PVDF Innovations in Automating Filtration Plant Operations

PVDF Filtration Evolution

The evolution of PVDF filtration technology has been marked by significant advancements in material science and process engineering. Initially developed in the 1960s, polyvinylidene fluoride (PVDF) quickly gained recognition for its exceptional chemical resistance and mechanical strength, making it an ideal candidate for filtration applications.

In the early stages, PVDF membranes were primarily used in laboratory settings for small-scale separations. The 1970s saw the first commercial applications of PVDF in water treatment, particularly in the production of ultrapure water for the semiconductor industry. This period was characterized by the development of basic flat sheet and hollow fiber membrane configurations.

The 1980s brought about a revolution in PVDF membrane manufacturing techniques. The introduction of phase inversion processes allowed for greater control over pore size and distribution, significantly enhancing filtration efficiency. This decade also saw the expansion of PVDF filtration into new industries, including pharmaceuticals and food processing.

The 1990s marked a turning point in PVDF filtration technology with the advent of surface modification techniques. These innovations allowed for the tailoring of membrane surface properties, improving fouling resistance and selectivity. Concurrently, the development of more robust PVDF formulations extended the lifespan of filtration systems, reducing operational costs.

As we entered the 21st century, the focus shifted towards enhancing the sustainability and efficiency of PVDF filtration systems. The integration of nanotechnology led to the creation of nanocomposite PVDF membranes with superior performance characteristics. Additionally, the development of chlorine-resistant PVDF grades expanded the technology's applicability in harsh chemical environments.

Recent years have seen a surge in research aimed at automating PVDF filtration plant operations. This trend is driven by the need for more efficient, reliable, and cost-effective water treatment solutions. Innovations in this area include the development of smart membranes with integrated sensors for real-time monitoring of filtration performance and the implementation of artificial intelligence for predictive maintenance and process optimization.

The latest frontier in PVDF filtration evolution is the integration of Internet of Things (IoT) technologies. This advancement allows for remote monitoring and control of filtration plants, enabling operators to make data-driven decisions and optimize plant performance from anywhere in the world. Furthermore, the incorporation of machine learning algorithms is paving the way for self-adjusting filtration systems that can adapt to changing water quality conditions autonomously.

Automated Plant Demand

The automation of filtration plant operations using PVDF (Polyvinylidene Fluoride) innovations has become increasingly crucial in meeting the growing demand for efficient and reliable water treatment processes. As industries and municipalities face mounting pressure to optimize their operations, the need for automated solutions has surged, driving the development of advanced PVDF-based technologies.

The demand for automated plant operations stems from several key factors. Firstly, there is a pressing need to reduce operational costs and improve efficiency. Manual operation of filtration plants is labor-intensive and prone to human error, leading to inconsistent performance and increased maintenance requirements. By implementing automated systems, plant operators can significantly reduce labor costs while ensuring more consistent and reliable operation.

Secondly, the increasing complexity of water treatment processes necessitates more sophisticated control systems. Modern filtration plants must handle a wide range of contaminants and adapt to varying water quality conditions. Automated PVDF-based systems can continuously monitor water quality parameters and adjust treatment processes in real-time, ensuring optimal performance under diverse conditions.

Environmental regulations and quality standards are becoming more stringent, driving the demand for precise control and monitoring capabilities. Automated PVDF filtration systems can provide accurate data logging and reporting, helping plant operators demonstrate compliance with regulatory requirements. This level of precision and accountability is difficult to achieve with manual operations alone.

The push for sustainability and resource conservation has also fueled the demand for automated plant operations. PVDF-based automated systems can optimize chemical usage, reduce energy consumption, and minimize waste generation. By fine-tuning processes based on real-time data, these systems can achieve significant improvements in resource efficiency, aligning with broader sustainability goals.

Furthermore, the water industry faces a growing skills gap, with experienced operators retiring and fewer young professionals entering the field. Automated PVDF filtration systems can help bridge this gap by reducing the reliance on manual interventions and providing intuitive interfaces that require less specialized knowledge to operate effectively.

The COVID-19 pandemic has accelerated the trend towards automation, as water treatment facilities seek to minimize on-site staffing requirements and ensure operational continuity during crises. Remote monitoring and control capabilities offered by automated PVDF systems have become increasingly valuable in this context, allowing for efficient plant management with reduced physical presence.

As water scarcity becomes a global concern, there is a growing need for advanced water reuse and desalination technologies. Automated PVDF filtration systems play a crucial role in these applications, enabling the precise control required for producing high-quality reclaimed water or desalinated water for various end-uses.

PVDF Tech Challenges

PVDF (Polyvinylidene fluoride) technology in automating filtration plant operations faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the complexity of integrating PVDF membrane systems with existing plant infrastructure. Many filtration plants have legacy systems that are not easily compatible with advanced PVDF technologies, requiring substantial modifications and investments.

The fouling of PVDF membranes remains a persistent issue, particularly in industrial applications where the feed streams contain high levels of contaminants. This fouling leads to reduced flux rates, increased energy consumption, and more frequent cleaning cycles, all of which impact operational efficiency. Developing effective anti-fouling strategies that do not compromise the membrane's integrity or filtration performance is an ongoing challenge.

Another significant hurdle is the optimization of PVDF membrane properties for specific applications. While PVDF offers excellent chemical resistance and thermal stability, fine-tuning its pore size, surface chemistry, and mechanical properties to meet the diverse requirements of different industries and processes is complex. This customization is crucial for achieving optimal filtration performance but often requires extensive research and development efforts.

The automation of PVDF-based filtration systems presents its own set of challenges. Implementing real-time monitoring and control systems that can accurately assess membrane performance, predict fouling, and autonomously adjust operational parameters is technically demanding. The development of robust sensors and algorithms capable of handling the variability in feed compositions and environmental conditions is an area that requires significant advancement.

Scalability is another critical issue facing PVDF technology in large-scale filtration plants. While PVDF membranes perform well in laboratory and pilot-scale operations, maintaining consistent performance and efficiency when scaling up to industrial-scale applications can be problematic. This includes challenges in membrane module design, flow distribution, and maintaining uniform transmembrane pressure across large membrane areas.

The environmental impact and sustainability of PVDF membrane production and disposal are also growing concerns. As regulations become more stringent, developing eco-friendly manufacturing processes and finding effective ways to recycle or safely dispose of used PVDF membranes are becoming increasingly important challenges for the industry to address.

Lastly, the cost-effectiveness of PVDF technology in comparison to traditional filtration methods remains a significant barrier to widespread adoption. While PVDF membranes offer superior performance in many applications, the initial investment and operational costs can be prohibitive for some industries. Reducing the overall cost of PVDF-based filtration systems while maintaining their high performance is a key challenge that requires innovative approaches in material science and process engineering.

Current PVDF Solutions

01 PVDF membrane manufacturing automation

Automated processes for manufacturing PVDF membranes, including extrusion, stretching, and surface treatment. These systems improve efficiency, consistency, and quality control in membrane production for various applications such as filtration and separation technologies.- PVDF membrane manufacturing automation: Automated processes for manufacturing PVDF membranes, including extrusion, stretching, and surface treatment. These systems improve efficiency, consistency, and quality control in the production of PVDF membranes for various applications such as filtration and separation.

- Automated PVDF coating systems: Development of automated coating systems for applying PVDF to various substrates. These systems utilize precision control mechanisms and advanced dispensing technologies to ensure uniform and consistent PVDF coatings, enhancing the performance and durability of coated products.

- PVDF-based sensor and actuator automation: Integration of PVDF materials in automated sensor and actuator systems. PVDF's piezoelectric properties are utilized in developing smart sensors and actuators for various industrial applications, including process control, robotics, and structural health monitoring.

- Automated PVDF recycling and processing: Development of automated systems for recycling and processing PVDF materials. These systems include sorting, cleaning, and reprocessing technologies to efficiently recycle PVDF waste and convert it into reusable materials, promoting sustainability in PVDF-based industries.

- PVDF-based energy harvesting automation: Automation of PVDF-based energy harvesting systems, leveraging the material's piezoelectric properties. These systems include automated fabrication of PVDF energy harvesters and integration with power management circuits for efficient energy collection from ambient vibrations and mechanical stress.

02 Automated PVDF coating systems

Development of automated coating systems for applying PVDF to various substrates. These systems utilize precision control mechanisms and advanced dispensing technologies to ensure uniform coating thickness and optimal adhesion, enhancing the performance and durability of coated products.Expand Specific Solutions03 PVDF sensor and actuator automation

Integration of PVDF-based sensors and actuators in automated systems for various applications. These piezoelectric devices are used in robotics, vibration control, and precision positioning, leveraging PVDF's unique properties for enhanced system performance and responsiveness.Expand Specific Solutions04 Automated PVDF recycling processes

Development of automated systems for recycling PVDF materials, including sorting, cleaning, and reprocessing. These processes aim to improve the sustainability of PVDF usage by efficiently recovering and repurposing the material from end-of-life products.Expand Specific Solutions05 PVDF-based energy harvesting automation

Automated systems utilizing PVDF's piezoelectric properties for energy harvesting applications. These technologies include wearable devices, smart textiles, and infrastructure monitoring systems that convert mechanical energy into electrical energy, enabling self-powered automation solutions.Expand Specific Solutions

Filtration Industry Leaders

The PVDF innovations in automating filtration plant operations are currently in a growth phase, with increasing market size and technological advancements. The global market for automated filtration systems is expanding rapidly, driven by the need for efficient and cost-effective water treatment solutions. The technology maturity varies among key players, with companies like Repligen Corp., Asahi Kasei Corp., and Pall Corp. leading in innovation. These firms are developing advanced PVDF membrane technologies and automation systems for filtration plants. Other significant contributors include EMD Millipore Corp. and Sartorius Stedim Biotech GmbH, who are focusing on integrating smart technologies and data analytics into their filtration solutions. The competitive landscape is characterized by a mix of established industry leaders and emerging players, with ongoing research and development efforts aimed at improving process efficiency and reducing operational costs in filtration plant automation.

Asahi Kasei Corp.

Arkema, Inc.

PVDF Automation Patents

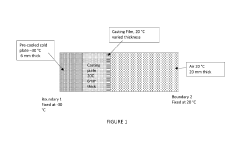

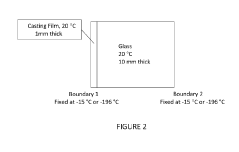

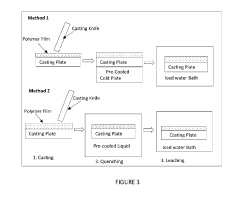

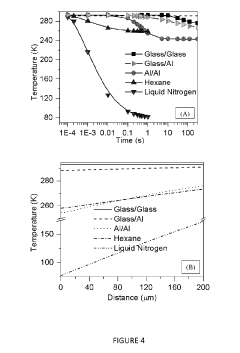

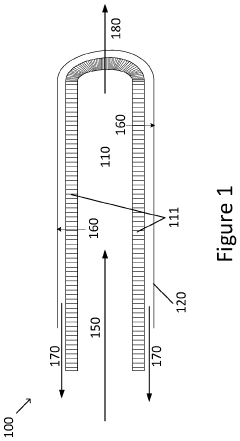

- A process involving unidirectional cooling of a polymeric dope solution cast onto a substrate, where one surface is cooled below the melting temperature of the solvent, creating a temperature gradient that controls solvent crystallite size and prevents agglomeration, resulting in membranes with average pore sizes of 0.01-10 μm and improved flux characteristics.

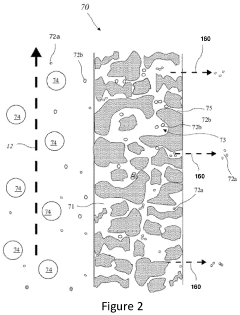

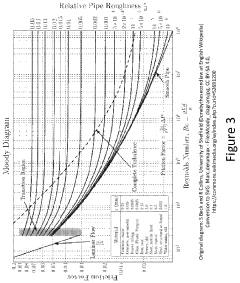

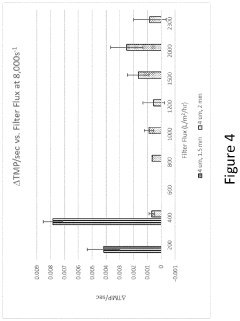

- The implementation of non-laminar feed flows through tubular depth filters (TDFs) with specific geometries and operational conditions, such as Reynolds numbers greater than 2000, promotes turbulent flow, reducing fouling and enhancing filter flux, thereby increasing process capacity.

Regulatory Compliance

Regulatory compliance is a critical aspect of PVDF innovations in automating filtration plant operations. As the water treatment industry evolves, stringent regulations are being implemented to ensure the safety and quality of water supplies. These regulations directly impact the design, operation, and maintenance of filtration plants, necessitating advanced automation solutions that can meet compliance requirements efficiently and consistently.

In the United States, the Environmental Protection Agency (EPA) sets and enforces standards for drinking water quality under the Safe Drinking Water Act. These regulations mandate specific treatment techniques, monitoring protocols, and reporting requirements for filtration plants. PVDF membrane filtration systems must demonstrate their ability to consistently remove contaminants to levels below the maximum contaminant levels (MCLs) set by the EPA.

Automated PVDF filtration systems are increasingly being designed with built-in compliance features. These include real-time monitoring of water quality parameters, automated data logging, and reporting functionalities. Such systems can continuously track turbidity, pH, chlorine residuals, and other key indicators, ensuring that the treated water meets regulatory standards at all times. This level of automation not only enhances compliance but also reduces the risk of human error in monitoring and reporting.

The European Union's Drinking Water Directive (DWD) sets similar standards for water quality and treatment processes. PVDF filtration plants operating in EU member states must adhere to these regulations, which are often more stringent than those in other regions. Automated systems that can adapt to varying regulatory requirements across different jurisdictions are particularly valuable for multinational water treatment companies.

Regulatory compliance also extends to the materials used in filtration systems. PVDF membranes and associated components must meet food-grade standards and be certified for use in drinking water applications. Innovations in PVDF material science are focused on developing membranes that not only improve filtration efficiency but also meet or exceed regulatory requirements for material safety and durability.

As regulations evolve, automated PVDF filtration systems must be designed with flexibility to accommodate future changes. This includes the ability to upgrade software and adjust operating parameters to meet new or revised standards without requiring extensive hardware modifications. Cloud-based compliance management systems are emerging as a solution, allowing for remote updates and real-time regulatory guidance.

In conclusion, regulatory compliance is a driving force behind PVDF innovations in automating filtration plant operations. As regulations become more complex and stringent, automated systems that can ensure consistent compliance while optimizing operational efficiency will be essential for the future of water treatment technology.

Environmental Impact

The implementation of PVDF innovations in automating filtration plant operations has significant environmental implications. These advancements contribute to more efficient water treatment processes, reducing energy consumption and minimizing chemical usage. By optimizing filtration systems, PVDF-based technologies help decrease the overall environmental footprint of water treatment facilities.

One of the primary environmental benefits is the reduction in water waste. Automated PVDF filtration systems can more accurately monitor and control the filtration process, leading to improved water recovery rates. This efficiency translates to less water being discarded during the treatment process, conserving valuable water resources and reducing the strain on local ecosystems.

Furthermore, the durability and chemical resistance of PVDF membranes result in longer operational lifespans for filtration equipment. This longevity reduces the frequency of membrane replacements, thereby decreasing the amount of waste generated from discarded filtration components. The extended lifespan also means fewer resources are required for manufacturing replacement parts, contributing to a reduction in overall environmental impact.

The automation of filtration plant operations using PVDF innovations also leads to more precise chemical dosing. This precision minimizes the overuse of treatment chemicals, reducing the potential for harmful chemical residues in treated water and the surrounding environment. The reduced chemical usage not only benefits aquatic ecosystems but also decreases the environmental impact associated with the production and transportation of these chemicals.

Energy efficiency is another crucial environmental aspect of PVDF-based automated filtration systems. By optimizing the filtration process through real-time monitoring and adaptive control, these systems can operate at peak efficiency, reducing energy consumption. This energy reduction translates to lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

Moreover, the improved filtration efficiency of PVDF membranes in automated systems enhances the quality of treated water. This high-quality output reduces the need for additional treatment steps, further conserving energy and resources. The superior filtration also means fewer contaminants are released into the environment, protecting aquatic ecosystems and biodiversity.

In conclusion, the environmental impact of PVDF innovations in automating filtration plant operations is predominantly positive. These advancements contribute to water conservation, reduced chemical usage, improved energy efficiency, and enhanced water quality. As these technologies continue to evolve, they are likely to play an increasingly important role in sustainable water management practices, helping to address global environmental challenges related to water scarcity and pollution.