Why is PVDF Used for Membranes? Discover The Benefits of PVDF Membranes

PVDF Membrane Evolution

PVDF membrane technology has undergone significant evolution since its inception in the 1960s. Initially developed for industrial applications, PVDF membranes have steadily expanded their reach into various sectors, including water treatment, pharmaceuticals, and biotechnology.

The early stages of PVDF membrane development focused primarily on improving mechanical strength and chemical resistance. Researchers experimented with different polymer compositions and manufacturing techniques to enhance the membrane's durability and performance. By the 1980s, PVDF membranes had gained recognition for their exceptional chemical stability and resistance to chlorine, making them particularly valuable in water treatment applications.

The 1990s saw a shift towards optimizing the pore structure and surface properties of PVDF membranes. Scientists developed techniques to create more uniform pore sizes and distributions, leading to improved filtration efficiency and selectivity. This period also marked the introduction of hydrophilic modifications to PVDF membranes, addressing the inherent hydrophobicity of the material and expanding its applicability in aqueous environments.

In the early 2000s, nanotechnology began to play a crucial role in PVDF membrane evolution. Researchers incorporated nanoparticles and nanofibers into the membrane structure, enhancing properties such as fouling resistance, flux, and selectivity. This era also saw the development of composite PVDF membranes, combining the strengths of PVDF with other materials to create high-performance filtration solutions.

The past decade has witnessed a focus on sustainability and energy efficiency in PVDF membrane technology. Efforts have been made to reduce the environmental impact of membrane production and improve the energy efficiency of membrane-based processes. Additionally, researchers have explored the potential of PVDF membranes in emerging applications, such as energy storage and gas separation.

Recent advancements in PVDF membrane technology include the development of self-cleaning and antifouling membranes, as well as the integration of smart materials for responsive filtration systems. These innovations aim to address long-standing challenges in membrane performance and longevity, particularly in demanding industrial environments.

Looking ahead, the evolution of PVDF membranes is likely to continue along several key trajectories. These include further improvements in membrane durability and lifespan, the development of more selective and efficient filtration capabilities, and the integration of advanced materials and technologies to create multifunctional membrane systems. As environmental concerns and resource scarcity become increasingly pressing, PVDF membranes are expected to play a crucial role in addressing global challenges related to water treatment, energy production, and sustainable manufacturing processes.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) membranes has been experiencing significant growth across various industries due to their unique properties and versatile applications. The global PVDF membrane market is projected to expand at a robust rate, driven by increasing adoption in water treatment, pharmaceuticals, and food and beverage sectors.

In the water treatment industry, PVDF membranes are gaining traction due to their excellent chemical resistance, high mechanical strength, and superior filtration capabilities. The growing need for clean water, coupled with stringent environmental regulations, is fueling the demand for advanced membrane technologies. PVDF membranes are particularly sought after for their ability to effectively remove contaminants and microorganisms from water, making them ideal for both industrial and municipal water treatment applications.

The pharmaceutical sector represents another key market for PVDF membranes. These membranes are extensively used in drug manufacturing processes, particularly in sterile filtration and bioprocessing applications. The increasing focus on biopharmaceuticals and the need for high-purity products are driving the adoption of PVDF membranes in this sector. Additionally, the growing emphasis on quality control and regulatory compliance in pharmaceutical manufacturing is further boosting the demand for reliable filtration solutions.

In the food and beverage industry, PVDF membranes are finding widespread use in various processes, including clarification, concentration, and purification. The rising consumer demand for high-quality, safe food products is propelling the need for advanced filtration technologies. PVDF membranes offer excellent performance in terms of product quality, process efficiency, and cost-effectiveness, making them a preferred choice for many food and beverage manufacturers.

The electronics industry is also emerging as a significant market for PVDF membranes. These membranes are used in the production of lithium-ion batteries, where they serve as separators. With the growing demand for electric vehicles and portable electronic devices, the market for PVDF membranes in this sector is expected to witness substantial growth in the coming years.

Geographically, Asia Pacific is anticipated to be the fastest-growing market for PVDF membranes, driven by rapid industrialization, urbanization, and increasing investments in water treatment infrastructure. North America and Europe are also significant markets, with a strong focus on technological advancements and stringent environmental regulations driving adoption.

Overall, the market demand for PVDF membranes is poised for continued growth, fueled by their superior performance characteristics, expanding applications across diverse industries, and the global push towards sustainable and efficient processes. As research and development efforts continue to enhance the properties and applications of PVDF membranes, their market potential is expected to expand further, opening up new opportunities across various sectors.

PVDF Membrane Challenges

Despite the numerous advantages of PVDF membranes, several challenges persist in their development and application. These challenges primarily stem from the inherent properties of PVDF and the complex requirements of various filtration processes.

One of the main challenges is the hydrophobic nature of PVDF. While this property is beneficial in certain applications, it can lead to membrane fouling and reduced flux in aqueous environments. The hydrophobicity can cause organic molecules and particles to adhere to the membrane surface, decreasing its efficiency over time. This necessitates frequent cleaning and maintenance, which can increase operational costs and downtime.

Another significant challenge is the limited chemical resistance of PVDF membranes to certain solvents and extreme pH conditions. Although PVDF exhibits excellent resistance to many chemicals, it can be degraded by strong bases, amines, and some organic solvents. This limitation restricts its use in certain industrial processes where such chemicals are prevalent, requiring careful consideration of the operating environment.

The mechanical strength of PVDF membranes, while generally good, can be a limiting factor in high-pressure applications. As filtration processes become more demanding, there is a need for membranes that can withstand higher pressures without compromising their integrity or performance. Enhancing the mechanical properties of PVDF membranes without sacrificing their other beneficial characteristics remains a challenge for researchers and manufacturers.

Temperature stability is another area of concern. While PVDF membranes perform well in a wide range of temperatures, they can experience thermal degradation at elevated temperatures, particularly above 150°C. This limits their application in high-temperature processes and necessitates the development of more thermally stable PVDF formulations or alternative materials for such environments.

The production of PVDF membranes with consistent pore size and distribution across large surface areas is also challenging. Achieving uniformity in membrane structure is crucial for ensuring consistent filtration performance, but it becomes increasingly difficult as membrane sizes increase. This challenge is particularly relevant in industrial-scale applications where large membrane areas are required.

Lastly, the environmental impact of PVDF membrane production and disposal is an emerging concern. As sustainability becomes a key focus across industries, there is a growing need to develop more eco-friendly production processes and end-of-life solutions for PVDF membranes. This includes addressing issues related to the use of solvents in membrane fabrication and the recyclability of used membranes.

Current PVDF Solutions

01 Chemical resistance and durability

PVDF membranes offer excellent chemical resistance and durability, making them suitable for harsh environments and prolonging their operational lifespan. They can withstand exposure to various chemicals, acids, and solvents, maintaining their structural integrity and performance over time.- Chemical resistance and durability: PVDF membranes offer excellent chemical resistance and durability, making them suitable for various applications in harsh environments. They can withstand exposure to a wide range of chemicals, acids, and solvents, ensuring long-lasting performance and reliability in filtration and separation processes.

- High thermal stability: PVDF membranes exhibit high thermal stability, allowing them to maintain their structural integrity and performance at elevated temperatures. This property makes them ideal for use in high-temperature applications, such as industrial processes and energy storage systems.

- Excellent filtration efficiency: PVDF membranes provide superior filtration efficiency due to their unique pore structure and surface properties. They can effectively remove contaminants, particles, and microorganisms from various liquids and gases, making them valuable in water treatment, pharmaceutical, and biotechnology applications.

- Hydrophobic and oleophobic properties: PVDF membranes possess both hydrophobic and oleophobic characteristics, allowing them to repel water and oils. This property makes them useful in applications requiring selective separation of liquids, such as oil-water separation and membrane distillation processes.

- Versatility in membrane modification: PVDF membranes can be easily modified to enhance their properties or introduce new functionalities. Surface modification techniques, such as grafting or coating, can be applied to improve hydrophilicity, antifouling properties, or add specific chemical groups for targeted applications in various industries.

02 High filtration efficiency

PVDF membranes provide high filtration efficiency, effectively removing contaminants and particles from liquids and gases. Their porous structure allows for precise control of pore size, enabling selective filtration of various substances while maintaining high flow rates.Expand Specific Solutions03 Thermal stability

PVDF membranes exhibit excellent thermal stability, allowing them to operate effectively across a wide range of temperatures. This property makes them suitable for applications in both high and low-temperature environments, maintaining their structural integrity and performance.Expand Specific Solutions04 Hydrophobic and oleophobic properties

PVDF membranes possess both hydrophobic and oleophobic properties, making them resistant to water and oil-based substances. This characteristic enhances their ability to separate different phases and improves their overall filtration performance in various applications.Expand Specific Solutions05 Versatility in applications

PVDF membranes offer versatility in various applications, including water treatment, gas separation, pharmaceutical processing, and biotechnology. Their unique properties make them suitable for use in diverse industries, providing effective solutions for filtration and separation challenges.Expand Specific Solutions

Key PVDF Manufacturers

The PVDF membrane market is in a growth phase, driven by increasing demand in water treatment, pharmaceuticals, and industrial applications. The global market size is projected to expand significantly, with key players like Arkema, Pall Corp., and Evoqua Water Technologies leading innovation. Technological maturity varies across applications, with companies such as Solvay, Toray Advanced Materials, and W. L. Gore & Associates pushing boundaries in membrane performance and durability. Research institutions like Zhejiang University and Nanjing Tech University are contributing to advancements in PVDF membrane technology, while collaborations between industry and academia are accelerating development in this competitive landscape.

Arkema, Inc.

Pall Corp.

PVDF Membrane Innovations

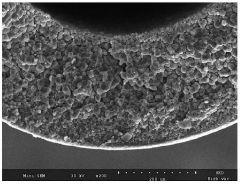

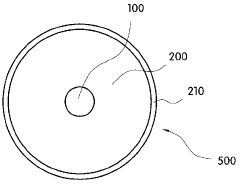

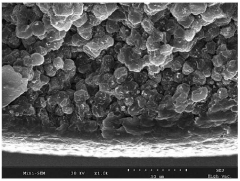

- A PVDF hollow fiber membrane design featuring a support layer with a spherulite-like structure and a selective layer with a cross-sectional thickness of 5% or less of the total thickness, along with specific diameter and pore size ranges, to enhance mechanical strength and water permeability.

- The development of microporous PVDF membranes with a lattice of filamentous webs, featuring a gradient of pore sizes from a microporous surface to a coarse pore surface, and the use of polyvinylpyrrolidone (PVP) and hydroxypropylcellulose (HPC) to enhance hydrophilicity and structural integrity, along with a method involving casting, exposure to humid air, and quenching in a water bath to create membranes with exceptional flow rates and porosity.

Environmental Impact

The environmental impact of PVDF membranes is a critical consideration in their widespread adoption across various industries. PVDF membranes offer several environmental benefits that contribute to their popularity in filtration and separation processes.

One of the primary environmental advantages of PVDF membranes is their exceptional chemical resistance. This property allows them to withstand harsh chemical environments, reducing the need for frequent replacements and minimizing waste generation. The durability of PVDF membranes translates to a longer operational lifespan, which in turn reduces the overall environmental footprint associated with membrane production and disposal.

PVDF membranes also demonstrate excellent thermal stability, enabling their use in high-temperature applications. This characteristic allows for more efficient processes in industries such as wastewater treatment and chemical processing, potentially reducing energy consumption and associated greenhouse gas emissions.

In water treatment applications, PVDF membranes play a crucial role in improving water quality and conservation efforts. Their high filtration efficiency helps remove contaminants, microorganisms, and particulate matter from water sources, contributing to the production of clean, potable water. This is particularly significant in regions facing water scarcity, as PVDF membranes can facilitate water reuse and recycling initiatives.

The hydrophobic nature of PVDF membranes makes them less prone to fouling compared to other membrane materials. This property reduces the frequency of chemical cleaning processes, thereby minimizing the use of harsh cleaning agents and their subsequent release into the environment. The reduced fouling also leads to more consistent performance and lower energy requirements for membrane operation.

PVDF membranes have shown promise in emerging environmental applications, such as the removal of microplastics from water bodies. Their ability to effectively capture small particles makes them a potential solution for addressing this growing environmental concern.

However, it is important to note that the production of PVDF membranes does have some environmental implications. The manufacturing process involves the use of fluoropolymers, which can have a significant carbon footprint. Additionally, the end-of-life disposal of PVDF membranes requires careful consideration to prevent potential environmental contamination.

Ongoing research and development efforts are focused on improving the sustainability of PVDF membrane production and exploring recycling options. These initiatives aim to further enhance the overall environmental profile of PVDF membranes, ensuring that their benefits continue to outweigh potential drawbacks in the long term.

PVDF Membrane Standards

PVDF membrane standards play a crucial role in ensuring the quality, consistency, and performance of PVDF membranes across various applications. These standards provide guidelines for manufacturing processes, testing methods, and performance criteria that PVDF membranes must meet to be considered suitable for specific uses.

One of the primary standards governing PVDF membranes is ASTM D6908, which outlines the standard practice for integrity testing of water filtration membrane systems. This standard provides a framework for evaluating the integrity of PVDF membranes used in water treatment applications, ensuring that they meet the required performance levels for particle removal and contaminant rejection.

ISO 16140 is another important standard that applies to PVDF membranes used in microbiological testing. This standard sets forth the validation procedures for alternative methods of microbiological analysis, including those utilizing PVDF membranes for microbial detection and enumeration.

For pharmaceutical and bioprocessing applications, PVDF membranes must comply with USP Class VI standards. These standards ensure that the materials used in the membranes are biocompatible and do not leach harmful substances into the processed fluids. Additionally, PVDF membranes used in these industries often need to meet FDA regulations for food contact and pharmaceutical processing.

In the field of water treatment, NSF/ANSI 61 certification is crucial for PVDF membranes used in drinking water systems. This standard evaluates the potential health effects of materials that come into contact with drinking water, ensuring that PVDF membranes do not introduce harmful contaminants into the water supply.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts PVDF membrane standards, particularly in terms of the chemicals used in their production and any potential environmental or health risks associated with their use.

For industrial applications, PVDF membranes often need to meet specific industry standards. For instance, in the oil and gas sector, NACE (National Association of Corrosion Engineers) standards may apply to PVDF membranes used in corrosive environments.

Manufacturers of PVDF membranes typically conduct rigorous testing to ensure compliance with these standards. This includes pore size distribution analysis, bubble point testing, and chemical compatibility assessments. Many also provide detailed specifications and certifications to demonstrate adherence to relevant standards.

As technology and applications evolve, PVDF membrane standards continue to be updated and refined. Organizations such as ASTM International, ISO, and industry-specific bodies regularly review and revise these standards to keep pace with advancements in membrane technology and changing regulatory requirements.