Clothing collar tailoring version ruler

A technology of a ruler and a collar, applied in the field of clothing cutting tools, can solve the problems that the ruler is not suitable for storage, inconvenient for enterprises, violated, etc., and achieves the effect of saving ruler paper and storage space, accurate size scaling, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

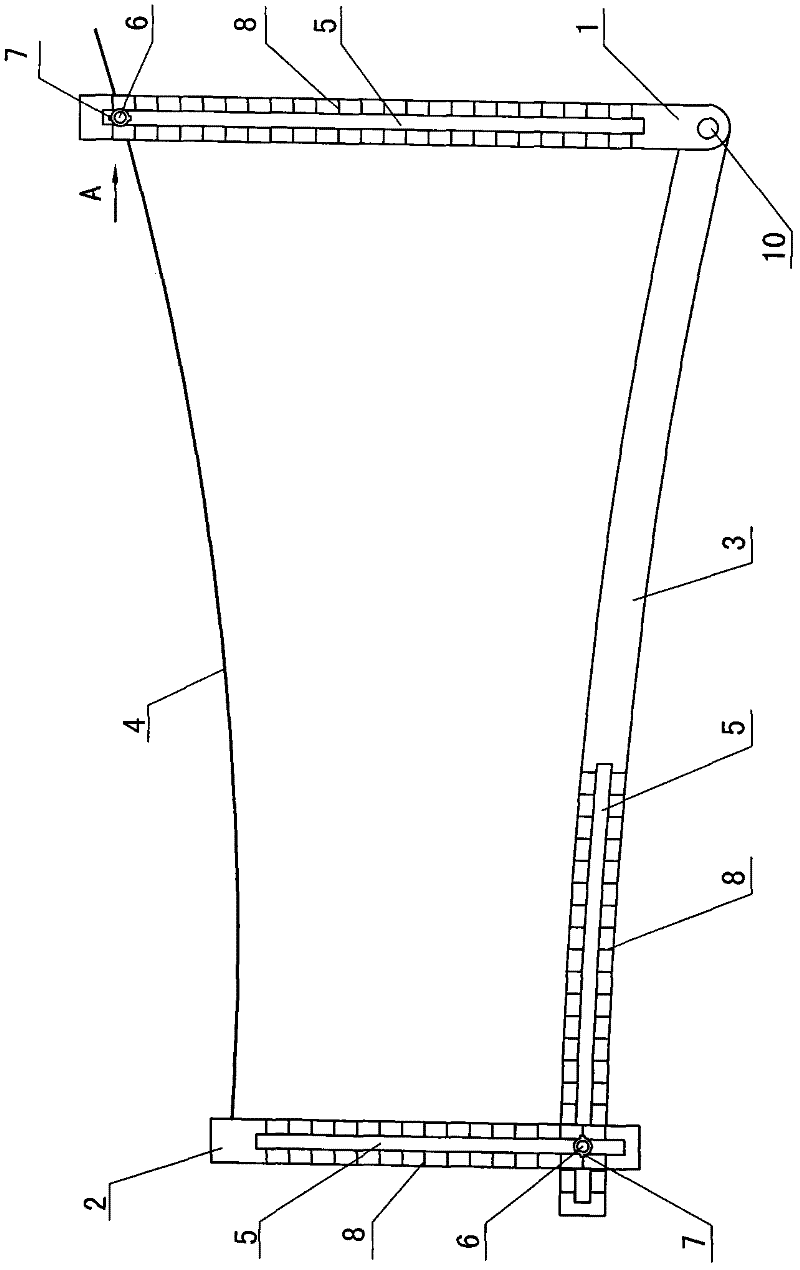

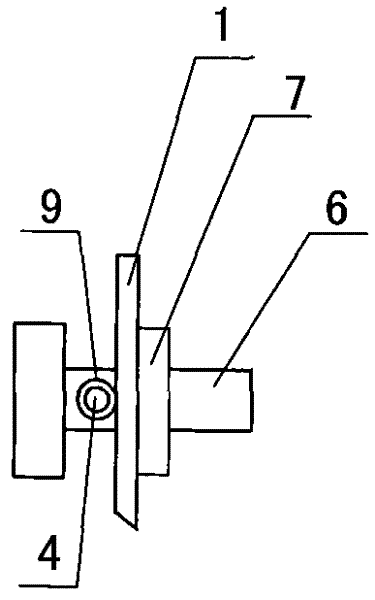

[0016] exist Figure 1-2 In the shown embodiment: the long straight-line ruler 1 simulates the front stop of the collar, the short straight-line ruler 2 simulates the rear midline of the collar, the arc-shaped ruler 3 simulates the lower arc of the collar, and the elastic adjustment rod 4 simulates the upper collar arc, wherein the long straight line ruler 1, the short straight line ruler 2 and the curved version ruler 3 are all provided with an axial guide groove 5, and both sides of the guide groove 5 are provided with a scale 8. One end of the short straight-line ruler 2 is fixedly connected with one end of the adjusting rod, and the other end of the short straight-line ruler 2 is connected with one end of the arc-shaped ruler 3 through the screw rod 6 and the nut 7 arranged in the guide grooves 5 of the above-mentioned two rulers. Connection, wherein the screw rod 6 vertically passes through the guide groove 5 on the above two version rulers, and can slide in the guide gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com