PVDF Trends in Industrial Filtration: Optimizing Performance

PVDF Filtration Evolution

The evolution of PVDF filtration in industrial applications has been marked by significant advancements in material science and membrane technology. Initially developed in the 1960s, polyvinylidene fluoride (PVDF) quickly gained recognition for its exceptional chemical resistance and thermal stability. These properties made it an ideal candidate for filtration applications in harsh industrial environments.

In the early stages, PVDF membranes were primarily used in specialized industries such as pharmaceutical and semiconductor manufacturing. The 1980s saw a broadening of PVDF applications, as improvements in polymer synthesis and membrane fabrication techniques led to enhanced performance characteristics. This period marked the beginning of PVDF's widespread adoption in water treatment and food processing industries.

The 1990s brought about a revolution in PVDF membrane morphology. Researchers developed asymmetric and hollow fiber PVDF membranes, significantly increasing filtration efficiency and flux rates. These innovations allowed for more compact filtration systems, reducing the overall footprint of industrial installations while maintaining high throughput.

The turn of the millennium heralded a new era of surface modification techniques for PVDF membranes. Scientists began experimenting with hydrophilic coatings and grafting methods to address one of PVDF's primary limitations: its inherent hydrophobicity. These modifications greatly improved the membrane's resistance to fouling, a critical factor in maintaining long-term filtration performance in industrial settings.

In recent years, the focus has shifted towards enhancing the sustainability and longevity of PVDF filtration systems. Researchers have been exploring ways to incorporate nanomaterials and smart polymers into PVDF membranes, creating self-cleaning and stimuli-responsive filtration solutions. These advanced membranes can adapt to changing process conditions, optimizing performance and reducing maintenance requirements.

The latest trend in PVDF filtration evolution involves the integration of digital technologies. Smart sensors and real-time monitoring systems are being incorporated into PVDF filtration units, allowing for predictive maintenance and process optimization. This convergence of material science and digital technology is paving the way for more efficient and reliable industrial filtration processes.

As environmental regulations become more stringent, PVDF filtration systems are evolving to meet higher standards of effluent quality. Recent developments have focused on improving the removal of micropollutants and emerging contaminants, positioning PVDF as a key technology in advanced wastewater treatment and water reuse applications.

Industrial Demand Analysis

The industrial demand for PVDF (Polyvinylidene Fluoride) in filtration applications has been steadily increasing due to its exceptional chemical resistance, thermal stability, and mechanical strength. This growing demand is driven by several factors across various industries, including water treatment, chemical processing, pharmaceuticals, and food and beverage production.

In the water treatment sector, PVDF membranes are increasingly preferred for their ability to effectively remove contaminants while maintaining high flux rates. The global water scarcity crisis and stricter environmental regulations have led to a surge in demand for advanced filtration technologies, with PVDF membranes playing a crucial role in both municipal and industrial water treatment processes.

The chemical processing industry has also contributed significantly to the rising demand for PVDF filtration solutions. As chemical manufacturers seek to improve their production efficiency and product quality, PVDF membranes offer superior resistance to harsh chemicals and solvents, making them ideal for separating and purifying various chemical compounds.

In the pharmaceutical sector, the need for high-purity filtration systems has driven the adoption of PVDF membranes. These membranes are essential in the production of pharmaceuticals, biotechnology products, and medical devices, where contamination control is paramount. The growing emphasis on quality assurance and regulatory compliance in the pharmaceutical industry further fuels the demand for PVDF-based filtration solutions.

The food and beverage industry has also recognized the benefits of PVDF filtration systems. With increasing consumer awareness about food safety and quality, manufacturers are investing in advanced filtration technologies to ensure product purity and extend shelf life. PVDF membranes are particularly valued for their ability to withstand frequent cleaning and sterilization processes without compromising performance.

Market analysis indicates that the global PVDF membrane market is expected to grow at a compound annual growth rate (CAGR) of over 7% in the coming years. This growth is attributed to the expanding industrial applications and the continuous development of new PVDF-based filtration products with enhanced performance characteristics.

The demand for PVDF in industrial filtration is also influenced by the trend towards sustainability and energy efficiency. PVDF membranes offer longer operational lifespans and require less frequent replacements compared to traditional filtration materials, resulting in reduced waste and lower operational costs for industries.

As industries continue to prioritize process optimization and product quality, the demand for high-performance PVDF filtration solutions is expected to remain strong. Manufacturers are focusing on developing innovative PVDF membrane designs that offer improved flux rates, enhanced fouling resistance, and greater durability to meet the evolving needs of various industrial sectors.

PVDF Challenges in Filtration

Polyvinylidene fluoride (PVDF) membranes have gained significant traction in industrial filtration due to their excellent chemical resistance and mechanical strength. However, several challenges persist in optimizing their performance for diverse applications.

One of the primary challenges is membrane fouling, which occurs when particles, colloids, or biological matter accumulate on the membrane surface or within its pores. This phenomenon leads to reduced flux, increased energy consumption, and shortened membrane lifespan. The hydrophobic nature of PVDF exacerbates this issue, as it promotes the adhesion of organic foulants and biofilm formation.

Pore size control and distribution present another significant hurdle. Achieving a uniform pore size distribution is crucial for maintaining consistent filtration efficiency across the membrane. However, the phase inversion process used in PVDF membrane fabrication can result in a wide range of pore sizes, potentially compromising the membrane's selectivity and overall performance.

The trade-off between permeability and selectivity remains a persistent challenge. While smaller pores enhance selectivity, they also reduce permeability, necessitating higher operating pressures and energy consumption. Conversely, larger pores improve permeability but may compromise the membrane's ability to reject certain contaminants effectively.

Chemical stability, although a strength of PVDF, can still be a limiting factor in extreme environments. Prolonged exposure to highly alkaline solutions or certain organic solvents can degrade PVDF membranes, limiting their applicability in specific industrial processes.

Thermal stability is another area of concern, particularly in high-temperature applications. While PVDF exhibits good thermal resistance compared to many polymeric membranes, its performance can degrade at elevated temperatures, restricting its use in certain high-temperature filtration processes.

The mechanical strength of PVDF membranes, while generally good, can be compromised under high-pressure operations or in the presence of abrasive particles. This can lead to membrane compaction or damage, reducing filtration efficiency and membrane longevity.

Lastly, the environmental impact of PVDF membrane production and disposal poses a growing challenge. As sustainability becomes increasingly important in industrial processes, finding eco-friendly alternatives or developing efficient recycling methods for PVDF membranes is becoming a critical area of focus.

Addressing these challenges requires innovative approaches in membrane design, material science, and process engineering. Researchers and industry professionals are actively exploring solutions such as surface modifications, composite membrane structures, and advanced fabrication techniques to overcome these limitations and further optimize PVDF membrane performance in industrial filtration applications.

Current PVDF Optimization Techniques

01 Improved mechanical properties of PVDF

PVDF can be modified to enhance its mechanical properties such as tensile strength, impact resistance, and flexibility. This can be achieved through various methods including blending with other polymers, adding reinforcing fillers, or optimizing the crystalline structure of PVDF. These improvements make PVDF suitable for a wide range of applications requiring high mechanical performance.- Improved mechanical properties of PVDF: PVDF can be modified or blended with other materials to enhance its mechanical properties such as tensile strength, impact resistance, and flexibility. This improvement allows for broader applications in various industries, including automotive, aerospace, and construction.

- Enhanced thermal stability and chemical resistance: PVDF exhibits excellent thermal stability and chemical resistance, making it suitable for use in harsh environments. These properties can be further improved through specific formulations or processing techniques, enabling its use in high-temperature applications and corrosive chemical environments.

- Electrical and piezoelectric properties: PVDF demonstrates unique electrical and piezoelectric properties, making it valuable in sensor and actuator applications. These properties can be optimized through various methods, including controlling crystallinity and orientation of the polymer chains.

- Improved processing and fabrication techniques: Advanced processing and fabrication techniques have been developed to enhance PVDF performance. These include methods for producing high-quality films, fibers, and membranes with improved uniformity and controlled porosity, leading to better overall performance in various applications.

- Environmental and energy applications: PVDF's unique properties make it suitable for environmental and energy applications. It is used in the development of efficient membranes for water treatment, as well as in energy storage devices such as lithium-ion batteries and fuel cells, where its stability and chemical resistance are particularly valuable.

02 Enhanced thermal stability and flame retardancy

PVDF exhibits excellent thermal stability and can be further improved to enhance its flame retardant properties. This can be accomplished by incorporating flame retardant additives or modifying the polymer structure. The improved thermal performance allows PVDF to be used in high-temperature applications and environments where fire resistance is critical.Expand Specific Solutions03 Electrical and piezoelectric properties

PVDF demonstrates unique electrical and piezoelectric properties, making it suitable for various electronic and sensor applications. These properties can be optimized through techniques such as stretching, poling, or incorporating conductive fillers. The enhanced electrical performance enables PVDF to be used in energy harvesting devices, sensors, and actuators.Expand Specific Solutions04 Chemical resistance and barrier properties

PVDF exhibits excellent chemical resistance and barrier properties against various substances. These properties can be further improved through surface modifications or the addition of specific additives. The enhanced chemical resistance and barrier performance make PVDF suitable for applications in harsh chemical environments and packaging industries.Expand Specific Solutions05 Processing and fabrication techniques

Various processing and fabrication techniques can be employed to enhance the performance of PVDF products. These include optimizing extrusion parameters, developing novel molding techniques, and exploring advanced manufacturing methods such as 3D printing. Improved processing techniques result in better control over the final properties and expand the range of possible applications for PVDF.Expand Specific Solutions

Key PVDF Filter Manufacturers

The PVDF industrial filtration market is in a growth phase, driven by increasing demand for high-performance filtration solutions across various industries. The market size is expanding, with a projected CAGR of 7-8% over the next five years. Technologically, PVDF membranes are mature but continue to evolve, with companies like Arkema, Asahi Kasei, and Evoqua Water Technologies leading innovation. These firms, along with Pall Corp. and MANN+HUMMEL GmbH, are focusing on optimizing PVDF membrane performance through advanced manufacturing techniques and novel material compositions. Emerging players such as Repligen Corp. and Mott Corp. are also contributing to technological advancements, particularly in specialized applications and niche markets.

Arkema, Inc.

Asahi Kasei Corp.

Innovative PVDF Membrane Designs

- A process involving unidirectional cooling of a cast polymeric film, where a polymeric dope solution is cast onto a substrate and subjected to a temperature gradient, allowing for controlled solvent crystallization and polymer diffusion to create membranes with average pore sizes of 0.01-10 μm, enhancing flux properties and mechanical strength.

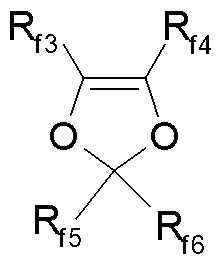

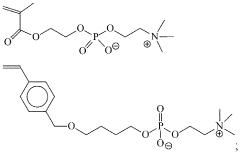

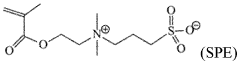

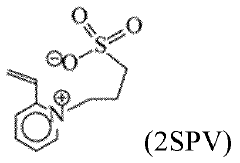

- Incorporating a copolymer comprising zwitterionic moieties into PVDF membranes to enhance hydrophilicity, permeability, and anti-fouling properties while maintaining mechanical and chemical stability, using a composition with a weight ratio of copolymer to PVDF between 0.1/99.9 and 25/75, and molecular weight ranging from 25,000 to 350,000 g/mol.

Environmental Impact of PVDF Filters

The environmental impact of PVDF (polyvinylidene fluoride) filters in industrial filtration processes is a critical consideration as industries strive for sustainable practices. PVDF filters offer excellent chemical resistance and durability, making them popular in various applications. However, their production and disposal pose significant environmental challenges.

The manufacturing process of PVDF filters involves the use of fluoropolymers, which can contribute to greenhouse gas emissions. The production of these filters requires energy-intensive processes, potentially increasing the carbon footprint of industrial operations. Additionally, the use of chemical solvents in PVDF membrane production may lead to air and water pollution if not properly managed.

During their operational lifecycle, PVDF filters generally have a positive environmental impact by effectively removing contaminants from industrial processes. This helps reduce the release of harmful substances into the environment and improves the overall quality of industrial effluents. The high efficiency of PVDF filters in removing particulates and other pollutants contributes to cleaner water and air emissions from industrial facilities.

However, the end-of-life disposal of PVDF filters presents environmental challenges. These filters are not biodegradable and can persist in the environment for extended periods. Improper disposal may lead to soil and water contamination. Incineration of PVDF filters can release toxic compounds, including hydrogen fluoride, which poses risks to human health and the environment.

Recycling PVDF filters is technically challenging due to their complex composition and potential contamination from filtered materials. This limitation often results in these filters being sent to landfills, contributing to the growing problem of plastic waste accumulation.

To mitigate the environmental impact, industries are exploring more sustainable alternatives and improved disposal methods. Research is ongoing to develop bio-based or more easily recyclable filter materials that can match the performance of PVDF. Additionally, advancements in filter cleaning and regeneration technologies are helping to extend the lifespan of PVDF filters, reducing the frequency of replacement and disposal.

Efforts are also being made to improve the recyclability of PVDF filters through innovative material recovery processes. Some companies are investigating chemical recycling methods to break down PVDF into its constituent monomers, which can then be used to produce new filters or other products.

In conclusion, while PVDF filters offer significant benefits in industrial filtration, their environmental impact throughout their lifecycle must be carefully managed. Balancing the performance advantages with sustainability concerns remains a key challenge for the industry, driving ongoing research and innovation in filter materials and recycling technologies.

PVDF Filtration Standards

PVDF filtration standards play a crucial role in ensuring the quality, consistency, and performance of filtration systems across various industries. These standards encompass a wide range of specifications, testing methods, and performance criteria that manufacturers and end-users must adhere to when designing, producing, and implementing PVDF-based filtration solutions.

One of the primary standards governing PVDF filtration is the ASTM F838-15a, which outlines the standard test method for determining the bacterial retention efficiency of membrane filters. This standard is particularly important for applications in the pharmaceutical and biotechnology industries, where sterile filtration is critical. It provides a standardized approach to evaluate the ability of PVDF membranes to remove microorganisms from liquid streams.

The ISO 16889:2008 standard is another key reference for PVDF filtration, specifically addressing the multi-pass method for evaluating filtration performance of hydraulic and lube oil filters. This standard is essential for industries such as automotive and aerospace, where hydraulic systems require high-performance filtration to maintain operational efficiency and equipment longevity.

For water treatment applications, the NSF/ANSI 61 standard is particularly relevant. It sets health effects criteria for components used in drinking water systems, including PVDF-based filtration membranes. Compliance with this standard ensures that PVDF filters do not leach harmful contaminants into the treated water, making them safe for use in municipal and residential water treatment systems.

The European Membrane Society (EMS) has also established guidelines for membrane characterization, which are applicable to PVDF filtration membranes. These guidelines provide standardized methods for measuring key membrane properties such as pore size distribution, surface charge, and chemical resistance, enabling consistent evaluation and comparison of different PVDF membrane products.

In the food and beverage industry, PVDF filtration systems must comply with FDA regulations, particularly 21 CFR 177.2510, which specifies the requirements for polymers used in food-contact applications. This regulation ensures that PVDF materials used in filtration do not introduce harmful substances into food products during processing.

The development and implementation of these standards have significantly contributed to the advancement of PVDF filtration technology. They provide a framework for continuous improvement in membrane performance, durability, and efficiency. As the demands for more sophisticated filtration solutions grow, these standards are regularly reviewed and updated to keep pace with technological advancements and emerging industry needs.

Adherence to these standards not only ensures regulatory compliance but also fosters innovation in PVDF filtration technology. Manufacturers are continuously challenged to develop new materials and designs that meet or exceed these stringent requirements, driving progress in areas such as fouling resistance, flux rates, and selectivity of PVDF membranes.