How to Use PVDF in Optical Applications for Clarity Improvement?

PVDF in Optics: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in optical applications, particularly for improving clarity and performance. The evolution of PVDF in optics can be traced back to the 1960s when its unique properties were first discovered. Initially used in electrical and mechanical applications, PVDF's potential in optics became apparent as researchers explored its piezoelectric and pyroelectric characteristics.

The development of PVDF for optical applications has been driven by the increasing demand for high-performance, lightweight, and flexible optical components. As traditional glass and plastic materials faced limitations in certain applications, PVDF offered a compelling alternative due to its excellent transparency, low refractive index, and resistance to harsh environments.

Over the years, significant advancements have been made in understanding and manipulating PVDF's molecular structure to enhance its optical properties. The discovery of different crystalline phases of PVDF, particularly the β-phase, has been crucial in optimizing its performance for optical applications. Researchers have focused on developing methods to control the crystallization process and increase the β-phase content, which is responsible for many of PVDF's desirable optical characteristics.

The trend in PVDF optical technology has been moving towards nanoscale engineering and composite materials. By incorporating nanoparticles or creating nanostructured PVDF films, researchers have achieved remarkable improvements in optical clarity, light transmission, and antireflective properties. This has opened up new possibilities for PVDF in advanced optical systems, including flexible displays, optical sensors, and photonic devices.

The primary objective in using PVDF for optical clarity improvement is to leverage its unique properties to create optical components that outperform traditional materials in specific applications. This includes developing PVDF-based films and coatings with enhanced transparency, reduced haze, and improved light management capabilities. Additionally, researchers aim to exploit PVDF's flexibility and processability to create novel optical devices that can be integrated into curved or flexible surfaces.

Another key goal is to overcome the inherent limitations of PVDF, such as its relatively high crystallinity, which can affect optical clarity. Efforts are being made to develop new processing techniques and PVDF copolymers that maintain the material's beneficial properties while minimizing factors that could impair optical performance.

As the field progresses, the focus is shifting towards multifunctional PVDF optical materials that combine clarity improvement with other desirable properties such as self-cleaning, anti-fogging, or energy harvesting capabilities. This multidisciplinary approach aims to create versatile PVDF-based optical solutions that can address complex challenges in various industries, from consumer electronics to aerospace and biomedical applications.

Market Analysis for PVDF Optical Applications

The market for PVDF in optical applications is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. PVDF, or polyvinylidene fluoride, has emerged as a promising material for improving clarity in optical applications due to its unique properties.

The global PVDF market is projected to expand steadily over the next few years, with a particular focus on its use in optical applications. This growth is primarily attributed to the material's excellent optical properties, including high transparency, low refractive index, and resistance to UV radiation. These characteristics make PVDF an attractive option for manufacturers seeking to enhance the clarity and performance of their optical products.

One of the key drivers of market demand for PVDF in optical applications is the growing need for advanced materials in the electronics and display industries. As consumer electronics continue to evolve, there is an increasing emphasis on improving screen clarity and durability. PVDF coatings and films are being utilized to enhance the optical properties of displays, touchscreens, and other electronic components, leading to improved visual quality and user experience.

The automotive sector is another significant market for PVDF optical applications. With the rise of advanced driver assistance systems (ADAS) and autonomous vehicles, there is a growing demand for high-clarity materials in sensors, cameras, and other optical components. PVDF's ability to maintain clarity in harsh environmental conditions makes it an ideal choice for these applications.

In the aerospace and defense industries, PVDF is gaining traction for use in optical windows, lenses, and protective coatings. The material's resistance to extreme temperatures and chemicals, combined with its optical clarity, makes it suitable for demanding aerospace applications where reliability and performance are critical.

The medical and healthcare sectors are also contributing to the market growth of PVDF in optical applications. The material's biocompatibility and optical properties make it suitable for use in medical imaging devices, endoscopes, and other diagnostic equipment where clarity is essential for accurate diagnoses and treatments.

As sustainability becomes an increasingly important factor in material selection, PVDF's recyclability and long lifespan are attracting attention from environmentally conscious manufacturers. This trend is expected to further drive the adoption of PVDF in optical applications across various industries.

However, the market for PVDF in optical applications faces some challenges, including competition from alternative materials and the need for continuous innovation to meet evolving industry requirements. Manufacturers and researchers are actively working on developing new PVDF formulations and processing techniques to further enhance its optical properties and expand its applications.

PVDF Optical Technology: Current State and Challenges

Polyvinylidene fluoride (PVDF) has emerged as a promising material in optical applications, particularly for improving clarity. However, its current state and implementation face several challenges that require addressing for optimal performance. The optical properties of PVDF, including its high transparency and low refractive index, make it an attractive option for various optical components and coatings. Nevertheless, the material's inherent characteristics also present obstacles that researchers and engineers must overcome.

One of the primary challenges in utilizing PVDF for optical clarity improvement is its semicrystalline nature. The crystalline regions within PVDF can cause light scattering, potentially reducing overall transparency. Researchers are actively working on methods to control and minimize crystallinity without compromising the material's other beneficial properties. This includes exploring different processing techniques, such as rapid cooling or the addition of nucleating agents, to manipulate the crystal structure.

Another significant hurdle is the optimization of PVDF film thickness for specific optical applications. While thinner films generally offer better clarity, they may lack the mechanical strength required for certain uses. Balancing optical performance with structural integrity remains a key focus area for developers working with PVDF in optical systems.

The surface properties of PVDF also present challenges in optical applications. The material's inherent hydrophobicity can lead to issues with adhesion and coating uniformity. Researchers are investigating surface modification techniques, such as plasma treatment or chemical functionalization, to improve PVDF's compatibility with other optical materials and enhance its overall performance in multilayer systems.

Furthermore, the long-term stability of PVDF in optical applications is an area of ongoing research. Exposure to UV radiation and environmental factors can potentially degrade the material's optical properties over time. Developing effective stabilization methods and protective coatings is crucial for ensuring the longevity of PVDF-based optical components.

The integration of PVDF into existing optical manufacturing processes poses additional challenges. Many current production methods are optimized for traditional optical materials, and adapting these processes for PVDF may require significant modifications. This includes addressing issues related to thermal processing, as PVDF's relatively low melting point can complicate its use in certain high-temperature applications.

Despite these challenges, the potential benefits of PVDF in optical applications continue to drive research and development efforts. Its unique combination of optical clarity, chemical resistance, and flexibility makes it a valuable material for innovations in fields such as display technologies, optical sensors, and photovoltaics. As researchers work to overcome the current limitations, PVDF is poised to play an increasingly important role in advancing optical clarity and performance across various industries.

Existing PVDF-based Optical Clarity Solutions

01 Improving PVDF clarity through composition modification

Enhancing the clarity of PVDF can be achieved by modifying its composition. This may involve incorporating specific additives or adjusting the polymer structure to reduce light scattering and increase transparency. The process often includes careful selection of monomers, controlling crystallization, and optimizing the molecular weight distribution.- Improving PVDF clarity through composition modification: Enhancing the clarity of PVDF can be achieved by modifying its composition. This may involve incorporating specific additives, adjusting the molecular weight distribution, or blending with other compatible polymers. These modifications can help reduce light scattering and improve the overall transparency of the PVDF material.

- Processing techniques for enhanced PVDF clarity: Various processing techniques can be employed to improve the clarity of PVDF. These may include optimizing extrusion parameters, controlling cooling rates, or applying specific heat treatments. Such techniques can help minimize crystallinity and reduce the size of crystalline domains, resulting in improved optical properties.

- Surface treatment methods for PVDF clarity enhancement: Surface treatments can be applied to PVDF to enhance its clarity. These may involve chemical etching, plasma treatment, or the application of specialized coatings. Such treatments can modify the surface properties of PVDF, reducing light scattering and improving overall transparency.

- Nanocomposite approach for improving PVDF clarity: Incorporating nanoparticles or nanofillers into PVDF can significantly enhance its clarity. These nanocomposites can help reduce the size of crystalline domains, improve light transmission, and maintain or enhance other desirable properties of PVDF. Careful selection and dispersion of nanofillers are crucial for achieving optimal clarity.

- Optical property enhancement through PVDF copolymerization: Copolymerization of PVDF with other monomers can lead to improved clarity. By carefully selecting comonomers and controlling the copolymerization process, the resulting material can exhibit enhanced optical properties while maintaining the desirable characteristics of PVDF. This approach allows for tailoring the polymer structure to achieve the desired balance of properties.

02 Processing techniques for enhanced PVDF clarity

Various processing techniques can be employed to improve the clarity of PVDF. These may include controlled cooling rates during molding, stretching the material to orient polymer chains, or using specific extrusion parameters. Advanced processing methods can help reduce haze and increase light transmission through the PVDF material.Expand Specific Solutions03 Blending PVDF with other polymers for clarity

Blending PVDF with compatible polymers can enhance its clarity. This approach involves selecting polymers that have similar refractive indices or that can form miscible blends with PVDF. The resulting composite materials often exhibit improved optical properties while maintaining the desirable characteristics of PVDF.Expand Specific Solutions04 Surface treatment methods for PVDF clarity

Surface treatments can be applied to PVDF to improve its clarity. These treatments may include plasma processing, chemical etching, or the application of specialized coatings. Such methods can reduce surface roughness, minimize light scattering, and enhance the overall transparency of PVDF products.Expand Specific Solutions05 Nanocomposite approach for PVDF clarity enhancement

Incorporating nanoparticles or nanostructures into PVDF can significantly improve its clarity. This approach often involves the use of nanoscale additives that are carefully dispersed within the PVDF matrix. The resulting nanocomposites can exhibit enhanced optical properties due to reduced light scattering and improved molecular organization.Expand Specific Solutions

Key Players in PVDF Optical Industry

The use of PVDF in optical applications for clarity improvement is an emerging field in the advanced materials industry. This sector is currently in a growth phase, with increasing market demand driven by the need for high-performance optical components. The global market for PVDF in optical applications is expanding, though still relatively niche compared to traditional optical materials. Technologically, the field is progressing rapidly, with companies like Arkema, Saint-Gobain, and FUJIFILM leading innovation. These firms are developing specialized PVDF formulations and processing techniques to enhance optical clarity and performance. Other players such as Carl Zeiss SMT and II-VI Delaware are also contributing to advancements in PVDF-based optical solutions, indicating a competitive and dynamic landscape with potential for significant growth and technological breakthroughs.

Arkema, Inc.

FUJIFILM Corp.

Core Innovations in PVDF Optical Technology

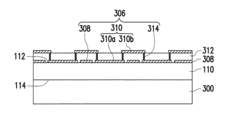

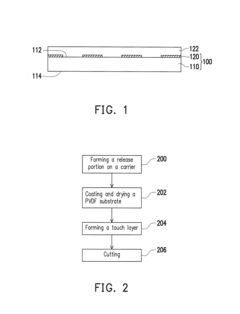

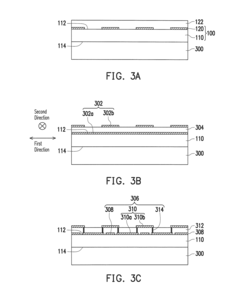

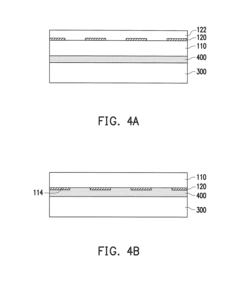

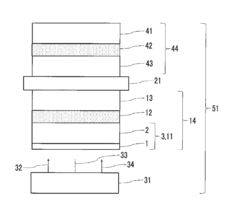

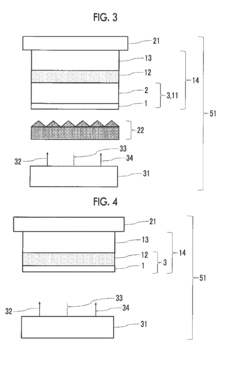

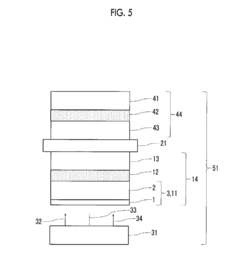

- A touch panel comprising a PVDF substrate with an inorganic nano-modified material dispersion, where the touch electrode structure is disposed on at least one surface of the PVDF substrate, and optionally a passivation layer or functional film is used to enhance optical properties and tactile feedback.

- A liquid crystal display device configuration is implemented where an optical thin film with a specific refractive index and thickness is positioned at the air interface of the backlight side polarizer, optimizing light transmittance and color reproducibility by matching the refractive index and thickness product to the peak wavelength of emission line light, thereby achieving high transmittance and color accuracy.

Environmental Impact of PVDF in Optics

The use of Polyvinylidene Fluoride (PVDF) in optical applications for clarity improvement has significant environmental implications that warrant careful consideration. PVDF, a fluoropolymer known for its excellent optical properties, has gained traction in various optical applications due to its ability to enhance clarity and light transmission. However, its environmental impact throughout its lifecycle must be thoroughly assessed.

During the production phase of PVDF, the primary environmental concern lies in the emission of fluorinated compounds. These emissions, if not properly controlled, can contribute to air pollution and potentially harm the ozone layer. Manufacturers have implemented advanced emission control technologies to mitigate these risks, but the energy-intensive nature of PVDF production still contributes to carbon emissions and resource depletion.

In its application phase, PVDF's durability and resistance to degradation offer both advantages and challenges from an environmental perspective. The longevity of PVDF-based optical components reduces the need for frequent replacements, thereby minimizing waste generation. However, this same resistance to degradation poses challenges for end-of-life management, as PVDF does not readily biodegrade in natural environments.

The disposal and recycling of PVDF-containing optical products present unique environmental challenges. While PVDF can be recycled, the process is complex and energy-intensive due to its high melting point and chemical stability. Improper disposal of PVDF products can lead to long-term environmental persistence, potentially impacting soil and water ecosystems.

On a positive note, the use of PVDF in optical applications can indirectly contribute to environmental benefits. By improving optical clarity and efficiency in devices such as solar panels and light-emitting diodes (LEDs), PVDF can enhance energy efficiency and reduce overall energy consumption. This indirect effect may partially offset the environmental impacts associated with its production and disposal.

Research into more environmentally friendly alternatives and improved recycling technologies for PVDF is ongoing. Efforts are being made to develop bio-based or more easily recyclable polymers with similar optical properties. Additionally, advancements in green chemistry are exploring ways to reduce the environmental footprint of PVDF production processes.

In conclusion, while PVDF offers significant benefits in optical applications for clarity improvement, its environmental impact is complex and multifaceted. Balancing the material's performance advantages with its environmental implications requires a holistic approach, considering the entire lifecycle from production to disposal. As technology advances, it is crucial to continue developing more sustainable practices in the use and management of PVDF in optical applications.

PVDF Optical Standards and Regulations

The use of PVDF in optical applications for clarity improvement is subject to various standards and regulations to ensure safety, performance, and consistency. These standards are established by international organizations, national bodies, and industry associations to guide manufacturers, researchers, and end-users in the proper implementation of PVDF in optical systems.

One of the primary standards governing PVDF in optical applications is ISO 11979-8, which specifically addresses the requirements for ophthalmic implants. This standard outlines the testing methods and acceptance criteria for optical clarity, including light transmission, haze, and refractive index measurements. Manufacturers must adhere to these guidelines to ensure that PVDF-based optical components meet the necessary quality and performance benchmarks.

In the United States, the Food and Drug Administration (FDA) regulates the use of PVDF in medical optical devices through its 510(k) clearance process. This regulatory pathway requires manufacturers to demonstrate that their PVDF-based optical products are substantially equivalent to predicate devices in terms of safety and effectiveness. The FDA also provides guidance on the biocompatibility testing of materials used in optical applications, including PVDF.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) also impact the use of PVDF in optical applications, particularly for medical devices. These regulations mandate comprehensive clinical evaluations and post-market surveillance for PVDF-based optical products to ensure ongoing safety and performance.

Industry-specific standards, such as those set by the American Society for Testing and Materials (ASTM), provide detailed testing protocols for evaluating the optical properties of PVDF. ASTM D1003, for instance, outlines the standard test method for haze and luminous transmittance of transparent plastics, which is applicable to PVDF films used in optical applications.

The International Electrotechnical Commission (IEC) has established standards relevant to PVDF in optoelectronic applications. IEC 60068-2-78 addresses environmental testing procedures, including those for optical materials like PVDF, ensuring their reliability under various conditions.

Compliance with these standards and regulations is crucial for manufacturers and researchers working with PVDF in optical applications. It not only ensures product quality and safety but also facilitates market access and acceptance. As the field of optical applications continues to evolve, these standards are regularly reviewed and updated to keep pace with technological advancements and emerging safety considerations in PVDF usage for clarity improvement.