How to Use PVDF to Achieve Enhanced Signal Detection?

PVDF Signal Detection Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material for enhanced signal detection across various applications. The evolution of PVDF technology can be traced back to its discovery in the 1940s, with significant advancements in its piezoelectric properties occurring in the 1960s. Since then, PVDF has garnered increasing attention in the field of sensor technology due to its unique combination of flexibility, durability, and sensitivity to mechanical and thermal stimuli.

The primary objective of utilizing PVDF for enhanced signal detection is to leverage its piezoelectric and pyroelectric properties to create highly sensitive and responsive sensing systems. These properties allow PVDF to generate an electrical response when subjected to mechanical stress or temperature changes, making it ideal for a wide range of sensing applications. The goal is to develop sensors that can detect minute changes in pressure, vibration, or temperature with high accuracy and reliability.

As technology continues to advance, there is a growing demand for sensors that can operate in diverse environments and provide real-time, precise data. PVDF-based sensors have the potential to meet these requirements, offering advantages such as low cost, lightweight construction, and compatibility with flexible substrates. The development of PVDF sensors aims to address challenges in various industries, including healthcare, automotive, aerospace, and environmental monitoring.

The current technological landscape shows a trend towards miniaturization and integration of sensing systems. PVDF's versatility allows for its incorporation into compact, multifunctional devices that can simultaneously detect multiple parameters. This aligns with the broader trend of Internet of Things (IoT) and smart sensor networks, where distributed, interconnected sensors play a crucial role in data collection and analysis.

Looking ahead, the future of PVDF in signal detection is likely to focus on enhancing sensitivity, expanding the range of detectable stimuli, and improving signal processing techniques. Research efforts are being directed towards optimizing PVDF film fabrication methods, exploring novel composite materials, and developing advanced signal amplification and noise reduction algorithms. These advancements aim to push the boundaries of what can be detected and measured, opening up new possibilities in fields such as structural health monitoring, biomedical diagnostics, and energy harvesting.

In conclusion, the background and objectives of PVDF signal detection reflect a dynamic and evolving field with significant potential for innovation. As researchers and engineers continue to explore and refine PVDF-based sensing technologies, we can anticipate breakthroughs that will enable more sophisticated, reliable, and versatile signal detection systems across a wide spectrum of applications.

Market Analysis for PVDF-based Sensors

The market for PVDF-based sensors is experiencing significant growth, driven by the increasing demand for high-performance sensing technologies across various industries. PVDF (Polyvinylidene Fluoride) has emerged as a versatile material for sensor applications due to its unique piezoelectric, pyroelectric, and ferroelectric properties. These characteristics make PVDF-based sensors particularly suitable for detecting pressure, vibration, temperature changes, and other physical phenomena with high sensitivity and accuracy.

The global market for PVDF-based sensors is primarily segmented into automotive, healthcare, industrial, consumer electronics, and aerospace sectors. In the automotive industry, PVDF sensors are increasingly being utilized for tire pressure monitoring systems, impact detection, and engine diagnostics. The healthcare sector is adopting PVDF sensors for medical imaging, patient monitoring, and wearable health devices. Industrial applications include process control, structural health monitoring, and predictive maintenance in manufacturing facilities.

Consumer electronics represent a rapidly growing market segment for PVDF-based sensors, with applications in smartphones, tablets, and wearable devices for touch sensing, gesture recognition, and haptic feedback. The aerospace industry is leveraging PVDF sensors for structural health monitoring of aircraft components and vibration detection in turbines.

Market trends indicate a shift towards miniaturization and integration of PVDF sensors, enabling their incorporation into compact and portable devices. This trend is particularly evident in the development of flexible and stretchable PVDF sensors for wearable technology applications. Additionally, there is a growing focus on enhancing the sensitivity and reliability of PVDF sensors through advanced manufacturing techniques and material modifications.

The market landscape is characterized by a mix of established sensor manufacturers and innovative startups specializing in PVDF technology. Key market players are investing in research and development to improve sensor performance, reduce production costs, and expand application areas. Collaborations between sensor manufacturers and end-user industries are becoming more common, driving customized solutions and accelerating market adoption.

Geographically, North America and Europe currently lead the PVDF sensor market, owing to their strong presence in automotive and healthcare industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing automotive production, and growing investments in healthcare infrastructure.

Challenges in the PVDF sensor market include the need for standardization of sensor specifications, addressing long-term stability issues in harsh environments, and competition from alternative sensing technologies. Despite these challenges, the market outlook remains positive, with technological advancements and expanding application areas driving sustained growth in the PVDF-based sensor market.

Current PVDF Technology Challenges

Polyvinylidene fluoride (PVDF) has emerged as a promising material for enhanced signal detection, yet several challenges persist in its current technological landscape. One of the primary obstacles is the optimization of PVDF's piezoelectric properties. While PVDF exhibits inherent piezoelectric characteristics, achieving consistent and high-performance signal detection across various applications remains a significant hurdle.

The sensitivity and selectivity of PVDF-based sensors pose another critical challenge. As the demand for more precise and reliable signal detection increases, researchers are grappling with the need to enhance PVDF's ability to discriminate between target signals and background noise. This is particularly crucial in environments with multiple interfering factors or when detecting weak signals.

Manufacturing processes and scalability present additional hurdles in PVDF technology. The production of high-quality, uniform PVDF films with controlled crystalline structures is essential for optimal performance. However, maintaining consistency in large-scale production while ensuring cost-effectiveness remains a significant challenge for widespread adoption.

The long-term stability and durability of PVDF-based sensors are also areas of concern. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can affect the performance and lifespan of PVDF devices. Developing robust PVDF sensors that maintain their signal detection capabilities over extended periods and under varying conditions is a key focus for researchers and engineers.

Integration of PVDF sensors with existing systems and technologies presents another set of challenges. Compatibility issues, signal processing requirements, and the need for seamless integration into diverse applications demand innovative solutions. This includes addressing challenges related to interface design, power consumption, and data transmission.

Furthermore, the development of flexible and wearable PVDF-based sensors introduces unique challenges. Balancing flexibility with performance, ensuring comfort for users, and maintaining signal integrity in dynamic environments are complex issues that researchers are actively addressing.

Lastly, the exploration of novel PVDF composites and hybrid materials represents both an opportunity and a challenge. While these materials offer potential for enhanced performance, their development and optimization require extensive research and testing to overcome issues related to material compatibility, processing techniques, and overall system integration.

Existing PVDF Signal Enhancement Solutions

01 PVDF-based piezoelectric sensors for signal detection

PVDF is used as a piezoelectric material in sensors for detecting various signals. These sensors can convert mechanical stress or vibration into electrical signals, making them suitable for applications in pressure sensing, vibration monitoring, and acoustic detection.- PVDF-based sensors for signal detection: PVDF is utilized in the development of sensors for various signal detection applications. Its piezoelectric properties make it suitable for detecting mechanical, thermal, and electrical signals. These sensors can be used in diverse fields such as healthcare, environmental monitoring, and industrial processes.

- PVDF membrane technology for signal enhancement: PVDF membranes are employed to enhance signal detection in various analytical techniques. These membranes can be functionalized or modified to improve selectivity and sensitivity in detecting specific molecules or compounds. This technology is particularly useful in biochemical and environmental analysis.

- PVDF-based acoustic and ultrasonic devices: PVDF is used in the fabrication of acoustic and ultrasonic devices for signal detection and generation. Its unique properties allow for the creation of thin, flexible transducers that can be used in medical imaging, non-destructive testing, and underwater acoustics.

- PVDF nanocomposites for enhanced signal detection: Nanocomposites incorporating PVDF and various nanoparticles or nanostructures are developed to improve signal detection capabilities. These materials can exhibit enhanced sensitivity, broader detection range, and improved stability compared to pure PVDF, making them suitable for advanced sensing applications.

- Signal processing techniques for PVDF-based sensors: Advanced signal processing techniques are developed to optimize the performance of PVDF-based sensors. These methods include noise reduction algorithms, signal amplification, and data fusion techniques to improve the accuracy and reliability of signal detection in various applications.

02 PVDF membranes for filtration and signal detection

PVDF membranes are utilized in filtration systems that can also incorporate signal detection capabilities. These membranes can be functionalized or modified to detect specific molecules or particles while performing filtration tasks, enabling dual functionality in various applications.Expand Specific Solutions03 PVDF-based electrochemical sensors

PVDF is employed in the development of electrochemical sensors for signal detection. These sensors utilize the polymer's properties to create sensitive and selective platforms for detecting various analytes, including ions, gases, and biomolecules.Expand Specific Solutions04 PVDF nanofibers for enhanced signal detection

PVDF nanofibers are used to create high-surface-area structures for improved signal detection. These nanofibers can be functionalized or combined with other materials to enhance sensitivity and selectivity in various sensing applications, including chemical and biological detection.Expand Specific Solutions05 PVDF-based acoustic emission sensors

PVDF is utilized in acoustic emission sensors for detecting and analyzing signals generated by material deformation or damage. These sensors can be applied in structural health monitoring, non-destructive testing, and process control applications across various industries.Expand Specific Solutions

Key PVDF Industry Players

The use of PVDF for enhanced signal detection is in a growth phase, with increasing market size and technological advancements. The market is driven by the demand for high-performance sensors across various industries. Companies like Hitachi Ltd., Samsung Electronics Co., Ltd., and IBM are at the forefront of PVDF technology development, leveraging their R&D capabilities to improve signal detection sensitivity and accuracy. Academic institutions such as MIT and Zhejiang University are contributing to fundamental research, while specialized firms like Comet Technologies USA, Inc. are focusing on practical applications. The technology's maturity is progressing, with ongoing efforts to optimize PVDF properties and integration methods for enhanced signal detection in diverse fields.

Hitachi Ltd.

Samsung Electronics Co., Ltd.

Core PVDF Innovations for Signal Detection

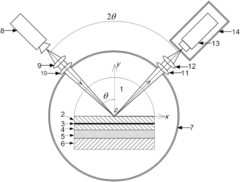

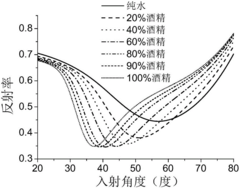

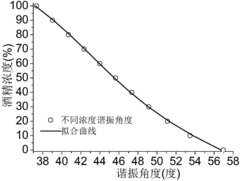

- Using the terahertz surface plasmon resonance effect of PVDF film, through a semicircular silicon prism, a silicon-oxygen film and a Schottky diode detector, a rotating stage is used to scan to form an angle-reflection coefficient curve, and the resonance peak position is calculated to measure the alcohol concentration and establish Standard solubility-resonance peak measurement calibration curve to achieve high-precision alcohol concentration measurement.

- The use of two poled polyvinylidene fluoride (PVdF) sheets with anisotropic piezoelectric properties, where one direction is more sensitive to pressure waves than the other two, connected in a specific electrical configuration to enhance directional sensitivity, including electroless copper coatings and a PTFE inner electrode for stiffness and conductive connections.

PVDF Material Properties and Limitations

Polyvinylidene fluoride (PVDF) is a highly versatile polymer with unique properties that make it particularly suitable for signal detection applications. Its piezoelectric and pyroelectric characteristics allow it to convert mechanical stress or temperature changes into electrical signals, making it an ideal material for sensors and transducers.

PVDF exhibits excellent mechanical properties, including high tensile strength and impact resistance. This durability enables the creation of robust sensing devices capable of withstanding harsh environments and prolonged use. The material's flexibility is another key advantage, allowing for the fabrication of thin films and complex shapes that can conform to various surfaces or be integrated into compact devices.

One of the most significant properties of PVDF for signal detection is its high piezoelectric coefficient. This characteristic results in a strong electrical response to mechanical deformation, enabling the detection of minute vibrations, pressure changes, or acoustic waves. The material's broad frequency response range further enhances its utility in diverse sensing applications, from low-frequency structural monitoring to high-frequency ultrasonic detection.

PVDF also demonstrates remarkable chemical resistance, maintaining its properties when exposed to many solvents, acids, and bases. This chemical stability ensures consistent performance in various environments and extends the lifespan of PVDF-based sensors. Additionally, the material's low water absorption rate contributes to its reliability in humid conditions.

However, PVDF does have certain limitations that must be considered in signal detection applications. The material's relatively low Curie temperature limits its use in high-temperature environments, as it can lose its piezoelectric properties when exposed to excessive heat. This constraint necessitates careful thermal management in sensor design and application.

Another challenge is the variability in PVDF's piezoelectric response depending on its crystalline structure. The β-phase of PVDF exhibits the strongest piezoelectric effect, but achieving and maintaining this phase can be complex, requiring specific processing techniques such as mechanical stretching or electrical poling.

The sensitivity of PVDF to electromagnetic interference (EMI) is another factor that can impact signal detection accuracy. Shielding and proper circuit design are often necessary to mitigate this issue, especially in environments with high electromagnetic noise.

Despite these limitations, PVDF's unique combination of properties continues to drive its adoption in advanced sensing technologies. Ongoing research focuses on enhancing its performance through composite formulations, nanostructuring, and novel processing methods, aiming to overcome current constraints and expand its applications in signal detection.

Environmental Impact of PVDF Technology

The environmental impact of PVDF (Polyvinylidene Fluoride) technology in signal detection applications is a crucial consideration for sustainable development and responsible innovation. PVDF, as a piezoelectric polymer, offers unique properties that enable enhanced signal detection capabilities. However, its production, use, and disposal can have significant environmental implications.

The manufacturing process of PVDF involves the use of fluorine-containing compounds, which can contribute to greenhouse gas emissions if not properly managed. The production of PVDF requires energy-intensive processes, potentially increasing the carbon footprint of signal detection systems that utilize this material. Additionally, the synthesis of PVDF may involve the use of solvents and other chemicals that, if released into the environment, could pose risks to ecosystems and human health.

During the operational phase, PVDF-based signal detection systems generally have a low environmental impact. The material's durability and long lifespan contribute to reduced waste generation and resource consumption over time. Furthermore, the high sensitivity of PVDF sensors can lead to more efficient and accurate detection systems, potentially reducing energy consumption in various applications.

End-of-life considerations for PVDF technology present both challenges and opportunities. PVDF is not biodegradable, which means it can persist in the environment for extended periods if not properly disposed of. However, the material's recyclability offers a potential solution to mitigate its environmental impact. Developing efficient recycling processes for PVDF-based components can significantly reduce waste and conserve resources.

The use of PVDF in signal detection may also have indirect environmental benefits. For instance, in environmental monitoring applications, PVDF sensors can enable more accurate and timely detection of pollutants or ecological changes. This improved detection capability can lead to faster response times and more effective environmental protection measures.

As the demand for advanced signal detection technologies grows, it is essential to consider the life cycle environmental impact of PVDF-based systems. This includes assessing the material's sourcing, production efficiency, energy consumption during use, and end-of-life management. Implementing green chemistry principles in PVDF synthesis and exploring bio-based alternatives could further reduce the environmental footprint of this technology.

In conclusion, while PVDF technology offers significant advantages in signal detection, its environmental impact must be carefully managed. Balancing the benefits of enhanced detection capabilities with sustainable practices throughout the material's lifecycle is crucial for responsible technological advancement in this field.