Two-step cutting method and jig for Mini BOX tube leg cutting

A technology of tube legs and fixtures, applied in the field of optical communication, can solve problems such as high risk and inability to carry out the mounting process, and achieve the effects of avoiding material loss, ensuring production capacity, and solving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

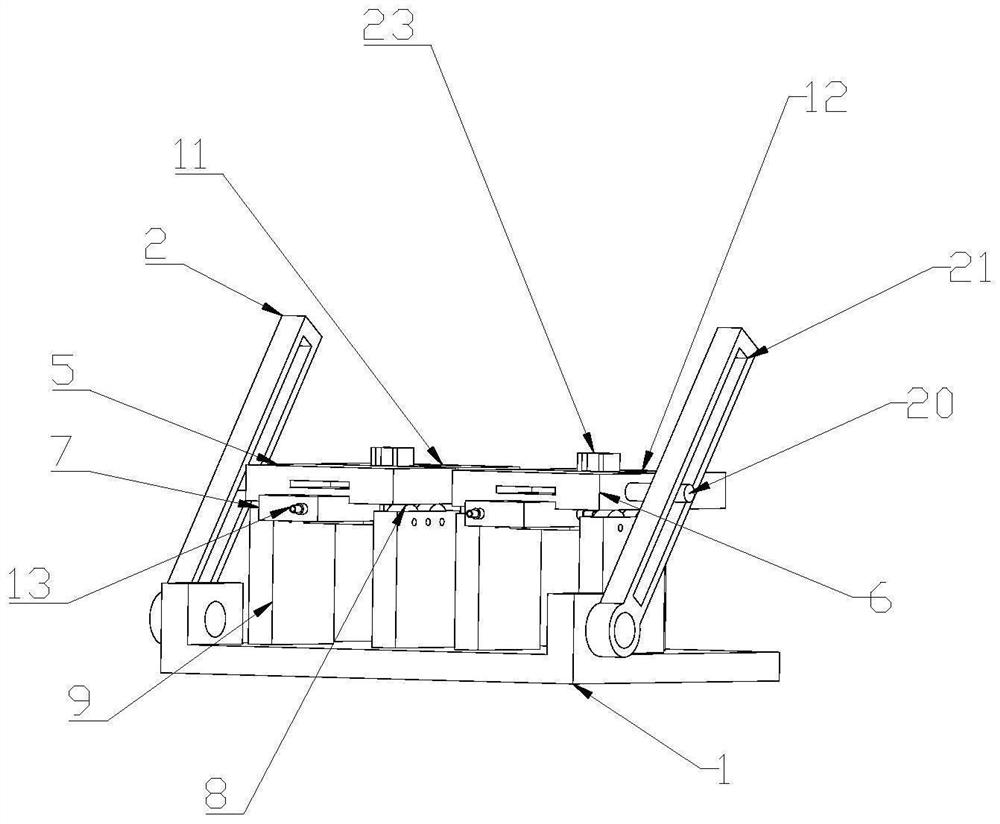

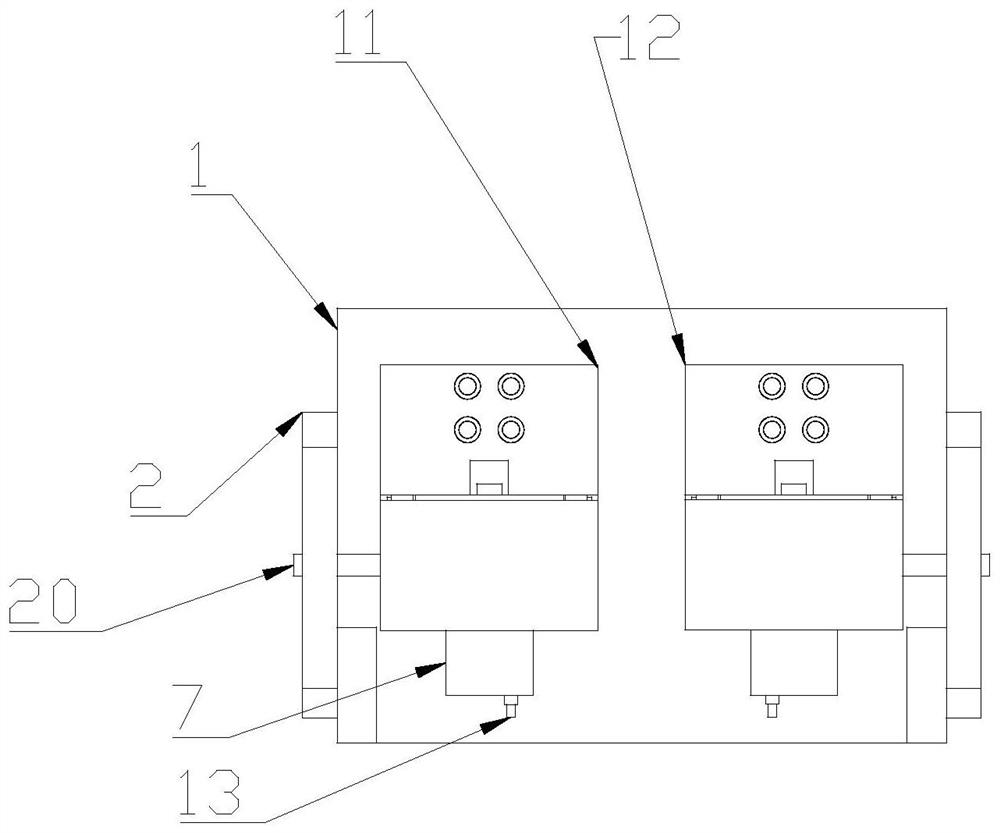

[0046] The specific embodiments provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0047] A two-step cutting method for the cutting of Mini BOX tube legs, comprising the following steps:

[0048] 1) Design a jig that can fix the Mini BOX and has a horizontal cutter head 3 and a vertical cutter head 4 for cutting;

[0049] 2) First, the vertical cutter head 4 completes the cutting on both sides of the Mini BOX tube leg side skirt 27 in the first step;

[0050] 3) Finally, use the horizontal cutter head 3 to complete the cutting of the bottom of the Mini BOX tube leg side skirt 27 in the second step.

[0051] like Figure 1-15 As shown in the figure, a jig for the cutting of Mini BOX tube legs, including a base 1, a grip rod 2, a horizontal cutter head tube seat placement table 11, a vertical cutter head tube seat placement table 12, a horizontal cutter head moving table 5, a horizontal cutter head cutter head 3, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com