How to Advance PVDF Processing Techniques for Consistency?

PVDF Processing Evolution and Objectives

Polyvinylidene fluoride (PVDF) processing has undergone significant evolution since its discovery in the 1940s. Initially, PVDF was primarily used in niche applications due to its unique properties, including chemical resistance and piezoelectric characteristics. Over time, advancements in polymer science and manufacturing technologies have expanded its potential across various industries.

The early stages of PVDF processing focused on basic extrusion and molding techniques. However, as demand grew for more sophisticated applications, researchers and engineers began exploring ways to enhance PVDF's processability and performance. This led to the development of new processing methods, such as solution casting, electrospinning, and melt spinning, which allowed for the creation of PVDF films, fibers, and membranes with tailored properties.

A significant milestone in PVDF processing was the discovery of its different crystalline phases and their impact on material properties. This knowledge prompted efforts to control and manipulate these phases during processing, leading to PVDF products with enhanced piezoelectric, ferroelectric, and pyroelectric properties. The ability to fine-tune these characteristics opened up new possibilities in sensor technology, energy harvesting, and advanced filtration systems.

In recent years, the focus has shifted towards achieving greater consistency in PVDF processing. This objective is driven by the increasing demand for high-performance PVDF products in critical applications, such as aerospace, automotive, and medical industries. Consistency in processing is crucial for ensuring uniform material properties, reproducible performance, and reliable product quality across different batches and production runs.

The current technological landscape presents both challenges and opportunities for advancing PVDF processing techniques. Key objectives include optimizing process parameters to achieve consistent crystalline phase formation, developing in-line monitoring and control systems for real-time process adjustment, and exploring novel additives or processing aids that can enhance PVDF's processability without compromising its unique properties.

Furthermore, there is a growing emphasis on sustainable and environmentally friendly processing methods. This includes efforts to reduce solvent use in PVDF processing, develop more energy-efficient manufacturing techniques, and explore recycling and upcycling strategies for PVDF products. These objectives align with broader industry trends towards green chemistry and circular economy principles.

As we look to the future, the evolution of PVDF processing techniques will likely be influenced by emerging technologies such as artificial intelligence and machine learning. These tools have the potential to revolutionize process optimization, predictive maintenance, and quality control in PVDF manufacturing, ultimately leading to unprecedented levels of consistency and efficiency in production.

Market Demand Analysis for PVDF Products

The global market for Polyvinylidene Fluoride (PVDF) products has been experiencing significant growth, driven by increasing demand across various industries. PVDF's unique properties, including chemical resistance, thermal stability, and excellent mechanical strength, make it a versatile material for numerous applications. The automotive sector has emerged as a key driver for PVDF demand, particularly in the production of lithium-ion batteries for electric vehicles. As the automotive industry continues its shift towards electrification, the demand for PVDF in battery separators and electrode binders is expected to surge.

In the construction industry, PVDF-based coatings and films are gaining popularity due to their durability and weather resistance. The growing emphasis on sustainable and energy-efficient buildings has led to increased adoption of PVDF-coated architectural panels and membranes. This trend is particularly pronounced in regions with harsh climates, where building materials need to withstand extreme weather conditions.

The electronics sector represents another significant market for PVDF products. The material's piezoelectric properties make it valuable in the production of sensors, transducers, and other electronic components. As smart devices and Internet of Things (IoT) technologies continue to proliferate, the demand for PVDF in this sector is projected to grow steadily.

In the chemical processing industry, PVDF's exceptional chemical resistance has led to its widespread use in pipes, fittings, and linings for handling corrosive materials. The increasing focus on safety and environmental regulations in chemical plants is driving the adoption of PVDF-based equipment, further boosting market demand.

The healthcare sector is also contributing to the growth of the PVDF market. The material's biocompatibility and resistance to sterilization processes make it suitable for medical devices and pharmaceutical packaging. As healthcare needs continue to expand globally, this sector is expected to provide sustained demand for PVDF products.

Geographically, Asia-Pacific remains the largest and fastest-growing market for PVDF products, driven by rapid industrialization, urbanization, and technological advancements in countries like China, Japan, and South Korea. North America and Europe also represent significant markets, with strong demand from established industries and ongoing research and development activities.

Despite the positive market outlook, challenges remain in the PVDF industry. The volatility of raw material prices, particularly fluorine-based compounds, can impact production costs and market dynamics. Additionally, environmental concerns related to fluoropolymer production and disposal are prompting research into more sustainable manufacturing processes and end-of-life solutions for PVDF products.

Current PVDF Processing Challenges

Polyvinylidene fluoride (PVDF) processing faces several significant challenges that hinder consistent production and optimal performance. One of the primary issues is the high melting point and melt viscosity of PVDF, which can lead to difficulties in achieving uniform melt flow during extrusion or injection molding processes. This inconsistency often results in variations in the final product's properties and appearance.

Another major challenge is the sensitivity of PVDF to processing conditions, particularly temperature and shear rate. Even slight deviations in these parameters can significantly affect the crystallinity, molecular orientation, and ultimately, the mechanical and electrical properties of the final product. This sensitivity makes it challenging to maintain consistent quality across different production batches or when scaling up production.

The presence of residual stress in PVDF products is also a persistent issue. The rapid cooling rates often employed in industrial processing can lead to the formation of internal stresses, which may cause dimensional instability, warpage, or even premature failure of the final product. Balancing the cooling rate to minimize residual stress while maintaining production efficiency remains a significant challenge.

Furthermore, the high corrosiveness of PVDF melt poses challenges in terms of equipment durability and maintenance. Processing equipment, particularly those parts in direct contact with the molten polymer, must be carefully selected and regularly maintained to prevent degradation and contamination of the PVDF material.

The incorporation of additives and fillers, often necessary to enhance specific properties of PVDF, presents additional processing challenges. Achieving uniform dispersion of these additives without compromising the inherent properties of PVDF requires careful control of processing conditions and often specialized equipment.

Lastly, the environmental and health concerns associated with the processing of fluoropolymers like PVDF are becoming increasingly important. The potential release of harmful substances during high-temperature processing necessitates stringent control measures and may limit processing options in certain applications or regions.

Addressing these challenges requires a multifaceted approach, combining advances in material science, process engineering, and equipment design. Innovations in areas such as in-situ monitoring, predictive modeling, and adaptive control systems hold promise for improving the consistency and efficiency of PVDF processing techniques.

Existing PVDF Processing Solutions

01 PVDF composition and preparation methods

Various methods and compositions for preparing PVDF with consistent properties are described. These include specific blending techniques, additives, and processing conditions to achieve desired consistency in the final product. The methods aim to improve the uniformity and stability of PVDF for different applications.- PVDF composition and preparation methods: Various methods and compositions for preparing PVDF with consistent properties are described. These include specific blending techniques, additives, and processing conditions to achieve desired consistency in the final product. The focus is on improving the uniformity and stability of PVDF materials for different applications.

- PVDF in membrane applications: PVDF is widely used in membrane applications due to its excellent chemical resistance and mechanical properties. Techniques for enhancing the consistency of PVDF membranes are explored, including surface modification, pore size control, and blending with other polymers to improve performance and durability.

- PVDF in electronic and energy storage devices: The use of PVDF in electronic components and energy storage devices, such as batteries and capacitors, is discussed. Methods to ensure consistent dielectric properties, piezoelectric performance, and thermal stability of PVDF in these applications are presented, focusing on enhancing the material's reliability and efficiency.

- PVDF coatings and films: Techniques for producing consistent PVDF coatings and films are explored. This includes methods for controlling thickness, adhesion, and surface properties. The focus is on achieving uniform coverage and maintaining the desired characteristics of PVDF films in various environmental conditions.

- PVDF blends and composites: The development of PVDF blends and composites with other materials to enhance consistency and specific properties is discussed. This includes the incorporation of nanoparticles, other polymers, or additives to improve mechanical strength, thermal stability, or electrical properties while maintaining overall consistency in the material's performance.

02 PVDF membrane fabrication techniques

Techniques for fabricating PVDF membranes with consistent properties are outlined. These include specific casting methods, phase inversion processes, and post-treatment techniques to ensure uniform pore size distribution and mechanical strength. The focus is on producing membranes with reliable performance for filtration and separation applications.Expand Specific Solutions03 PVDF-based composite materials

Development of PVDF-based composite materials with consistent properties is discussed. These composites incorporate various fillers, nanoparticles, or other polymers to enhance specific properties of PVDF while maintaining consistency. The focus is on achieving a balance between improved performance and reproducible characteristics.Expand Specific Solutions04 PVDF consistency in electronic applications

Methods to ensure PVDF consistency in electronic applications, such as sensors, actuators, and energy harvesting devices, are presented. These include specific processing techniques and material formulations to achieve reliable piezoelectric and ferroelectric properties. The emphasis is on producing PVDF components with consistent performance for electronic devices.Expand Specific Solutions05 Quality control and characterization of PVDF consistency

Techniques for quality control and characterization of PVDF consistency are outlined. These include various analytical methods, testing protocols, and standards to assess and ensure the uniformity of PVDF properties. The focus is on developing reliable methods to evaluate and maintain consistency in PVDF production and processing.Expand Specific Solutions

Key Players in PVDF Industry

The PVDF processing techniques market is in a growth phase, driven by increasing demand in various industries. The market size is expanding, with a projected CAGR of around 7% over the next five years. Technologically, PVDF processing is advancing, but challenges in consistency remain. Key players like Applied Materials, Inc., Arkema France SA, and DuPont de Nemours, Inc. are investing heavily in R&D to improve processing techniques. Emerging companies such as Zhejiang Juhua Technology Center Co., Ltd. and Guangdong University of Technology are also contributing to innovations. The focus is on developing more efficient and reliable methods for PVDF processing, with a particular emphasis on enhancing consistency across different applications and scales of production.

Arkema France SA

Zhonghao Chenguang Research Institute of Chemical Ind Co Ltd

Innovative PVDF Processing Patents

- Adopting high-gloss PVDF sheet processing technology, including raw material drying, extrusion, three-roller processing, infrared heating, cooling, cutting, inspection and heat treatment steps, by optimizing the parameters of each step such as temperature, time and rotation speed, ensuring that the sheet The finish and pass rate.

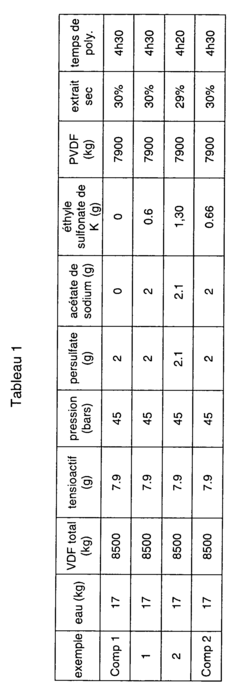

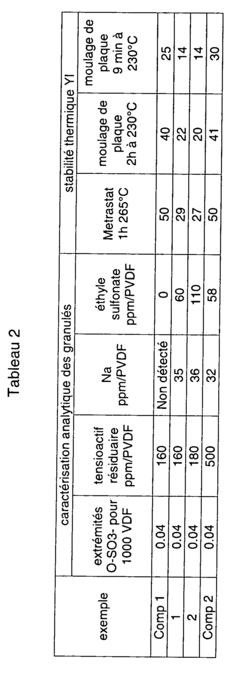

- A method involving radical polymerization of vinylidene fluoride in aqueous dispersion using a persulfate initiator, followed by washing to reduce surfactant residues below 300 ppm, and subsequent addition of sodium acetate and potassium alkyl sulfonate to enhance thermal stability, ensuring the PVDF produced is free from undesirable surfactant residues.

Environmental Impact of PVDF Processing

The environmental impact of PVDF processing is a critical consideration in advancing techniques for consistency. PVDF (polyvinylidene fluoride) production and processing involve several stages that can have significant environmental implications. The primary areas of concern include energy consumption, greenhouse gas emissions, waste generation, and potential chemical releases.

PVDF manufacturing typically requires high temperatures and pressures, leading to substantial energy consumption. This energy-intensive process contributes to increased carbon emissions, particularly if the energy source is not renewable. Efforts to improve energy efficiency in PVDF processing, such as optimizing reaction conditions and implementing heat recovery systems, can significantly reduce the environmental footprint.

Chemical emissions during PVDF processing pose another environmental challenge. The production of PVDF involves the use of fluorinated compounds, which can potentially lead to the release of harmful substances if not properly managed. Volatile organic compounds (VOCs) and particulate matter emissions are also concerns during various stages of processing. Implementing advanced emission control technologies and closed-loop systems can help mitigate these issues.

Water usage and wastewater generation in PVDF processing present additional environmental considerations. The cleaning and cooling processes involved in PVDF production can consume substantial amounts of water and generate contaminated effluents. Developing water-efficient techniques and implementing effective wastewater treatment systems are crucial for minimizing the impact on local water resources.

Waste management is another key aspect of PVDF processing's environmental impact. Off-spec materials, process scraps, and packaging waste contribute to the overall waste stream. Implementing recycling and reuse strategies for PVDF materials can significantly reduce waste generation and promote a more circular economy approach in the industry.

The end-of-life considerations for PVDF products also play a role in their environmental impact. While PVDF is known for its durability, which can reduce the frequency of replacement and associated waste, its resistance to degradation poses challenges for disposal. Developing effective recycling and decomposition methods for PVDF products is essential for long-term environmental sustainability.

Advancements in PVDF processing techniques aimed at consistency can also contribute to reducing environmental impact. More consistent production processes can lead to fewer rejected batches, less waste, and more efficient use of resources. Technologies such as in-line monitoring and real-time process adjustments can help achieve this consistency while simultaneously reducing energy consumption and material waste.

Quality Control in PVDF Manufacturing

Quality control plays a crucial role in PVDF manufacturing, ensuring consistent product quality and performance. The process begins with rigorous raw material inspection, where incoming PVDF resins and additives are thoroughly tested for purity, molecular weight distribution, and contamination levels. Advanced spectroscopic techniques, such as Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR), are employed to verify the chemical composition and structural integrity of the raw materials.

During the manufacturing process, in-line monitoring systems are implemented to continuously track key parameters such as temperature, pressure, and viscosity. These real-time measurements allow for immediate adjustments to maintain optimal processing conditions. Rheological testing is conducted at various stages to assess the flow behavior and melt properties of the PVDF, ensuring proper extrusion or molding characteristics.

Post-production quality control involves comprehensive testing of the finished PVDF products. Mechanical properties, including tensile strength, elongation at break, and impact resistance, are evaluated using standardized testing methods. Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are utilized to verify the crystallinity, melting point, and thermal stability of the PVDF.

Surface properties and morphology are examined using advanced microscopy techniques, including scanning electron microscopy (SEM) and atomic force microscopy (AFM). These methods provide valuable insights into the uniformity of the PVDF surface and the presence of any defects or impurities. Additionally, contact angle measurements are performed to assess the hydrophobicity and surface energy of the PVDF, which are critical factors for many applications.

To ensure consistency across production batches, statistical process control (SPC) methods are implemented. Control charts and trend analysis are used to monitor key quality indicators over time, allowing for early detection of process drift or anomalies. Regular calibration and maintenance of processing equipment, coupled with operator training programs, further contribute to maintaining consistent PVDF quality.

Traceability is another essential aspect of quality control in PVDF manufacturing. Each batch of PVDF is assigned a unique identifier, enabling the tracking of raw materials, processing conditions, and quality test results throughout the production lifecycle. This comprehensive documentation facilitates root cause analysis in the event of any quality issues and supports continuous improvement initiatives.