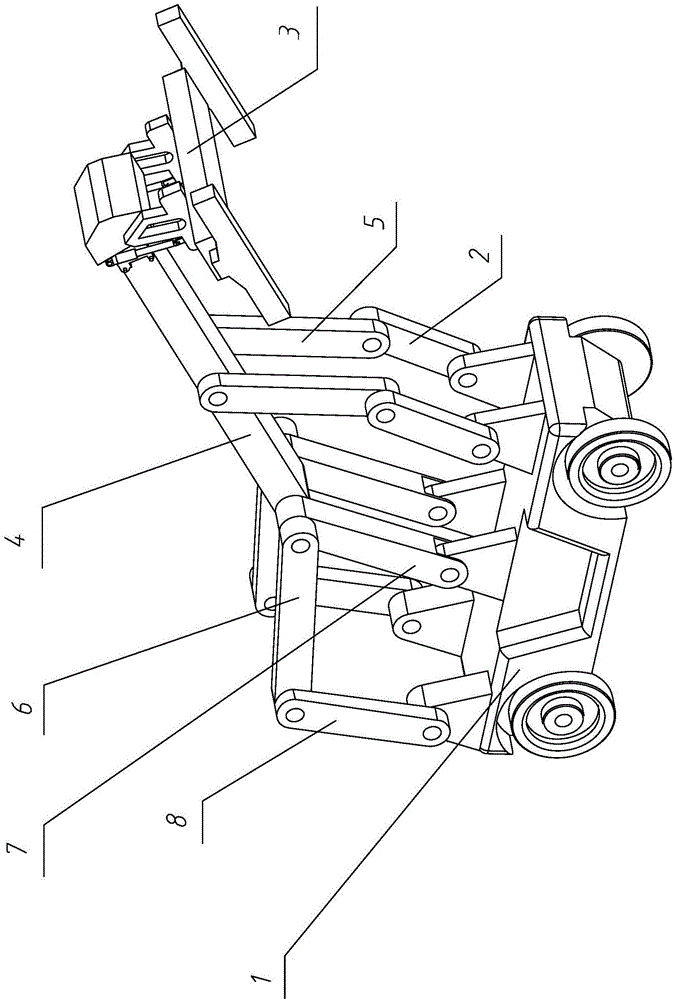

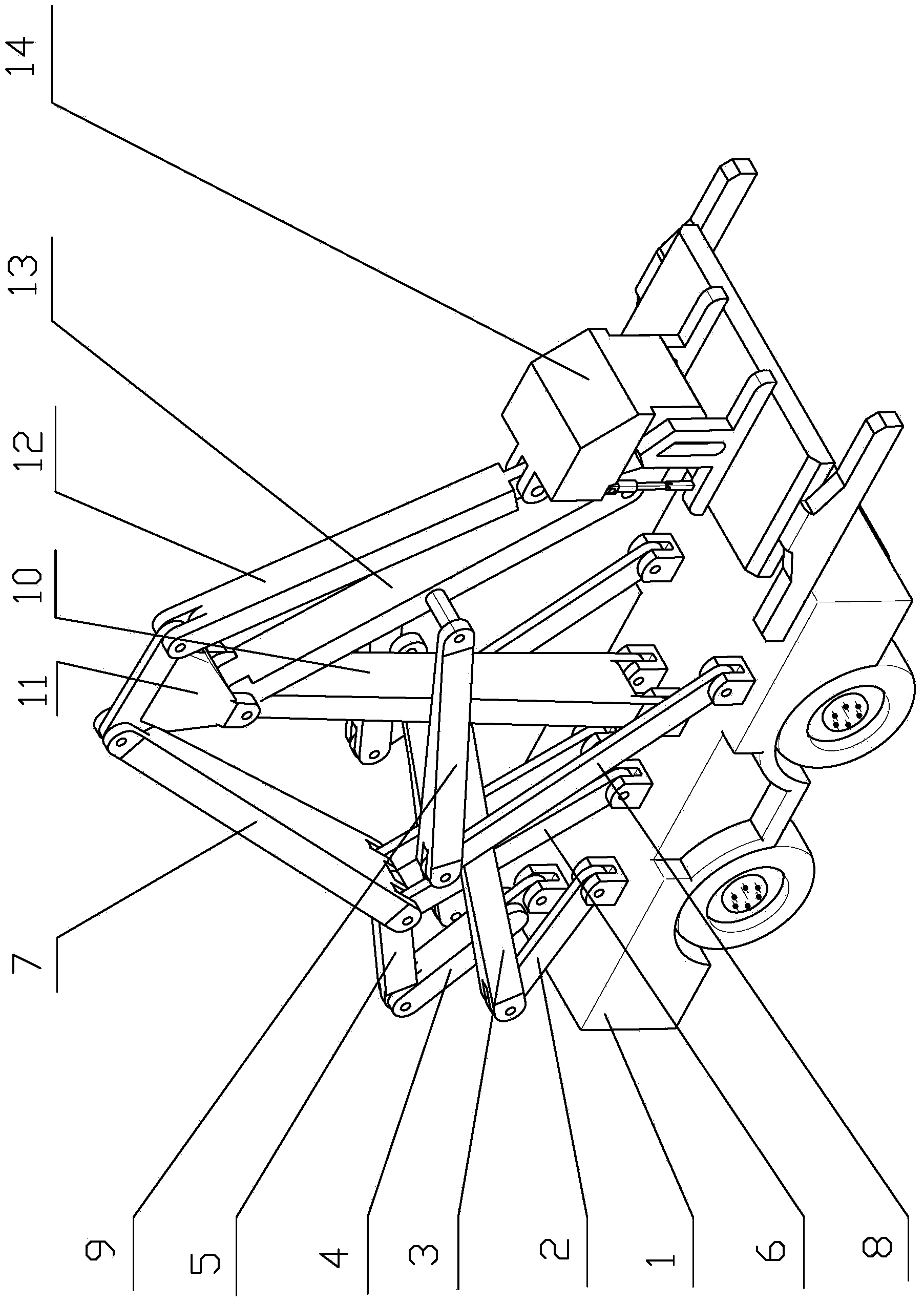

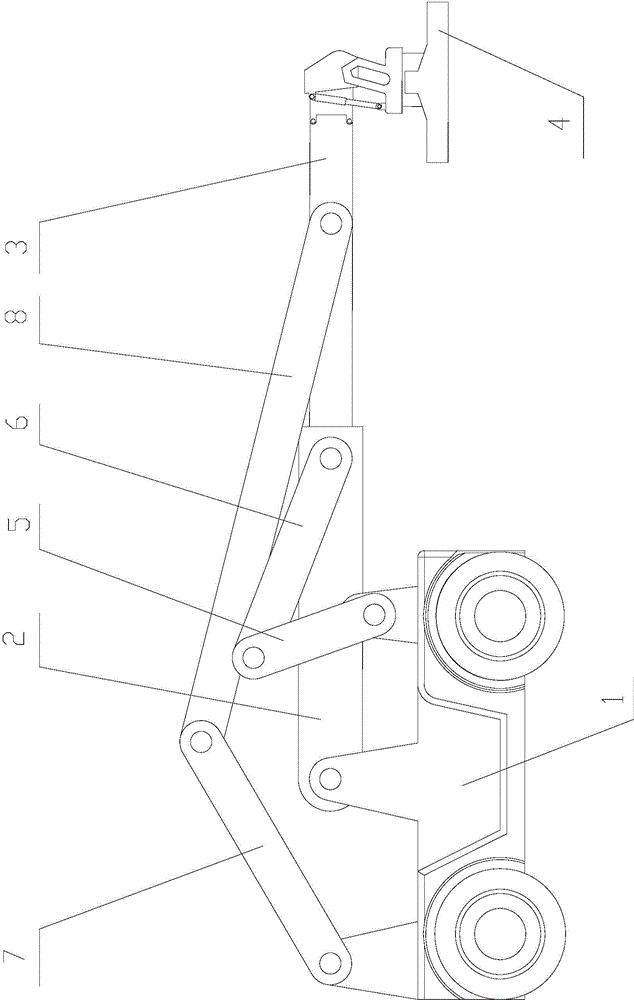

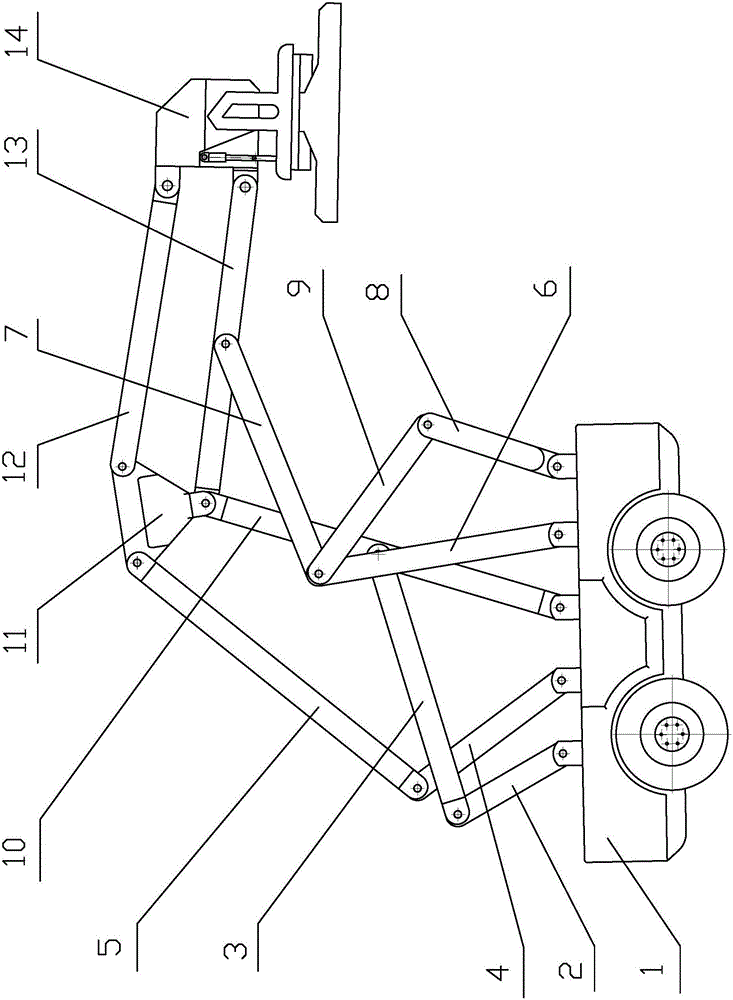

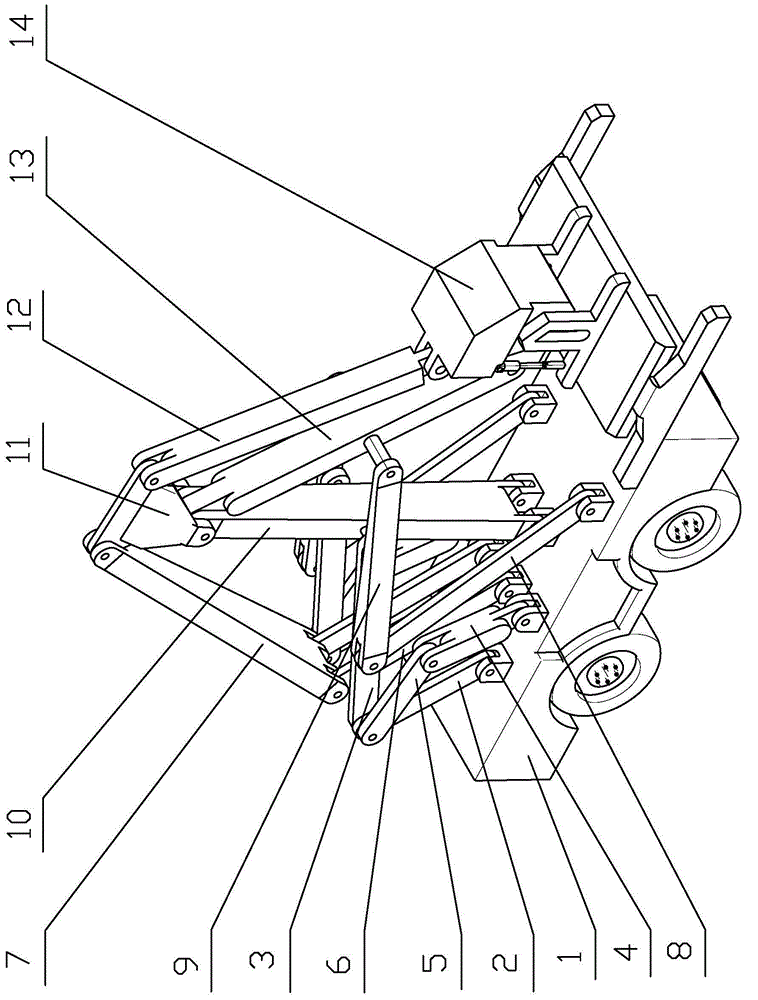

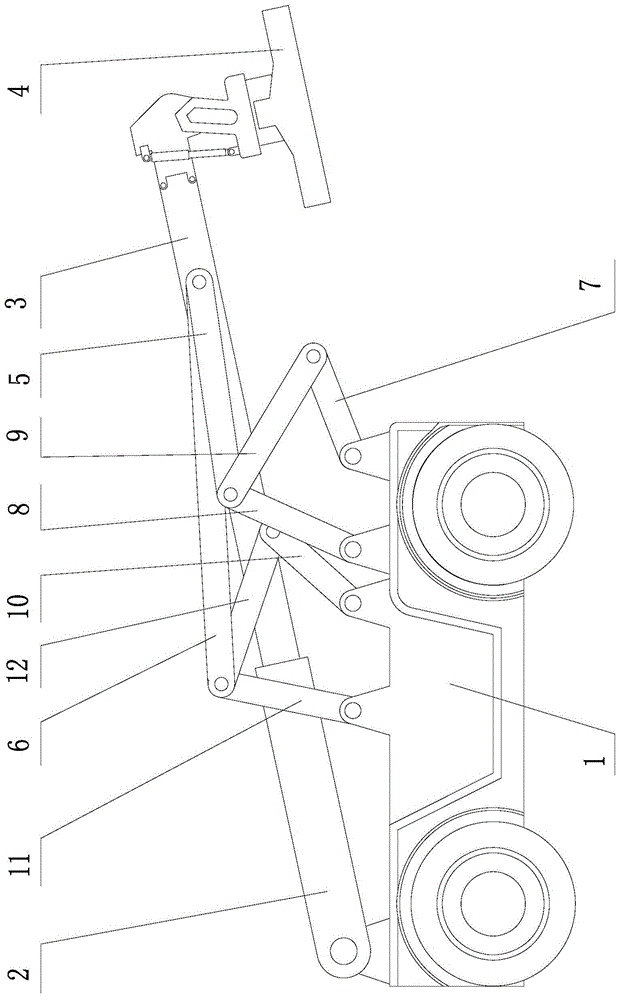

The invention relates to a plane two-degree-of-freedom seven-rod closed chain type reach stacker for containers. The plane two-degree-of-freedom seven-rod closed chain type reach stacker for the containers comprises a suspension arm and a suspension lifting and telescoping mechanism, wherein the suspension arm comprises a rotating arm and a telescopic arm; the rotating arm is hinged to the rear part of a frame; the telescopic arm is mounted on the rotating arm through a sliding pair; a clamping device is arranged at the front end of the suspension arm; the suspension arm lifting and telescoping mechanism comprises five-rod linkage mechanisms which are symmetrically arranged on the two sides of the suspension arm; each five-rod linkage mechanism comprises a front rocker, a front connecting rod, a rear connecting rod and a rear rocker; the front rockers and the rear rockers are hinged to the front part and the middle part of the frame respectively; the hinged points between the front connecting rods and the rear connecting rods are arranged on the telescopic arm. Ascending, telescoping and descending of the crane are realized under the drive of the five-rod linkage mechanisms. The plane two-degree-of-freedom seven-rod closed chain type reach stacker for the containers has the advantages of small movement inertia, flexible track output, high precision, high rigidity, excellent dynamic performance, high reliability and the like.

Owner:QINZHOU UNIV

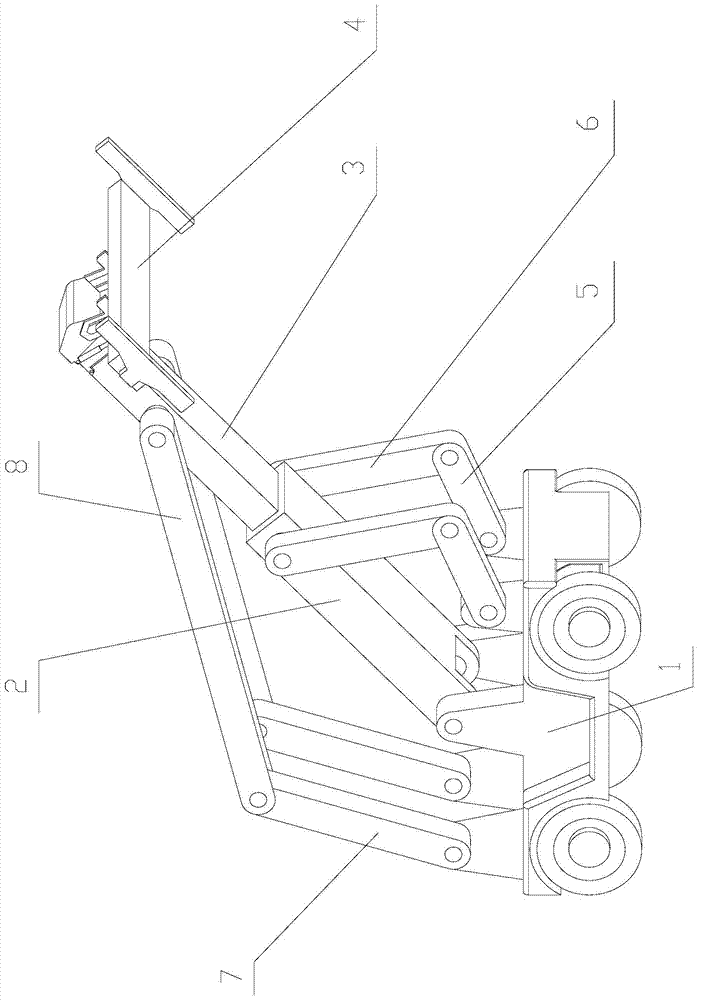

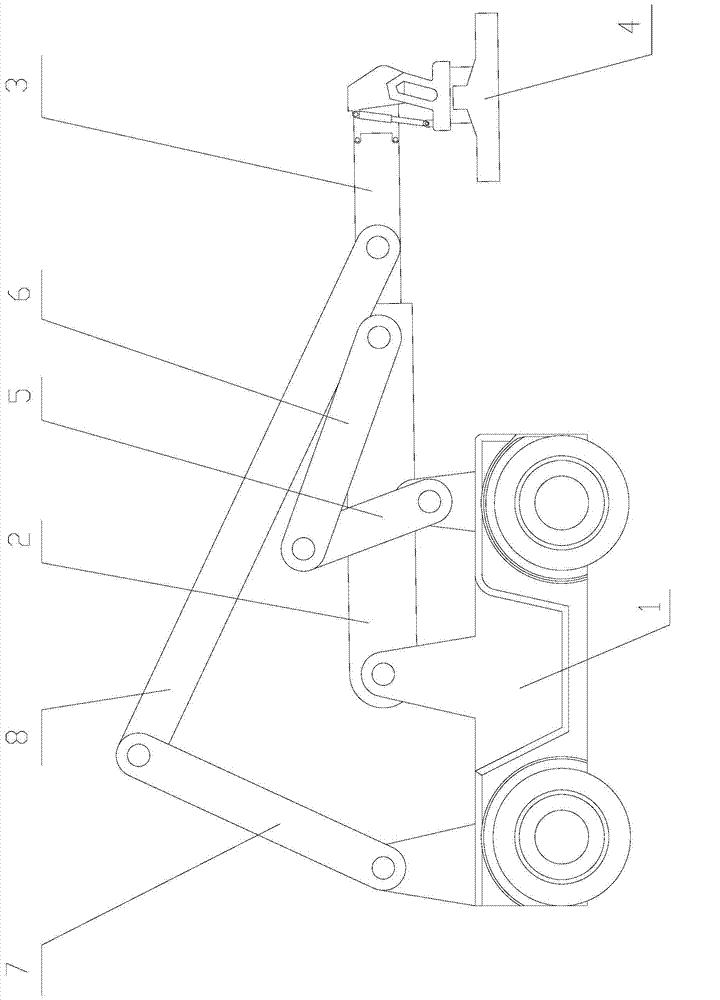

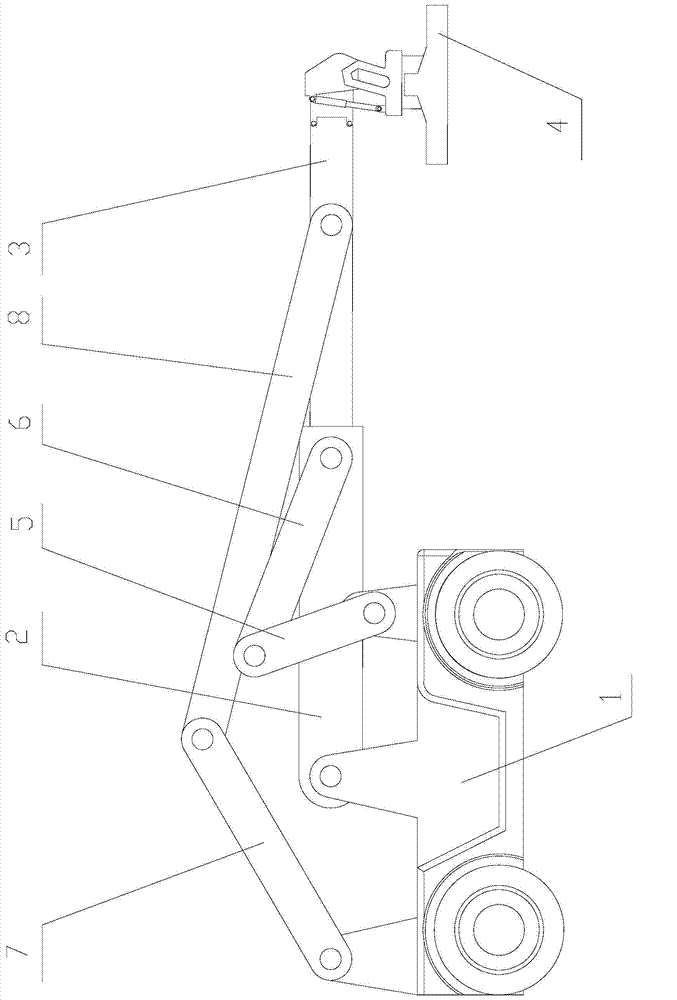

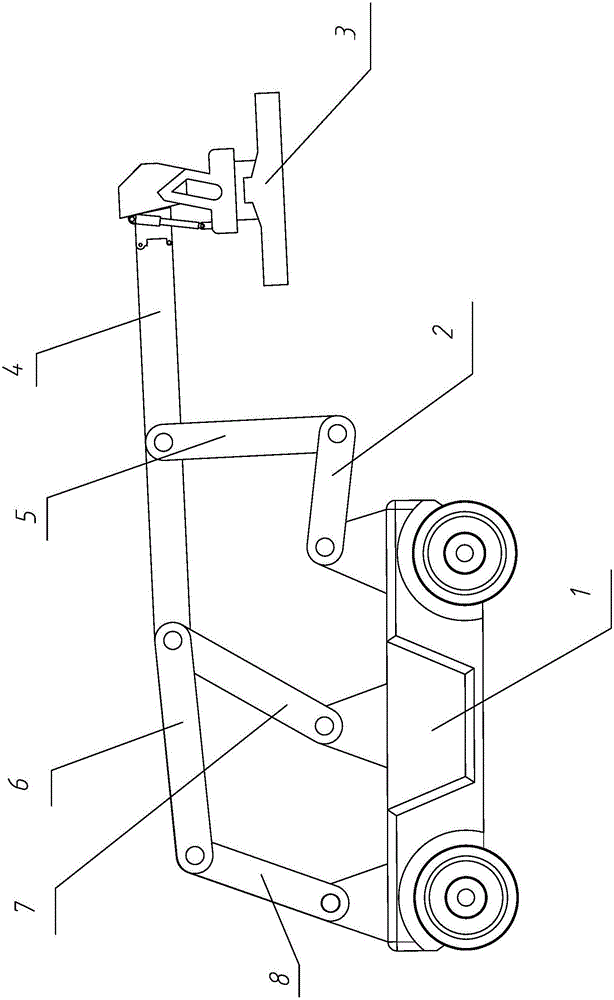

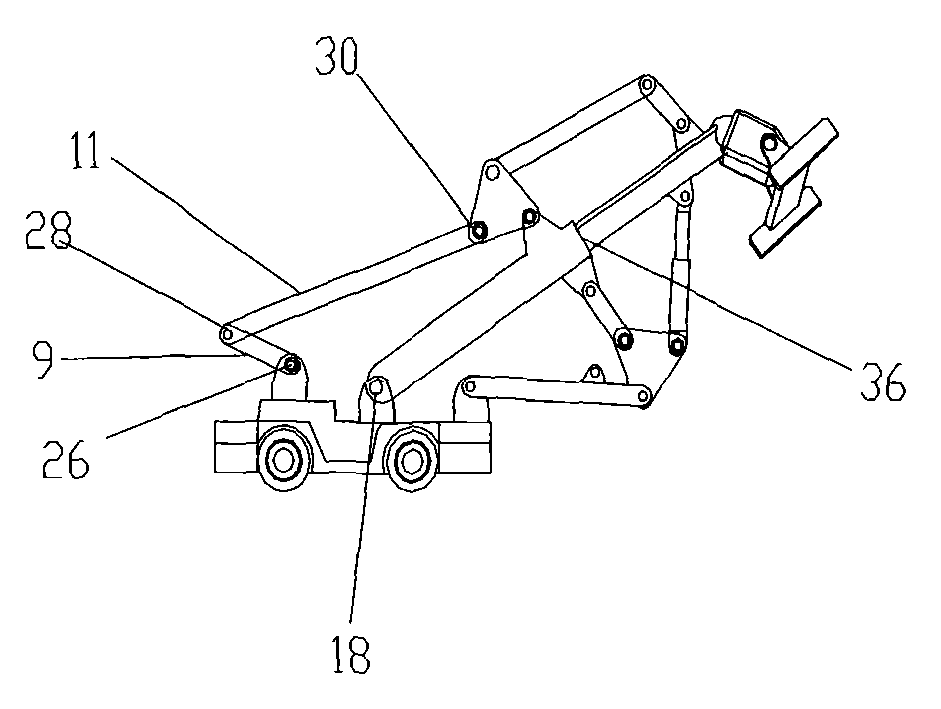

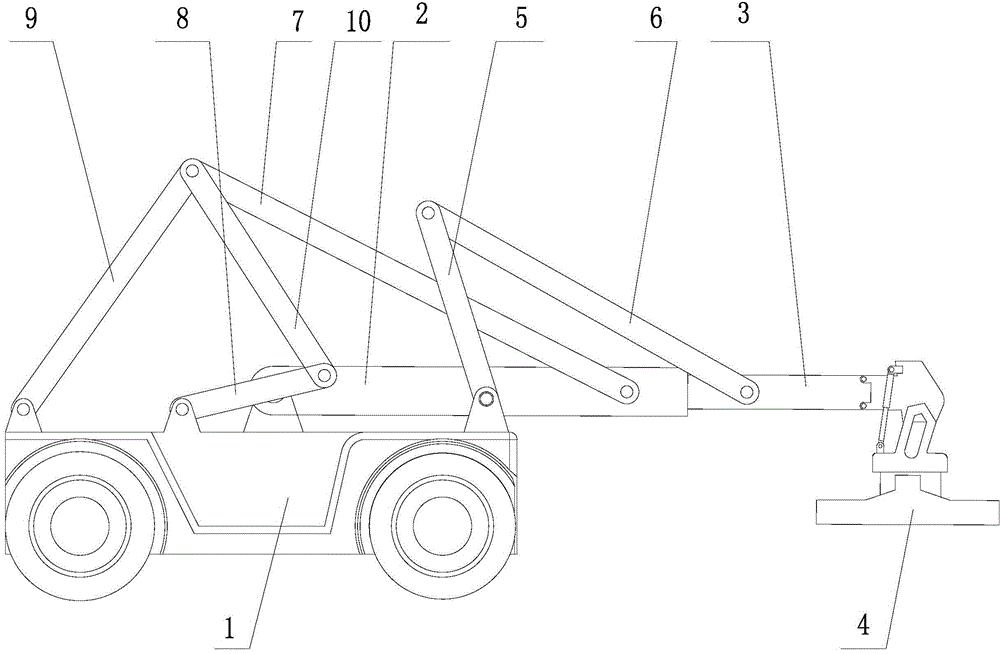

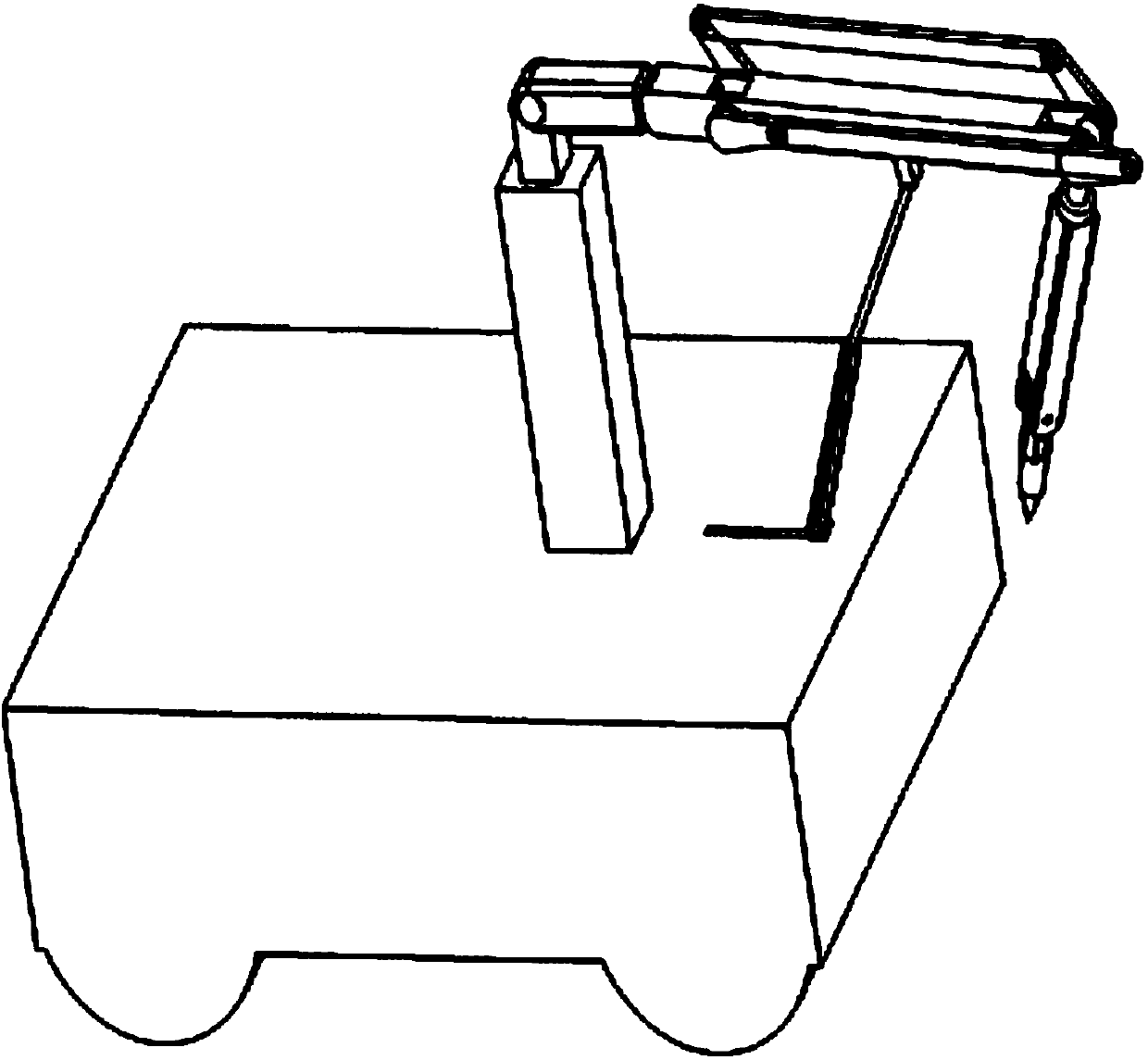

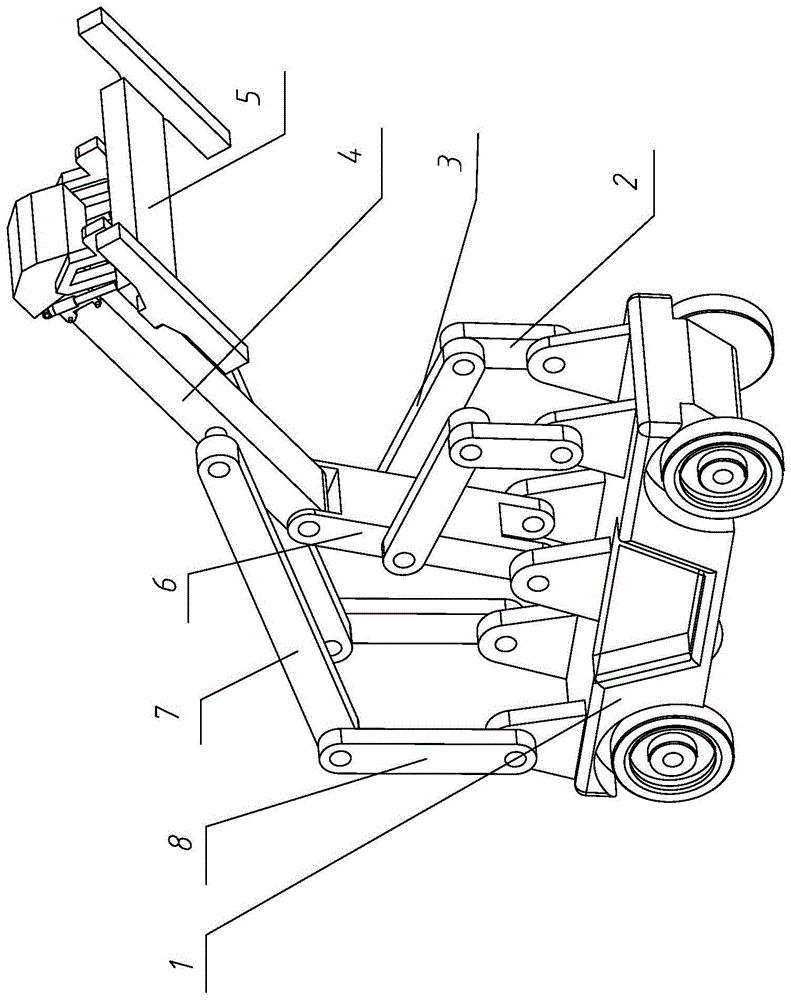

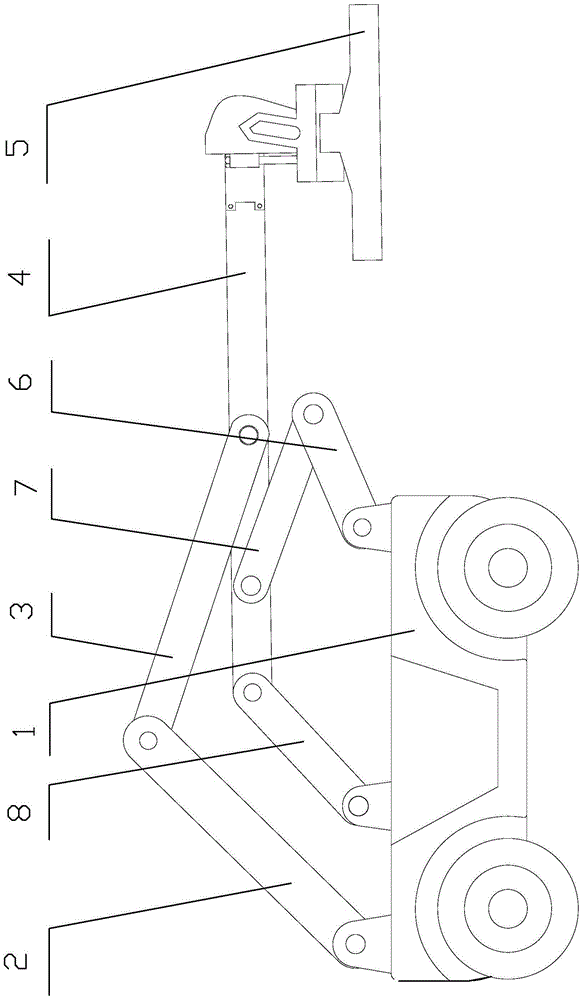

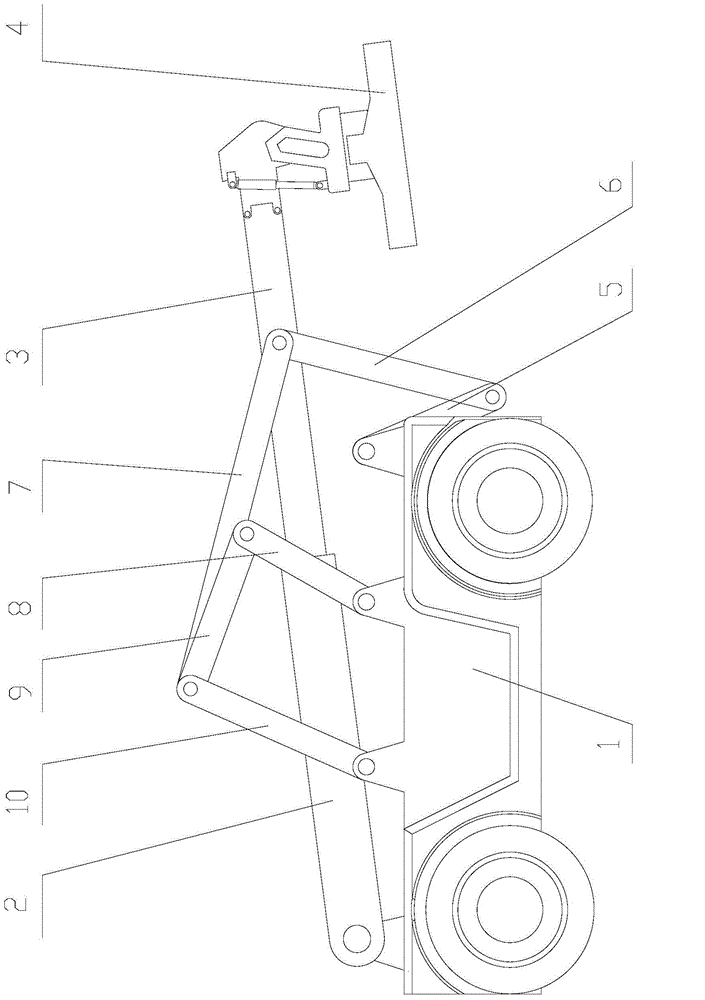

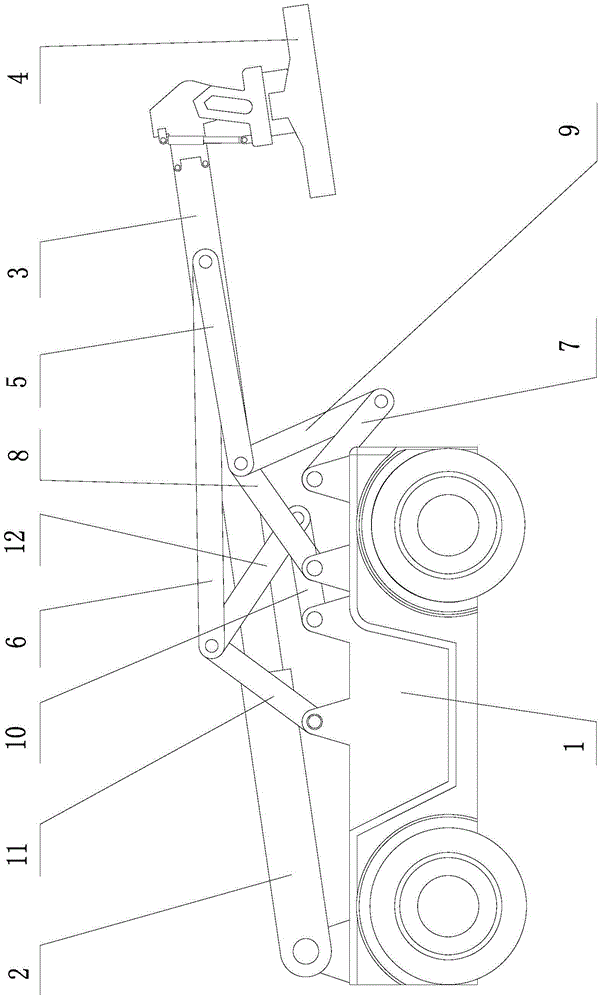

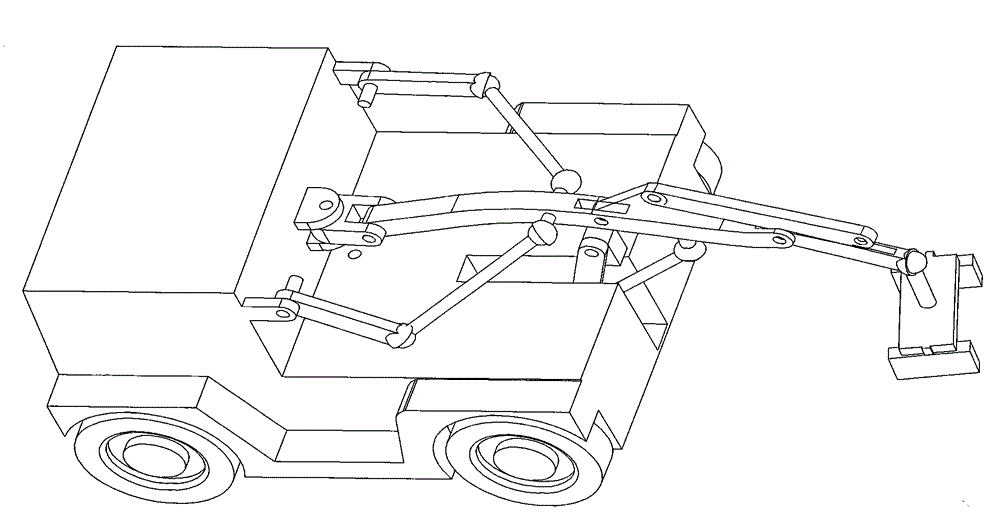

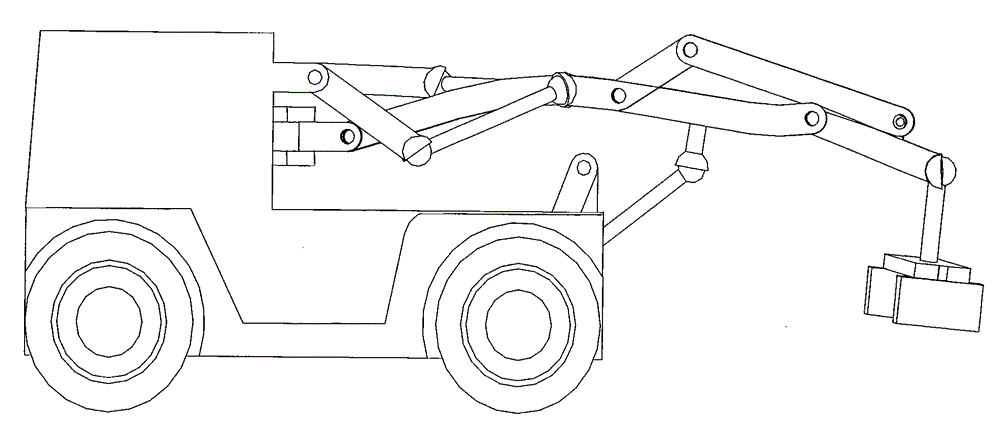

Plane two-degree-of-freedom seven-rod servo drive reach stacker for containers

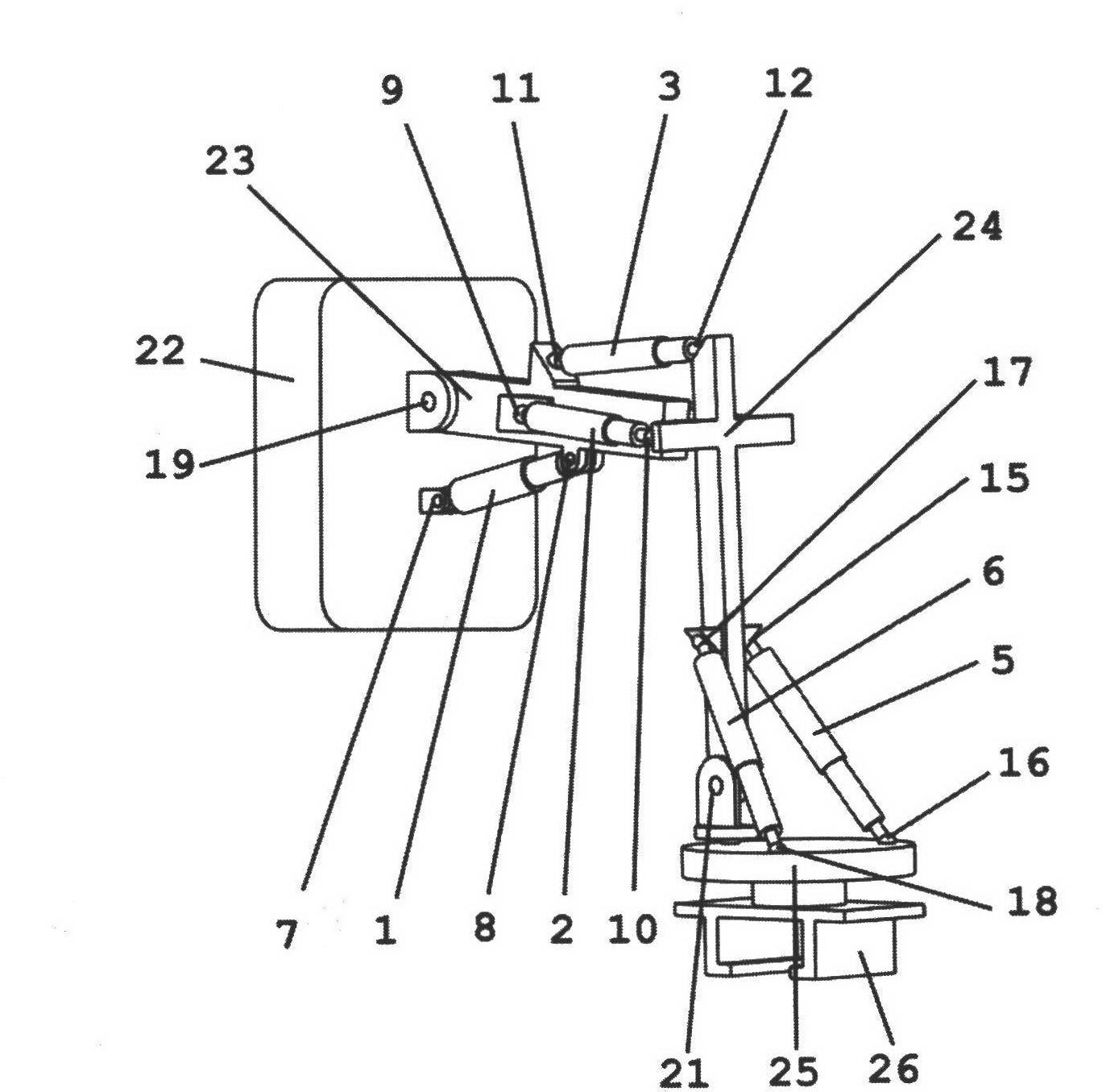

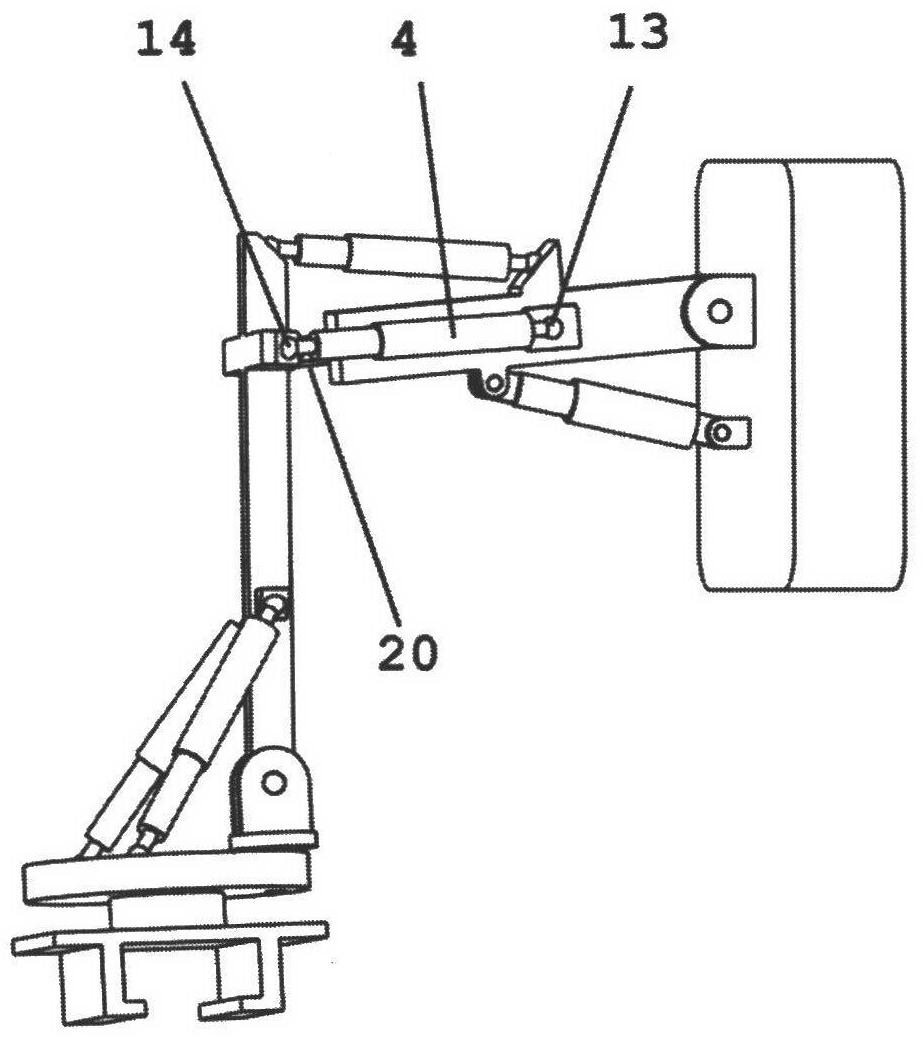

The invention relates to a plane two-degree-of-freedom seven-rod servo drive reach stacker for containers. The plane two-degree-of-freedom seven-rod servo drive reach stacker for the containers comprises a suspension arm, a suspension arm lifting mechanism and a suspension arm telescoping mechanism, wherein the lower end of a rotating arm of the suspension arm is hinged to the middle of a frame; a telescopic arm of the suspension arm is mounted on the rotating arm in a sliding manner; the suspension arm lifting mechanism comprises a lifting rocker and a lifting connecting rod; the lower end of the lifting rocker is hinged to the front part of the frame; the upper end of the lifting connecting rod is hinged to the rotating arm; the lifting rocker is hinged to the other two ends of the lifting connecting rod; the suspension arm telescoping mechanism comprises a telescopic rocker and a telescopic connecting rod; the lower end of the telescopic rocker is hinged to the rear part of the frame; the front end of the telescopic connecting rod is hinged to the telescopic arm; the telescopic rocker is hinged to the other two ends of the telescopic connecting rod. The plane two-degree-of-freedom seven-rod servo drive reach stacker for the containers realizes clamping, lifting and carrying operation of the containers under the combined drive of the suspension arm lifting mechanism and the suspension arm telescopic mechanism, and has the advantages of small movement inertia, flexible track output, high precision and the like.

Owner:QINZHOU UNIV

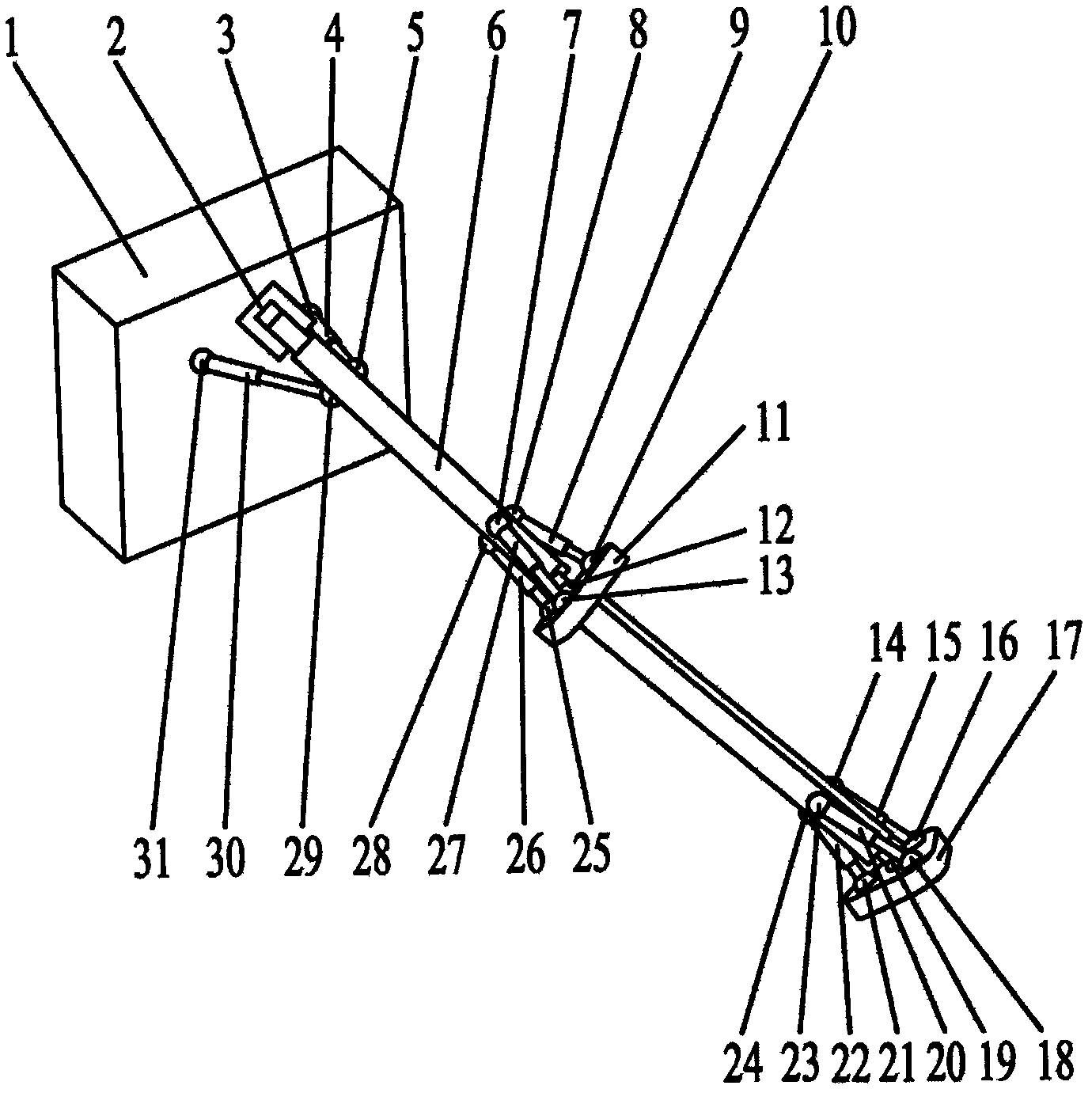

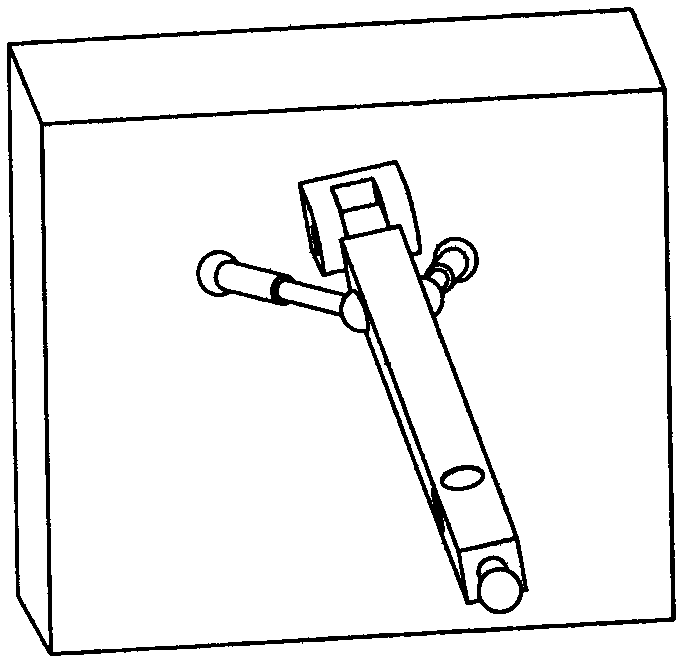

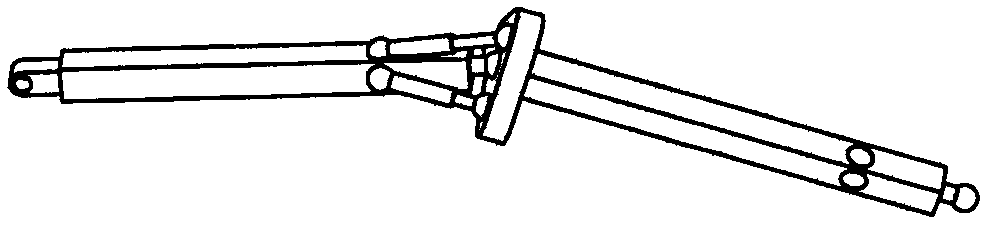

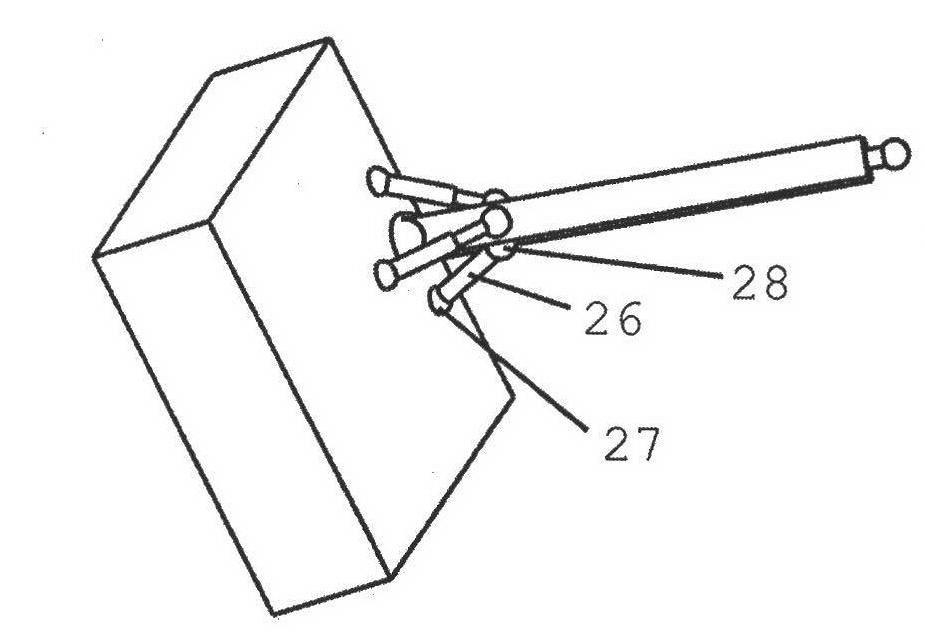

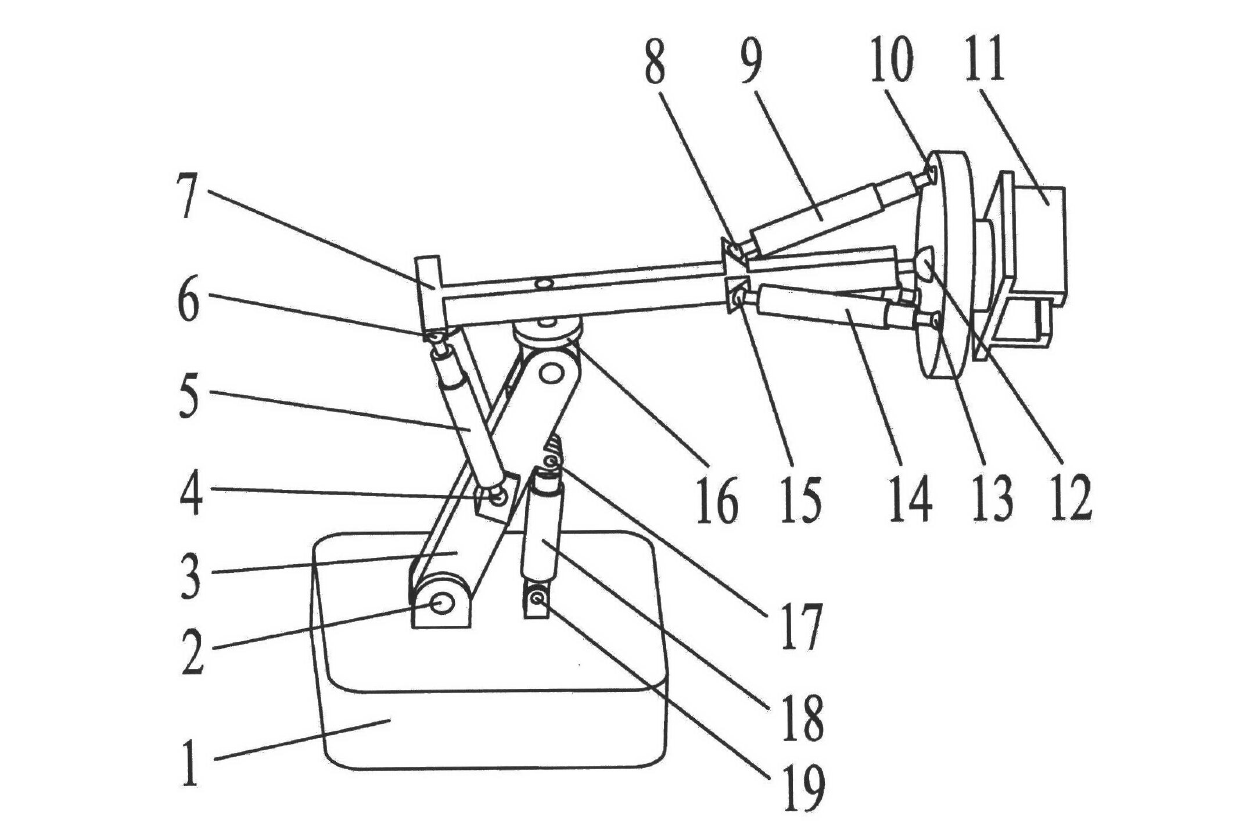

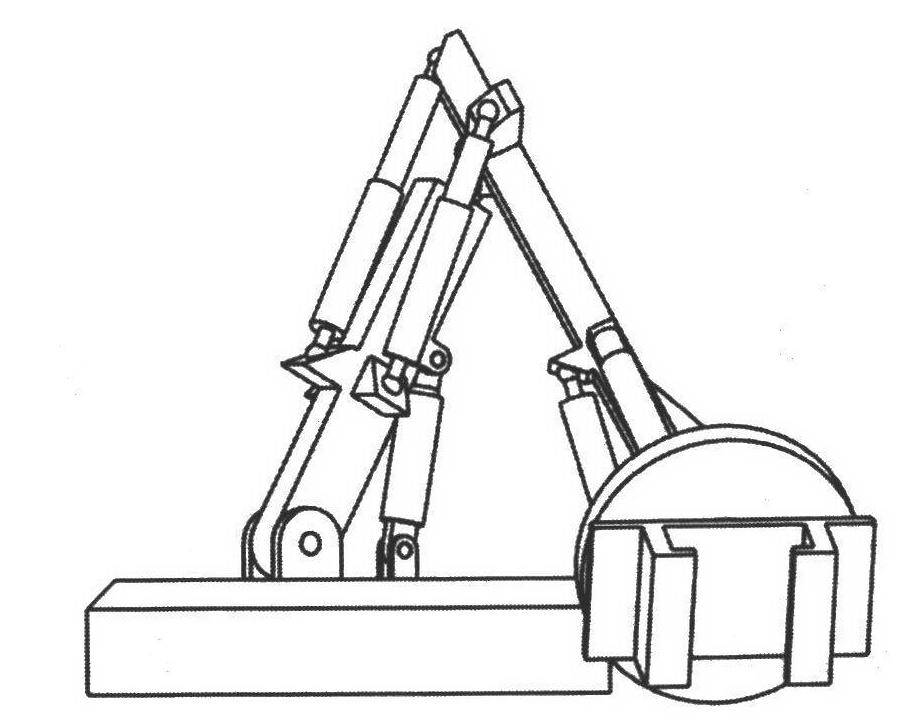

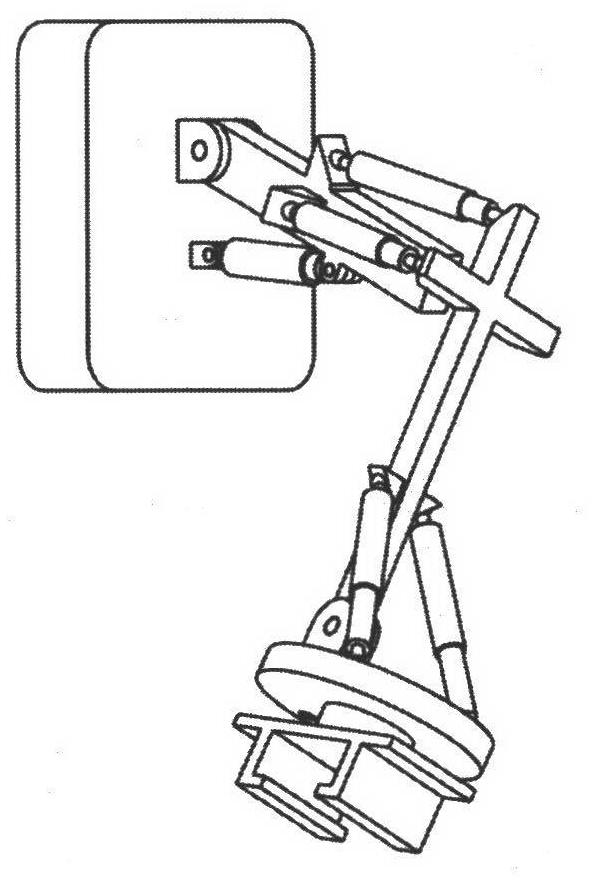

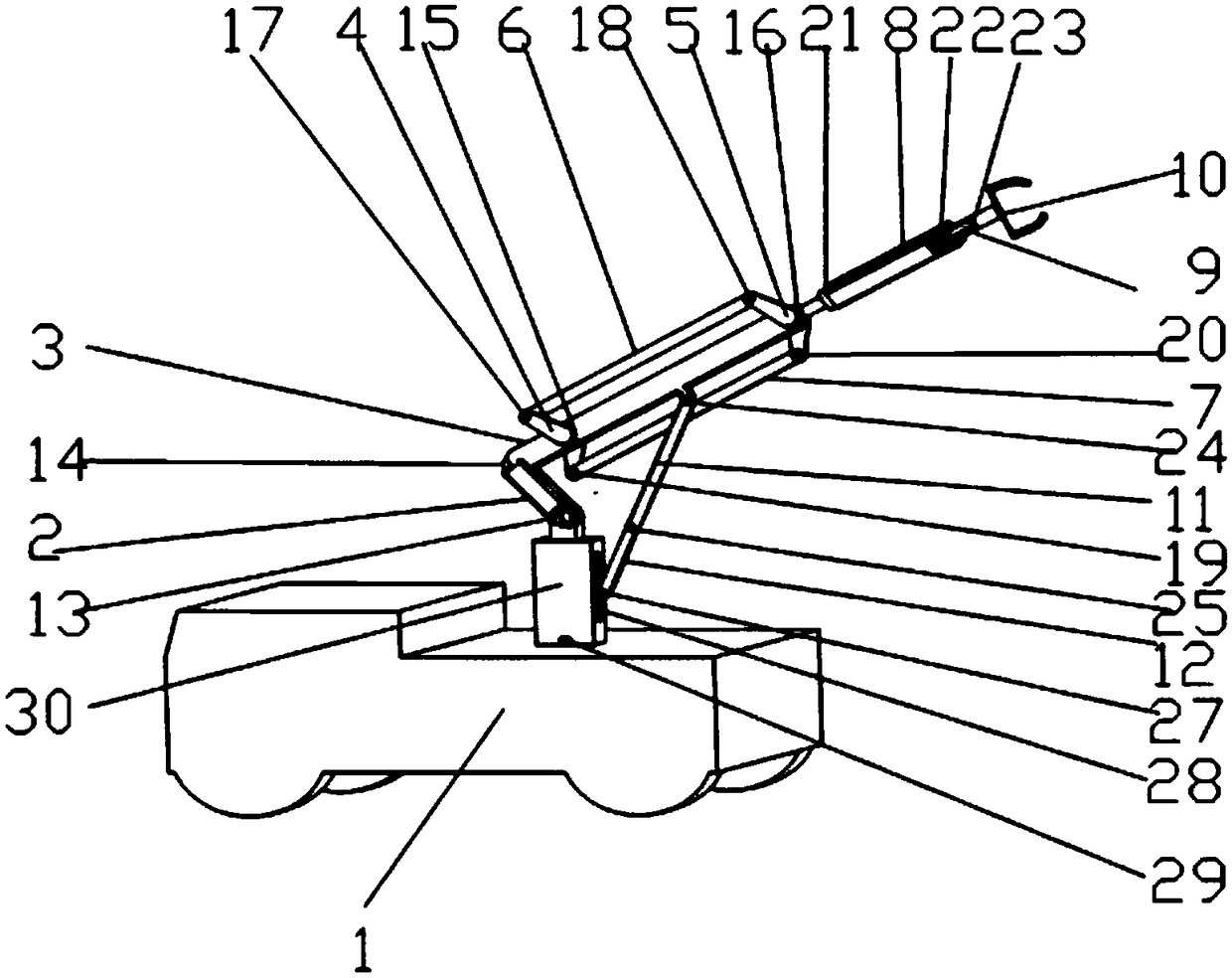

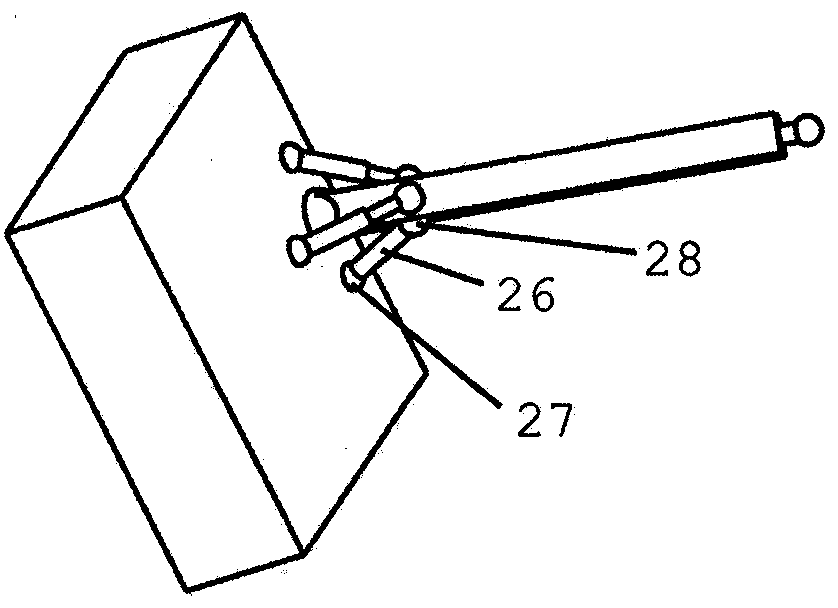

Spatial eight-degrees-of-freedom welding robot mechanism

InactiveCN102514001ALarge working spaceFlexible track outputProgramme-controlled manipulatorWelding/cutting auxillary devicesCompensation effectDegrees of freedom

The invention discloses a spatial eight-degrees-of-freedom welding robot mechanism, which comprises a two-dimensional rotating large arm mechanism, a three-dimensional rotating small arm mechanism and an end effector platform mechanism which are connected in series. The connected parts are parallelly driven by two linear drivers, three linear drivers and three linear drivers respectively to realize the large-working-space and flexible track output of the mechanism; and the whole mechanism has a simple and compact structure and a good error compensation effect; and the end effector platform is used for accommodating a welding gun or an electrode holder and other equipment. The spatial eight-degrees-of-freedom welding robot mechanism can be applied to industrial production such as carrying, stacking, assembly, cutting and the like, and also can be applied to the fields such as engineering machinery such as excavators, bionic mechanisms such as bionic arms and bionic legs, and the like.

Owner:GUANGXI UNIV

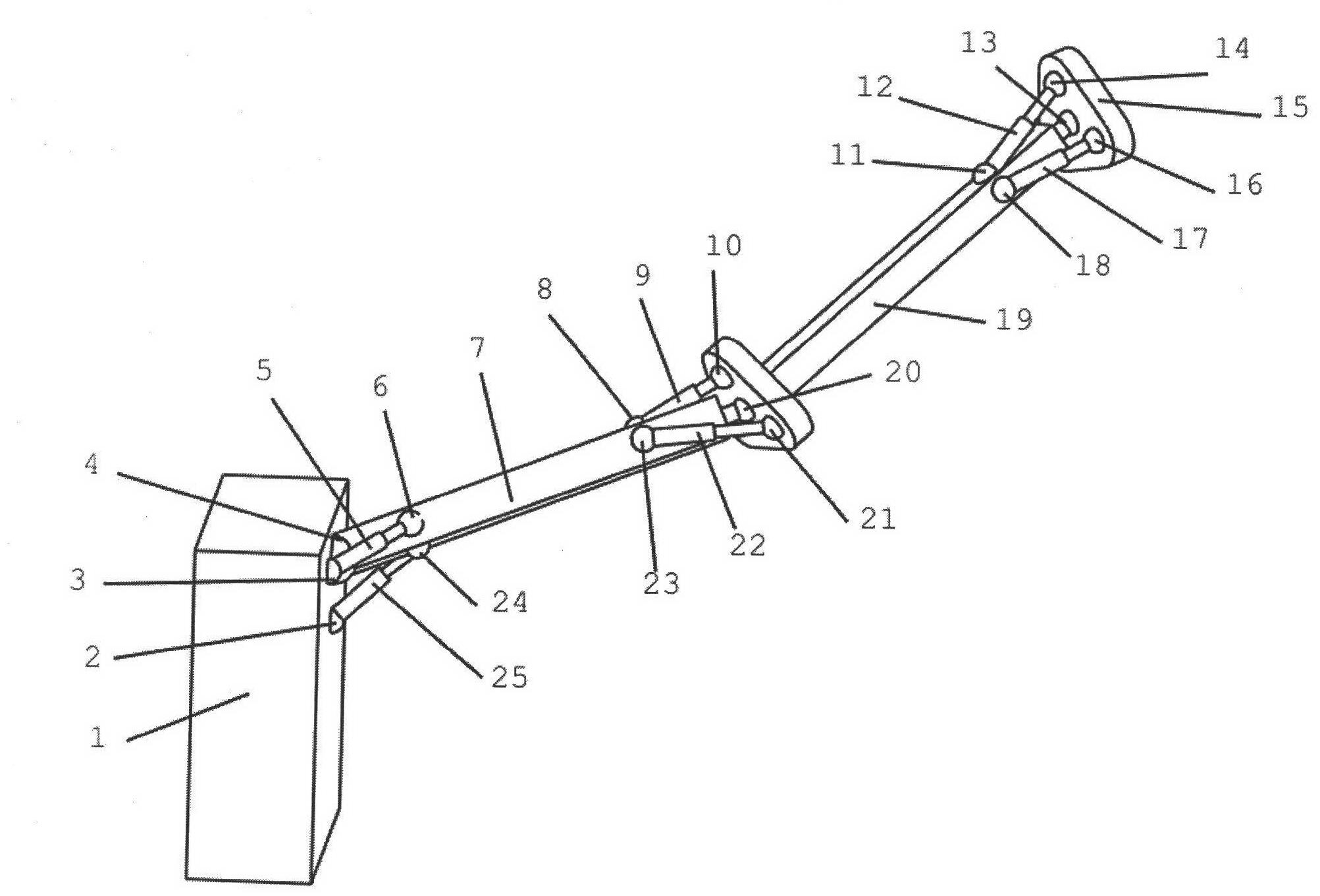

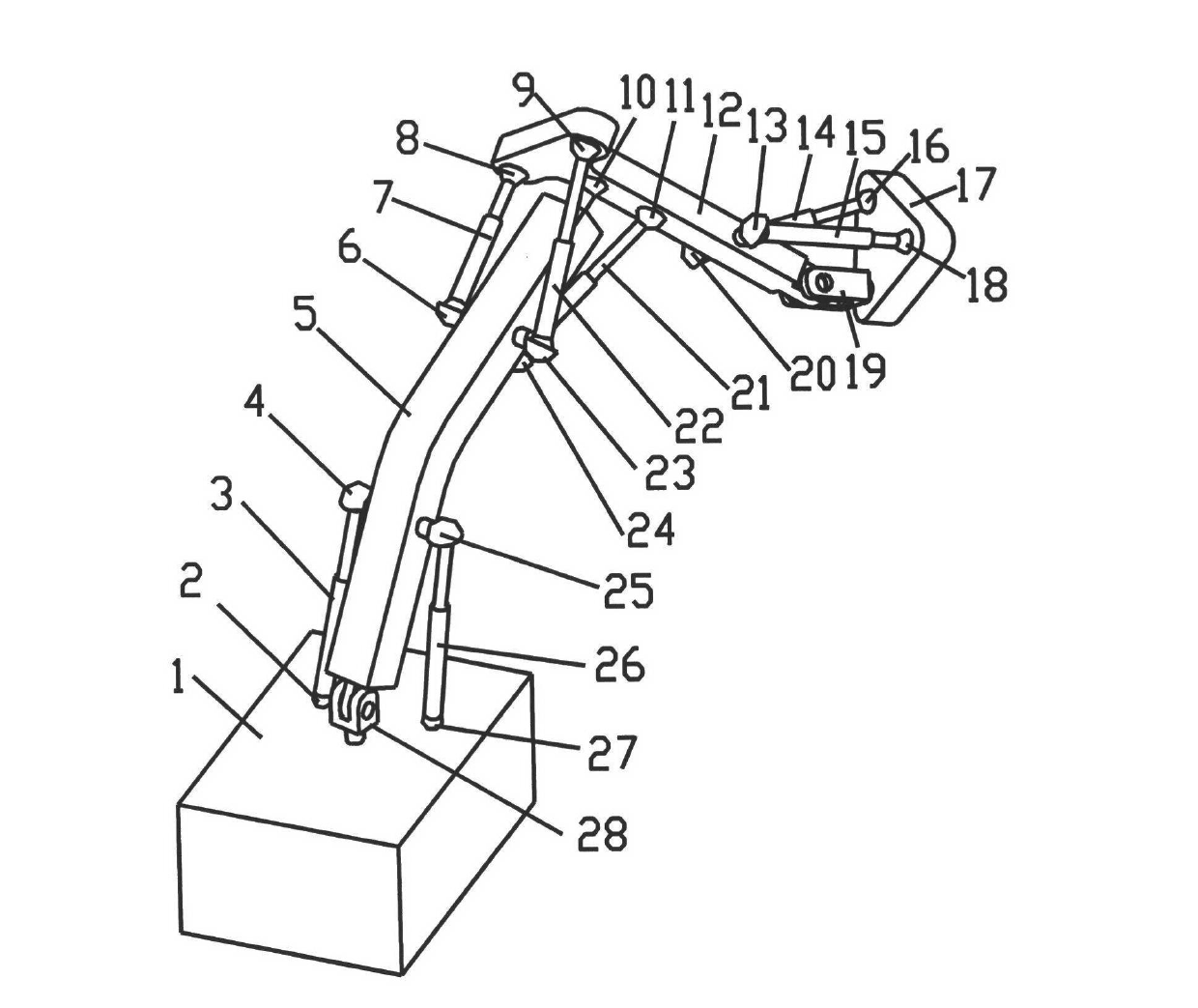

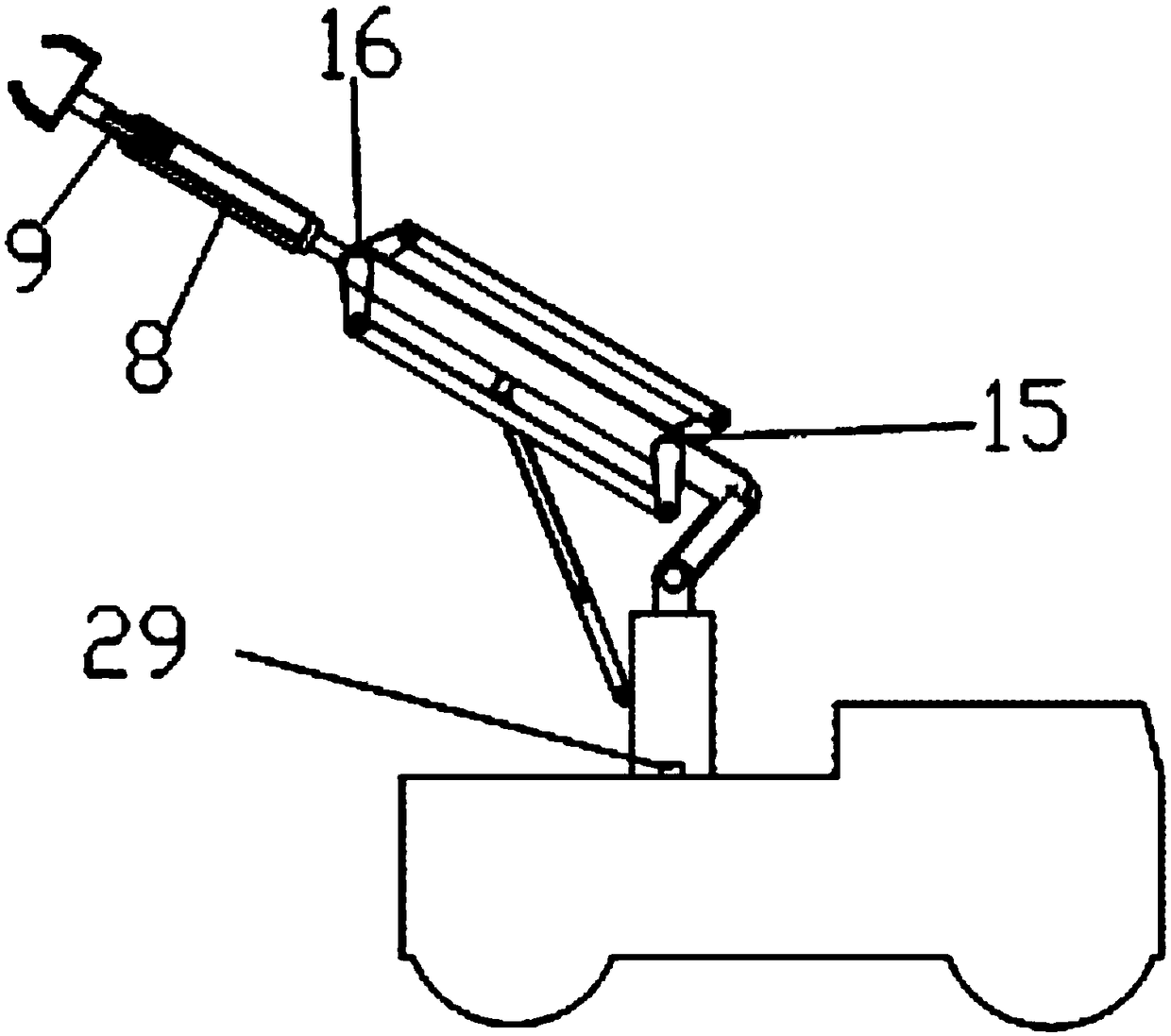

Nine-motion-degree robot mechanism

InactiveCN102357880ALarge working spaceFlexible track outputProgramme-controlled manipulatorEngineeringActuator

The invention relates to a nine-motion-degree robot mechanism. The nine-motion-degree robot comprises a big three-dimensional rotating arm mechanism, a small three-dimensional rotating arm mechanism and a three-dimensional rotating platform mechanism, which are serially connected to each other, wherein three linear drivers are in parallel connection and are used for driving each joint, thereby realizing a big operating space and a flexible track output of the mechanism. The nine-motion-degree robot mechanism is simple and compact in structure and is excellent in error compensation. By mounting end effectors with various different functions on a three-dimensional rotating platform, the nine-motion-degree robot mechanism can be applied to the production of industries, such as carrying, stacking, assembling, cutting, and the like, and also can be applied to the fields of engineering machinery, such as excavators, and bionic mechanisms, such as bionic arms, bionic legs and the like.

Owner:GUANGXI UNIV

Space crane with six degree of freedom

A space crane with six degree of freedom includes a lifting arm mechanism and an arm telescoping mechanism. The lifting arm mechanism is composed of a cargo boom and a suspension boom for the crane to complete spatial operations such as container grab, lifting and unloading; and the parallel boom telescoping mechanism consists of three mechanism sub-chains in series connection. A mechanism connection mode is adopted to enable the crane with compact structure and high reliability. The space crane with six degree of freedom can effectively overcome the shortcomings of high processing precision of hydraulic components, high maintenance cost, low reliability and easy oil leakage of a hydraulic crane, has the advantages of simple control and large work space, and can be widely used in complex operations such as container grab, lifting and unloading.

Owner:侯学志

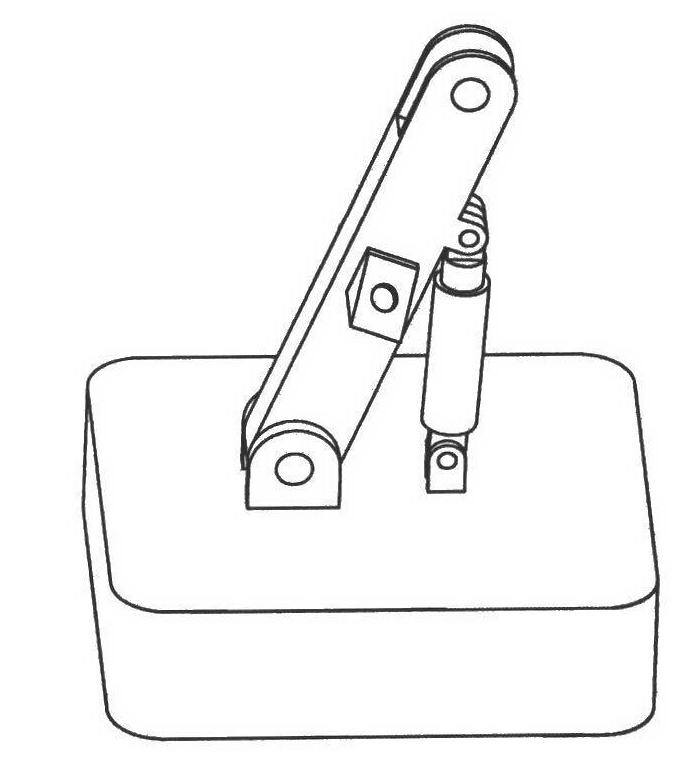

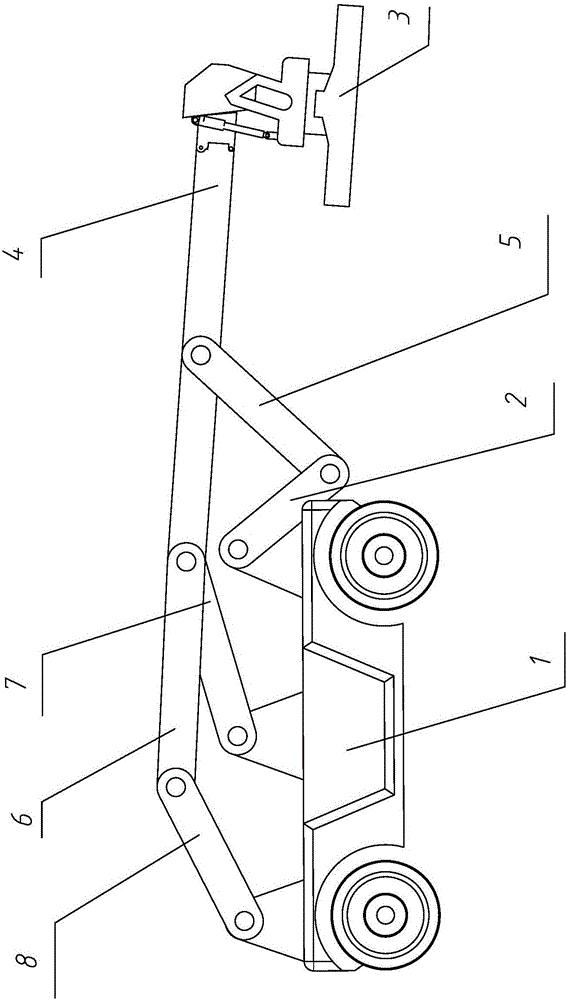

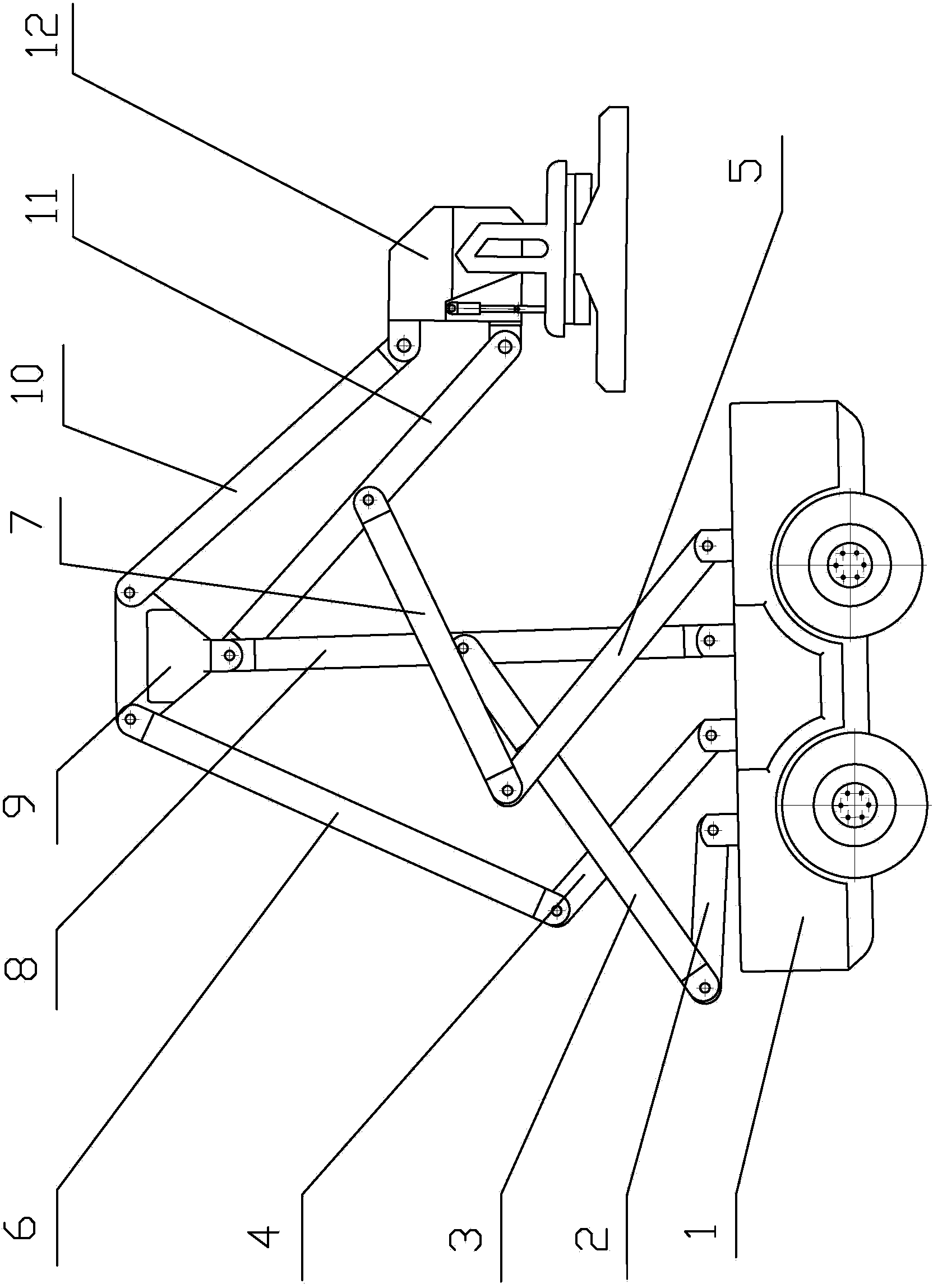

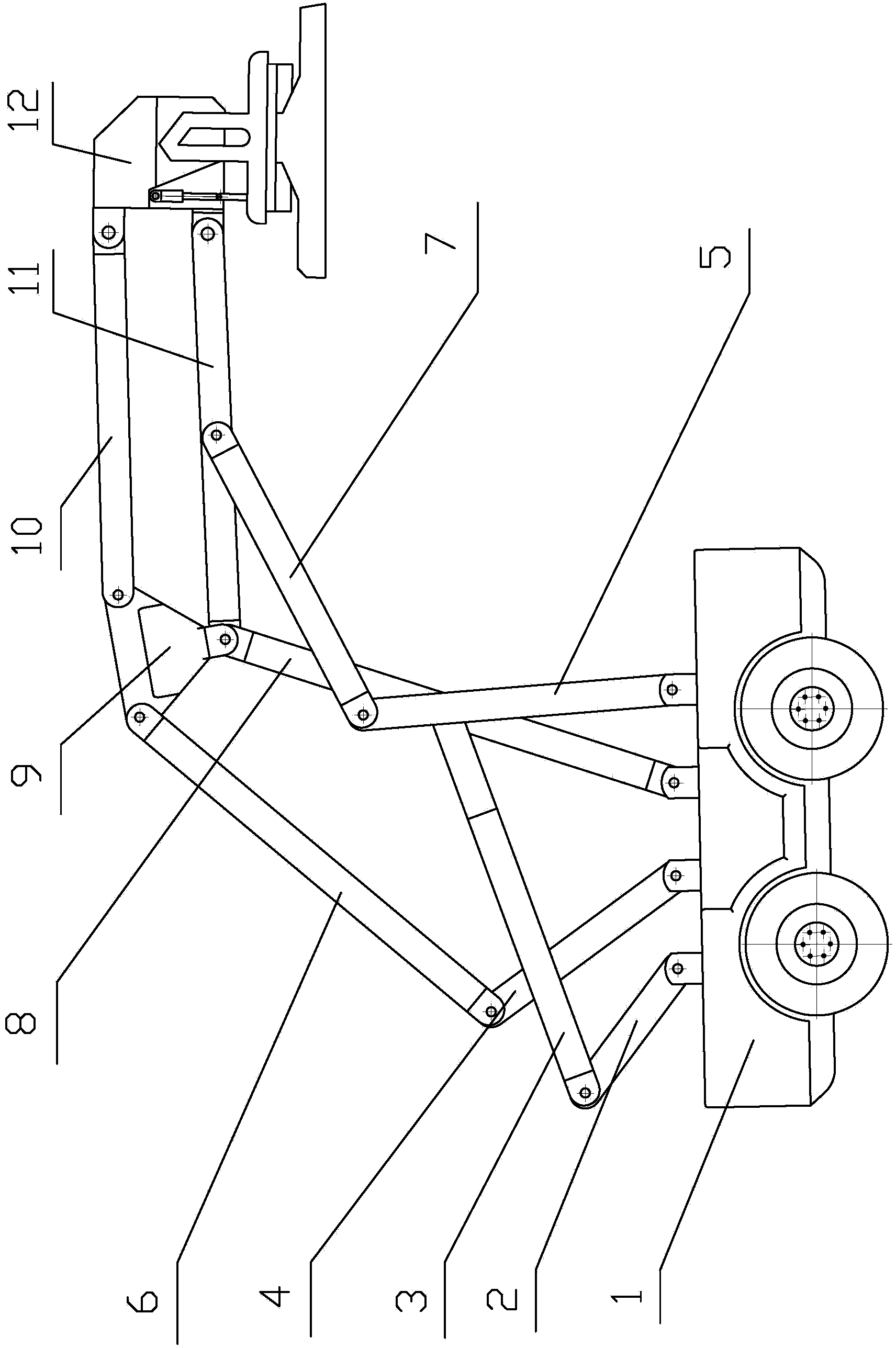

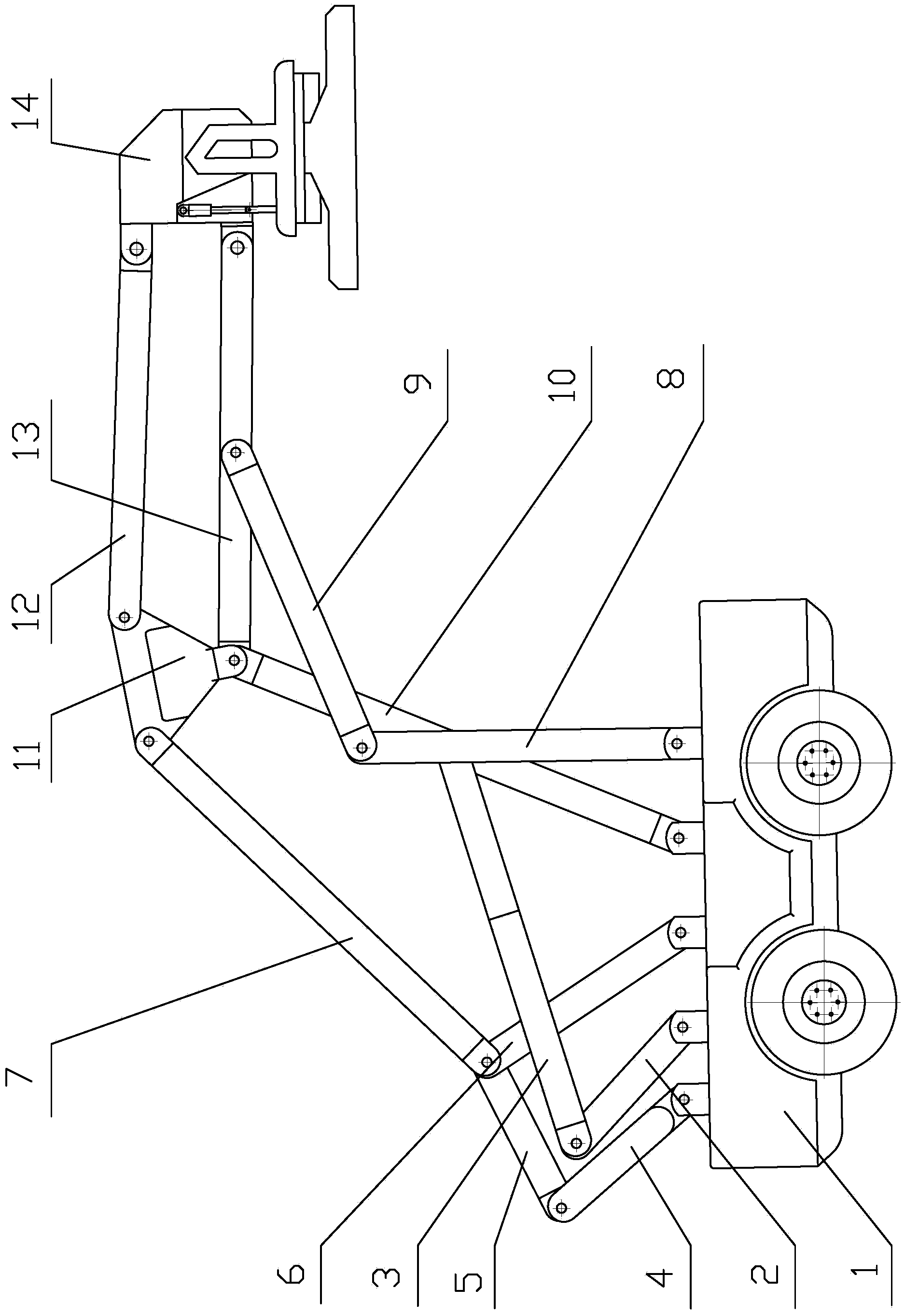

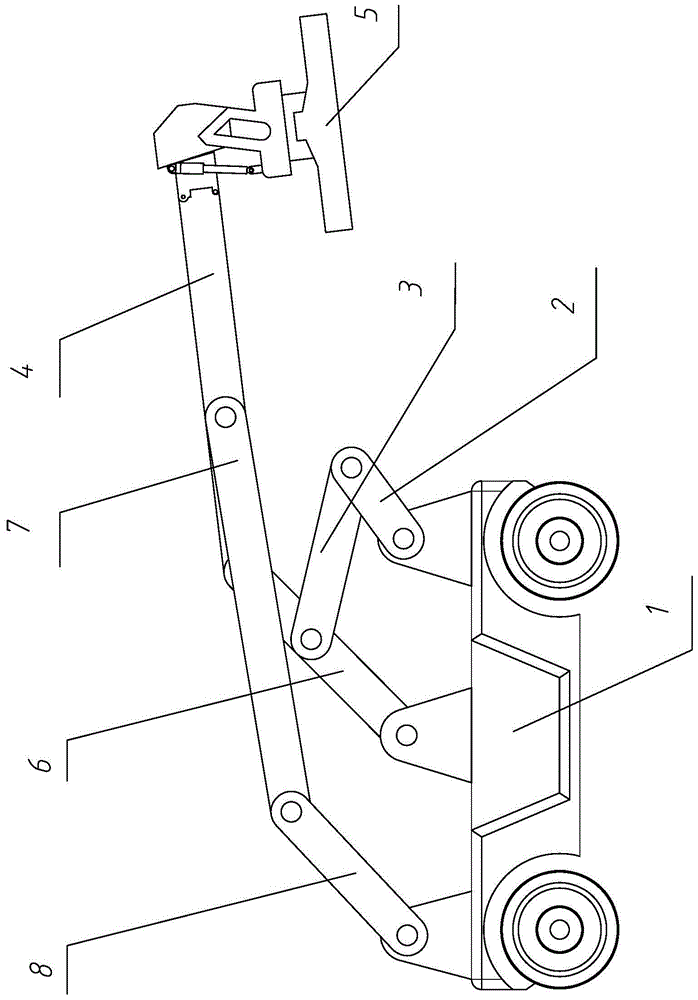

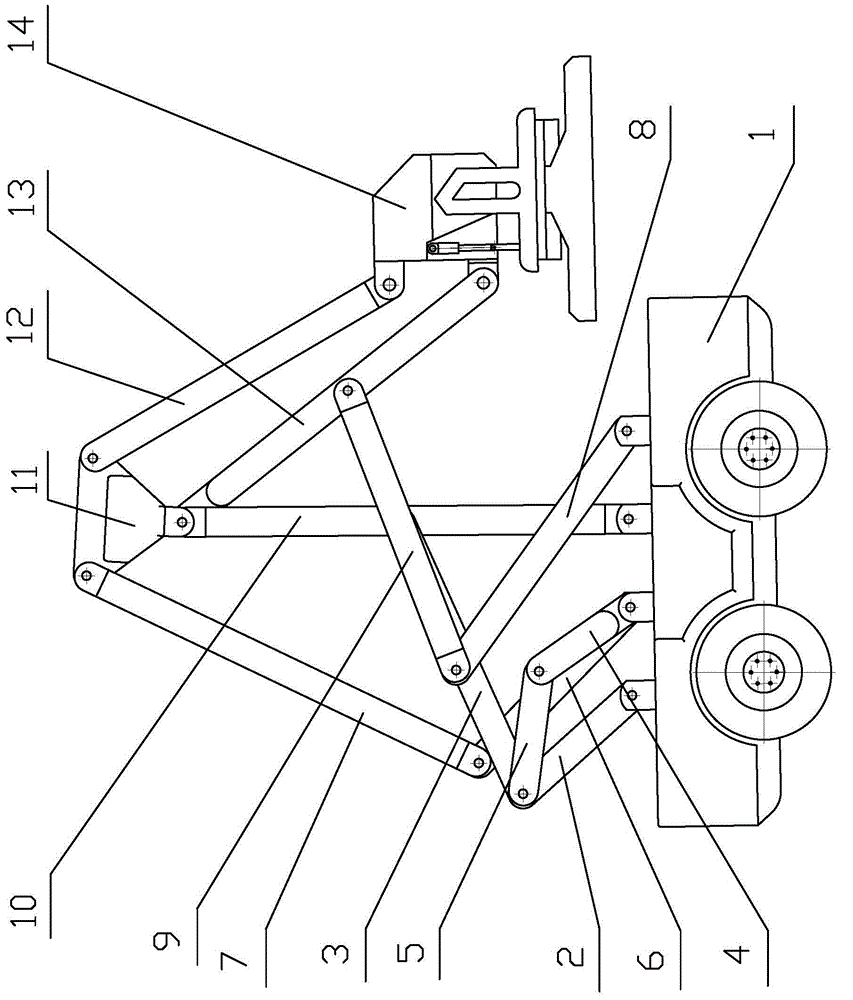

Two-degree-of-freedom driving controllable hoisting crane

The invention discloses a two-degree-of-freedom driving controllable hoisting cane comprising a hoisting arm arranged based on a frame, a hoisting arm lifting mechanism and a hoisting arm extending mechanism, wherein the hoisting arm comprises a rotating arm and an extending arm, the lower end of the rotating arm is hinged with the rear middle part of the frame, the rear end of the extending arm is hinged with the upper end of the rotating arm, and a clamping device is installed at the front end of the extending arm; the hoisting arm lifting mechanism is arranged at the front lower part of the hoisting arm and comprises a lifting rocker rod and a lifting connection rod, the lower end of the lifting rocker rod is hinged to the front part of the frame, the lower end of the lifting connection rod is hinged with the upper end of the lifting rocker rod, and the upper end of the lifting connection rod is hinged with the rear middle part of the extending arm; the hoisting arm extending mechanism is arranged at the rear upper part of the hoisting arm and comprises a protraction rocker rod and a protraction connection rod, the lower end of the protraction connection rod is hinged to the rear part of the frame, the rear end of the protraction connection rod is hinged to the upper end of the protraction rocker rod, and the front end of the protraction connection rod is hinged with the middle front part of the extending arm. The crane has the advantages of small movement inertia, flexible track output, high precision, good rigidity, good dynamic performance, high reliability and the like.

Owner:QINZHOU UNIV

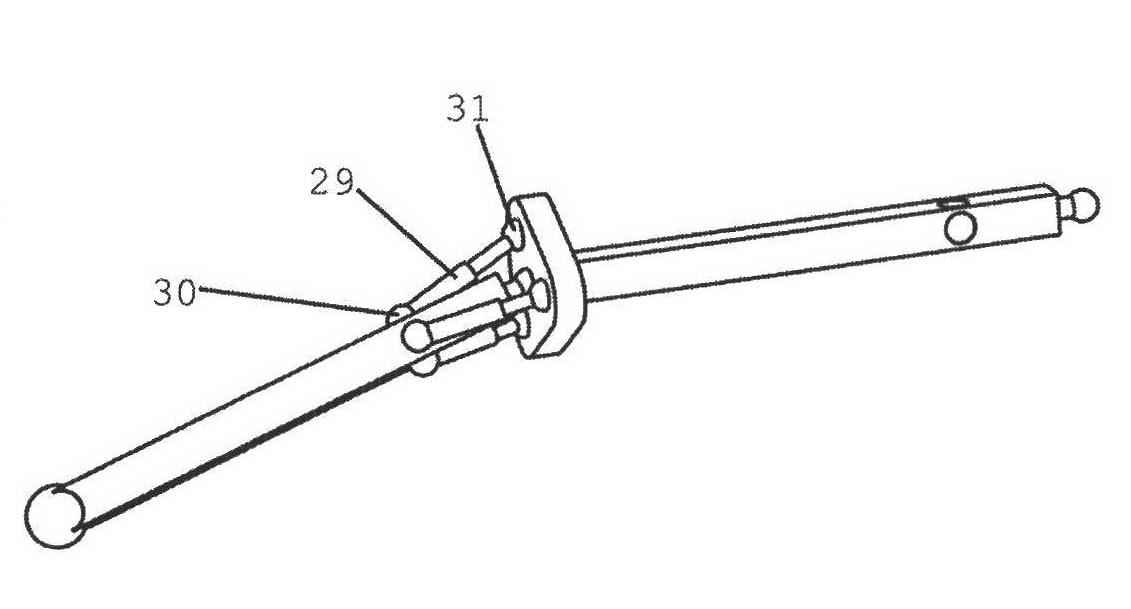

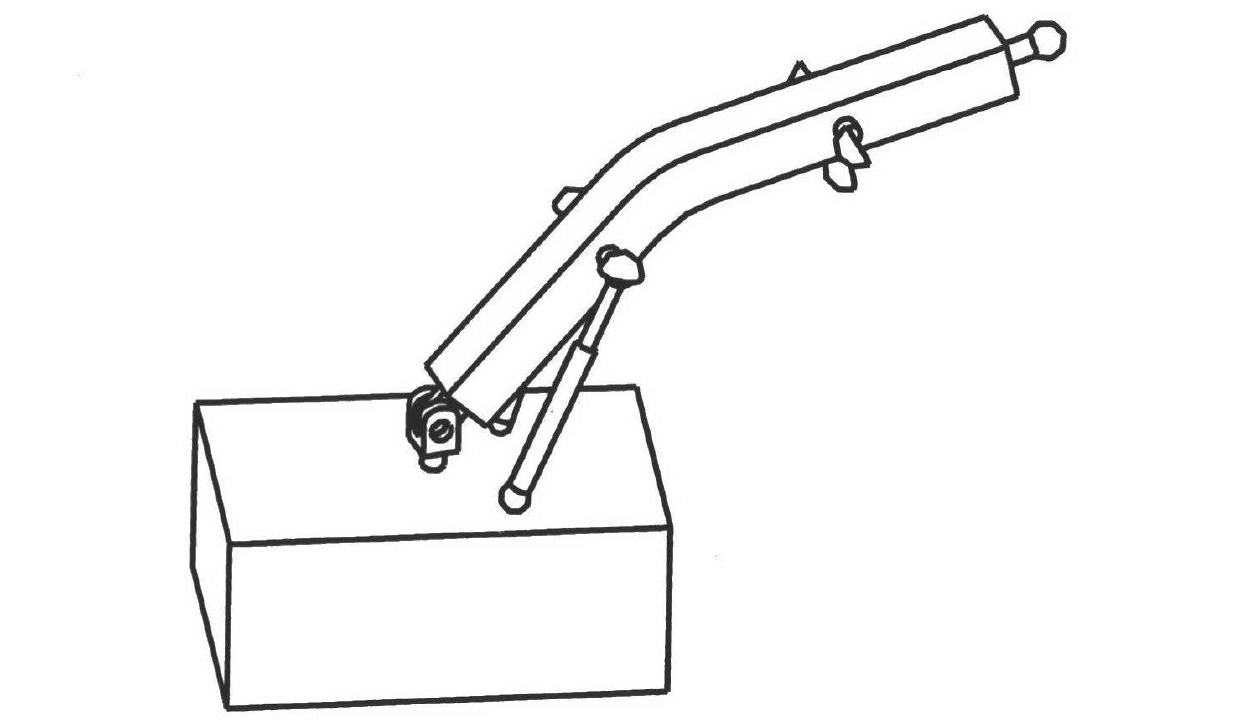

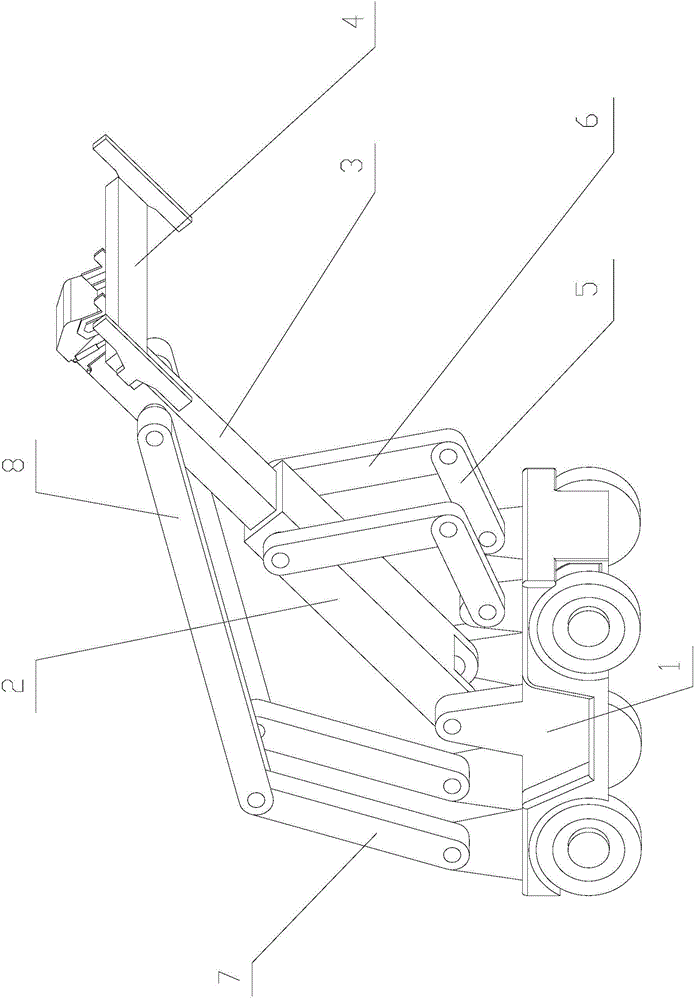

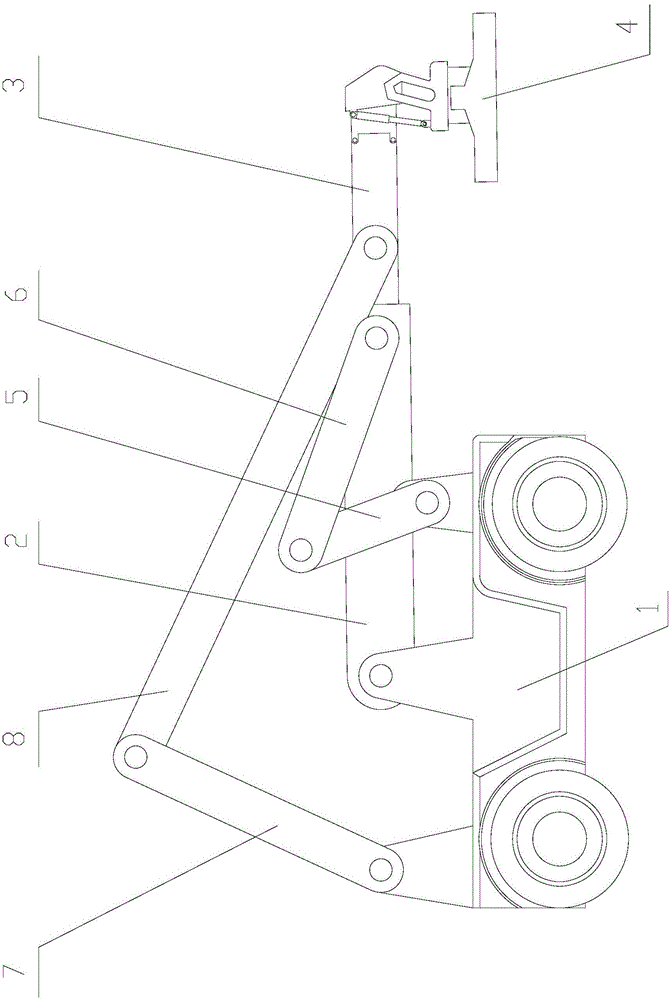

Spatial six-mobility drilling robot mechanism

InactiveCN102431030ALarge working spaceFlexible track outputProgramme-controlled manipulatorBoring/drilling componentsEngineeringActuator

The invention relates to a spatial six-mobility drilling robot mechanism, which comprises a one-dimensional rotating large arm mechanism, a two-dimensional rotating small arm mechanism and a three-dimensional rotating platform mechanism which are connected in series, wherein a rotating large arm is driven by a linear driver, a rotating small arm is driven by two linear drivers, a rotating platform is driven by three linear drivers in parallel, and a frame can be installed on a traveling device or a fixed rotating device. The drilling robot mechanism has the advantages of large working space, agile track, simple and compact overall structure, and good error compensation and strong impact bearing capability of the rotating platform which is uniformly distributively supported by the linear drivers, good stability during drilling and capability of realizing high-precision operation. According to the invention, various terminal actuators with different purposes are installed on a three-dimensional rotating platform, thus the spatial six-mobility drilling robot mechanism can be applied to carrying, stacking, assembling, cutting and other industrial production, and can also be applied to fields, such as excavators and other engineering machinery as well as bionic arms, bionic legs and other bionic mechanisms and the like.

Owner:GUANGXI UNIV

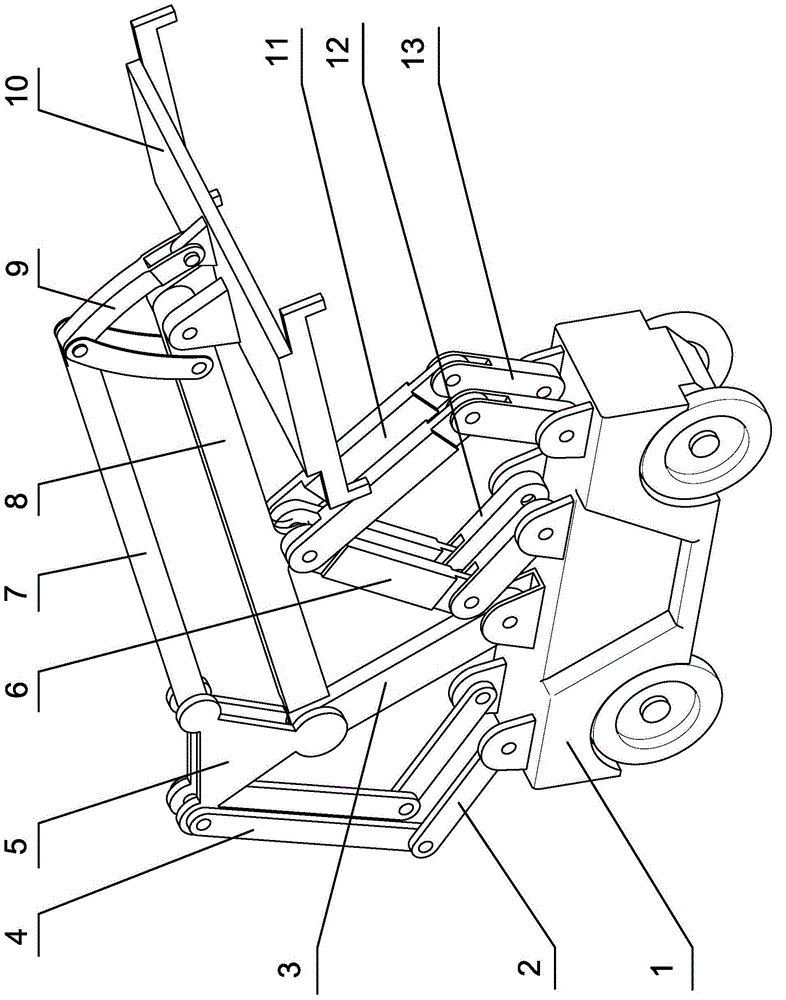

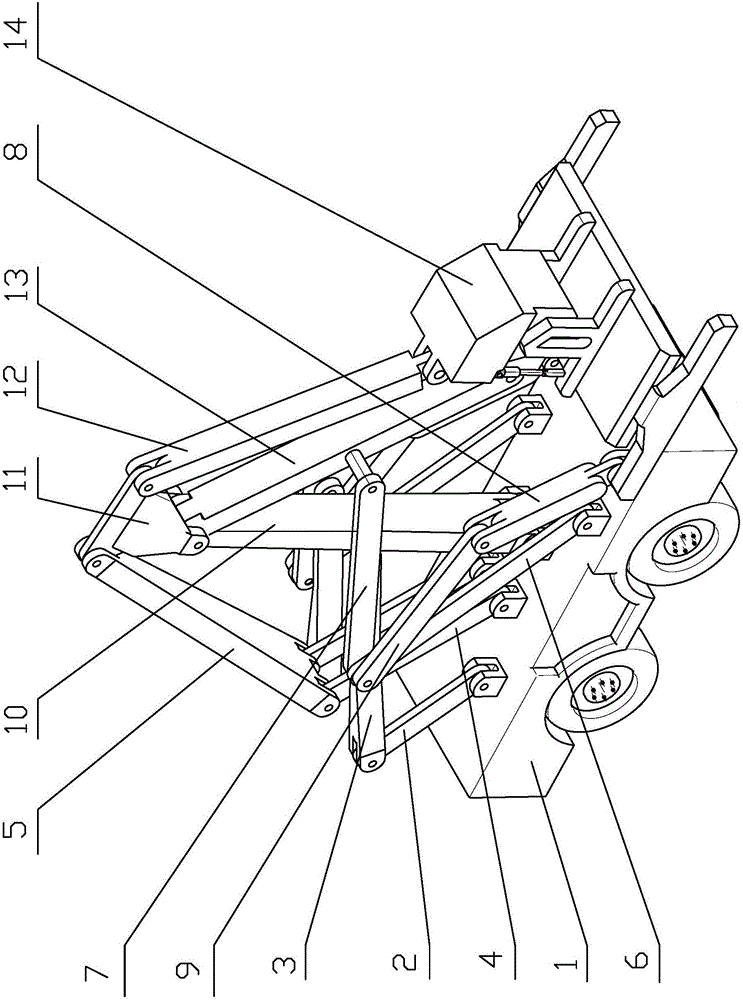

Plane two-freedom-degree nine-rod closed-chain type reach stacker

The invention discloses a plane two-freedom-degree nine-rod closed-chain type reach stacker. The plane two-freedom-degree nine-rod closed-chain type reach stacker comprises a crane jib and a crane jib lifting telescopic mechanism. A rotatable jib of the crane jib is hinged to the rear portion of a vehicle machine. A telescopic jib is installed on the rotatable jib through a sliding pair. The front end of the telescopic jib is provided with a clamping device. The crane jib lifting telescopic mechanism, namely a five-connecting-rod mechanism assembly comprises front rocking rods, front connecting rods, rear connecting rods and a four-connecting-rod mechanism, wherein the front rocking rods are hinged to the front portion of the vehicle frame, the front connecting rods are hinged to the front rocking rods, the four-connecting-rod mechanism is arranged in the middle of the vehicle frame, and front four-connecting-rod mechanism rocking rods and rear four-connecting-rod mechanism rocking rods are hinged to the vehicle frame. The hinged point between each rear connecting rod and the corresponding rear four-connecting-rod mechanism rocking rod and the hinged point between each rear connecting rod and the corresponding four-connecting-rod mechanism connecting rod are composite hinges. The hinged point between each front connecting rod and the corresponding rear connecting rod is arranged on the telescopic jib. The plane two-freedom-degree nine-rod closed-chain type reach stacker has the advantages that the movement inertia is small, track output is flexible, the precision is high, the rigidity and the dynamic performance are good, and the reliability is high.

Owner:QINZHOU UNIV

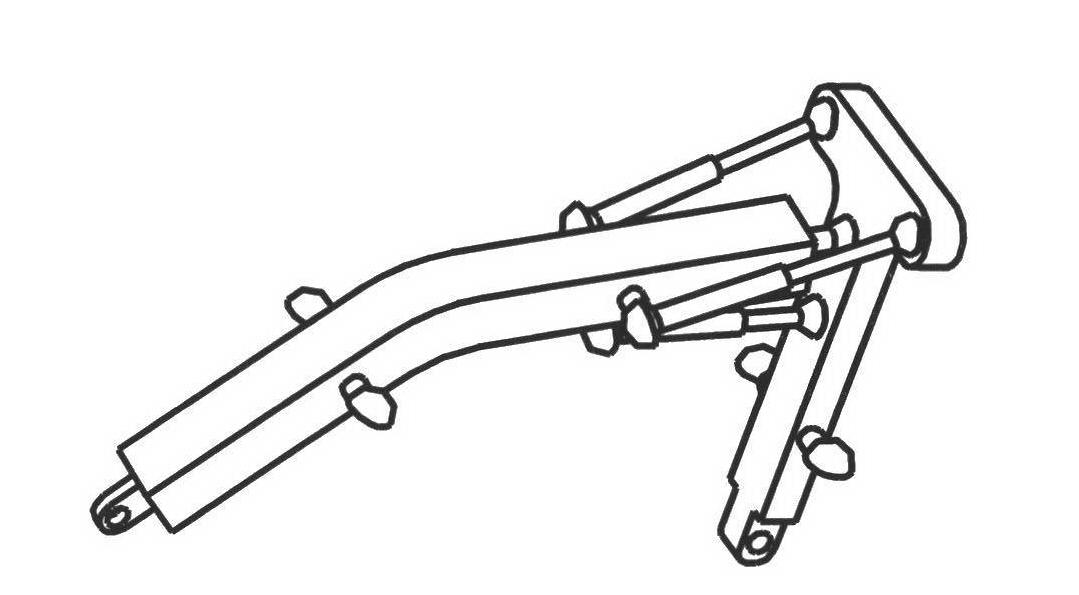

Seven-range of motion carrying robot

InactiveCN102513993AReduce cumulative errorFlexible track outputProgramme-controlled manipulatorArmsRange of motionEngineering

The invention relates to a seven-range of motion carrying robot, which comprises a large arm, a small arm, a movable platform, a machine frame, a first linear driver, a second linear driver and a third linear driver, a fourth linear driver, a fifth linear driver, a sixth linear driver and a seventh linear driver, wherein the large arm is driven by the first linear driver; the small arm is driven by the second linear driver, the third linear driver and the fourth linear driver in parallel to realize three-dimensional rotation; and the movable platform is driven by the fifth linear driver, the sixth linear driver and the seventh linear driver in parallel to realize the three-dimensional rotation. The seven-range of motion carrying robot has the advantages of large operating space, flexible track output, high rigidity, high bearing capacity, small accumulated error, high accuracy and the like.

Owner:GUANGXI UNIV

Six-motion stacking robot

InactiveCN102514000ALarge working spaceFlexible track outputProgramme-controlled manipulatorStacking articlesControl theoryWorking space

The invention relates to a six-motion stacking robot. The six-motion stacking robot comprises a big arm, a second connecting rod, a moveable platform, a machine frame, a first linear driver, a second linear driver, a third linear driver, a fourth linear driver, a fifth linear driver, a sixth linear driver and a seventh linear driver, wherein the big arm is driven through the first linear driver; the second connecting rod is driven through the second linear driver, the third linear driver and the fourth linear driver in parallel to realize three-dimension rotation; and the moveable platform is driven through the fifth linear driver, the sixth linear driver and the seventh linear driver in parallel to realize three-dimension rotation. The robot has the advantages of big working space, flexible track output, high rigidity, convenience in error compensation, capability of realizing precise positioning and the like.

Owner:GUANGXI UNIV

Spatial seven-mobility robot mechanism

InactiveCN102431029ALarge working spaceFlexible track outputProgramme-controlled manipulatorEngineeringActuator

The invention relates to a spatial seven-mobility robot mechanism, which comprises a two-dimensional rotating large arm mechanism, a three-dimensional rotating small arm mechanism and a two-dimensional rotating terminal execution platform mechanism, wherein the two-dimensional rotating large arm mechanism comprises a two-dimensional rotating large arm, a first linear driver and a second linear driver; the three-dimensional rotating small arm mechanism comprises a three-dimensional rotating small arm, a third linear driver, a fourth linear driver and a fifth linear driver; and the two-dimensional rotating terminal execution platform mechanism comprises a two-dimensional rotating terminal execution platform, a sixth linear driver and a seventh linear driver. The two-dimensional rotating large arm mechanism, the three-dimensional rotating small arm mechanism and the two-dimensional rotating terminal execution platform mechanism are connected in series, thus large working space and flexible track output of the robot mechanism are realized, and the robot mechanism has a simple and compact overall structure and good error compensation. According to the invention, various terminal actuators with different purposes are installed on a flange disc of the two-dimensional rotating terminal execution platform, thus the spatial seven-mobility robot mechanism can be applied to carrying, stacking, assembling, cutting and other industrial production, and has strong practicability.

Owner:GUANGXI UNIV

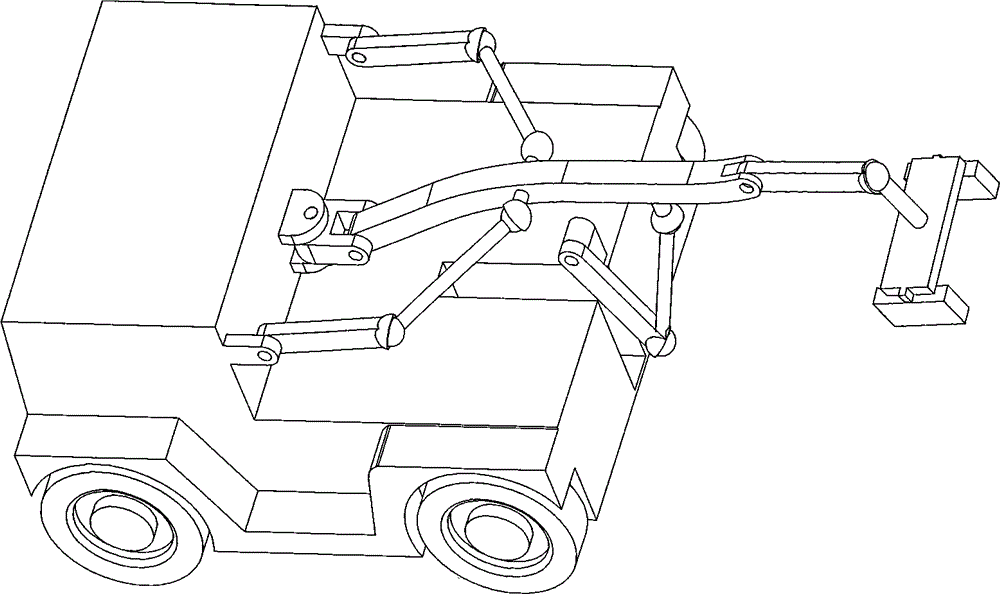

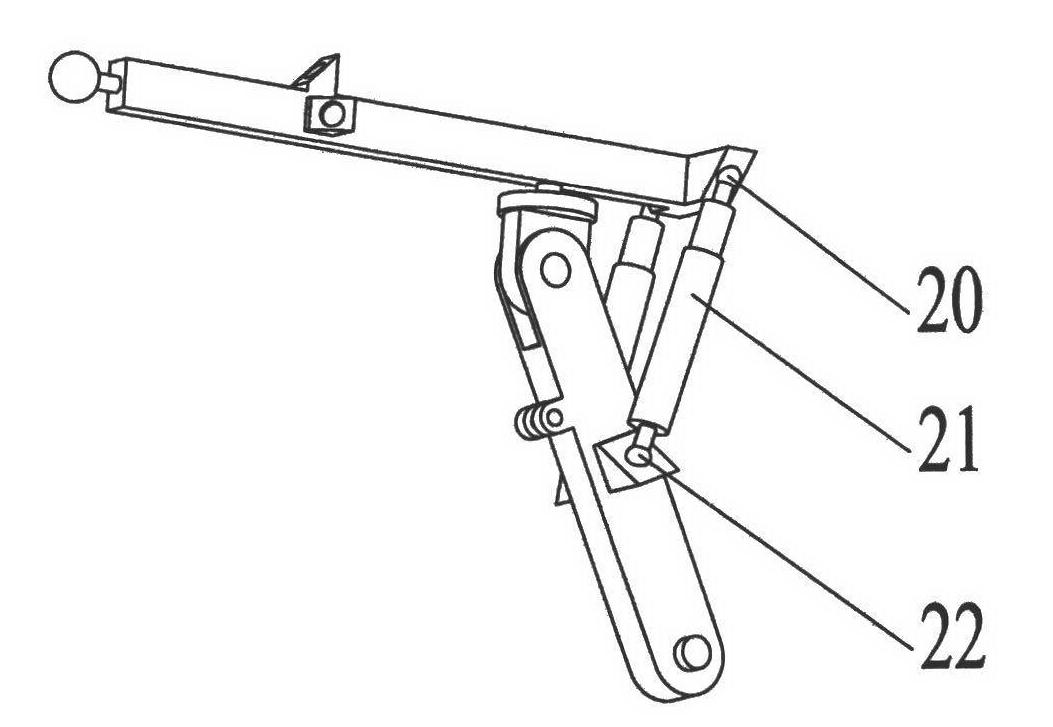

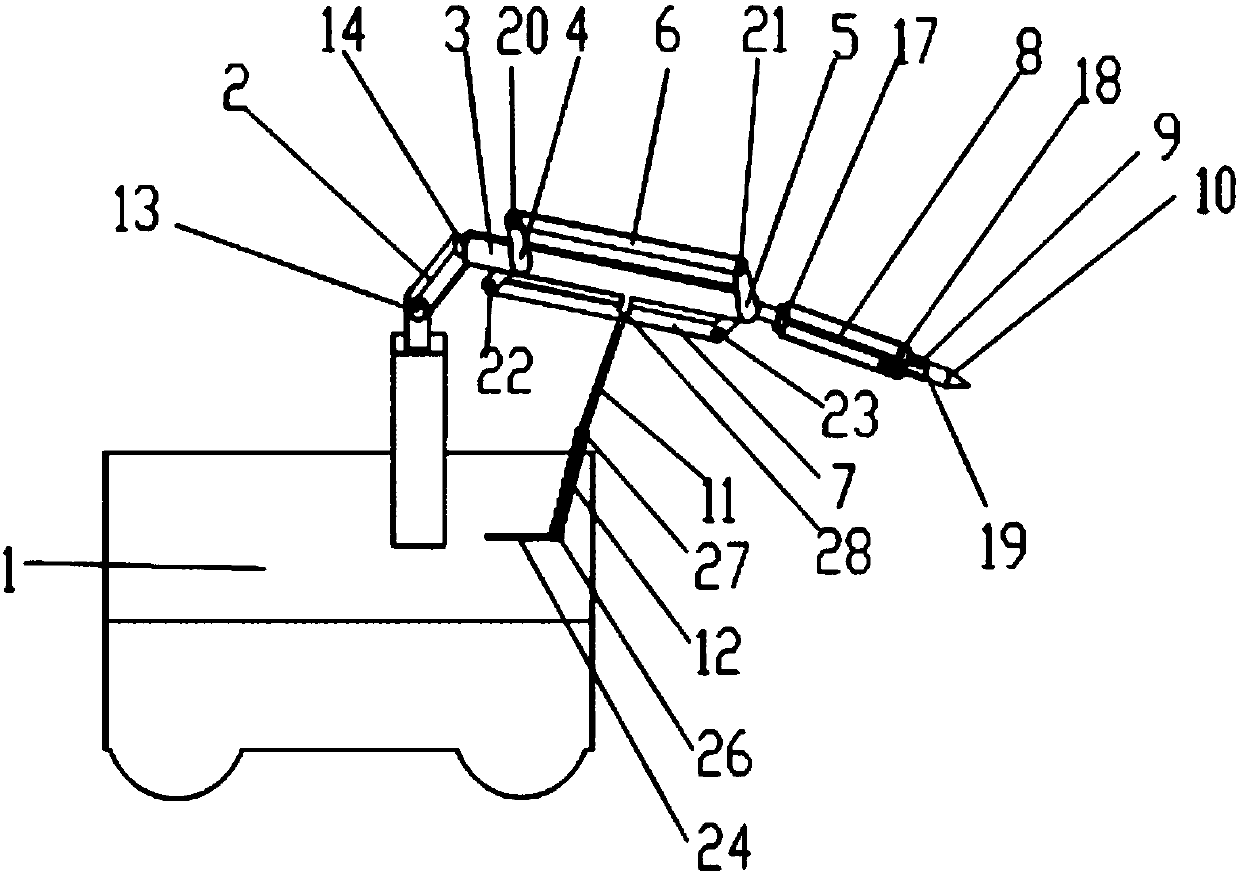

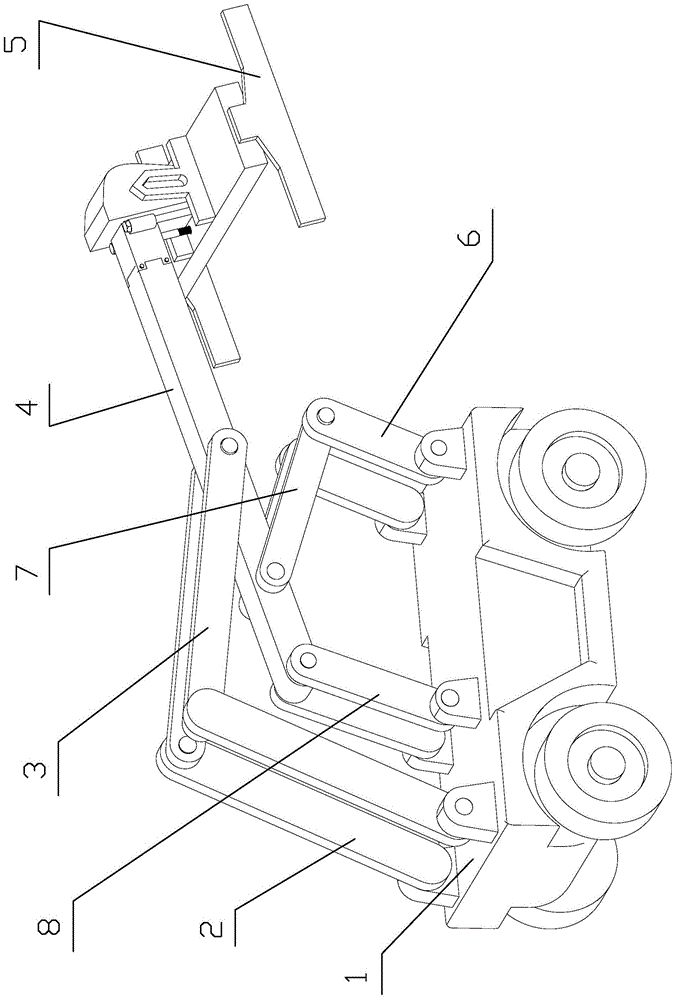

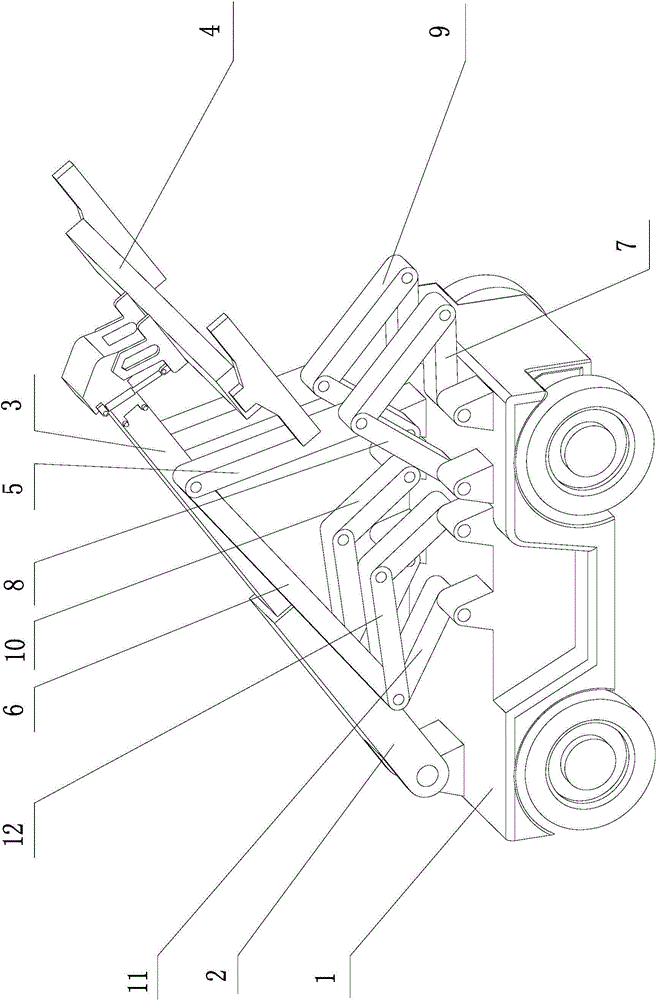

Two-degree-of-freedom double-closed-loop hybrid drive reach-stack crane

The invention discloses a two-degree-of-freedom double-closed-loop combination drive reach stacker comprising a hoisting arm, a hoisting arm lifting mechanism and a hoisting arm telescoping mechanism, wherein the lower end of a pitching arm of the hoisting arm is hinged with the middle part of a frame, a swing arm of the hoisting arm is hinged to the pitching arm; the hoisting arm lifting mechanism comprises a lifting rocker rod and a lifting connection rod, the lower end of the lifting rocker rod is hinged with the front part of the frame, the upper end of the lifting connection rod is hinged with a body of the swing arm, the other two ends of the lifting rocker rod and the lifting connection rod are hinged; the hoisting arm telescoping mechanism comprises a telescoping rocker rod and a telescoping connection rod, the lower end of the telescoping rocker rod is hinged with the rear part of the frame, a composite hinge is formed by the front end of the telescoping connection rod and the hinge point of the swing arm and the pitching arm, and the other ends of the telescoping rocker rod and the telescoping connection rod are hinged. According to the reach stacker, a strategy of combination drive of a high-power general motor and a small-power servo motor is adopted, and compared with a pure servo motor or a hydraulic drive mode, the reach stacker has the advantages of high power output, high reliability, low construction cost, and low maintenance cost.

Owner:QINZHOU UNIV

Non-linear input mechanism type crane with metamorphic function

The invention discloses a non-linear input mechanism type crane with a metamorphic function. The non-linear input mechanism type crane with the metamorphic function comprises a crane jib telescopic mechanism, a metamorphic control mechanism and a jib adjusting mechanism. The crane jib telescopic mechanism is composed of a crane arm, a jib, a balance weight and lifting loading and unloading pliers and capable of enabling the crane to complete space operations of grabbing, hoisting and swing and unloading of containers; the metamorphic control mechanism and the jib adjusting mechanism are both formed by the connection of connecting rods, and the movement adjustment of the jib is completed through the movement combination effect of the connecting rods. The non-linear input mechanism type crane with the metamorphic function adopts the mechanism type connection, accordingly, the crane has the advantages that the structure is compact, the reliability is high, the control is simple, and the work space is large, and the defects that hydraulic elements of a hydraulic crane is high in machining precision requirement, high in maintenance cost, low in reliability and prone to oil leaking can be effectively overcome.

Owner:侯学志

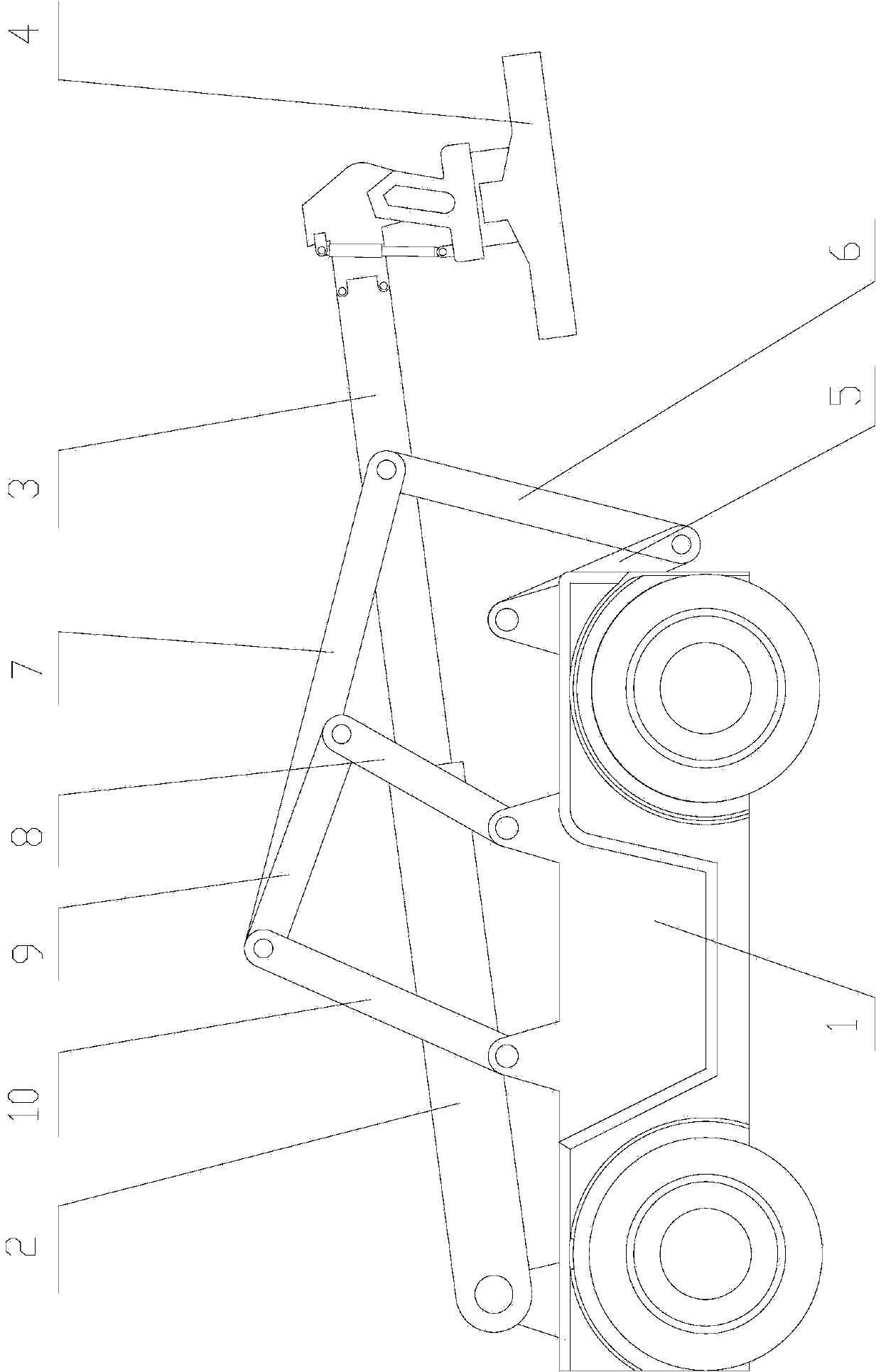

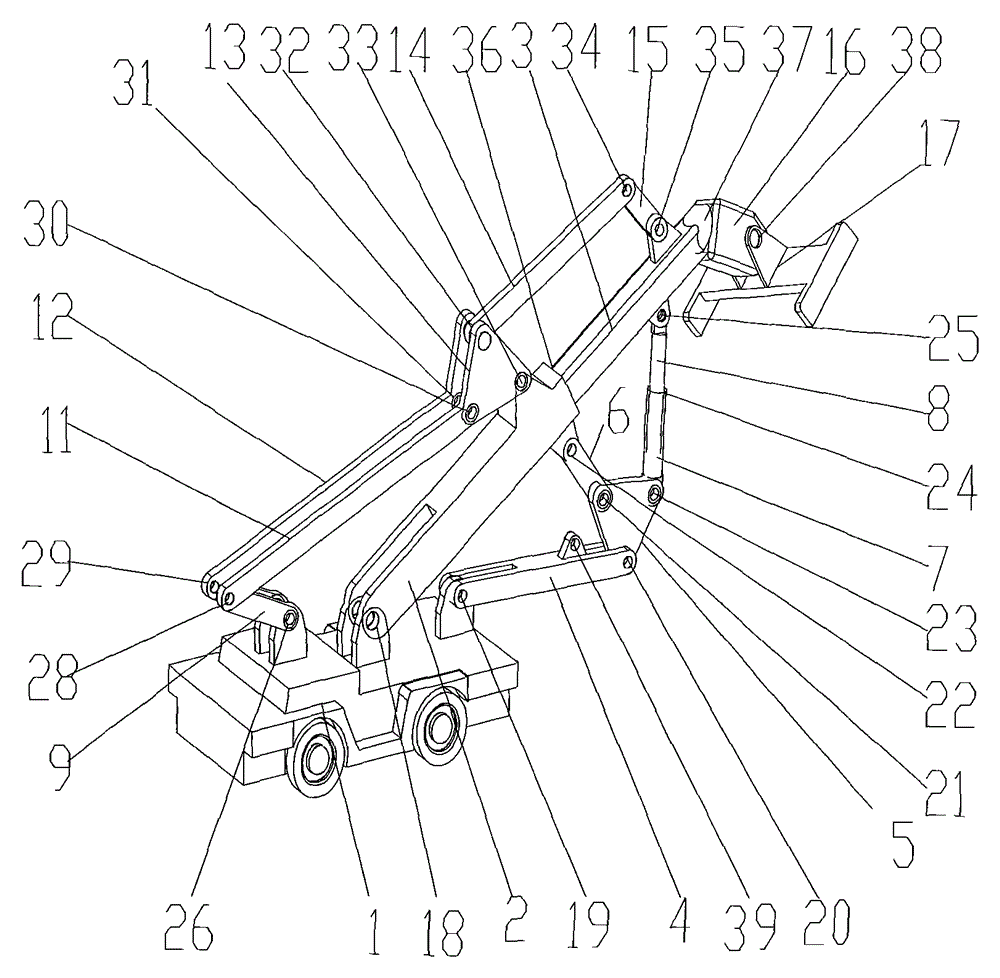

Three-degree-of-freedom hybrid drive container reach stacker crane

InactiveCN103848356AIncrease power outputImprove reliabilityCranesLoad-engaging elementsVehicle frameThree degrees of freedom

The invention discloses a three-degree-of-freedom hybrid drive container reach stacker crane. A suspension arm comprises a rotating arm, an upper lift arm and a lower lift arm; two ends of the rotating arm are respectively hinged with the middle front part of a cartridge and the lower corner of a triangular support; the rear end of the upper lift arm is hinged with the front corner of the triangular support, and the rear end of the lower lift arm and the rotating arm form a composite hinge; the front ends of the upper lift arm and the lower lift arm are hinged with the clamping device; a suspension arm lift mechanism comprises front, middle and rear connecting rod assemblies which are arranged symmetrically at two sides of the suspension arm; the front connecting rod assembly comprises a front rocker rod and a front connecting rod which are hinged; the front rocker rod is hinged to the front part of the cartridge, the front connecting rod is hinged with the lower lift arm; the middle connecting rod assembly comprises a middle rocker rod and a middle connecting rod which are hinged, the middle rocker rod is hinged with the middle rear part of the cartridge; the middle connecting rod is hinged with the rear corner of the triangular support; the rear connecting rod assembly comprises a rear rocker rod and a rear connecting rod which are hinged; the rear rocker rod is hinged with the rear part of the cartridge; the rear connecting rod is hinged with the rotating arm. The three-degree-of-freedom hybrid drive container reach stacker crane is subjected to multi-motor hybrid driving, is great in power, high in reliability, low in manufacturing cost, and easy to maintain.

Owner:QINZHOU UNIV

Heavy-duty container reach stacker crane

InactiveCN103848352BImprove carrying capacityLow costProgramme-controlled manipulatorCranesVehicle frameEngineering

The invention discloses a heavy-load-type container reach stacker crane. A suspension arm comprises a rotating arm, an upper lift arm and a lower lift arm; the front ends of the upper lift arm and the lower lift arm are provided with clamping devices; a suspension arm lift mechanism comprises front and rear connecting rod assemblies which are symmetrically arranged at two sides of the suspension arm; the front connecting rod assembly is a five-connecting-rod mechanism arranged below the front part of the suspension arm and comprises front rocker rods, front connecting rods, middle connecting rods and middle rocker rods; the rear connecting rod assembly is arranged behind the suspension arm and comprises rear rocker rods and rear connecting rods; drives of the front rocker rods and the rear rocker rods are both conventional high-power motors correspondingly arranged on a carriage; drives of the middle rocker rods are low-power servo motors correspondingly arranged on the carriage. According to the invention, the strategy that the high-power conventional motor and the low-power servo motors are used for hybrid driving is adopted, compared with the mode of pure servo motors or hydraulic driving, the heavy-load-type container reach stacker crane has greater power output, higher reliability and larger working space; meanwhile, the whole crane is low in manufacturing cos, and is low in maintaining cost.

Owner:QINZHOU UNIV

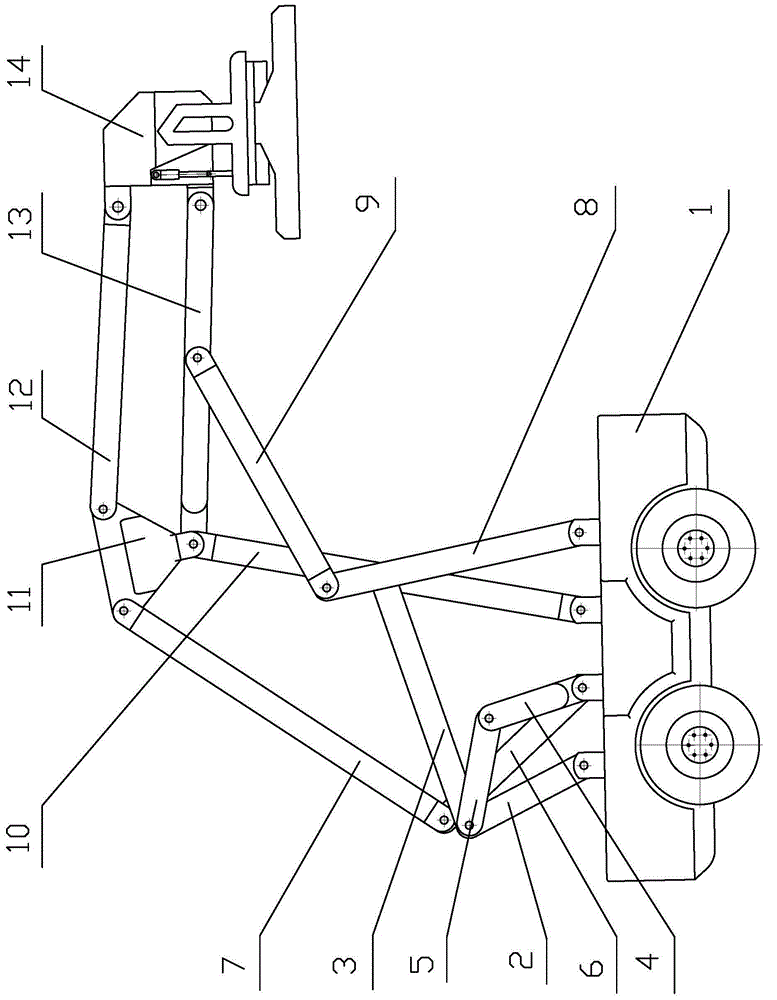

Plane two-degree-of-freedom nine-rod servo drive reach stacker for containers

The invention relates to a plane two-degree-of-freedom nine-rod servo drive reach stacker for containers. The plane two-degree-of-freedom nine-rod servo drive reach stacker for the containers comprises a suspension arm, a suspension arm lifting mechanism and a suspension arm telescoping mechanism, wherein the suspension arm comprises a rotating arm and a telescopic arm; the lower end of the rotating arm is hinged to the middle of a frame; the telescopic arm is mounted on the rotating arm through a sliding pair; a clamping device is arranged at the front end of the telescopic arm; the suspension arm telescoping mechanism comprises a telescopic rocker and a telescopic connecting rod; the telescopic rocker is hinged to the front part of the frame; the telescopic connecting rod is hinged to the telescopic arm and the telescopic connecting rod; the suspension arm lifting mechanism comprises a lifting four-rod linkage mechanism and a lifting transmission rod; the lifting four-rod linkage mechanism comprises front lifting rockers and rear lifting rockers, which are hinged to the rear part of the frame, as well as lifting connecting rods; the lifting transmission rod is hinged to one hinged point of the rotating arm and the lifting connecting rods. The plane two-degree-of-freedom nine-rod servo drive reach stacker for the containers realizes clamping, lifting and carrying operation of the containers under the combined driving of the suspension arm lifting mechanism and the suspension arm telescopic mechanism, and has the advantages of small movement inertia, flexible track output, high precision and the like.

Owner:QINZHOU UNIV

Twenty-degree-of-mobility and six-degree-of-freedom vehicle welding robot

InactiveCN108044275AEasy to controlFlexible drive modeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDegrees of freedom

The invention provides a twenty-degree-of-mobility and six-degree-of-freedom vehicle welding robot. The twenty-degree-of-mobility and six-degree-of-freedom vehicle welding robot comprises a serial connection welding main chain, a rocking arm fine adjustment control sub chain and an actuation mechanism sub chain. The serial connection welding main chain can control the vehicle robot to perform a six-degree-of-freedom motion in space; the rocking arm fine adjustment control sub chain is a four-rod mechanism formed by two rocking arms and two connecting rods, and is mounted on a large arm for fine adjustment control over the main chain through the four-rod mechanism; and the actuation mechanism sub chain supports and the adjusts the large arm. Through connection between multiple mechanical arms and a machine body, six-degree-of-freedom output of a terminal trajectory is realized; and the mechanism has the advantages of quick actions, high precision, low motion inertia, excellent power performances, compact structure, large working space, high bearing capacity, multiple motion trajectory output and simple control, and can be applied to multiple welding fields.

Owner:CHENGDU ZHENGGUANG ELECTRONICS TECH CO LTD

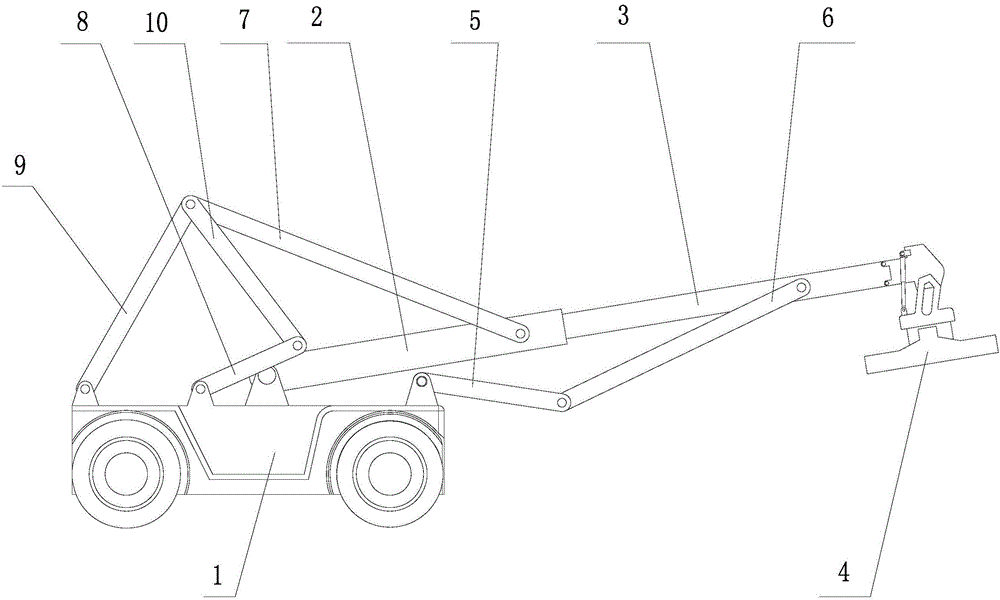

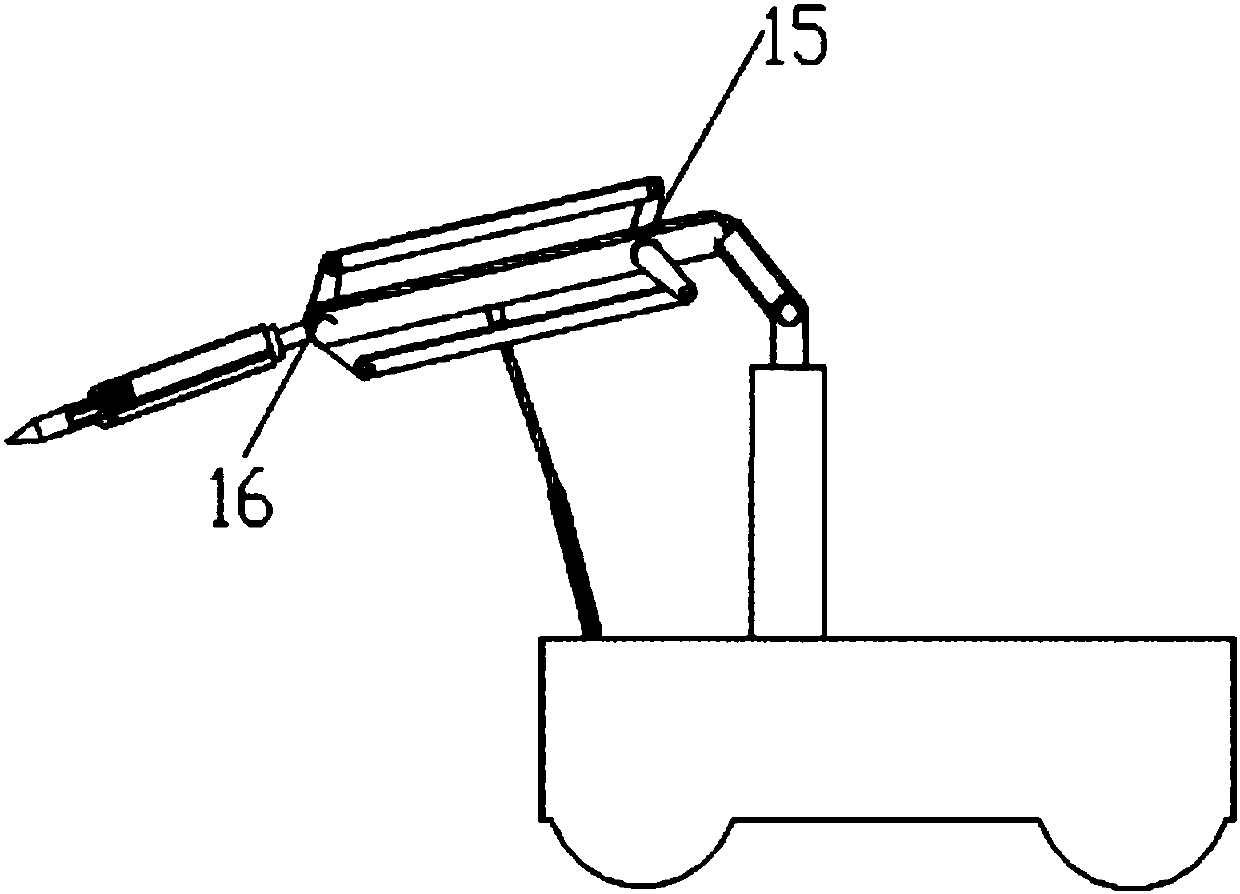

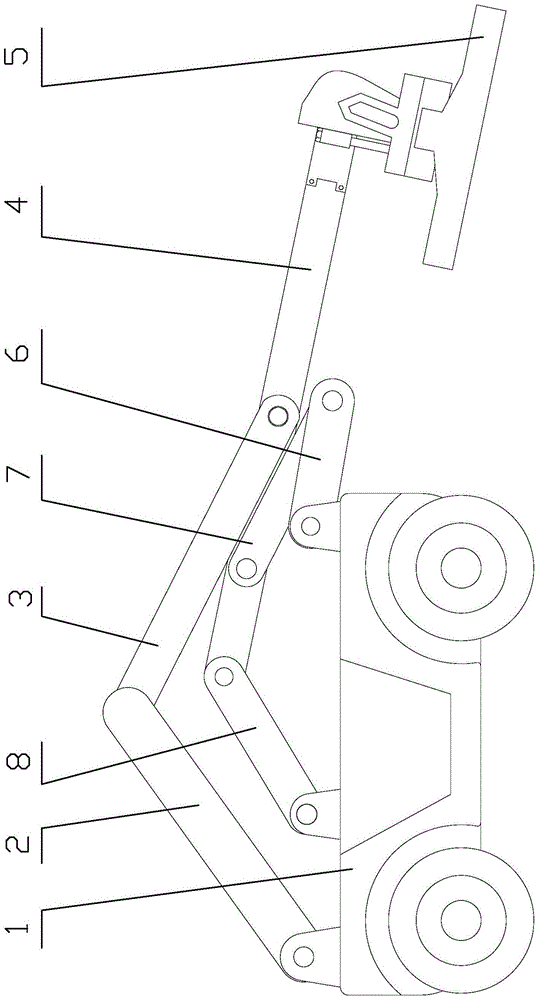

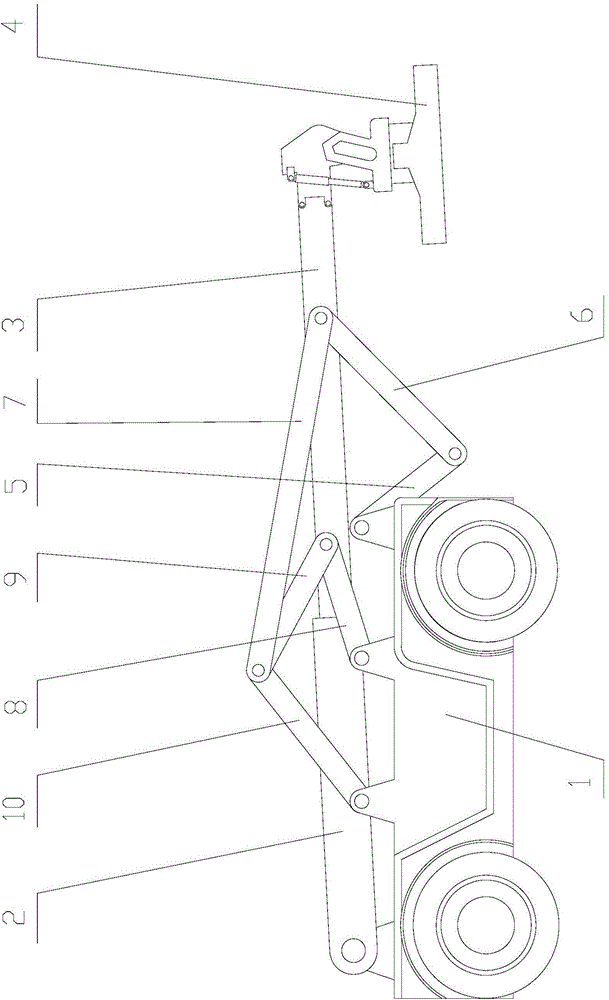

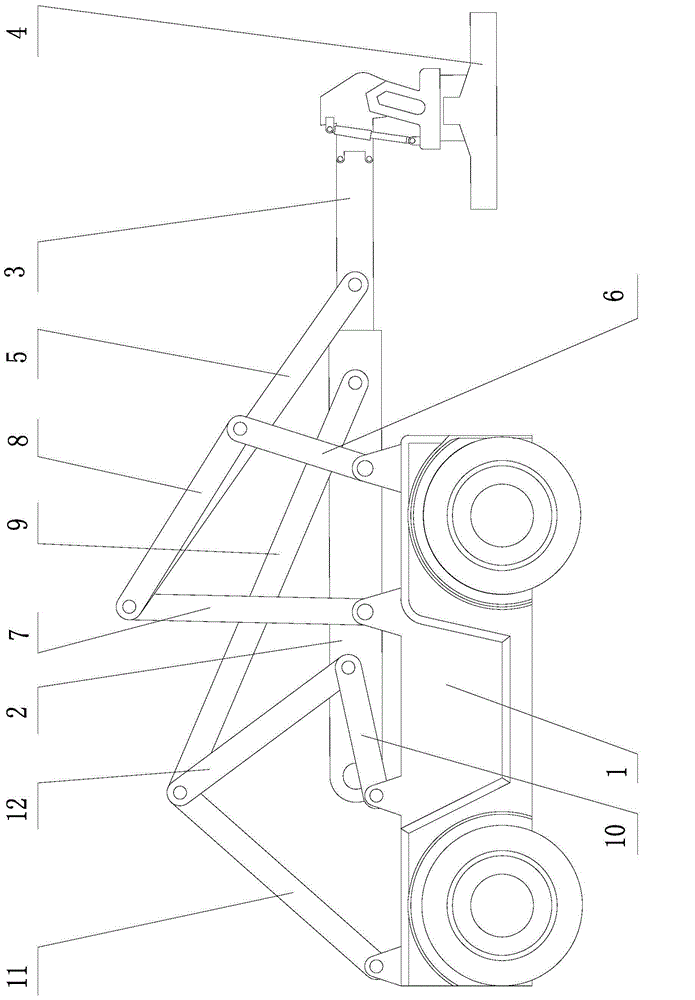

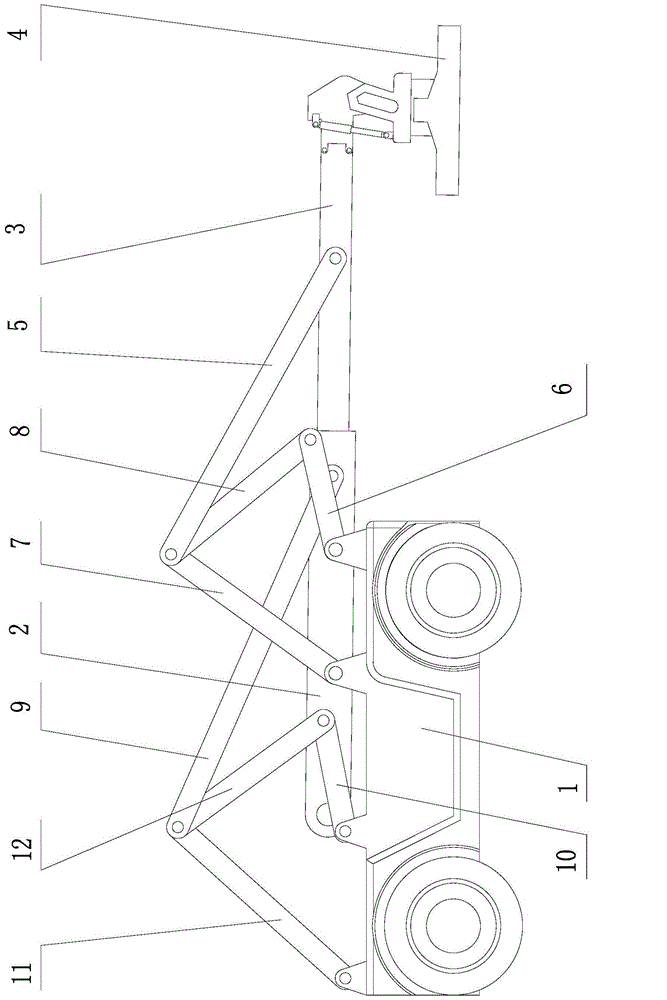

Plane two-degree-of-freedom seven-rod servo drive reach stacker for containers

The invention relates to a plane two-degree-of-freedom seven-rod servo drive reach stacker for containers. The plane two-degree-of-freedom seven-rod servo drive reach stacker for the containers comprises a suspension arm, a suspension arm lifting mechanism and a suspension arm telescoping mechanism, wherein the lower end of a rotating arm of the suspension arm is hinged to the middle of a frame; a telescopic arm of the suspension arm is mounted on the rotating arm in a sliding manner; the suspension arm lifting mechanism comprises a lifting rocker and a lifting connecting rod; the lower end of the lifting rocker is hinged to the front part of the frame; the upper end of the lifting connecting rod is hinged to the rotating arm; the lifting rocker is hinged to the other two ends of the lifting connecting rod; the suspension arm telescoping mechanism comprises a telescopic rocker and a telescopic connecting rod; the lower end of the telescopic rocker is hinged to the rear part of the frame; the front end of the telescopic connecting rod is hinged to the telescopic arm; the telescopic rocker is hinged to the other two ends of the telescopic connecting rod. The plane two-degree-of-freedom seven-rod servo drive reach stacker for the containers realizes clamping, lifting and carrying operation of the containers under the combined drive of the suspension arm lifting mechanism and the suspension arm telescopic mechanism, and has the advantages of small movement inertia, flexible track output, high precision and the like.

Owner:QINZHOU UNIV

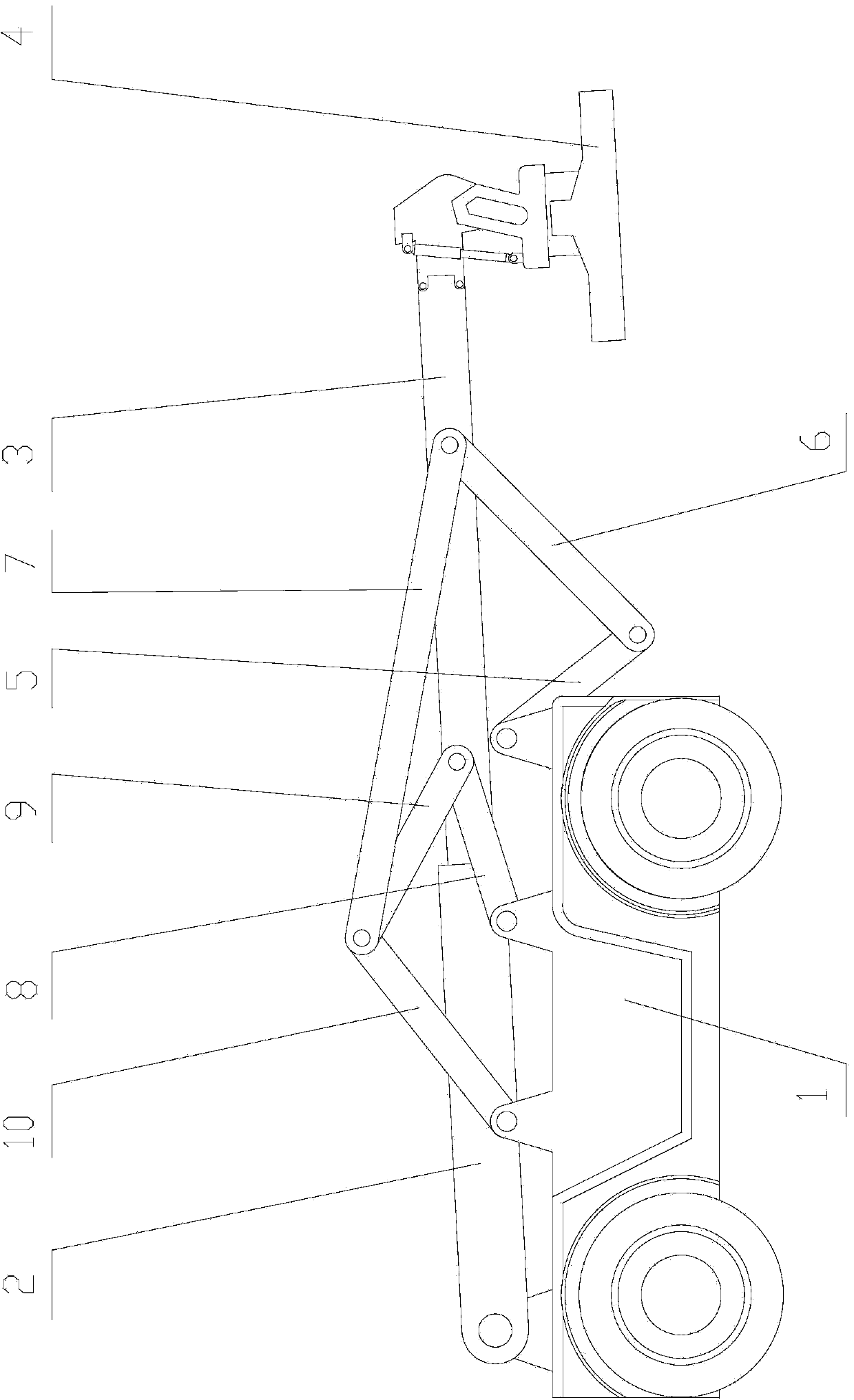

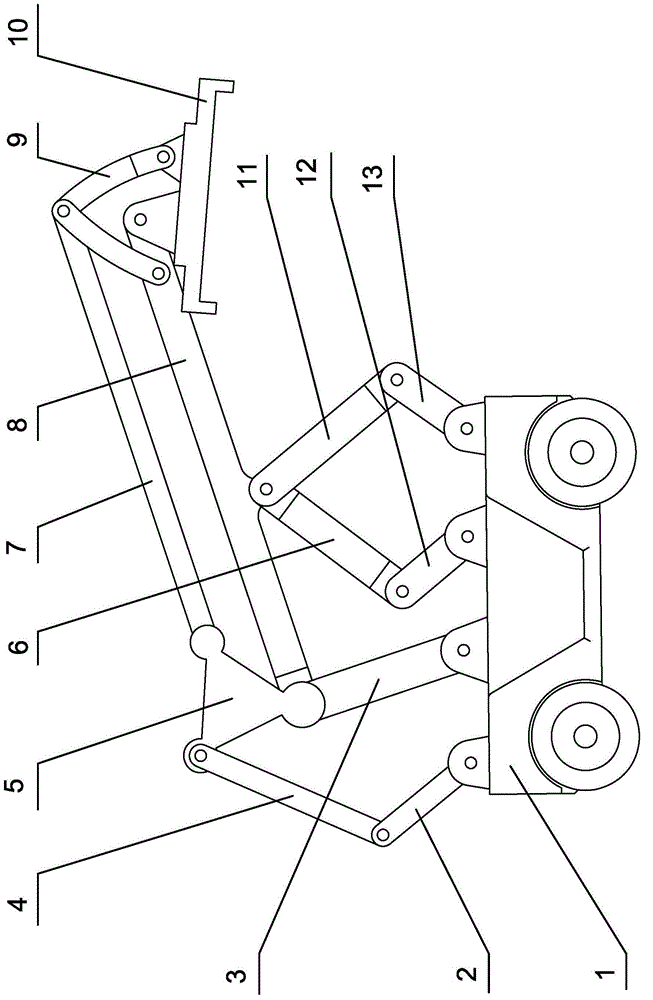

Two-degree-of-freedom seven-bar hybrid drive reach stacker crane

InactiveCN103787204BIncrease power outputImprove reliabilityProgramme-controlled manipulatorCranesDegrees of freedomEngineering

The invention discloses a two-DOF (Degree-of-Freedom) seven-bar hybrid-driven front hoisting crane, which comprises a hoisting arm, a hoisting arm elevating mechanism and a hoisting arm swinging mechanism, wherein the lower end of an elevating arm of the hoisting arm is hinged in the middle of a frame, and a swing arm of the hoisting arm is hinged with the elevating arm; the hoisting arm elevating mechanism comprises an elevating rocker bar and an elevating connecting bar, the lower end of the elevating rocker bar is hinged with the front part of the frame, the rear end of the elevating connecting bar is hinged with an arm body of the elevating arm, and the elevating rocker bar is hinged with the other two ends of the elevating connecting bar; the hoisting arm swinging mechanism consists of a swinging rocker bar and a swinging connecting bar, the lower end of the swinging rocker bar is hinged with the rear part of the frame, the front end of the swinging connecting bar is hinged with the swinging arm, and the swinging rocker bar is connected with the other two ends of the swinging connecting bar. The swinging rocker bar and the elevating rocker bar adopts the hybrid-driven strategy of a large-power conventional motor and a small-power servo motor, and compared with a purely servo motor or hydraulic driving mode, the two-DOF seven-bar hybrid-driven front hoisting crane has larger power output and higher reliability, and is low in manufacturing cost of the whole crane, and low in maintenance cost.

Owner:QINZHOU UNIV

Two-degree-of-freedom hybrid drive controllable hoisting crane

InactiveCN103787216BIncrease power outputImprove reliabilityProgramme-controlled manipulatorCranesEngineeringTwo degrees of freedom

The invention discloses a two-degree-of-freedom driving controllable hoisting cane comprising a hoisting arm arranged based on a frame, a hoisting arm lifting mechanism and a hoisting arm extending mechanism, wherein the hoisting arm comprises a rotating arm and an extending arm, the lower end of the rotating arm is hinged with the rear middle part of the frame, the rear end of the extending arm is hinged with the upper end of the rotating arm, and a clamping device is installed at the front end of the extending arm; the hoisting arm lifting mechanism is arranged at the front lower part of the hoisting arm and comprises a lifting rocker rod and a lifting connection rod, the lower end of the lifting rocker rod is hinged to the front part of the frame, the lower end of the lifting connection rod is hinged with the upper end of the lifting rocker rod, and the upper end of the lifting connection rod is hinged with the rear middle part of the extending arm; the hoisting arm extending mechanism is arranged at the rear upper part of the hoisting arm and comprises a protraction rocker rod and a protraction connection rod, the lower end of the protraction connection rod is hinged to the rear part of the frame, the rear end of the protraction connection rod is hinged to the upper end of the protraction rocker rod, and the front end of the protraction connection rod is hinged with the middle front part of the extending arm. The crane has the advantages of small movement inertia, flexible track output, high precision, good rigidity, good dynamic performance, high reliability and the like.

Owner:QINZHOU UNIV

3DOF Servo Drive Container Reach Stacker Crane

InactiveCN103848354BFlexible output trajectoryAdaptableProgramme-controlled manipulatorCranesVehicle frameThree degrees of freedom

The invention discloses a three-freedom-degree servo-driven front lifting crane for containers. The three-freedom-degree servo-driven front lifting crane comprises a rotating arm, an upper hoisting arm and a lower hoisting arm which are arranged on the basis of a frame, wherein a lifting arm comprises the rotating arm, the upper hoisting arm and the lower hoisting arm; clamping devices are arranged at the front ends of the upper hoisting arm and the lower hoisting arm; the lifting-arm hoisting mechanism comprises a front connecting rod component, a middle connecting rod component and a rear connecting rod component which are symmetrically arranged at the two sides of the lifting arm; the front connecting rod component comprises a four-bar linkage mechanism and a transmission rod; the middle connecting rod component comprises a middle rocking rod and a middle connecting rod; the rear connecting rod component comprises a rear rocking rod and a rear connecting rod; the front rocking rod, the middle rocking rod and the rear rocking rod of the four-bar linkage mechanism are respectively driven by rocking-rod servo motors. The three-freedom-degree servo-driven front lifting crane disclosed by the invention has the advantage that the technical problems of high processing and assembling requirement, short service life, oil leakage, inflexible action and the like in a conventional two-freedom-degree hydraulic type front lifting crane for the containers are relatively well solved.

Owner:QINZHOU UNIV

Three-degree-of-freedom link mechanism type hybrid drive reach stacker

InactiveCN103848355BIncrease power outputFlexible output trajectoryProgramme-controlled manipulatorCranesVehicle frameThree degrees of freedom

The invention discloses a link mechanism type hybrid-driven reach stacker with three freedom degrees. A lifting arm of the link mechanism type hybrid-driven reach stacker comprises a rotary arm, an upper lifting arm and a lower lifting arm; the front ends of the upper lifting arm and the lower lifting arm are respectively provided with a clamping device; a lifting arm lifting mechanism comprises a front connecting rod assembly and a rear connecting rod assembly which are symmetrically arranged at the two sides of the lifting arm; the front connecting rod assembly comprises a front rocking bar and a front connecting rod which are arranged under the front of the lifting arm; the rear connecting rod assembly comprises a four connecting rod mechanism and a transmission rod which are arranged behind the lifting arm, and a rear rocking bar and a rear connecting rod; the four connecting rod mechanism comprises a rocking bar, a connecting rod and an oscillating bar; the rocking bar is driven by a high-power conventional motor which is correspondingly arranged on a frame; the front rocking bar and the rear rocking bar are driven by a small-power servo motor which is correspondingly arranged on the frame. The link mechanism type hybrid-driven reach stacker has the three freedom degrees, is driven by the high-power conventional motor and the small-power servo motor in a combined way, and is flexible and changeable in output track, high in adaptability and working efficiency, high in power output and reliability and low in whole manufacturing cost and maintenance cost.

Owner:QINZHOU UNIV

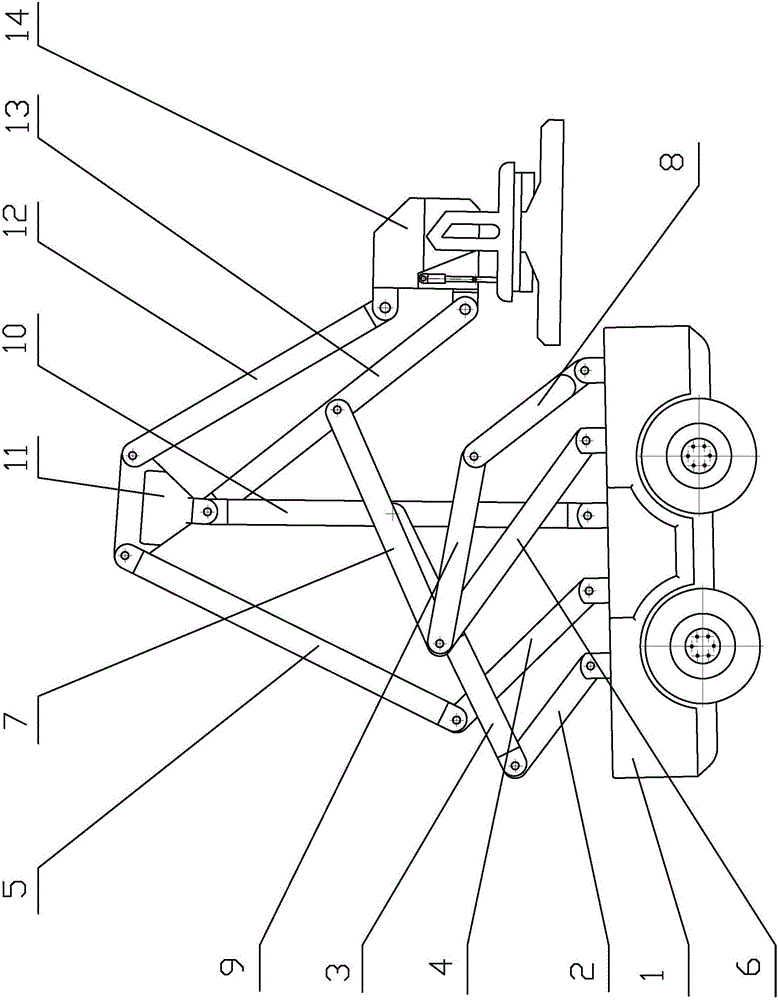

Plane two-freedom-degree nine-rod closed-chain type reach stacker

The invention discloses a plane two-freedom-degree nine-rod closed-chain type reach stacker. The plane two-freedom-degree nine-rod closed-chain type reach stacker comprises a crane jib and a crane jib lifting telescopic mechanism. A rotatable jib of the crane jib is hinged to the rear portion of a vehicle machine. A telescopic jib is installed on the rotatable jib through a sliding pair. The front end of the telescopic jib is provided with a clamping device. The crane jib lifting telescopic mechanism, namely a five-connecting-rod mechanism assembly comprises front rocking rods, front connecting rods, rear connecting rods and a four-connecting-rod mechanism, wherein the front rocking rods are hinged to the front portion of the vehicle frame, the front connecting rods are hinged to the front rocking rods, the four-connecting-rod mechanism is arranged in the middle of the vehicle frame, and front four-connecting-rod mechanism rocking rods and rear four-connecting-rod mechanism rocking rods are hinged to the vehicle frame. The hinged point between each rear connecting rod and the corresponding rear four-connecting-rod mechanism rocking rod and the hinged point between each rear connecting rod and the corresponding four-connecting-rod mechanism connecting rod are composite hinges. The hinged point between each front connecting rod and the corresponding rear connecting rod is arranged on the telescopic jib. The plane two-freedom-degree nine-rod closed-chain type reach stacker has the advantages that the movement inertia is small, track output is flexible, the precision is high, the rigidity and the dynamic performance are good, and the reliability is high.

Owner:QINZHOU UNIV

Plane two-degree-of-freedom eleven-rod double closed-loop sub-chain type container front-handling mobile crane

The invention discloses a plane two-degree-of-freedom eleven-rod double closed-loop sub-chain type container front-handling mobile crane. The plane two-degree-of-freedom eleven-rod double closed-loop sub-chain type container front-handling mobile crane comprises a suspension arm and a suspension arm hoisting and retracting mechanism, wherein a rotary arm of the suspension arm is hinged with the back part of a frame; a retractable arm is mounted on the rotary arm by a sliding pair; the retractable arm is provided with a clamping device; the suspension arm hoisting and retracting mechanism comprises five-connection-rod mechanism assemblies which are symmetrically arranged on the two sides of the suspension arm; each five-connection-rod mechanism assembly comprises a front four-connection-rod mechanism, a front assembly connection rod, a back assembly connection rod and a back four-connection-rod mechanism; each front four-connection-rod mechanism is arranged on the front part of the rack and each back four-connection-rod mechanism is arranged in the middle of the rack; the lower end of each front assembly connection rod is in compound hinging with a connection rod hinging point of each front four-connection-rod mechanism; the lower end of each back assembly connection rod is in the compound hinging with a connection rod hinging point of each back four-connection-rod mechanism; the upper ends of each front assembly connection rod and each back assembly connection rod are hinged on the suspension arm respectively. The plane two-degree-of-freedom eleven-rod double closed-loop sub-chain type container front-handling mobile crane has the advantages of small movement inertia, flexible track output, high precision, good rigidity, high reliability and the like.

Owner:QINZHOU UNIV

High-precision car stacking robot

InactiveCN108326836AEasy to controlFlexible drive modeProgramme-controlled manipulatorStacking articlesPower performanceControl theory

The invention provides a high-precision car stacking robot. The robot comprises a series-connection stacking main chain, a rocker arm fine adjustment control subchain and an execution mechanism subchain; the series-connection stacking main chain can control the car robot to carry out six-freedom-degree motion in the space; the rocker arm fine adjustment control subchain forms a four-rod mechanismcomposed of two rocker arms and two connecting rods, the four-rod mechanism is arranged on a large arm, and the main chain is subject to fine adjustment control through the four-rod mechanism; the execution mechanism subchain carries out supporting and adjusting on the large arm. Multiple mechanical arms are connected with a robot body, six-freedom-degree output of a tail end track can be achieved, and the robot has the beneficial effects of being rapid in action, high in precision, small in movement inertia, good in power performance, compact in structure, large in work space, large in bearing load, capable of achieving multi-motion-track output, simple in control and capable of being applied to multiple stacking occasions.

Owner:CHENGDU ZHENGGUANG ELECTRONICS TECH CO LTD

Six-freedom-degree crane having metamorphic function

A six-freedom-degree crane having a metamorphic function includes a hoisting jib mechanism, a jib telescoping mechanism and a metamorphism control mechanism. The hoisting jib mechanism is composed of a cargo boom and a suspension jib and enables the crane to complete grabbing, hoisting and unloading and such space operations of containers. The jib telescoping mechanism, which is in a parallel structure, is composed of three mechanical sub chains connected in series. The metamorphism control mechanism is formed by connection of linkage rods and is motion-synthesized with the hoisting jib mechanism. By means of the mechanical connection method, the crane is compact in structure and is high in reliability, so that the crane can effectively overcome the defects that hydraulic components of a hydraulic crane are high in processing precision requirement, high in maintaining cost and low in reliability degree and are liable to cause oil leakage. The six-freedom-degree crane is simple in control and is large in operating space, can be widely applied in grabbing, hoisting and unloading and such complex operations of the containers.

Owner:侯学志

Three-degree-of-freedom servo-driven closed-chain container front stacker crane

InactiveCN103848351BFlexible output trajectoryAdaptableProgramme-controlled manipulatorCranesVehicle frameThree degrees of freedom

Owner:QINZHOU UNIV

Nine-motion-degree robot mechanism

InactiveCN102357880BLarge working spaceFlexible track outputProgramme-controlled manipulatorEngineeringActuator

The invention relates to a nine-motion-degree robot mechanism. The nine-motion-degree robot comprises a big three-dimensional rotating arm mechanism, a small three-dimensional rotating arm mechanism and a three-dimensional rotating platform mechanism, which are serially connected to each other, wherein three linear drivers are in parallel connection and are used for driving each joint, thereby realizing a big operating space and a flexible track output of the mechanism. The nine-motion-degree robot mechanism is simple and compact in structure and is excellent in error compensation. By mounting end effectors with various different functions on a three-dimensional rotating platform, the nine-motion-degree robot mechanism can be applied to the production of industries, such as carrying, stacking, assembling, cutting, and the like, and also can be applied to the fields of engineering machinery, such as excavators, and bionic mechanisms, such as bionic arms, bionic legs and the like.

Owner:GUANGXI UNIV

Planer two-degrees-of-freedom eleven-rod servo drive container reach stacker crane

The invention relates to a planer two-degrees-of-freedom eleven-rod servo drive container reach stacker crane which comprises a boom, a boom elevating mechanism and a boom telescopic mechanism, wherein the boom comprises a swivel arm and a telescopic arm; the lower end of the swivel arm is hinged with the middle of a carriage; the telescopic arm is mounted on the swivel arm by a sliding pair; the telescopic arm is provided with a clamping device; the boom telescopic mechanism is arranged in front of the boom, and comprises a telescopic four-link mechanism and a telescopic transmission rod which are arranged symmetrically at both sides of the telescopic arm; the front end of the telescopic transmission rod is hinged with the telescopic arm, and a hinged point between the rear end of the telescopic transmission rod and a telescopic link form a compound hinge; the boom elevating mechanism is arranged behind the boom, and comprises an elevating four-link mechanism and an elevating transmission rod arranged symmetrically at both sides of the swivel arm; the front end of the elevating transmission rod is hinged with the swivel arm, and a hinged point between the rear end of the elevating transmission rod and an elevating link form a compound hinge. The planer two-degrees-of-freedom eleven-rod servo drive container reach stacker crane has the advantages of small motion inertia, flexible trace output, high precision and the like.

Owner:QINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com