How to Optimize PVDF in Outdoor Protective Coatings?

PVDF Coating Evolution

PVDF (polyvinylidene fluoride) coatings have undergone significant evolution since their introduction in the 1960s. Initially developed for industrial applications, these coatings quickly gained recognition for their exceptional durability and resistance to weathering, making them ideal for outdoor protective coatings.

The early stages of PVDF coating development focused primarily on improving adhesion to various substrates and enhancing UV resistance. Researchers experimented with different formulations and application techniques to overcome the inherent non-stick properties of fluoropolymers. This led to the introduction of primer systems and surface treatment methods that significantly improved the bonding of PVDF to metal surfaces.

In the 1970s and 1980s, the focus shifted towards enhancing the color stability and gloss retention of PVDF coatings. Manufacturers introduced pigment technologies specifically designed for fluoropolymer systems, resulting in coatings that could maintain their appearance for decades even in harsh outdoor environments. This breakthrough expanded the use of PVDF coatings in architectural applications, particularly for metal building panels and curtain walls.

The 1990s saw advancements in PVDF resin technology, with the development of new grades offering improved flexibility and impact resistance. These innovations allowed for the use of PVDF coatings on more complex geometries and in applications requiring greater mechanical performance. Additionally, water-based PVDF coating systems were introduced, addressing environmental concerns and regulatory pressures to reduce volatile organic compound (VOC) emissions.

In the 2000s, nanotechnology began to play a role in PVDF coating evolution. Researchers incorporated nanoparticles into PVDF formulations to enhance properties such as scratch resistance, self-cleaning capabilities, and anti-microbial performance. These advancements opened up new possibilities for PVDF coatings in specialized applications, including solar panel protection and high-performance industrial coatings.

Recent years have seen a focus on sustainability and energy efficiency in PVDF coating development. Cool roof technologies utilizing PVDF have been developed to reflect more solar radiation, reducing building energy consumption. Additionally, efforts have been made to incorporate recycled materials and bio-based components into PVDF coating formulations, aligning with global sustainability initiatives.

The ongoing evolution of PVDF coatings continues to address challenges in outdoor protective applications. Current research is exploring ways to further improve weatherability, extend service life, and enhance the ease of application. As environmental regulations become more stringent, there is also a push towards developing PVDF coating systems with even lower VOC content and reduced environmental impact throughout their lifecycle.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) in outdoor protective coatings has been steadily increasing due to its exceptional properties and performance in harsh environmental conditions. The global PVDF market size was valued at USD 937.5 million in 2020 and is projected to reach USD 1.5 billion by 2028, growing at a CAGR of 6.2% during the forecast period. This growth is primarily driven by the rising demand for durable and weather-resistant coatings in various industries, including construction, automotive, and aerospace.

In the construction sector, PVDF-based coatings are gaining popularity for their ability to protect buildings from UV radiation, chemical exposure, and extreme weather conditions. The increasing focus on sustainable and energy-efficient buildings has further boosted the demand for PVDF coatings, as they contribute to improved thermal management and reduced maintenance costs. The automotive industry is another significant consumer of PVDF coatings, particularly for exterior applications where long-lasting protection against corrosion and weathering is crucial.

The aerospace industry has also shown a growing interest in PVDF coatings due to their excellent resistance to high temperatures and chemical agents. As the aerospace sector continues to expand, the demand for advanced protective coatings is expected to rise, further driving the PVDF market growth. Additionally, the renewable energy sector, particularly solar panel manufacturers, has been adopting PVDF coatings to enhance the durability and efficiency of their products.

Geographically, Asia-Pacific is expected to be the fastest-growing market for PVDF coatings, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe remain significant markets, with a strong focus on high-performance coatings in various industries. The Middle East and Africa region is also showing promising growth potential, particularly in the construction and oil & gas sectors.

The increasing environmental regulations and growing awareness of sustainable practices have led to a shift towards water-based PVDF coatings, which offer reduced VOC emissions compared to solvent-based alternatives. This trend is expected to create new opportunities for market growth and innovation in PVDF coating formulations. Furthermore, the development of nano-enhanced PVDF coatings with improved scratch resistance and self-cleaning properties is likely to open up new application areas and drive market expansion.

As the demand for high-performance protective coatings continues to grow across various industries, optimizing PVDF in outdoor protective coatings remains a key focus for manufacturers and researchers. The market is expected to witness ongoing innovations in PVDF formulations, application techniques, and performance enhancements to meet the evolving needs of end-users and address challenges such as improved adhesion, flexibility, and cost-effectiveness.

Technical Challenges

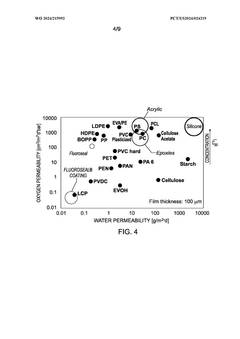

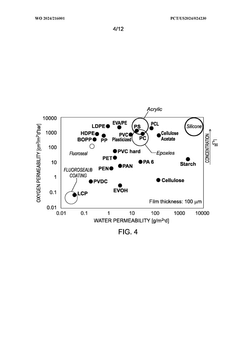

The optimization of PVDF in outdoor protective coatings faces several technical challenges that need to be addressed to enhance its performance and longevity. One of the primary issues is the degradation of PVDF under prolonged exposure to UV radiation. While PVDF is known for its excellent UV resistance compared to other polymers, continuous exposure can still lead to chain scission and crosslinking, affecting the coating's durability and aesthetic properties.

Another significant challenge is maintaining the adhesion of PVDF coatings to various substrates over time. The non-polar nature of PVDF can result in poor adhesion, especially on metal surfaces. This issue is exacerbated by thermal cycling and environmental stressors, potentially leading to delamination and coating failure. Developing effective primers and surface treatment techniques to improve adhesion without compromising the inherent properties of PVDF remains a complex task.

The formulation of PVDF coatings also presents challenges in balancing performance characteristics. Achieving the optimal blend of PVDF with other resins and additives to enhance properties such as flexibility, impact resistance, and chemical resistance while maintaining the core benefits of PVDF is a delicate process. Moreover, ensuring consistent dispersion of pigments and additives within the PVDF matrix without compromising the polymer's crystallinity is crucial for maintaining color stability and overall coating integrity.

Environmental concerns and regulatory pressures pose additional challenges. The need to reduce or eliminate volatile organic compounds (VOCs) in coating formulations has led to the development of water-based and high-solid PVDF systems. However, these alternatives often struggle to match the performance of traditional solvent-based systems, particularly in terms of application properties and final film characteristics.

The processing and application of PVDF coatings also present technical hurdles. The high melting point of PVDF necessitates specialized equipment and techniques for proper application, which can limit its use in certain contexts. Achieving uniform film thickness and appearance across large surfaces or complex geometries remains challenging, especially when considering the need for cost-effective application methods in industrial settings.

Furthermore, the long-term performance prediction and accelerated testing of PVDF coatings pose significant challenges. Developing accurate models and test methods that can reliably predict decades of outdoor exposure in a shorter timeframe is crucial for advancing PVDF coating technology. This includes understanding the synergistic effects of multiple environmental stressors on coating performance and developing standardized test protocols that correlate well with real-world performance.

Addressing these technical challenges requires a multidisciplinary approach, combining polymer science, surface chemistry, materials engineering, and environmental science. Innovations in nanotechnology, such as the incorporation of nanofillers to enhance specific properties, and advancements in polymer synthesis techniques offer promising avenues for overcoming these obstacles and further optimizing PVDF in outdoor protective coatings.

Current PVDF Solutions

01 PVDF membrane modification

Various techniques are employed to modify PVDF membranes, enhancing their properties for specific applications. These modifications can include surface treatments, blending with other polymers, or incorporating additives to improve characteristics such as hydrophilicity, fouling resistance, or mechanical strength.- PVDF membrane modification techniques: Various methods are employed to optimize PVDF membranes, including surface modification, blending with other polymers, and incorporating nanoparticles. These techniques aim to enhance properties such as hydrophilicity, fouling resistance, and mechanical strength, thereby improving the overall performance of PVDF membranes in applications like water treatment and separation processes.

- PVDF-based composite materials: Developing PVDF-based composite materials by combining PVDF with other materials such as graphene, carbon nanotubes, or metal oxides. These composites often exhibit enhanced properties like improved mechanical strength, electrical conductivity, or thermal stability, making them suitable for various applications in electronics, energy storage, and sensors.

- PVDF processing optimization: Optimizing PVDF processing parameters such as temperature, pressure, and solvent selection to improve the quality and properties of PVDF products. This includes techniques like solution casting, melt extrusion, and electrospinning, which can significantly affect the crystallinity, morphology, and performance of PVDF materials.

- PVDF for energy harvesting and storage: Utilizing PVDF's piezoelectric and ferroelectric properties for energy harvesting and storage applications. This includes developing PVDF-based materials for piezoelectric generators, sensors, and capacitors, as well as optimizing PVDF formulations for improved energy conversion efficiency and storage capacity.

- PVDF in coating and film applications: Optimizing PVDF formulations and processing techniques for coating and film applications. This involves improving properties such as weatherability, chemical resistance, and adhesion to various substrates. PVDF coatings and films find applications in architecture, automotive, and protective coatings for industrial equipment.

02 PVDF-based composite materials

Development of PVDF-based composite materials involves combining PVDF with other materials to create new products with enhanced properties. These composites can exhibit improved mechanical, thermal, or electrical characteristics, making them suitable for a wide range of applications in various industries.Expand Specific Solutions03 PVDF processing optimization

Optimization of PVDF processing techniques focuses on improving manufacturing methods to enhance the quality and properties of PVDF products. This can include adjustments to extrusion parameters, molding conditions, or post-processing treatments to achieve desired material characteristics and performance.Expand Specific Solutions04 PVDF for energy storage applications

Research and development efforts are directed towards optimizing PVDF for use in energy storage devices, such as batteries and capacitors. This includes modifying PVDF to enhance its dielectric properties, ionic conductivity, or compatibility with other battery components to improve overall energy storage performance.Expand Specific Solutions05 PVDF in filtration and separation technologies

Optimization of PVDF for filtration and separation applications involves improving membrane properties such as pore size distribution, flux, and selectivity. Techniques may include surface modifications, blending with other polymers, or incorporating functional additives to enhance separation efficiency and fouling resistance.Expand Specific Solutions

Key Industry Players

The optimization of PVDF in outdoor protective coatings is in a mature stage, with a growing market driven by increasing demand for durable and weather-resistant materials. The global PVDF market size is expected to reach significant value in the coming years, reflecting its widespread adoption. Technologically, companies like Arkema France SA, Arkema, Inc., and Solvay are at the forefront, continuously improving PVDF formulations for enhanced performance in outdoor applications. Emerging players such as Zhongtian Photovoltaic Materials Co., Ltd. and FSPG Hi-tech Co., Ltd. are also contributing to advancements, particularly in specialized applications. The competitive landscape is characterized by ongoing research and development efforts to enhance PVDF's properties, focusing on UV resistance, chemical stability, and long-term durability in harsh environments.

Arkema France SA

Zhongtian Photovoltaic Materials Co., Ltd.

PVDF Innovations

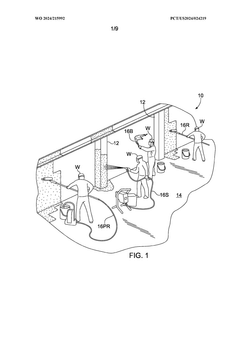

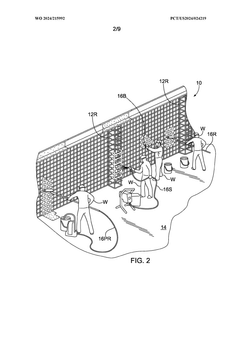

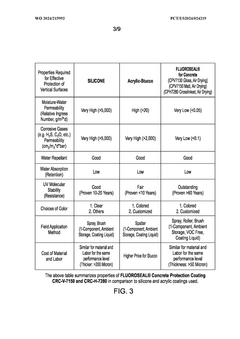

- A method involving the application of a liquidous coating of modified polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) material in an air dryable solution, which is highly fluorinated and has high polymer crystallinity, allowing it to be applied in the field without specialized equipment, effectively blocking moisture and corrosive gases, and providing long-term protection against corrosion.

- A method involving the application of two layers of modified polyvinylidene fluoride (PVDF) coatings in air-dryable solutions, with the undercoating containing a PVDF co-polymer blended with acrylic and the overcoating highly fluorinated, allowing application in situ on large metal structures without specialized equipment, providing superior moisture and gas barrier properties.

Environmental Impact

The environmental impact of PVDF (polyvinylidene fluoride) in outdoor protective coatings is a critical consideration for its optimization. PVDF-based coatings have gained popularity due to their exceptional durability and resistance to weathering, which contributes to extended product lifecycles and reduced maintenance requirements. This longevity inherently reduces the environmental burden associated with frequent repainting or replacement of coated surfaces.

However, the production of PVDF involves fluorine-based chemicals, which can have potential environmental implications. The manufacturing process may release greenhouse gases and other pollutants if not properly managed. To optimize PVDF's environmental profile, manufacturers are focusing on developing more eco-friendly production methods, such as water-based PVDF formulations that reduce the use of volatile organic compounds (VOCs) and minimize air pollution.

PVDF coatings also demonstrate excellent chemical resistance, which prevents the leaching of harmful substances into the environment over time. This characteristic is particularly important for applications in sensitive ecosystems or areas with strict environmental regulations. Furthermore, the high UV resistance of PVDF coatings helps protect underlying materials from degradation, potentially reducing waste and the need for premature replacements of coated products.

Energy efficiency is another aspect where PVDF coatings contribute positively to environmental sustainability. When used in cool roof applications, PVDF-based coatings with high solar reflectance can significantly reduce building energy consumption for cooling, thereby lowering carbon emissions associated with energy production.

End-of-life considerations are becoming increasingly important in the optimization of PVDF coatings. While PVDF is not biodegradable, research is being conducted to improve its recyclability. Some manufacturers are exploring methods to recover and reuse PVDF from old coatings, which could create a more circular economy for this material.

Water conservation is an additional area where PVDF coatings can have a positive environmental impact. The hydrophobic nature of PVDF results in self-cleaning surfaces that require less frequent washing, potentially reducing water consumption and the use of cleaning chemicals that may harm aquatic ecosystems.

As environmental regulations become more stringent globally, optimizing PVDF coatings to meet or exceed these standards is crucial. This includes developing formulations with lower environmental footprints, improving application techniques to minimize waste, and enhancing the overall lifecycle assessment of PVDF-based products. By addressing these environmental aspects, manufacturers can ensure that PVDF remains a sustainable choice for outdoor protective coatings in the long term.

Durability Assessment

Durability assessment is a critical aspect of optimizing PVDF in outdoor protective coatings. The longevity and performance of these coatings under various environmental conditions are paramount to their effectiveness. To evaluate the durability of PVDF-based coatings, a comprehensive testing regimen is essential.

Accelerated weathering tests form the cornerstone of durability assessment. These tests simulate prolonged exposure to UV radiation, moisture, and temperature fluctuations. QUV accelerated weathering chambers are commonly employed, subjecting coating samples to cycles of UV exposure and condensation. This process helps predict the long-term performance of PVDF coatings in outdoor environments.

Salt spray testing is another crucial component of durability assessment. This test evaluates the coating's resistance to corrosion, particularly in coastal or marine environments. PVDF coatings are exposed to a salt fog atmosphere for extended periods, typically ranging from 500 to 5000 hours, depending on the intended application and performance requirements.

Thermal cycling tests assess the coating's ability to withstand temperature extremes and rapid changes. These tests involve exposing coated samples to alternating hot and cold temperatures, simulating day-night cycles and seasonal variations. The coating's adhesion, flexibility, and resistance to cracking or delamination are evaluated throughout this process.

Chemical resistance testing is essential for determining the coating's durability against various environmental pollutants and cleaning agents. PVDF coatings are subjected to a range of chemicals, including acids, alkalis, and solvents, to assess their resistance to degradation and discoloration.

Abrasion resistance tests evaluate the coating's ability to withstand mechanical wear. Methods such as the Taber Abraser test or sand erosion tests are employed to simulate the effects of wind-borne particles and general wear and tear on the coating surface.

Impact resistance testing assesses the coating's ability to withstand sudden impacts without cracking or chipping. This is particularly important for applications where the coated surfaces may be subjected to hail, falling objects, or other forms of impact.

Long-term outdoor exposure testing, while time-consuming, provides the most accurate assessment of a coating's durability. Test panels are exposed to natural weathering conditions in various climates for extended periods, often several years, to evaluate real-world performance.

By conducting these comprehensive durability assessments, researchers and manufacturers can optimize PVDF formulations for outdoor protective coatings. The data gathered from these tests inform improvements in UV stability, corrosion resistance, and overall longevity, ensuring that PVDF-based coatings meet the demanding requirements of outdoor applications.