Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Crop shortcut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

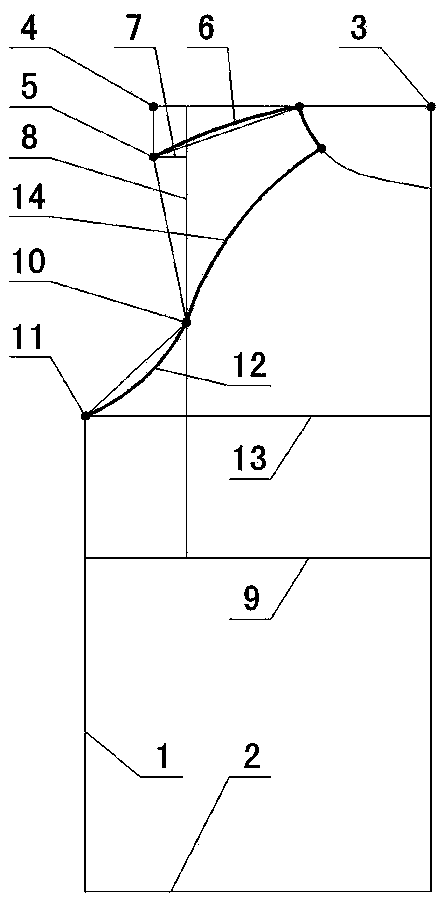

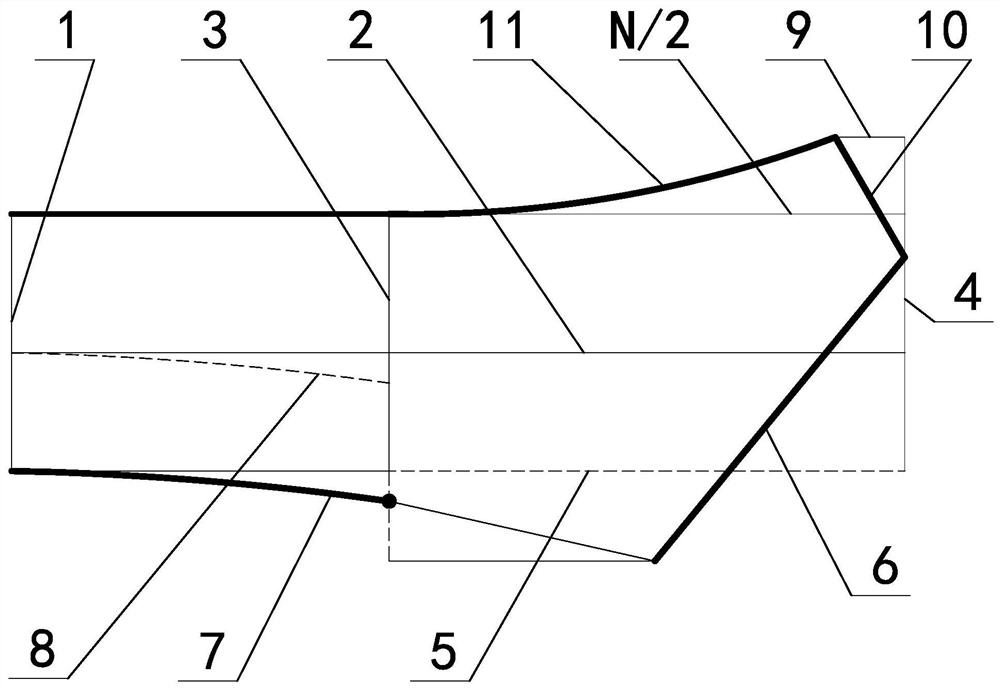

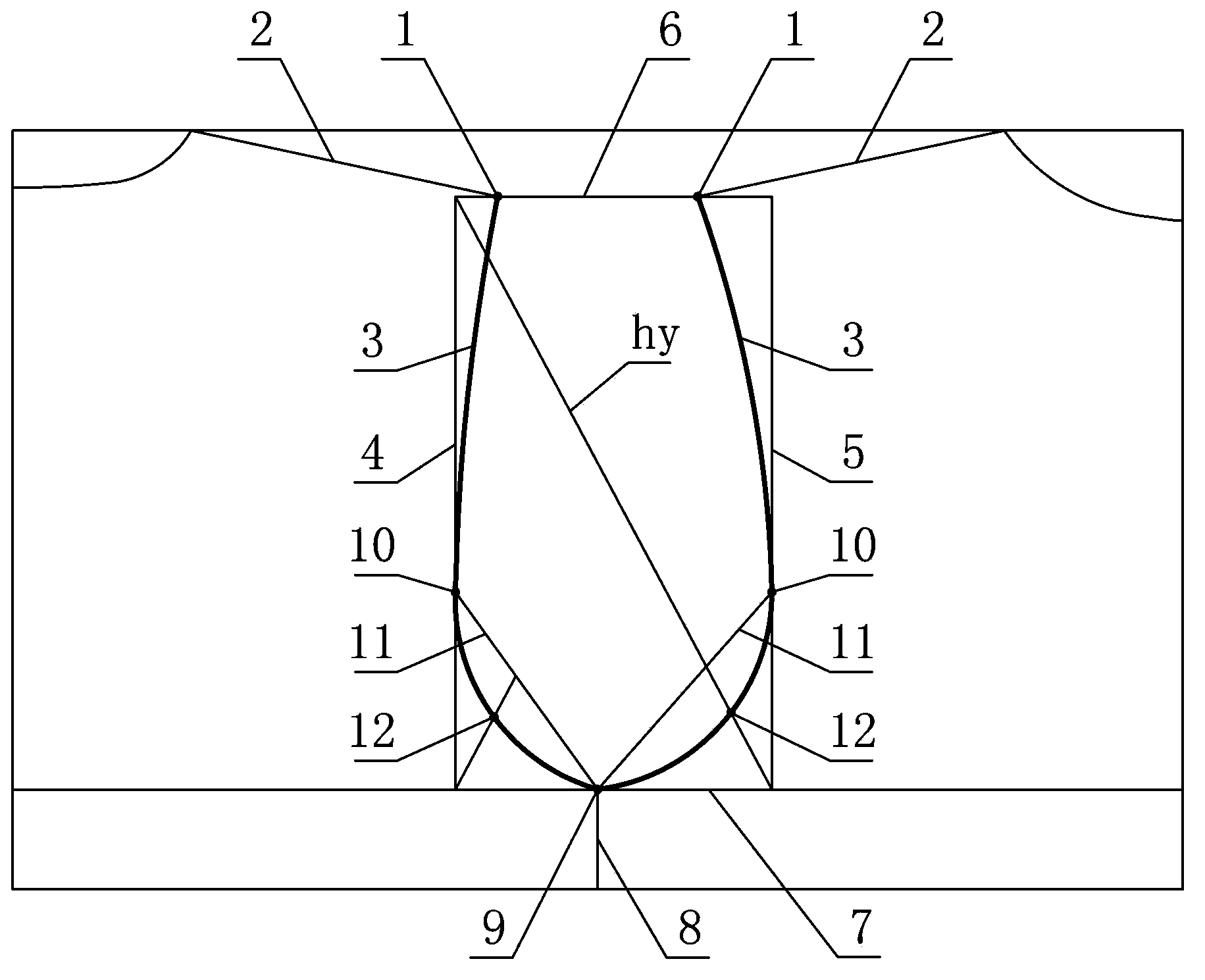

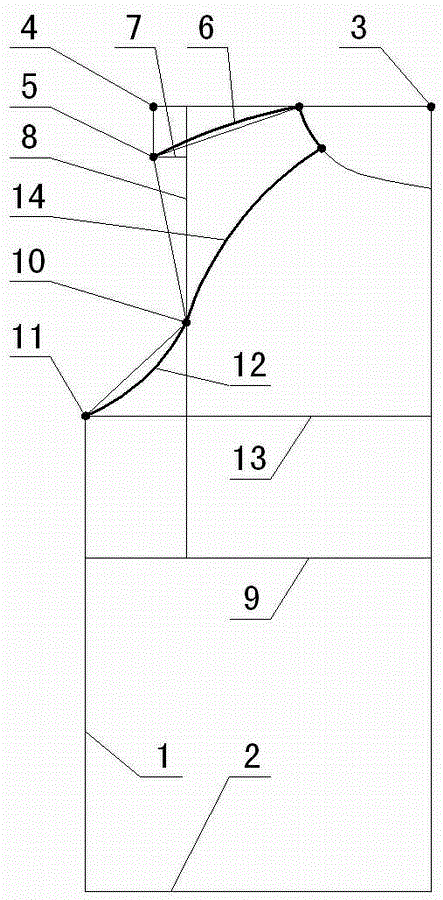

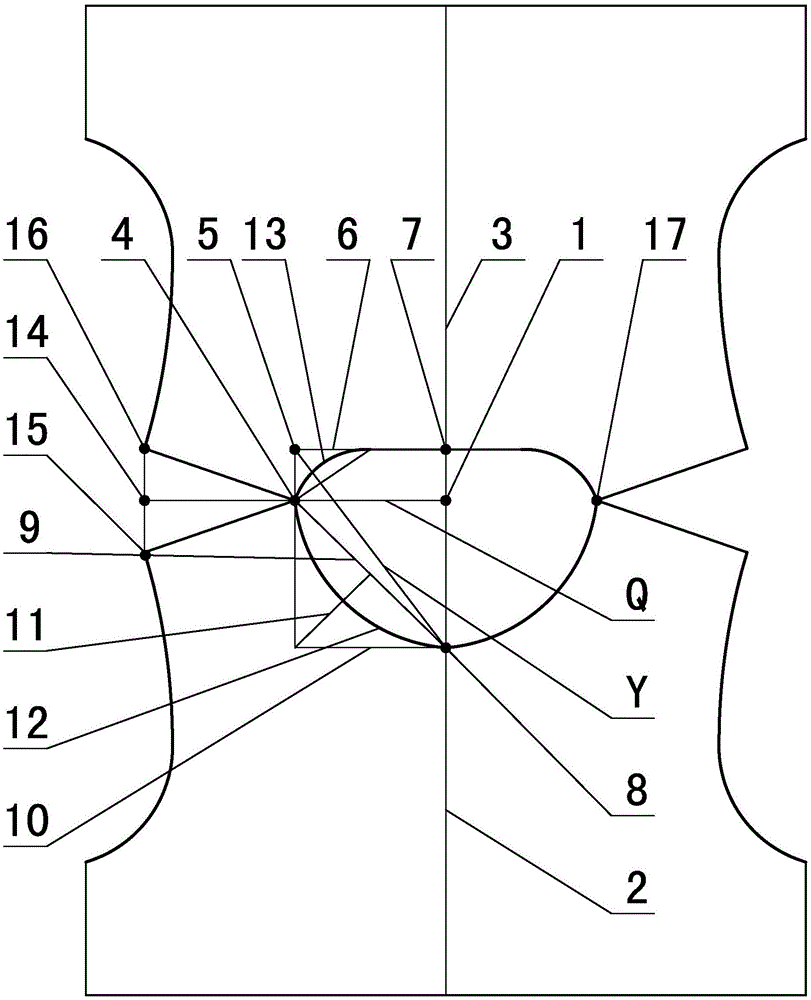

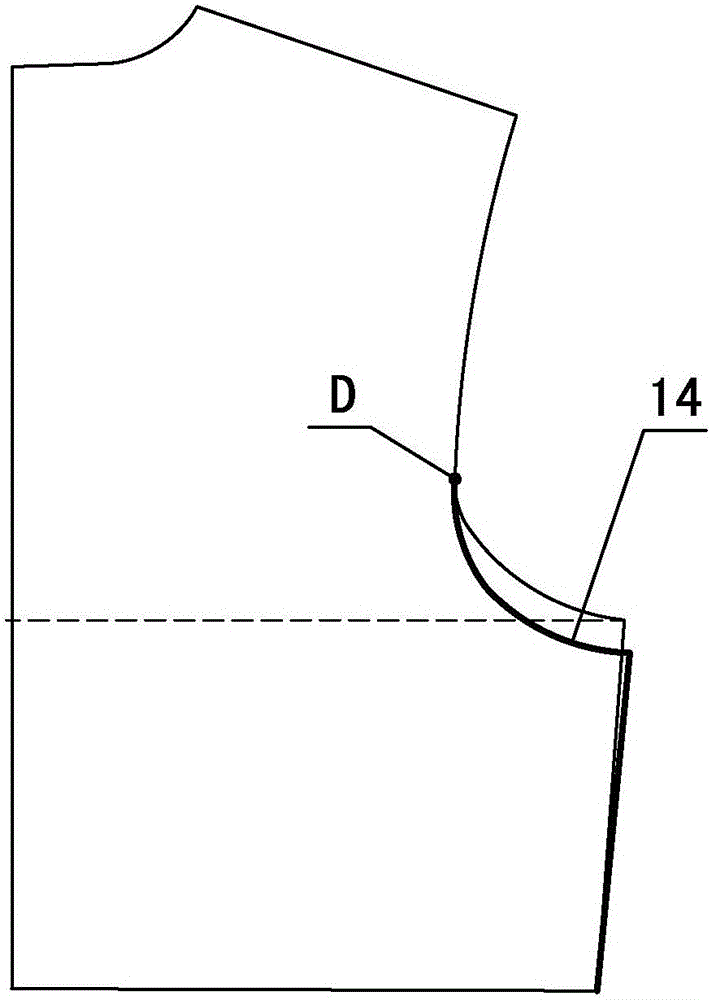

Original number tailoring method for clothing armhole

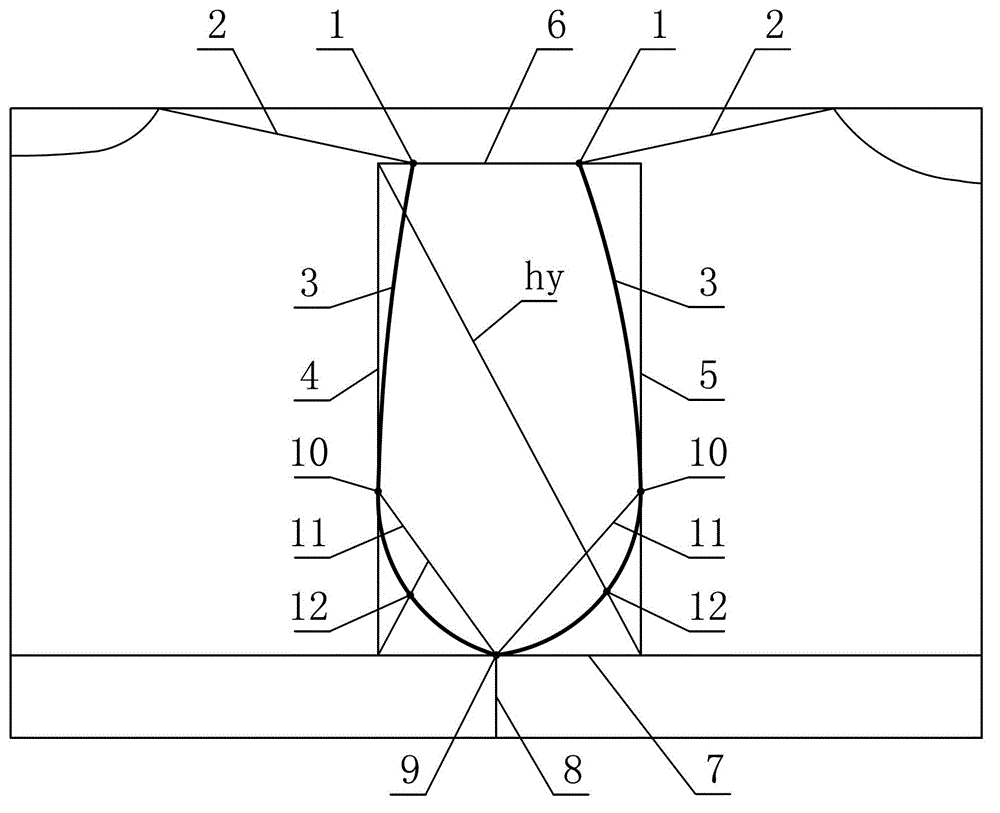

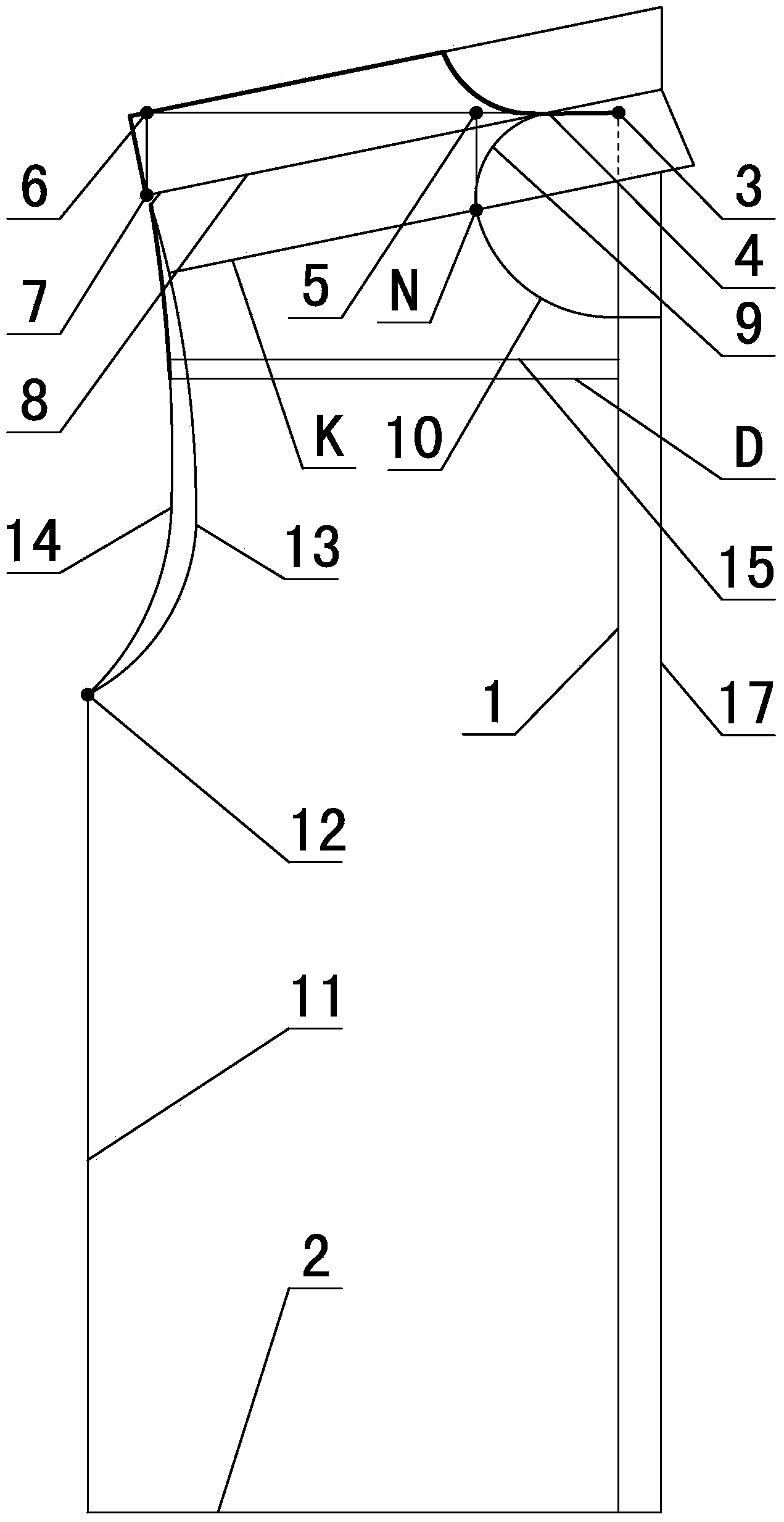

The invention relates to an original number tailoring method for a clothing armhole, which comprises the steps that original clothing numbers, namely the armhole perimeter, the chest width, the back width, the shoulder width, the chest circumference and the clothing length are determined according to anthropometric data; the armhole is designed into a notched ellipse; a diagonal line of an external rectangle of the notched ellipse is a perimeter mark hy; and the ratio of the perimeter mark hy to the armhole perimeter is y; an hy operational method is created; a base line of the external rectangle of the notched ellipse and an armhole circumflexion identification line are determined according to the original clothing numbers, such as the armhole perimeter, the chest width, the back width, the shoulder width and the chest circumference; then, relevant points are determined; and an armhole perimeter line is drawn. The armhole tailoring method is quick in tailoring and high in the precision of the armhole tailoring line, meets the fast-paced requirements of the clothing market on clothing transformation, is applicable to the tailoring of high-grade clothing, and is simple, convenient and practical.

Owner:NANJING JIHUA NO 3503 GARMENT

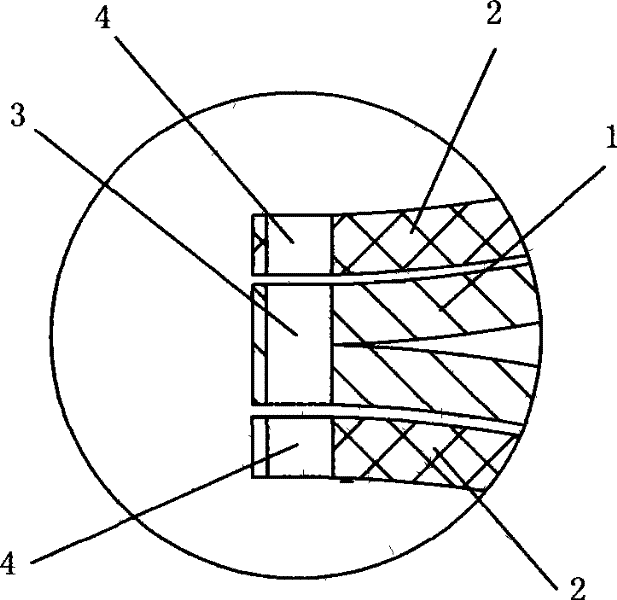

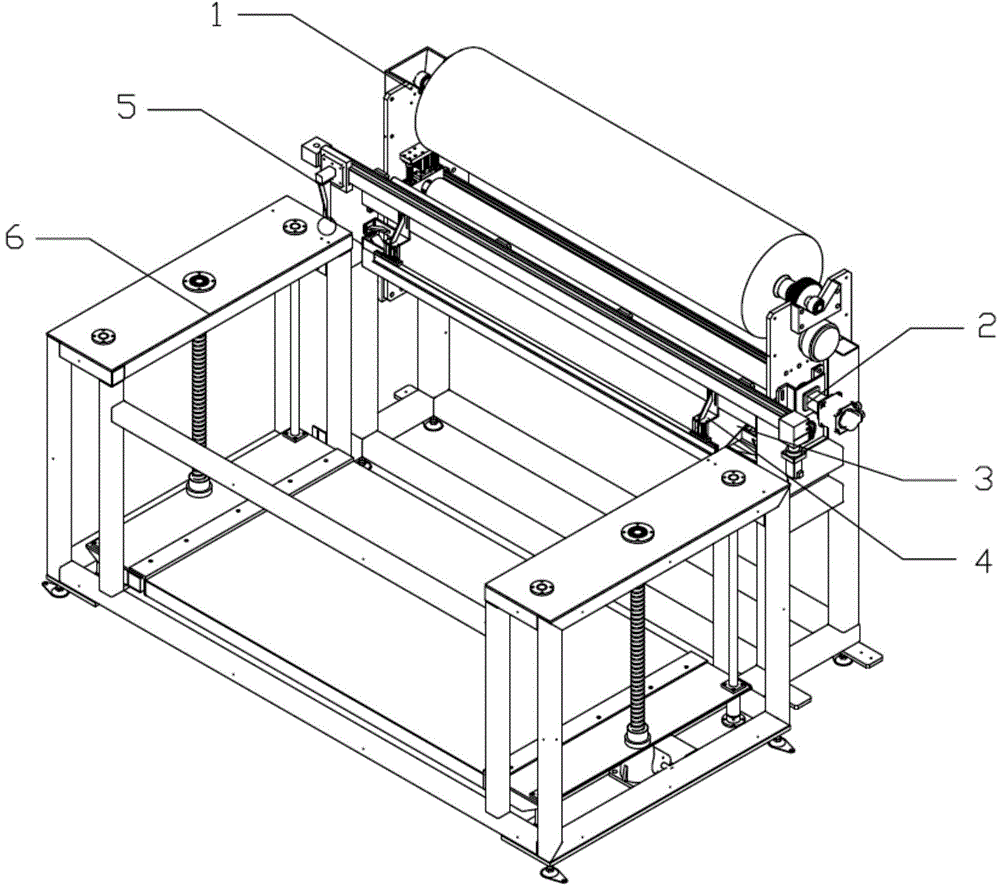

Automatic paper paving machine

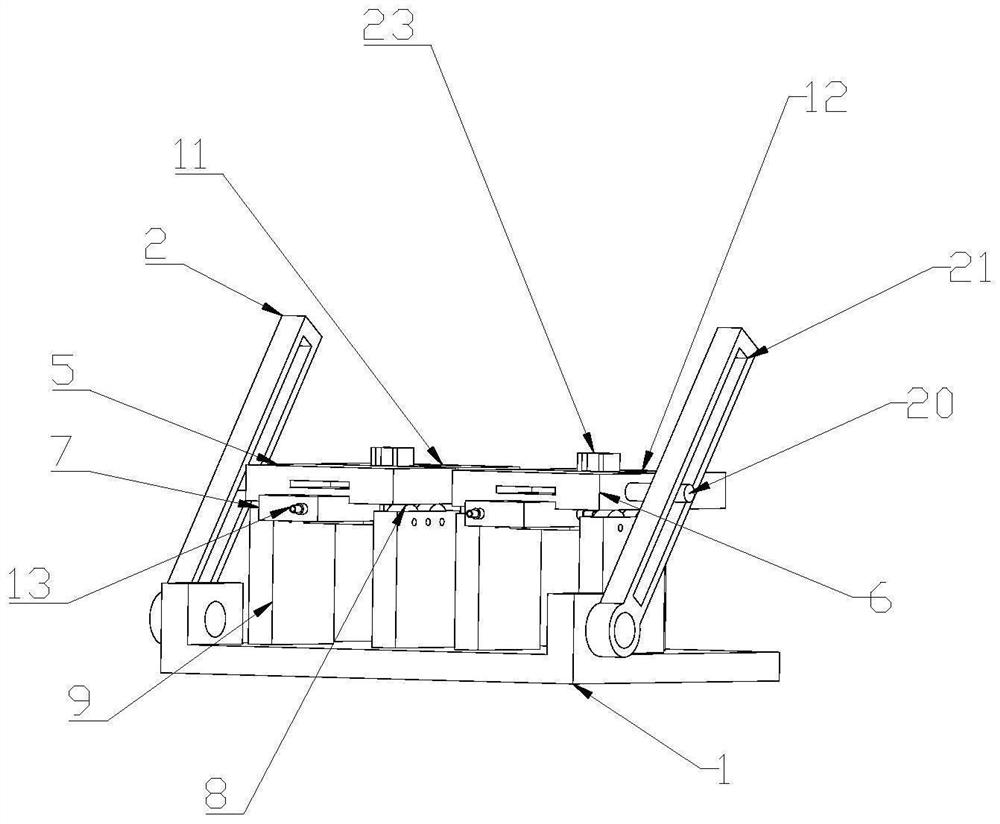

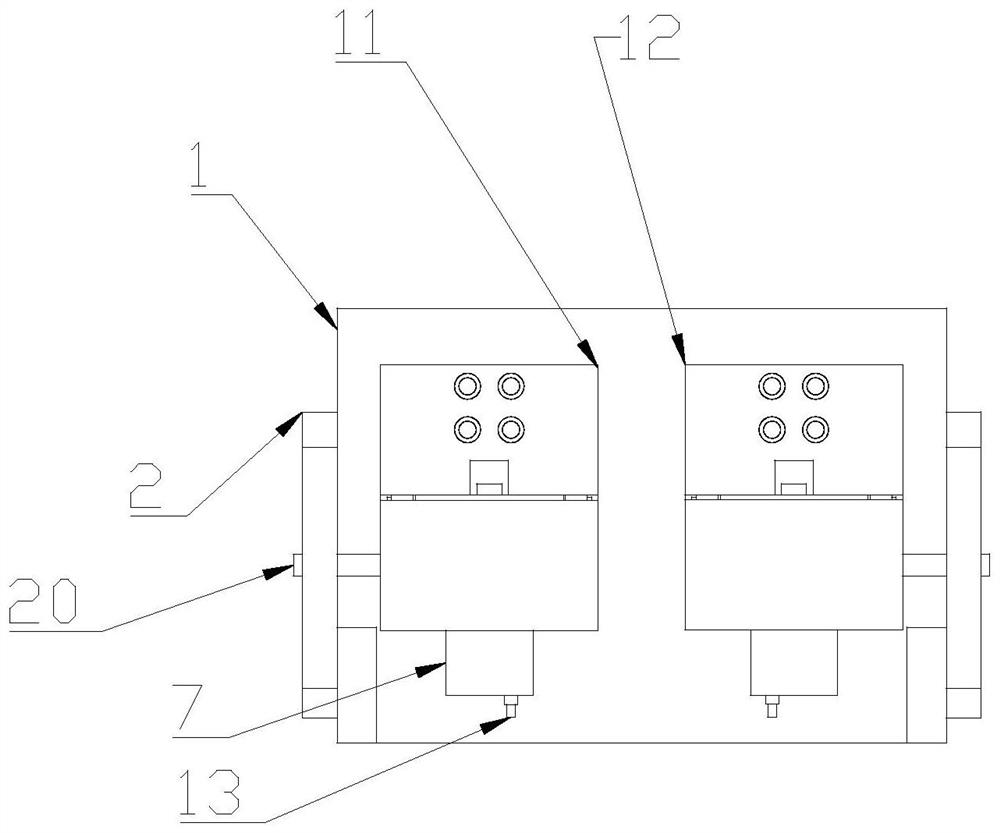

ActiveCN103387071AGood compression effectLess prone to deflectionPackagingArticle deliveryPulp and paper industryPaper sheet

The invention relates to an automatic paper paving machine, comprising an unreeling mechanism and a paper conveying mechanism, wherein the output end of the unreeling mechanism is connected with the paper conveying mechanism; the output end of the paper conveying mechanism is connected with a lifting platform; a blowing mechanism is arranged at the output end of the paper conveying mechanism; a paper cutting mechanism is arranged above the blowing mechanism; the paper conveying mechanism comprises a paper sheet thickness adjusting device. According to the automatic paper paving machine with the structure, a drive roller and a driven roller in the paper conveying mechanism are good in a pressing effect, paper sheets conveyed are flat and do not easily deflect, the paper paving precision is high, the driven roller and the drive roller can automatically adapt to the paper sheets with different thickness through a spring, and the universality is strong; the lifting platform is integrated with the paper conveying mechanism, the space is greatly saved, the blowing mechanism is used for assisting in conveying the paper sheets and preventing the paper sheets from flying up or stopping; a paper knife in the paper cutting mechanism is circular, the cutting is very rapid, and the cutting edge of the paper knife is lower than the surfaces of the paper sheets, so that two edges of the paper sheets can be completely cut off.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

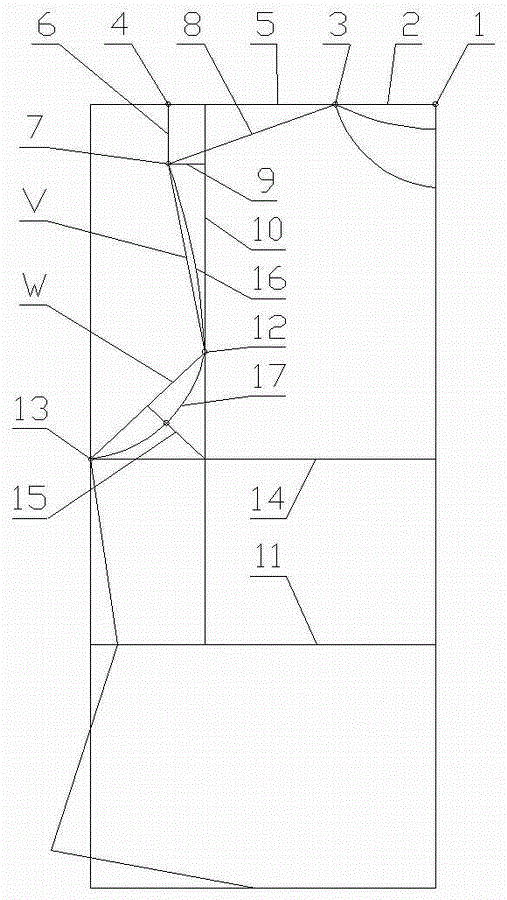

YVW original data cutting method for automatically determining clothes armhole depth

InactiveCN103622194AImprove accuracyCrop shortcutClothes making applicancesNeck circumferenceChest circumference

The invention discloses a YVW original data cutting method for automatically determining the clothes armhole depth. Clothes original data of the positions of armhole circumference, shoulder breadth, chest circumference, clothes length, neck circumference, waist light height and the like are determined according to human body measured data and preset clothes styles. The lengths of an upper sectioning reference line and a lower sectioning reference line of the cut-piece armhole are determined according to the armhole circumference original data by utilizing the armhole circumference rate, the height of the armhole outer side point and the armhole depth are automatically determined through the section reference lines to direct the shape change of the circumference lines of the upper portions and the lower portions of a front armhole and a rear armhole. The YVW original data cutting method is fast and convenient in cutting, can meet the requirement of the clothes market for precision and speed of clothes transform, the cut clothes have a high body comfortable degree, and is a simple, convenient and practical armhole cutting method.

Owner:广州纵歌服饰科技有限公司

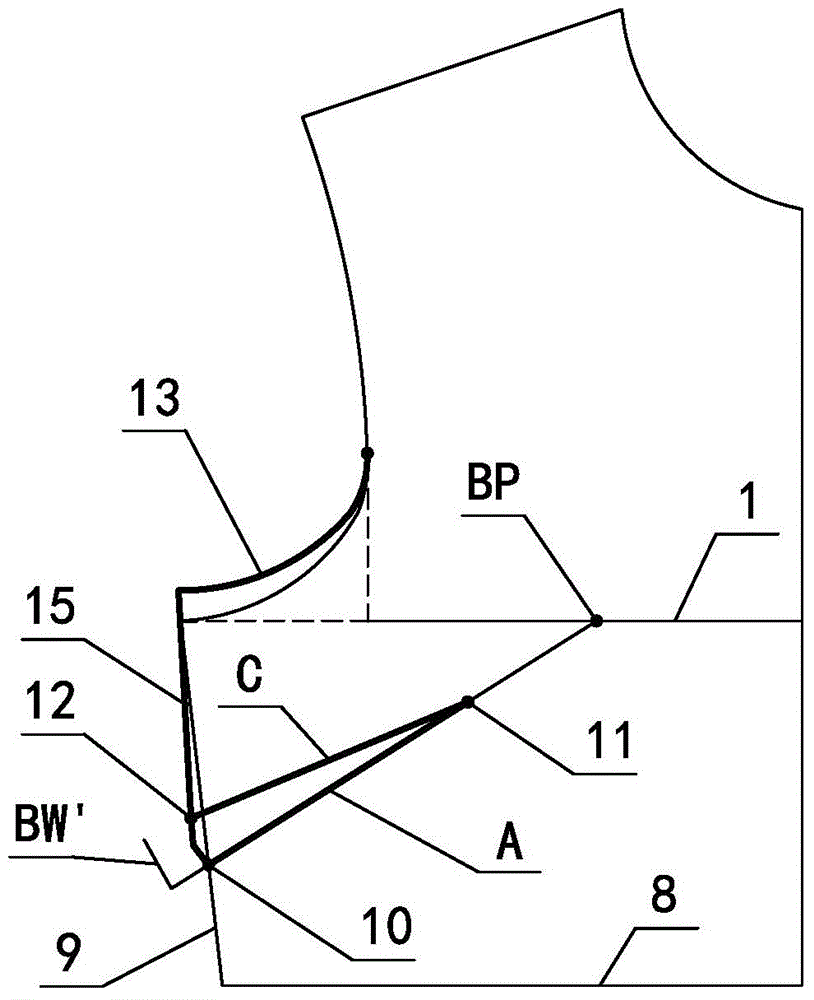

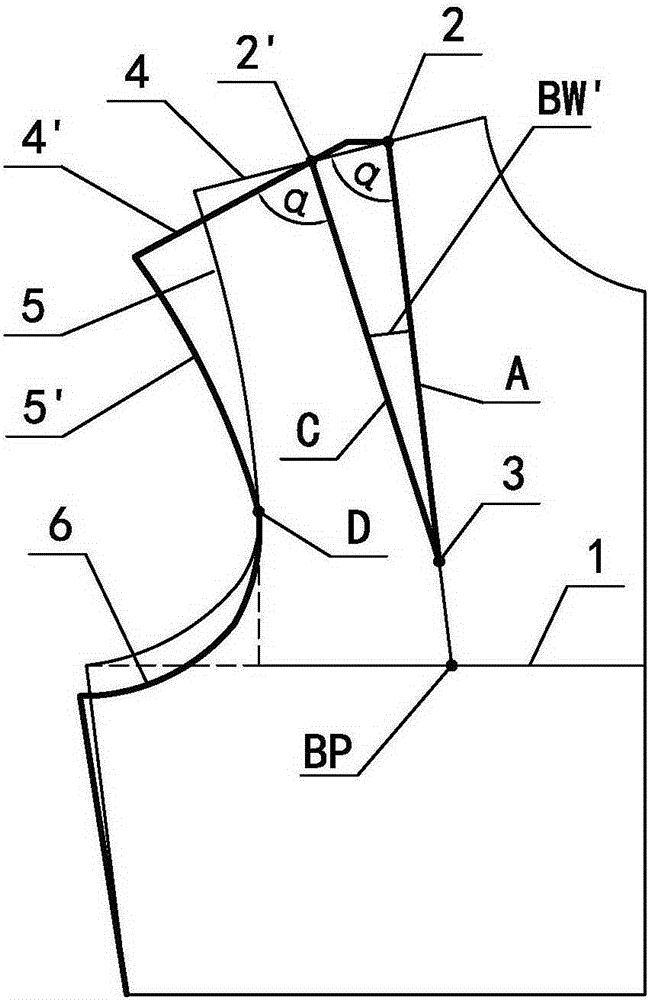

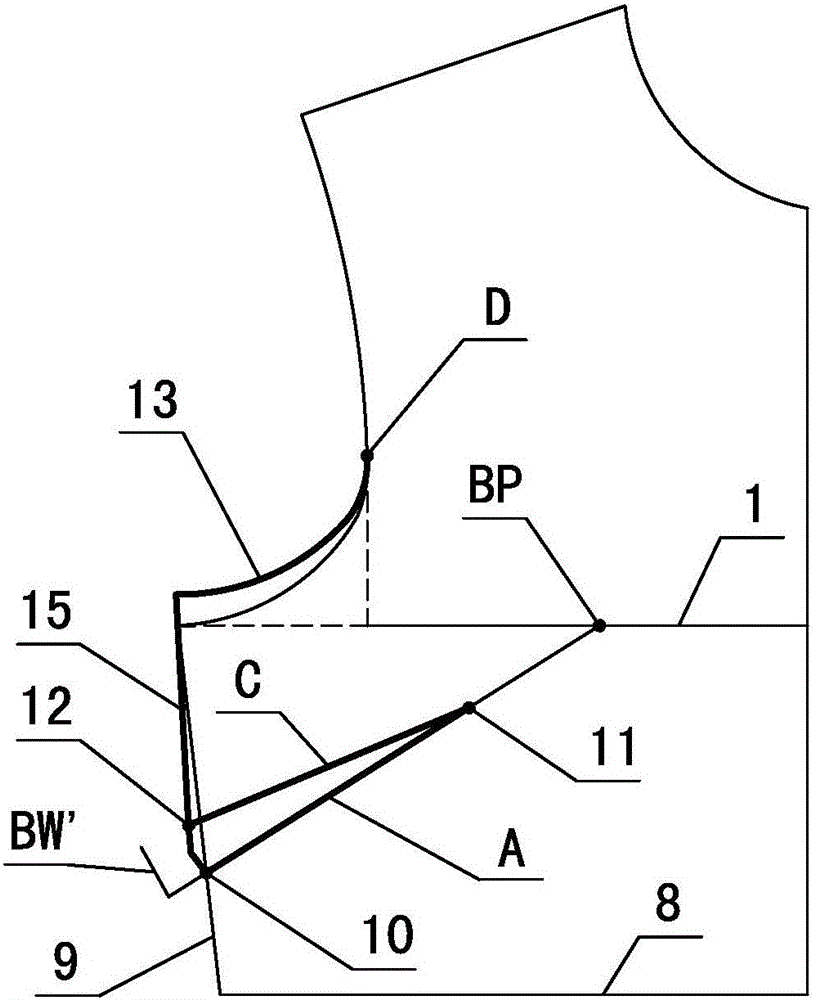

Variance-ratio original-number cutting method for clothes side breast dart

The invention discloses a variance-ratio original-number cutting method for a clothes side breast dart. The method comprises the following steps: determining the clothes specifications of chest circumference, waist circumference, shoulder width, chest width and armhole circumference according to the requirement on clothes style and human body measurement data; determining that the chest-waist difference is BW and the side breast dart variance-ratio coefficient is 10:BW'; acquiring the side breast dart amount which varies along with the style and model variations of the clothes according to a side breast dart point, a dart opening point, a side breast dart variance-ratio coefficient line BW', a dart length line A and a dart opening line C. By adopting the method, a large number of problems existing in a cutting method which applies an identical side breast dart amount to clothes of various models in the prior art are effectively solved, and a very high practical value is achieved.

Owner:苏州盛泽科技创业园发展有限公司

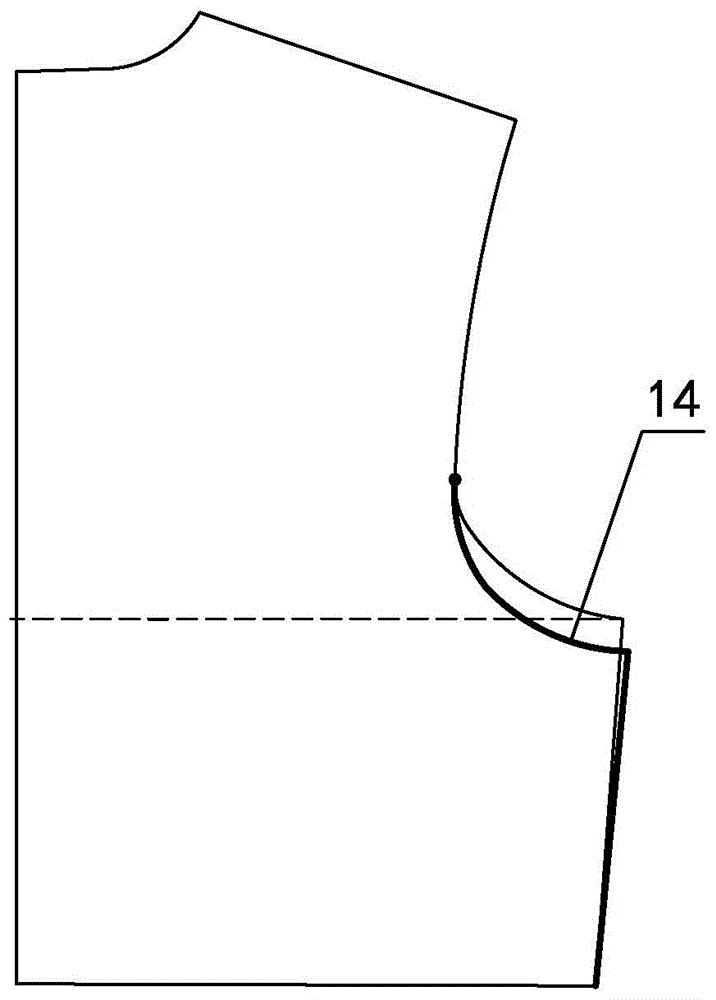

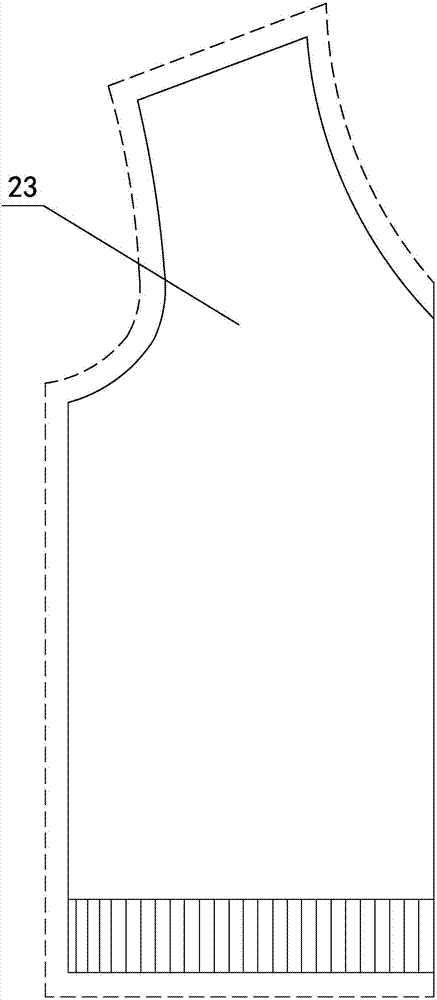

Original measuring data cutting method for clothes shoulder modeling

InactiveCN103622191AShoulder heightGuaranteed comfortClothes making applicancesOriginal dataEngineering

The invention discloses an original measuring data cutting method for clothes shoulder modeling. Clothes original measuring data of shoulder breadth, chest circumference, clothes length and neck circumference are determined according to human body measurement data and the preset clothes style. A cut piece rectangle is drawn with chest circumference divided by two as the width and the clothes length as the height, a clothes length point, a collar-shoulder point and a half-shoulder breadth point obtained by dividing the shoulder breadth original data by two, a small shoulder breadth is obtained, shoulder slope is proved, and shoulder modeling is achieved. The original measuring data cutting method for the clothes shoulder modeling is fast in cutting, simple, convenient and practical, and can implement the shoulder modeling of various clothes according to the clothes original data.

Owner:胡亨有

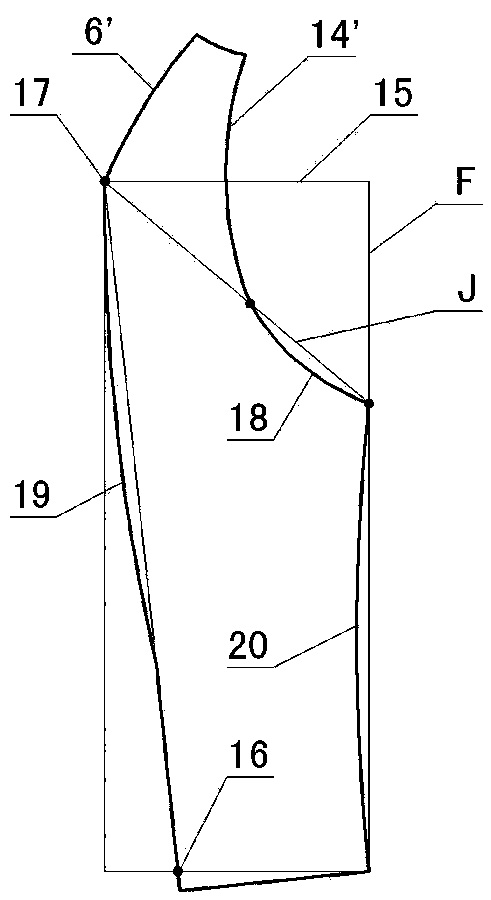

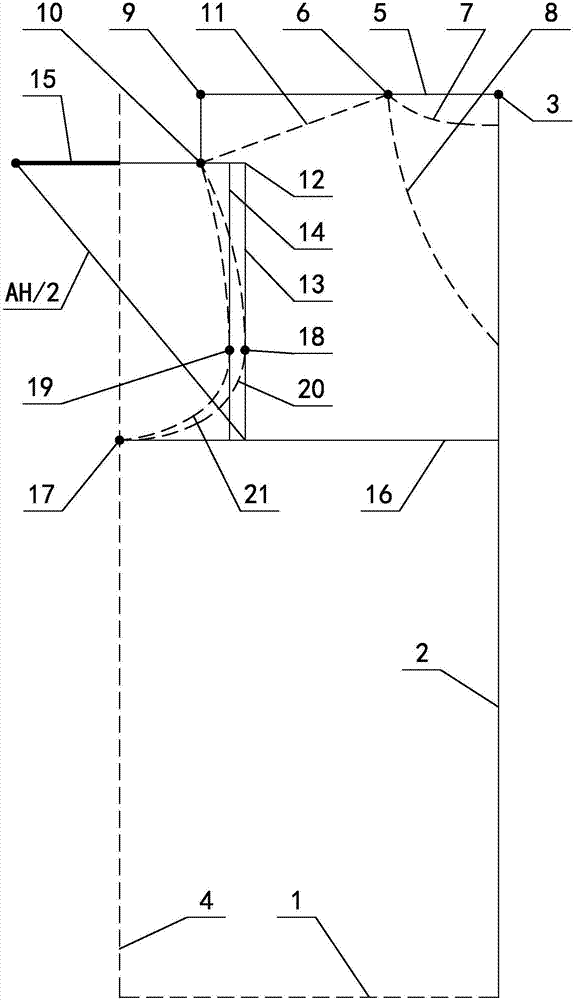

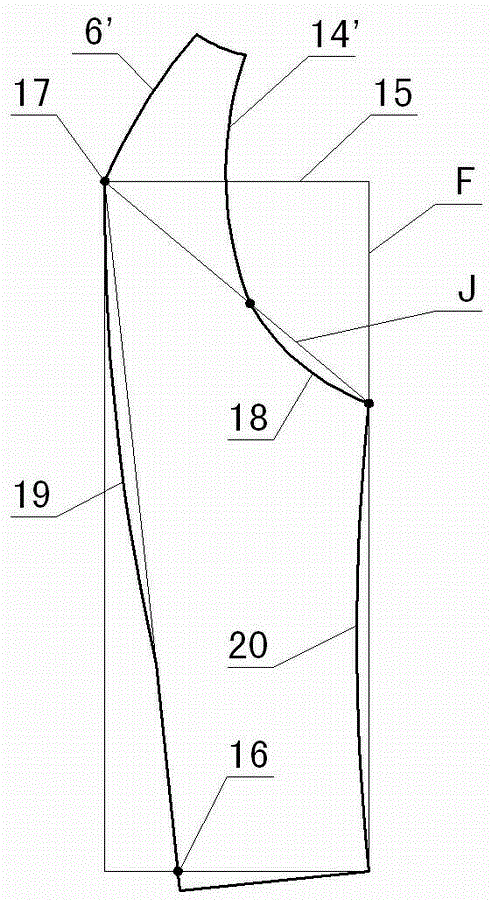

JF original number tailoring method of clothing raglan sleeve

ActiveCN103610252AIncrease uncertaintyCorrectly designedClothes making applicancesShoulder widthEngineering

The invention relates to a JF original number tailoring method of a clothing raglan sleeve. Clothing original numbers of the armhole perimeter, the sleeve length, the chest circumference, the shoulder width, the clothing length and the waist line height are determined according to human body measurement data; a sleeve top base line J and a sleeve width line F are used for guiding shaping of a sleeve top of a raglan sleeve piece through a shoulder piece dividing line, a shoulder line and an armhole arc line on a cloth piece. Designing, tailoring and manufacturing of a forming board for clothing with raglan sleeves can be carried out according to the clothing original numbers, and the JF original number tailoring method of the clothing raglan sleeve is simple, practical and convenient to carry out.

Owner:广州市佛伦斯实业有限责任公司

XE original number tailoring method of clothing chest and shoulder difference

ActiveCN103610253AHighly precise controlPrecise height controlClothes making applicancesShoulder widthHuman body

The invention relates to an XE original number tailoring method of a clothing chest and shoulder difference. Clothing original numbers of the shoulder width, the chest circumference, the clothing length, the collar length and the waist line height are determined according to human body measurement data and predetermined clothing styles; the small shoulder length is determined from 1 / 2 of the shoulder width element, the shoulder sloping amount is commuted, the chest and shoulder difference is then determined, and therefore the width and the height of an armhole are determined. The tailoring method of the clothing chest and shoulder difference is simple and practical, and the chest and shoulder difference is directly determined by the original number, namely the shoulder width.

Owner:苏州盛泽科技创业园发展有限公司

YVW original data cutting method for automatically determining clothes armhole depth

InactiveCN103622194BMeet cutting requirementsReduce mistakesClothes making applicancesShape changeOriginal data

The invention discloses a YVW original data cutting method for automatically determining the clothes armhole depth. Clothes original data of the positions of armhole circumference, shoulder breadth, chest circumference, clothes length, neck circumference, waist light height and the like are determined according to human body measured data and preset clothes styles. The lengths of an upper sectioning reference line and a lower sectioning reference line of the cut-piece armhole are determined according to the armhole circumference original data by utilizing the armhole circumference rate, the height of the armhole outer side point and the armhole depth are automatically determined through the section reference lines to direct the shape change of the circumference lines of the upper portions and the lower portions of a front armhole and a rear armhole. The YVW original data cutting method is fast and convenient in cutting, can meet the requirement of the clothes market for precision and speed of clothes transform, the cut clothes have a high body comfortable degree, and is a simple, convenient and practical armhole cutting method.

Owner:广州纵歌服饰科技有限公司

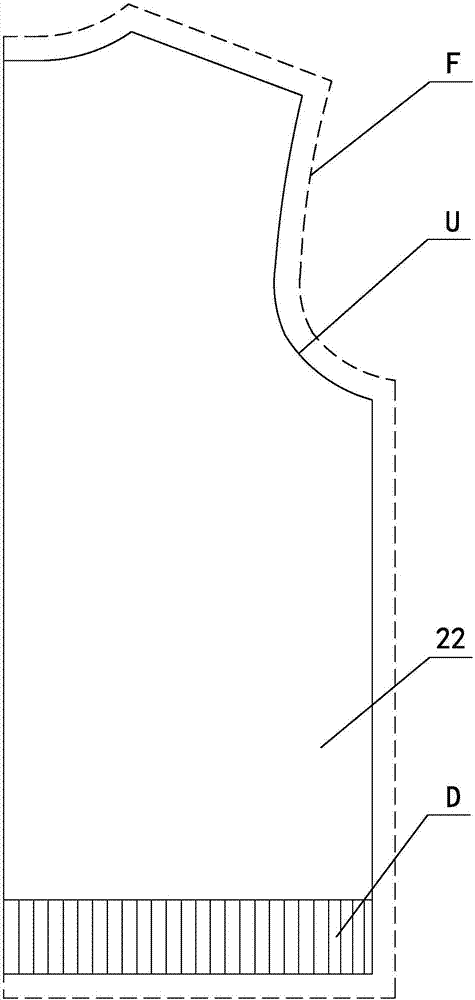

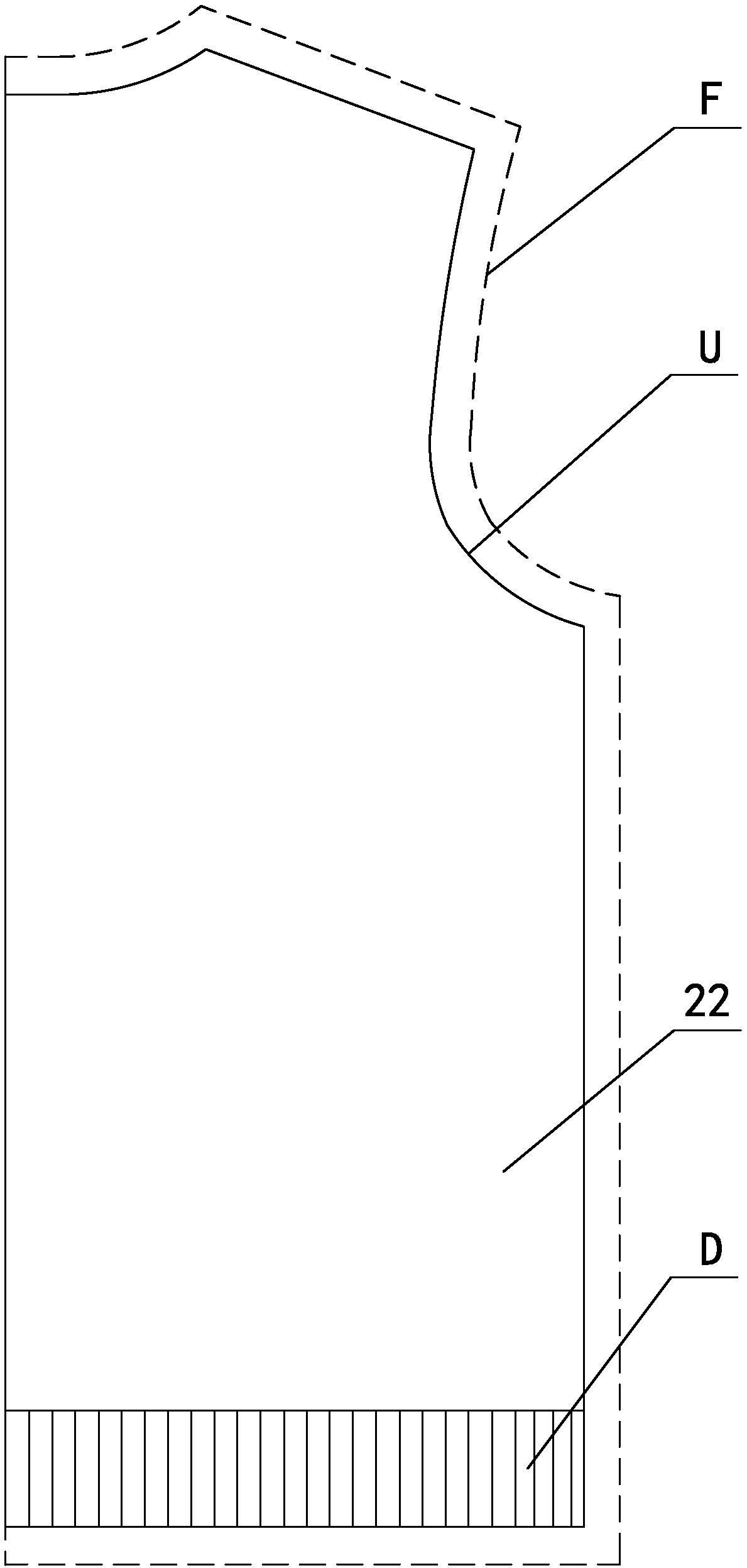

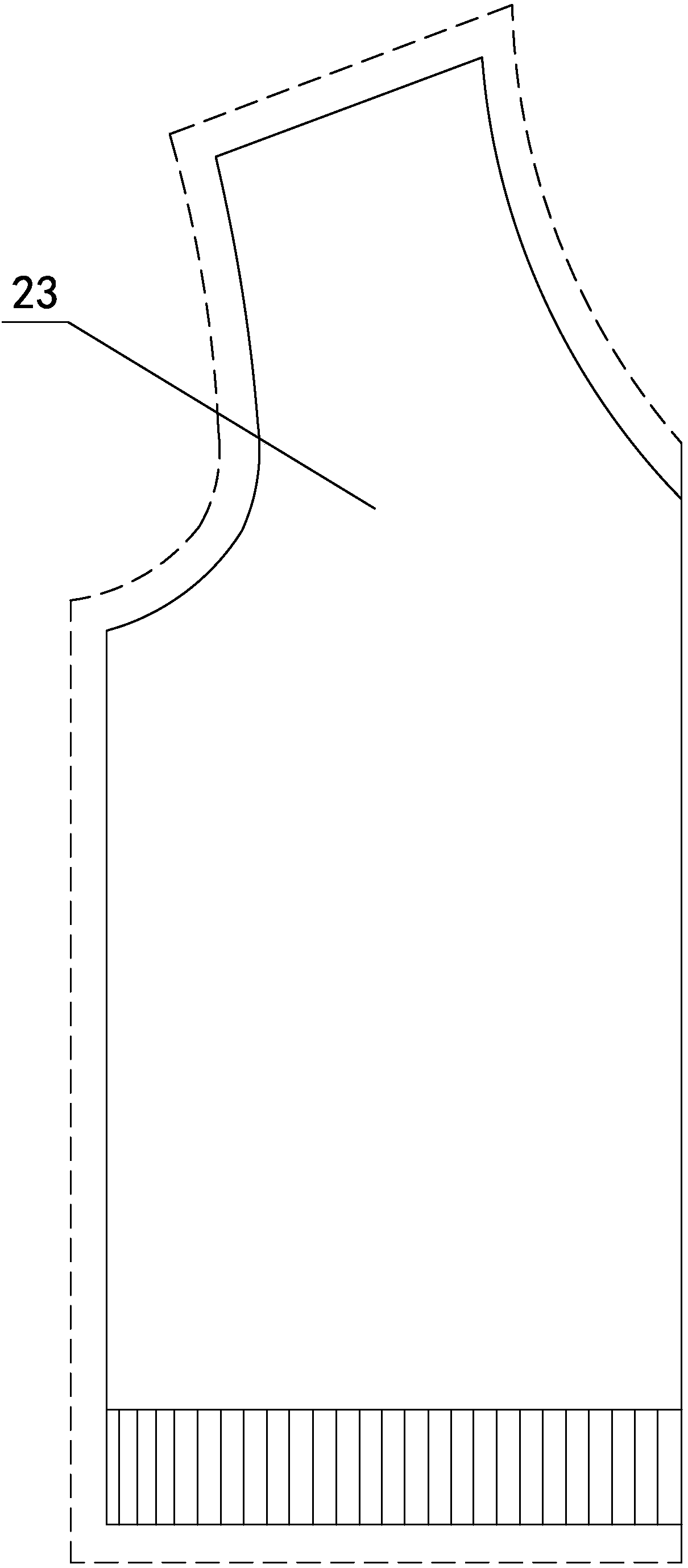

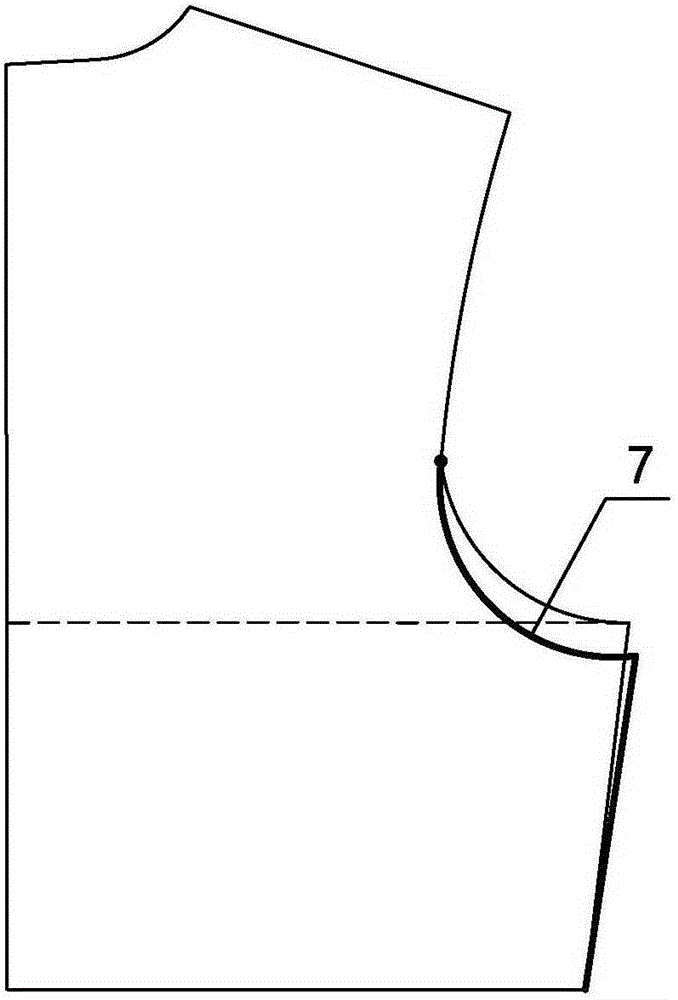

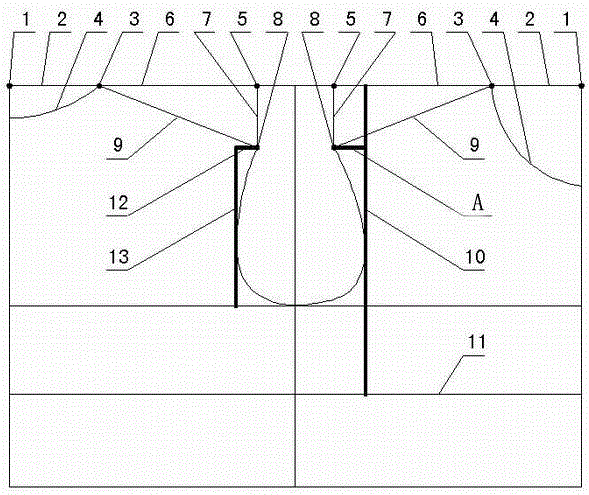

Clothing original number FUD fur sewing design cutting method

ActiveCN106983206ACrop shortcutSatisfy the accuracy and speed requirementsClothes making applicancesEngineeringAnthropometric data

The invention discloses a clothing original number FUD fur sewing design cutting method. According to the measurement data of a human body, the clothing style and the sewing process, the original numbers of the clothing specifications for the sewing edge width, the bottom width, and the clothing length and the related parts are determined, the sewing edge is set as F, and the bottom edge is set as D. The cutting is designed using an additional sewing element value method, to make the sewing edge, the bottom edge and a hub element U to be produced in synchronization with a clothing cut piece, through the sewing process, the finished clothing equaling to the original numbers of the specifications are obtained, the process achieves the clothing original number FUD fur sewing design cutting method which meets the requirements of the apparel market for clothing cutting precision and speed.

Owner:胡亨有

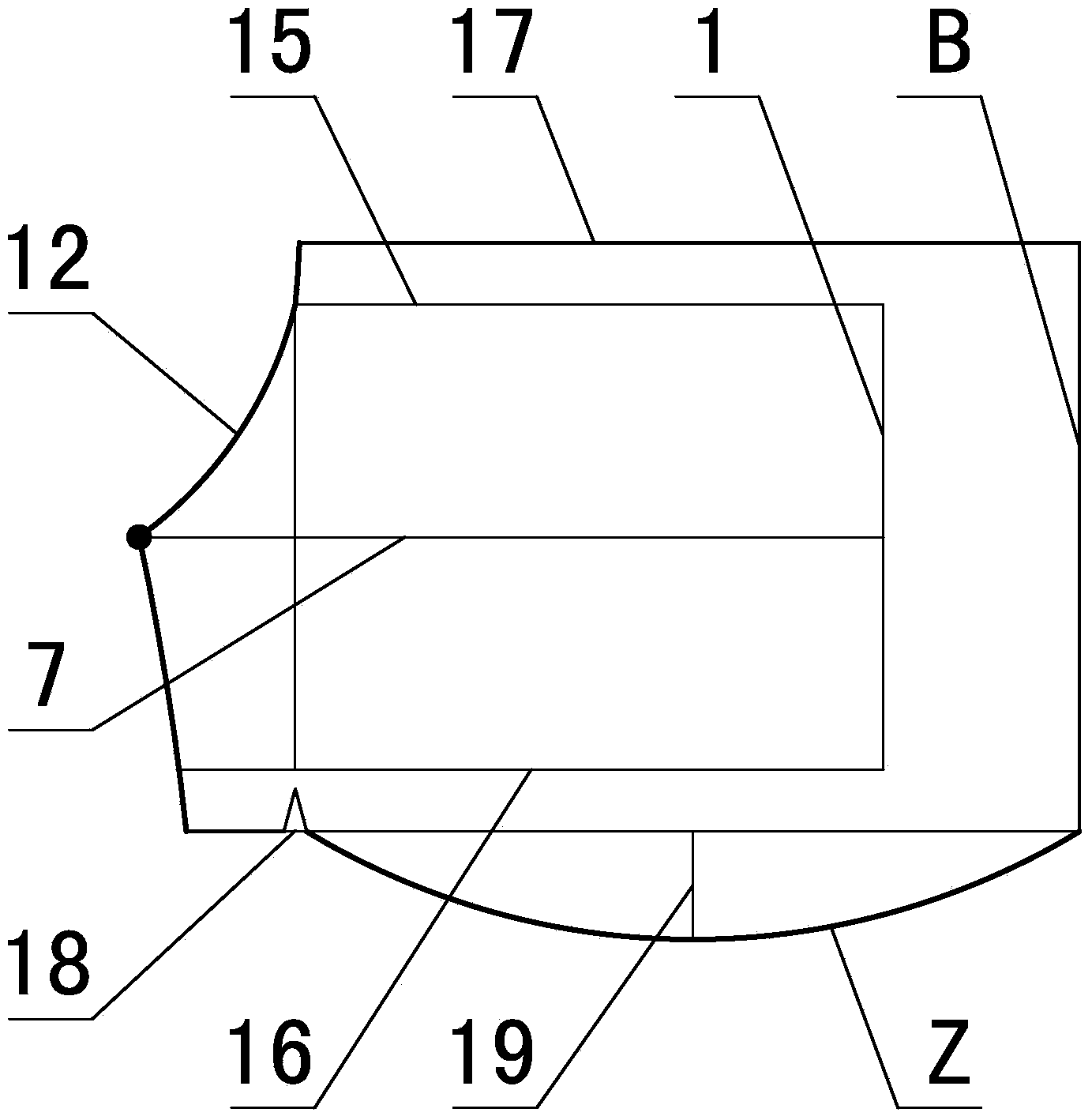

BZ original number tailoring method of clothing chest expanding piece

ActiveCN103610255ACrop shortcutImprove comfortClothes making applicancesEngineeringMechanical engineering

The invention discloses a BZ original number tailoring method of a clothing chest expanding piece. Clothing original numbers of the chest circumference, the waistline, the waist line height, the shoulder width, the collar length, the armhole and the clothing length are determined according to human body measurement data and predetermined clothing styles. A front collar length line, a rear collar length line, a shoulder line, a front armhole line and a rear armhole line are drawn on folded fabric, a waist contracting point, a bottom edge line and a side sewing line are determined, and a front and rear clothing piece mother board for sewing and tailoring is arranged on the side sewing line, the rear armhole line, the shoulder line, the rear collar length line and the bottom edge line. A chest upper piece dividing line and a chest lower piece dividing line are determined on the mother board, a chest expanding amount line and a chest rising amount line are drawn on a chest piece according to the chest expanding amount and the chest rising amount, and therefore tailoring of the chest expanding piece forming board is achieved. The BZ original tailoring method of the clothing chest expanding piece is fast in drawing and tailoring, capable of meeting the requirement for the changing precision and speed of clothing of a clothing market, simple, practical and convenient to use, and the drawn and tailored clothing is high in comfort degree.

Owner:苏州盛泽科技创业园发展有限公司

Clothing sharp collar separate design original data tailoring method

ActiveCN111772282AHigh precisionImprove wearing comfortClothes making applicancesOriginal dataSoftware engineering

The invention discloses a clothing sharp collar separate design original data tailoring method, which is characterized by determining related clothing specification original data such as collar length, collar middle width and the like according to clothing styles, and obtaining the ease amount of a sharp collar through a new technology of separately designing collars and controlling collar key elements according to the length of a collar piece. The problems that in the prior art, a longer time is consumed, the collar length cannot be calculated, the requirements of the garment market for the precision and speed of garment style change cannot be met, and garment comfort is poor are solved, and the original data design tailoring method which is precise, simple, fast and good in garment comfort is achieved.

Owner:胡亨有

Garment peaked collar separate design original number cutting method

ActiveCN111772282BHigh precisionImprove wearing comfortClothes making applicancesIndustrial engineeringManufacturing engineering

The invention discloses a cutting method of separate design original number of pointed lapel collar of clothing, which determines the original number of relevant clothing specifications such as collar length and collar width according to the clothing style, and controls the key elements of the lapel head by separately designing the lapel collar and the length of the collar piece New technology that gives the spiked collar a relaxed amount. It solves the problems of long time-consuming, inability to calculate the lapel length, inability to meet the accuracy and speed requirements of the clothing market for clothing style change and poor clothing comfort in the existing technical methods, and realizes a precise, simple and fast clothing comfort Good original number design cutting method.

Owner:胡亨有

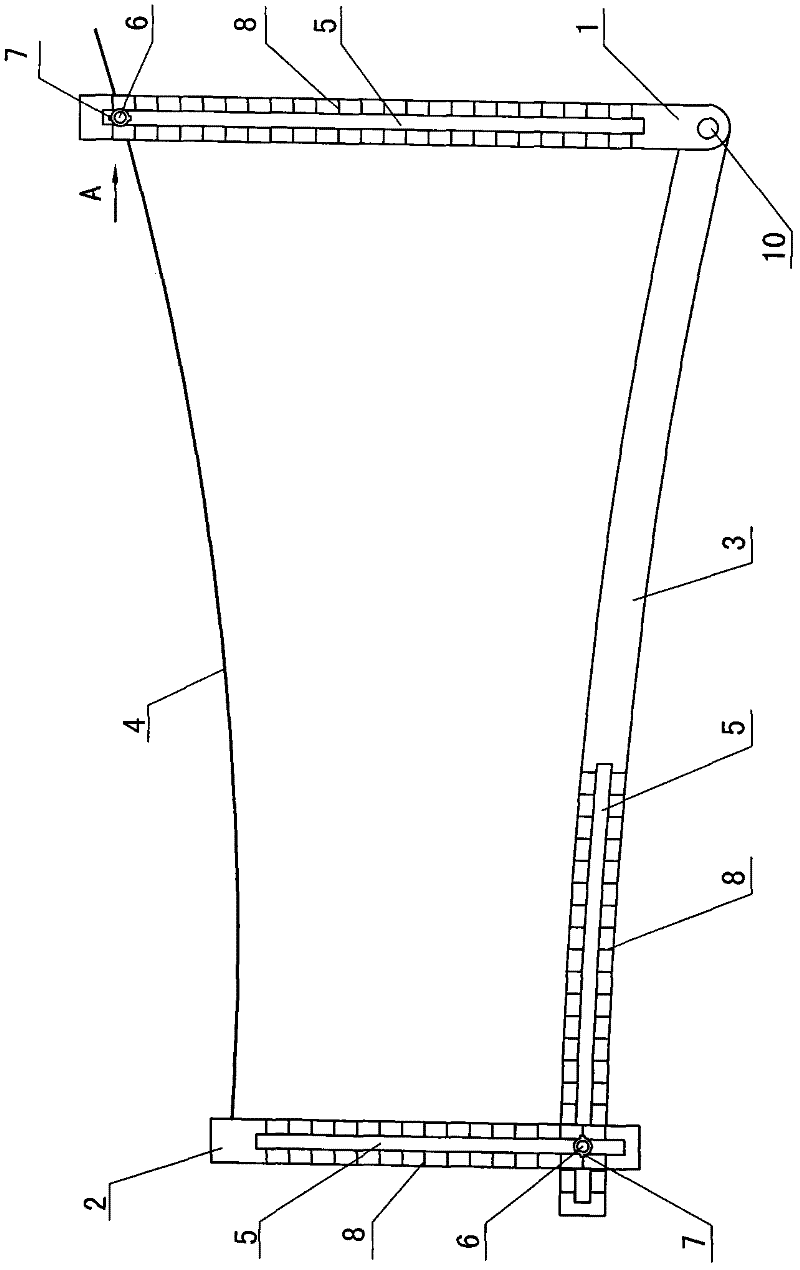

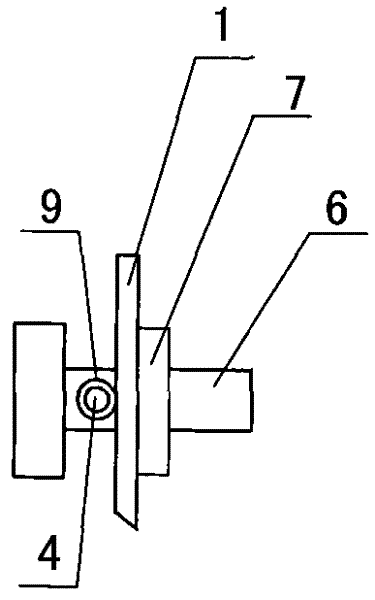

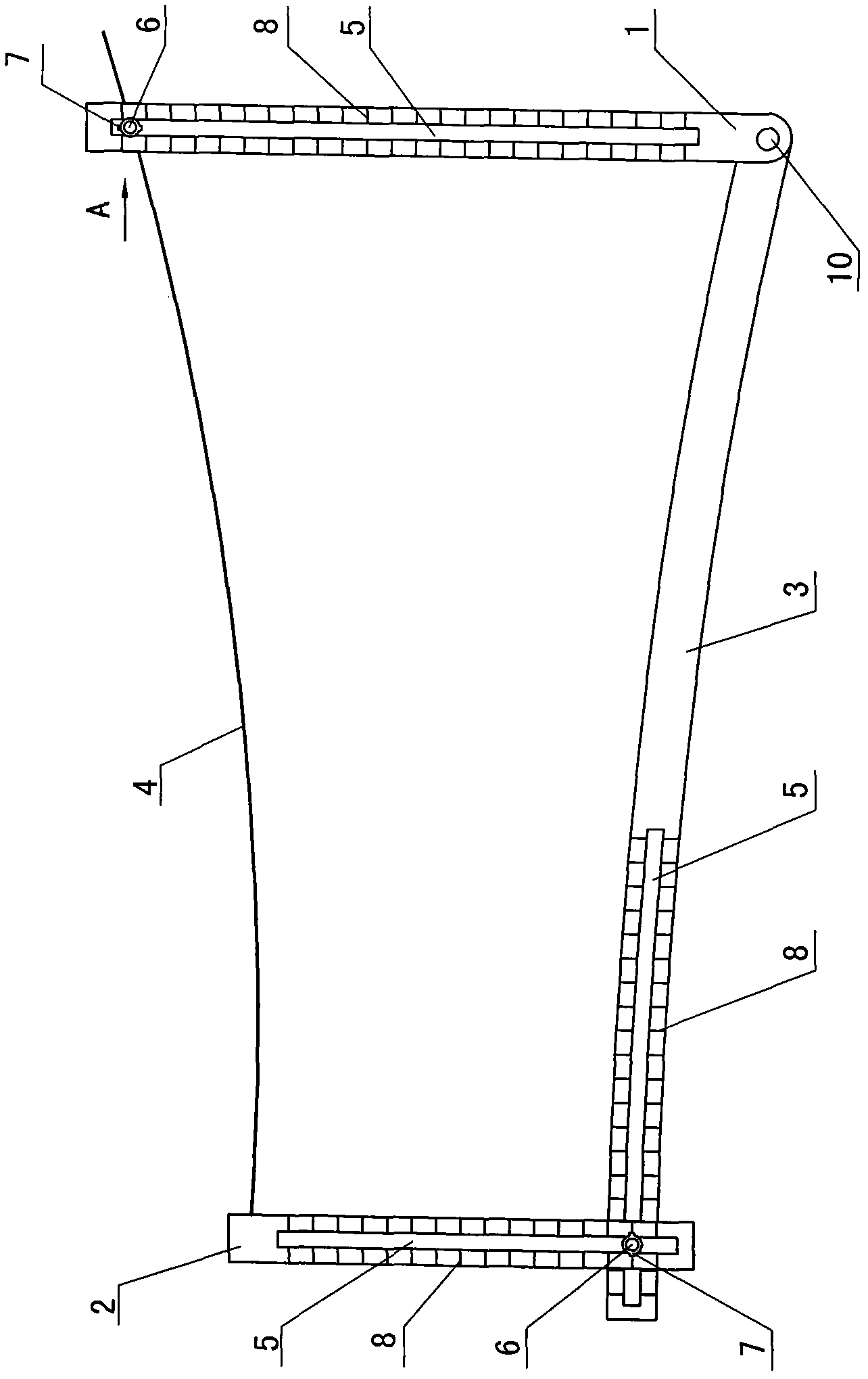

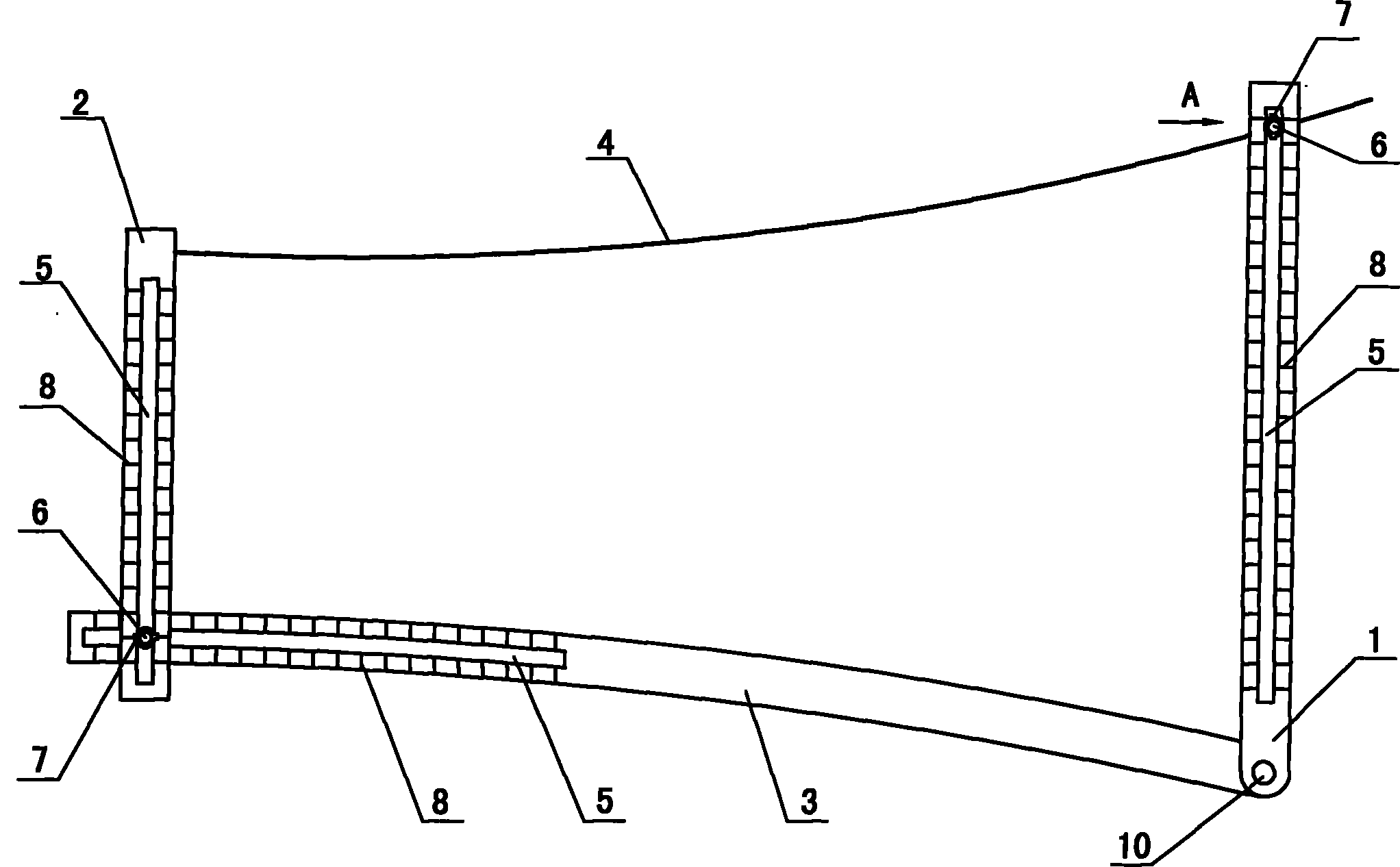

Clothing collar tailoring version ruler

ActiveCN101978913BAdjustment part sizeAdjust shapeClothes making applicancesSoftware engineeringEngineering

The invention provides a clothing collar tailoring version ruler. The clothing collar tailoring version ruler is characterized by comprising a long line version ruler for simulating the front edge of a collar, a short line version ruler for simulating the back center line of the collar, an arc-shaped version ruler for simulating the lower arc line of a collar circumference and an elastic adjusting rod for simulating the upper arc line of the collar circumference, wherein the long line version ruler, the short line version ruler and the arc-shaped version ruler are all provided with axial guide grooves; one end of the short line version ruler is fixedly connected with one end of the adjusting rod; the other end of the short line version ruler is connected with one end of the arc-shaped version ruler movably by regulating parts arranged in the two version rulers; the other end of the arc-shaped version ruler is connected with one end of the long line version ruler axially; and the otherend of the long line version ruler is connected with the other end of the elastic adjusting rod movably by an adjusting piece arranged in the guide groove. The clothing collar tailoring version rulercan change a size instantly by utilizing a clothing push board and a geometry structure principle and matching by the adjusting pieces, so as to fulfill the aim of adjusting the size of all parts of the collar and changing the shape of the collar; the clothing collar tailoring version ruler is convenient to operate; and the efficiency is high.

Owner:LUTAI TEXTILE

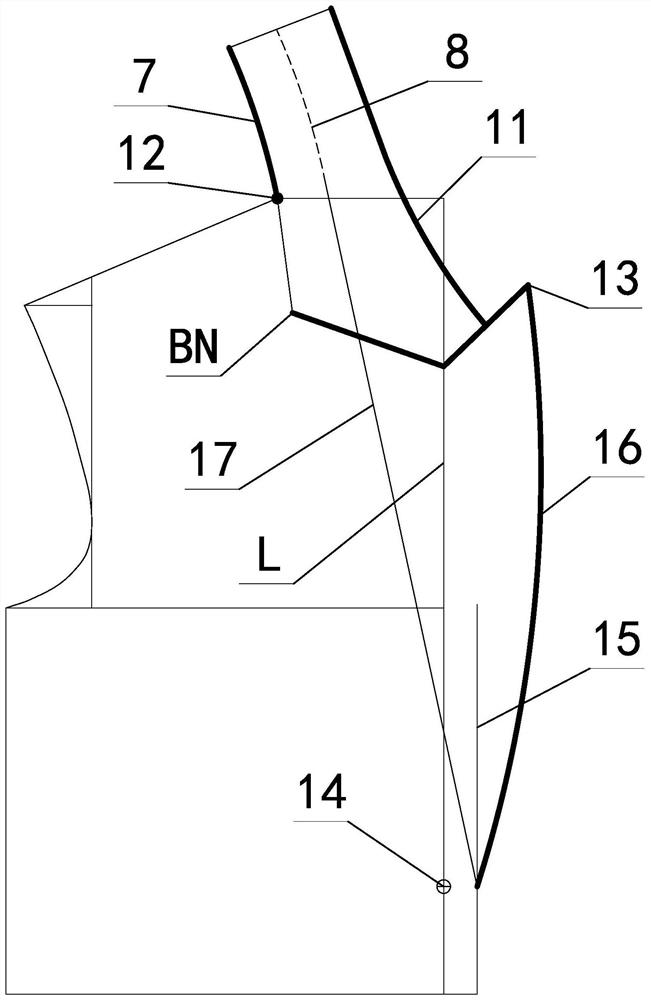

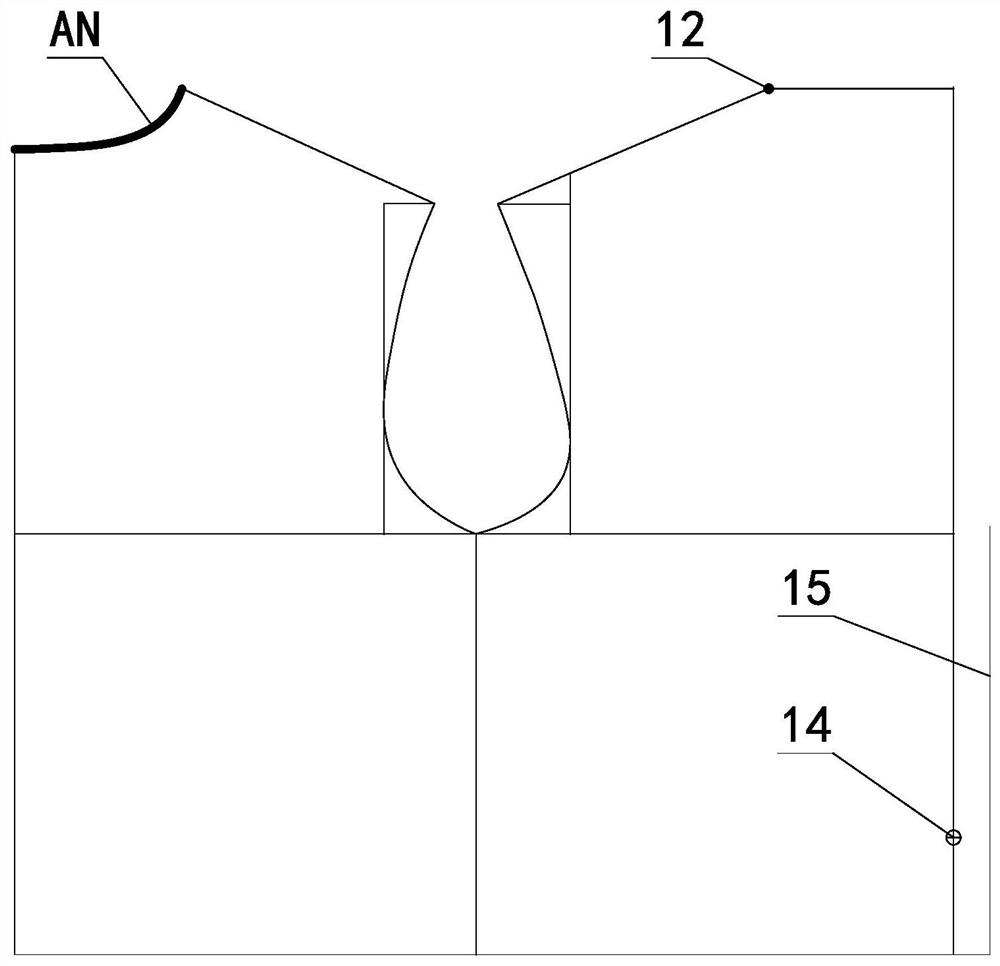

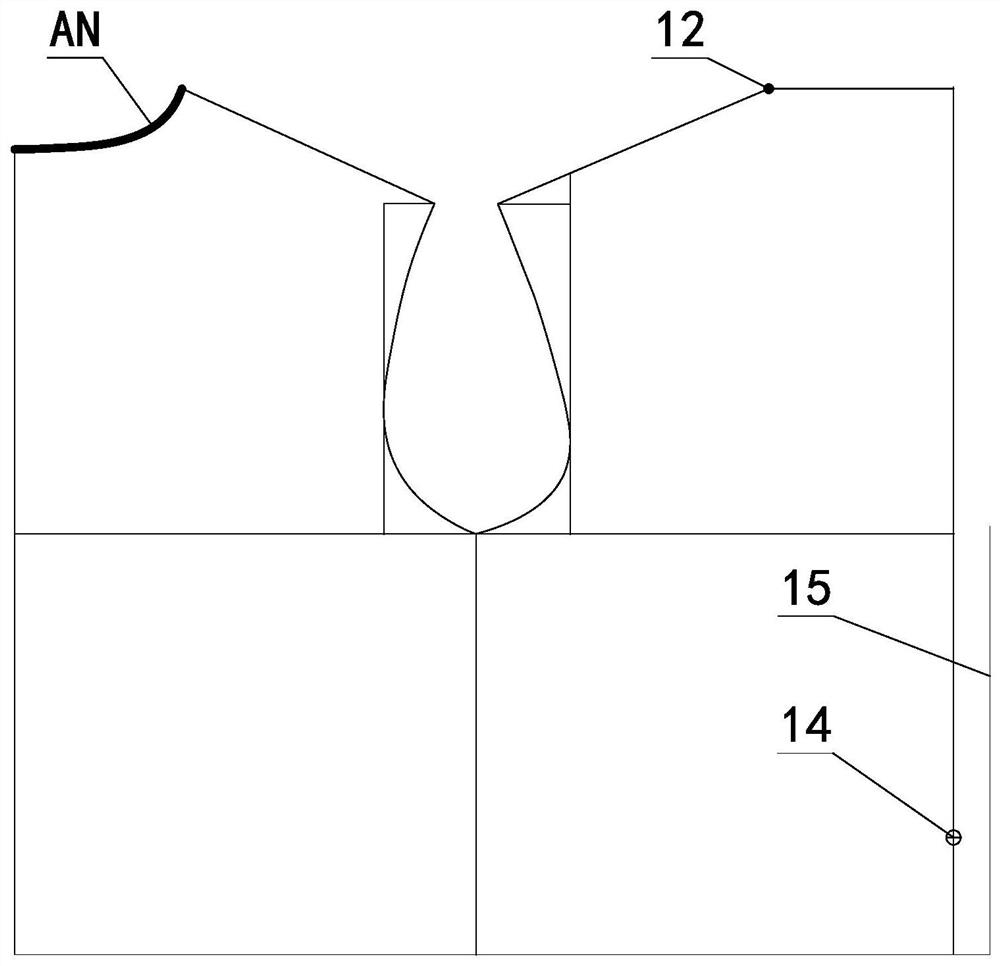

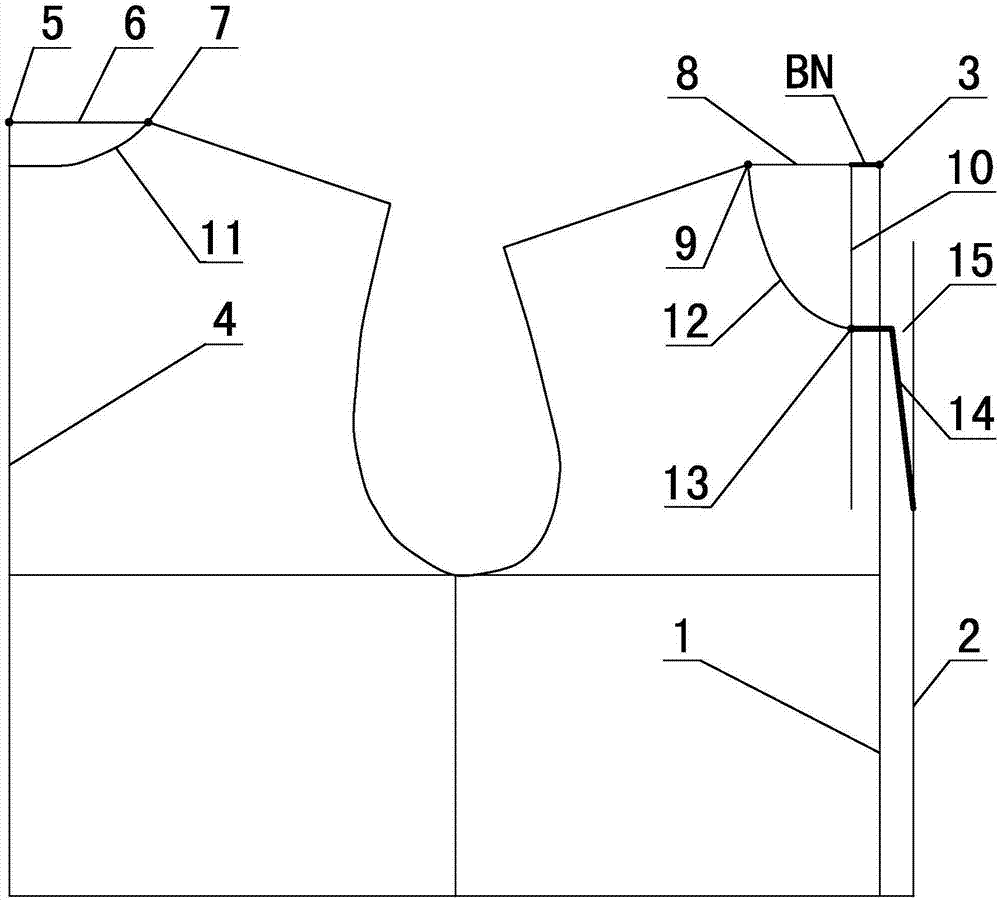

bn original number design and cutting method of garment skimming

ActiveCN106256276BEnsure human comfort requirementsEnsure design resultsClothes making applicancesEngineeringChest circumference

Owner:胡亨有

Original number tailoring method for clothing armhole

The invention relates to an original number tailoring method for a clothing armhole, which comprises the steps that original clothing numbers, namely the armhole perimeter, the chest width, the back width, the shoulder width, the chest circumference and the clothing length are determined according to anthropometric data; the armhole is designed into a notched ellipse; a diagonal line of an external rectangle of the notched ellipse is a perimeter mark hy; and the ratio of the perimeter mark hy to the armhole perimeter is y; an hy operational method is created; a base line of the external rectangle of the notched ellipse and an armhole circumflexion identification line are determined according to the original clothing numbers, such as the armhole perimeter, the chest width, the back width, the shoulder width and the chest circumference; then, relevant points are determined; and an armhole perimeter line is drawn. The armhole tailoring method is quick in tailoring and high in the precision of the armhole tailoring line, meets the fast-paced requirements of the clothing market on clothing transformation, is applicable to the tailoring of high-grade clothing, and is simple, convenient and practical.

Owner:NANJING JIHUA NO 3503 GARMENT

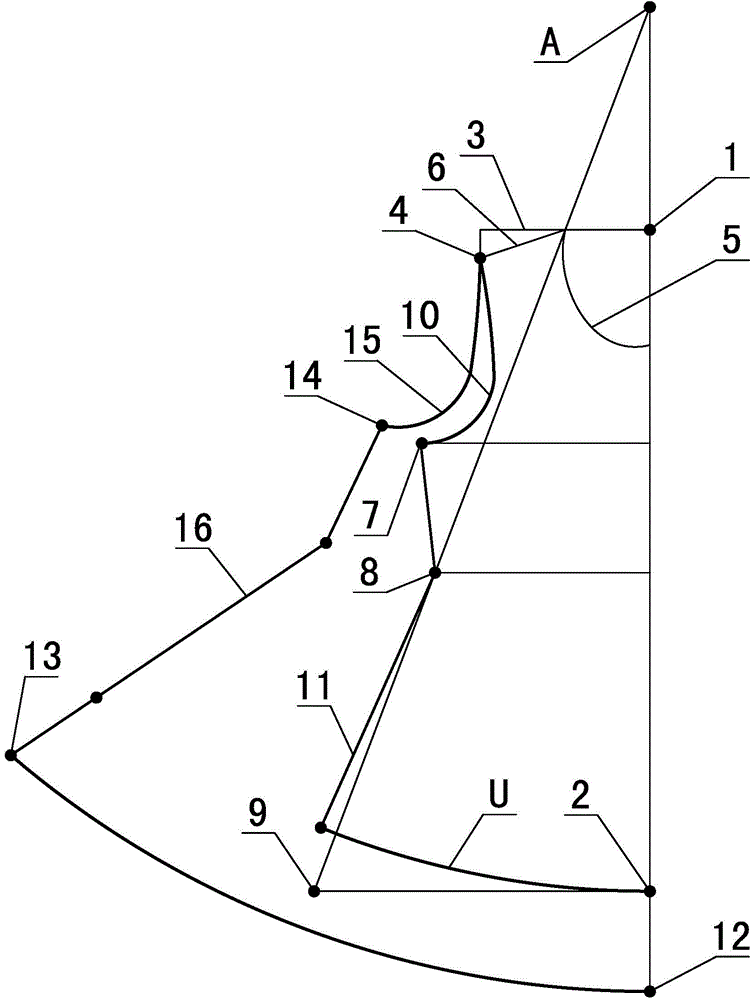

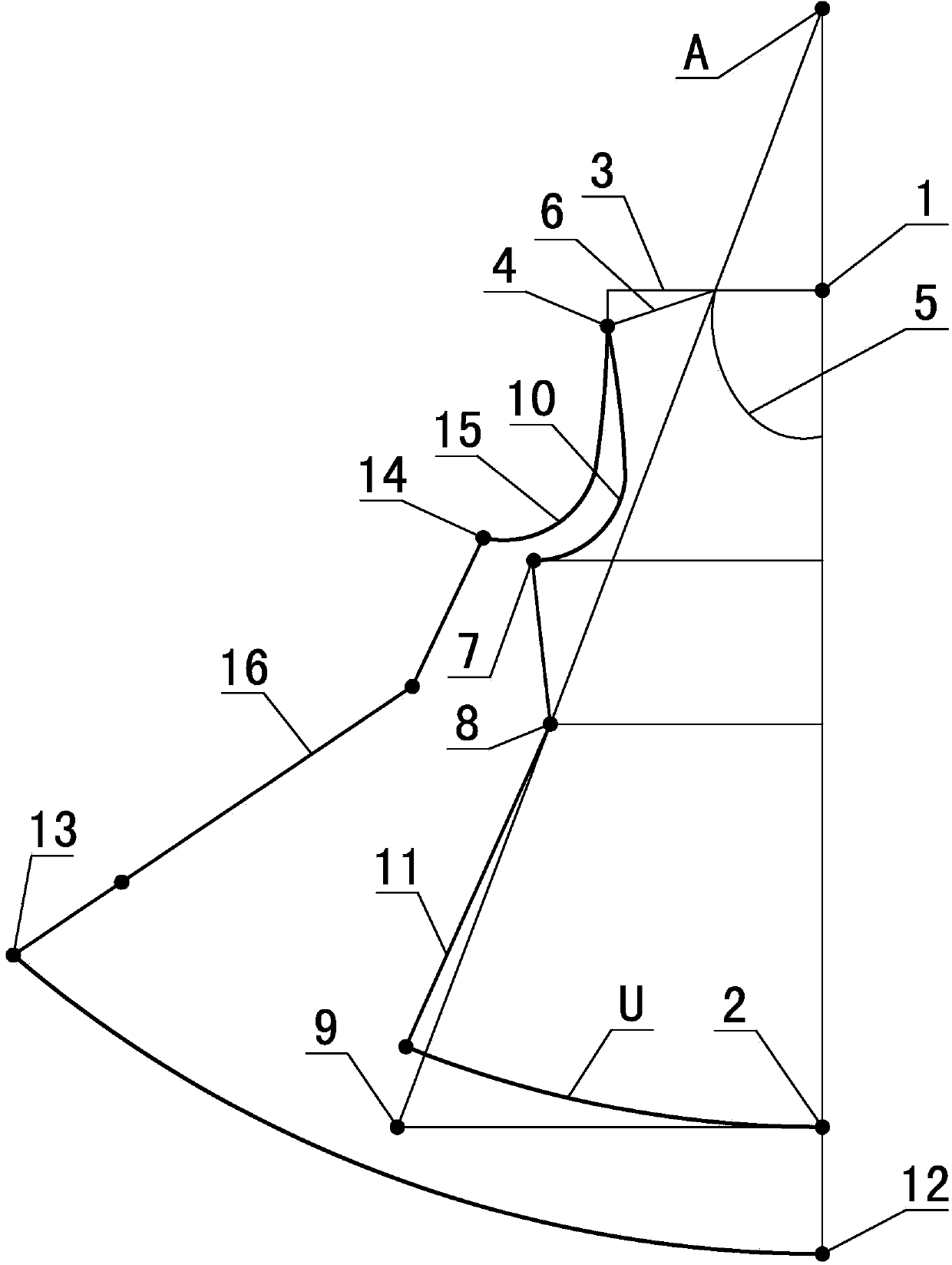

PJF original number tailoring method for garment puff sleeve top model

ActiveCN103622193BSatisfy the accuracy and speed requirementsCrop shortcutClothes making applicancesChest circumferenceBase line

The invention discloses a PJF original number tailoring method for a garment puff sleeve top model. The garment original numbers of the armhole perimeter, the sleeve length, the chest circumference and the like are determined according to human body measuring data, the puff sleeve top cardinal number P is determined according to the original armhole perimeter, and the sleeve top base line J and the sleeve width line F are combined, so that the puff sleeve top model is achieved. According to the method, drawing and tailoring are fast and high in accuracy, the requirements for precision and high speed of changing of garments on the garment market can be met, and the method is a simple and practical method for tailoring the garment puff sleeve top model.

Owner:苏州盛泽科技创业园发展有限公司

JF original number tailoring method of clothing raglan sleeve

ActiveCN103610252BIncrease uncertaintyCorrectly designedClothes making applicancesShoulder widthEngineering

The invention relates to a JF original number tailoring method of a clothing raglan sleeve. Clothing original numbers of the armhole perimeter, the sleeve length, the chest circumference, the shoulder width, the clothing length and the waist line height are determined according to human body measurement data; a sleeve top base line J and a sleeve width line F are used for guiding shaping of a sleeve top of a raglan sleeve piece through a shoulder piece dividing line, a shoulder line and an armhole arc line on a cloth piece. Designing, tailoring and manufacturing of a forming board for clothing with raglan sleeves can be carried out according to the clothing original numbers, and the JF original number tailoring method of the clothing raglan sleeve is simple, practical and convenient to carry out.

Owner:广州市佛伦斯实业有限责任公司

Clothing original number fud wool seam design and cutting method

ActiveCN106983206BSolve the complicated and cumbersome problem of repeated line drawingCrop shortcutClothes making applicancesEngineeringAnthropometric data

The invention discloses a clothing original number FUD fur sewing design cutting method. According to the measurement data of a human body, the clothing style and the sewing process, the original numbers of the clothing specifications for the sewing edge width, the bottom width, and the clothing length and the related parts are determined, the sewing edge is set as F, and the bottom edge is set as D. The cutting is designed using an additional sewing element value method, to make the sewing edge, the bottom edge and a hub element U to be produced in synchronization with a clothing cut piece, through the sewing process, the finished clothing equaling to the original numbers of the specifications are obtained, the process achieves the clothing original number FUD fur sewing design cutting method which meets the requirements of the apparel market for clothing cutting precision and speed.

Owner:胡亨有

Clothing collar tailoring version ruler

ActiveCN101978913AAdjustment part sizeAdjust shapeClothes making applicancesSoftware engineeringMiddle line

The invention provides a clothing collar tailoring version ruler. The clothing collar tailoring version ruler is characterized by comprising a long line version ruler for simulating the front edge of a collar, a short line version ruler for simulating the back center line of the collar, an arc-shaped version ruler for simulating the lower arc line of a collar circumference and an elastic adjusting rod for simulating the upper arc line of the collar circumference, wherein the long line version ruler, the short line version ruler and the arc-shaped version ruler are all provided with axial guide grooves; one end of the short line version ruler is fixedly connected with one end of the adjusting rod; the other end of the short line version ruler is connected with one end of the arc-shaped version ruler movably by regulating parts arranged in the two version rulers; the other end of the arc-shaped version ruler is connected with one end of the long line version ruler axially; and the other end of the long line version ruler is connected with the other end of the elastic adjusting rod movably by an adjusting piece arranged in the guide groove. The clothing collar tailoring version ruler can change a size instantly by utilizing a clothing push board and a geometry structure principle and matching by the adjusting pieces, so as to fulfill the aim of adjusting the size of all parts of the collar and changing the shape of the collar; the clothing collar tailoring version ruler is convenient to operate; and the efficiency is high.

Owner:LUTAI TEXTILE

Clothing neck line QY original data tailoring method automatically determining depth of open collar

ActiveCN103610254BImprove applicabilityHigh precisionClothes making applicancesShoulder widthEllipse

The invention discloses a clothing neck line QY original data tailoring method automatically determining depth of an open collar. Clothing original data of the neck line, the shoulder width, the clothes length and other parts are determined according to human body measurement data; the neck line is designed to be a circumference of an ellipse, the transverse radius of the ellipse is Q, the longitudinal diameter self control line of the ellipse is Y, and the fact that Y = the circumference of the ellipse / QY-Q is determined, the depth of the open collar is determined automatically according to the longitudinal height and the transverse width of the ellipse, and therefore the line marking, the tailoring and the plating of the neck line are achieved. According to the method, marking and tailoring are fast, precision is high, the requirements for fast changing of clothing by the clothing market can be met, and the clothing neck line QY original data tailoring method automatically determining the depth of the open collar is simple, practical and convenient to operate.

Owner:蒙阴世纪瑞凯服饰有限公司

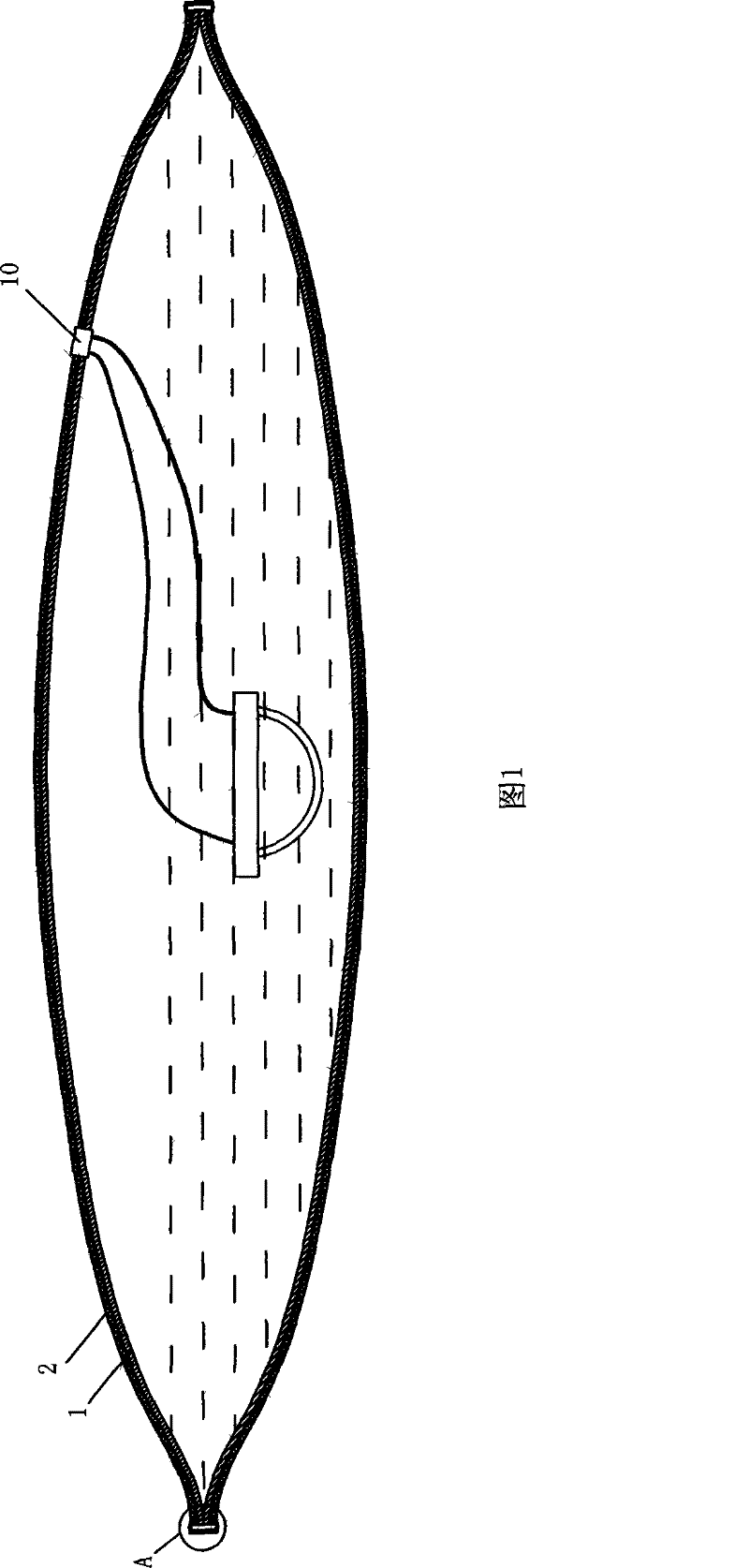

Electric warm water bag and manufacturing method therefor

InactiveCN101340742BWide range of choicesReduce manufacturing costOhmic-resistance heatingWarm waterMechanical engineering

The invention relates to an electric hot water bottle and a preparation method used for the electric hot water bottle. The electric hot water bottle of the invention comprises an independent software internal sleeve and an external sleeve; liquid is memorized in the internal sleeve; the edge of the internal sleeve is also provided with a first connecting part; the position on the external sleeve corresponding to the first connecting part is provided with a second connecting part which is matched with the first connecting part; the first connecting part and the second connecting part are fixedly connected directly with each other between the internal sleeve and the external sleeve by a fixed part, thus leading the connection of the edge of the internal sleeve and the corresponding external sleeve to be non-splittable structure. The electric hot water bag of the structure adopts an independent software internal sleeve, namely, the internal sleeve is individually formed; furthermore, the edge of the internal sleeve and the external sleeve are fixedly connected with each other by the fixed part in a non-splittable way; therefore, the external sleeve can select normal face fabric cloth as the material and has wide selection range; the preparation cost is reduced, furthermore, the type and pattern of the normal face fabric cloth can be designed as diversity so as to enhance the sense of beauty.

Owner:广东美美创新电器有限公司

Automatic paper laying machine

ActiveCN103387071BGood compression effectLess prone to deflectionPackagingArticle deliveryMachine shopPulp and paper industry

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

The variable ratio original number cutting method of clothing shoulder dart

ActiveCN104585942BCrop shortcutImprove comfortClothes making applicancesShoulder widthWaist Circumferences

The invention discloses a clothing shoulder-bust dart variant ratio original number clipping method. According to the method, garment measurements of shoulder breadth, chest circumference, waistline, chest breadth and armhole circumference are determined according to the clothing type requirement and human body measuring data, the chest-waist difference is determined to be BW, the shoulder-bust dart variant ratio coefficient is determined to be 10:BW', and the amount of the shoulder-bust dart changing along with changes of clothing types and models is obtained through a shoulder bust dart tip, a dart position mark, a shoulder-bust dart variant ratio coefficient line BW', a dart length line A and a dart opening line C. By means of the clothing shoulder-bust dart variant ratio original number clipping method, the problems existing in a clipping method that clothing of multiple models are clipped by the same volume of shoulder-bust dart are solved, and the method has very high practical value.

Owner:苏州盛泽科技创业园发展有限公司

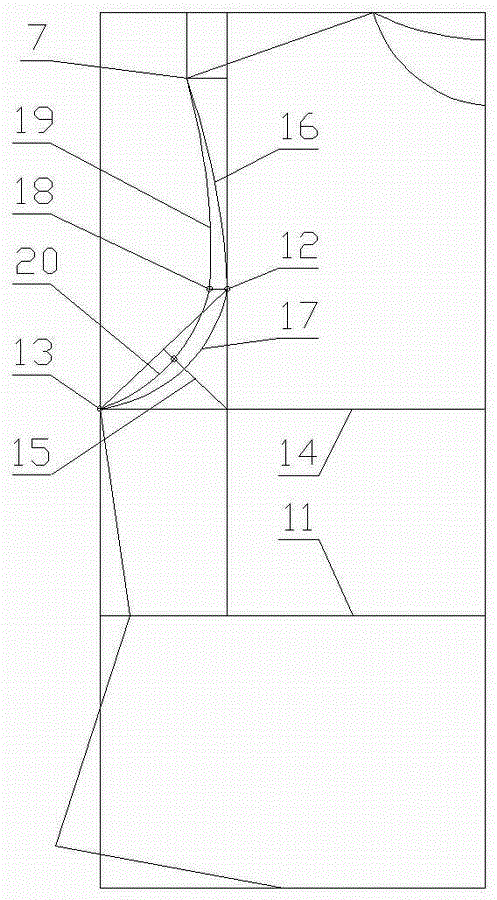

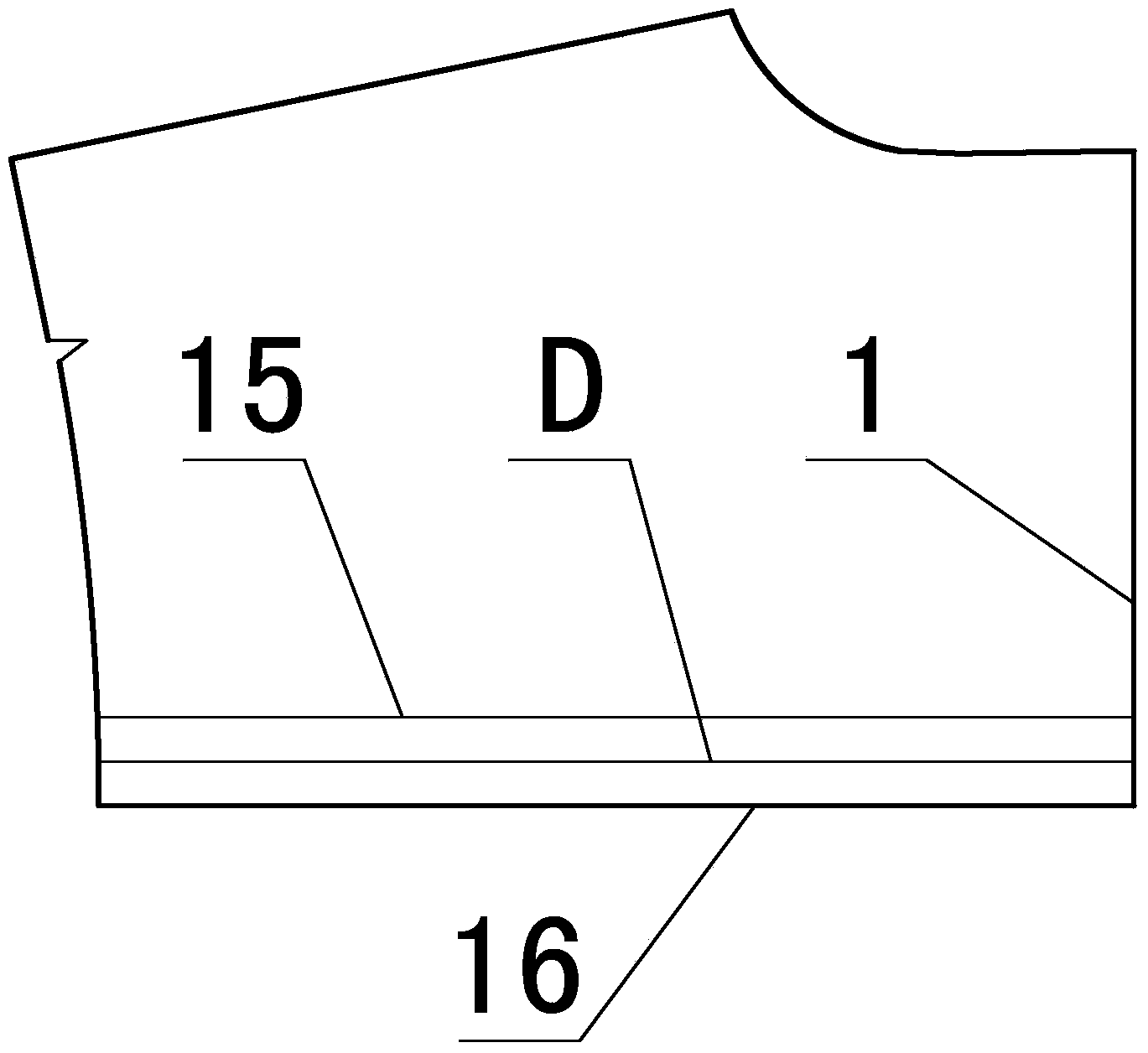

KND original number tailoring method of clothing shoulder piece

ActiveCN103610256BImprove comfortCrop shortcutClothes making applicancesHuman bodyPhysical medicine and rehabilitation

The invention discloses a KND clothing original number tailoring method of a clothing shoulder piece. Clothing original numbers of the shoulder width, the front overlap width, the collar length, the armhole, the chest circumference, the clothing length and the like are determined according to human body measurement data. Shoulder piece dividing is directly achieved in a clothing piece forming board supported by the clothing original numbers by a front shoulder dividing line K and a shoulder piece rear dividing line D. The KND clothing tailoring method is accurate and fast in drawing and tailoring, the clothing comfort degree is high, the requirement for fast changing of clothing of a clothing market can be met, and the KND clothing tailoring method of the clothing shoulder piece is simple, practical and convenient to use.

Owner:苏州盛泽科技创业园发展有限公司

Two-step cutting method and jig for Mini BOX tube leg cutting

The invention provides a two-step type cutting method and jig for cutting Mini BOX tube legs, and the method comprises the following steps: designing a jig which can fix Mini BOX and is provided with a horizontal tool bit and a vertical tool bit for cutting; the method comprises the following steps: firstly, cutting two sides of a MiniBOX tube leg side skirt in the first step by a vertical tool bit; and (3) finally, a horizontal tool bit is used for cutting the bottom of the side skirt of the MiniBOX pipe leg. The simple mechanical structure design is utilized through two-step cutting, operation is easy, the time for installing and fixing the pipe base can be greatly shortened, and an operator can conveniently and rapidly complete installation and fixing of the pipe base. Therefore, smooth production is greatly guaranteed, productivity is guaranteed, cost is saved, and material loss is avoided.

Owner:辽宁优迅科技有限公司

The Variable Ratio Original Number Cutting Method of Clothing Side Darts

The invention discloses a variance-ratio original-number cutting method for a clothes side breast dart. The method comprises the following steps: determining the clothes specifications of chest circumference, waist circumference, shoulder width, chest width and armhole circumference according to the requirement on clothes style and human body measurement data; determining that the chest-waist difference is BW and the side breast dart variance-ratio coefficient is 10:BW'; acquiring the side breast dart amount which varies along with the style and model variations of the clothes according to a side breast dart point, a dart opening point, a side breast dart variance-ratio coefficient line BW', a dart length line A and a dart opening line C. By adopting the method, a large number of problems existing in a cutting method which applies an identical side breast dart amount to clothes of various models in the prior art are effectively solved, and a very high practical value is achieved.

Owner:苏州盛泽科技创业园发展有限公司

XE original number tailoring method of clothing chest and shoulder difference

ActiveCN103610253BMeet growth requirementsImprove comfortClothes making applicancesShoulder widthHuman body

Owner:苏州盛泽科技创业园发展有限公司

JFT original number tailoring method of clothing sleeve top shape

ActiveCN103610251BHigh precisionComfortable to wearClothes making applicancesChest circumferenceBase line

The invention relates to a JFT original number tailoring method of a clothing sleeve top shape. Clothing original numbers of specifications such as the armhole perimeter, the sleeve length and the chest circumference are determined according to human body measurement data and clothing styles. The sleeve shape is finished by arranging a sleeve top base line J, a sleeve width line F and a sleeve top guiding line T. The method is proved to be reasonable and feasible according to practice. According to the JFT original number tailoring method for the clothing sleeve top shape, sleeve top shapes needed by various clothing styles and sizes can be obtained according to the clothing original numbers directly, and the JFT original number tailoring method of the clothing sleeve top shape is simple, practical and convenient to use.

Owner:绍兴市熠绦纺织服饰科技有限公司

Dress and skirt hem same-type transferred UA original number tailoring method

ActiveCN103622192BImprove the three-dimensional effectSatisfy the accuracy and speed requirementsClothes making applicancesShoulder widthEngineering

The invention discloses a dress and skirt hem same-type transferred UA original number tailoring method. Clothing original numbers of the size of a skirt hem, the length of a dress and skirt, the half shoulder width, the shoulder point height, the armhole depth, the 1 / 4 chest circumference, the 1 / 4 waistline, the waist line height and other portion specifications are determined according to anthropological measuring data; inside and outside same-type transferring of the circular arm type skirt hem is achieved due to the fact that a dress and skirt original point A is determined according to the skirt hem. According to the tailoring method, tailoring is rapid and high in precision, the requirement of garment markets for clothes rapid conversion can be met, and the original number tailoring method is simple and practical.

Owner:苏州盛泽科技创业园发展有限公司

Dress and skirt hem same-type transferred UA original number tailoring method

ActiveCN103622192AImprove applicabilityImprove comfortClothes making applicancesShoulder widthEngineering

The invention discloses a dress and skirt hem same-type transferred UA original number tailoring method. Clothing original numbers of the size of a skirt hem, the length of a dress and skirt, the half shoulder width, the shoulder point height, the armhole depth, the 1 / 4 chest circumference, the 1 / 4 waistline, the waist line height and other portion specifications are determined according to anthropological measuring data; inside and outside same-type transferring of the circular arm type skirt hem is achieved due to the fact that a dress and skirt original point A is determined according to the skirt hem. According to the tailoring method, tailoring is rapid and high in precision, the requirement of garment markets for clothes rapid conversion can be met, and the original number tailoring method is simple and practical.

Owner:苏州盛泽科技创业园发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com