How to Use PVDF in Cutting-Edge Nanotechnology Applications?

PVDF in Nanotechnology: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a versatile material with significant potential in cutting-edge nanotechnology applications. This synthetic fluoropolymer, known for its piezoelectric properties and chemical stability, has been the subject of extensive research and development over the past few decades. The evolution of PVDF in nanotechnology can be traced back to its discovery in 1948 by Kawai, who first observed its piezoelectric properties.

As nanotechnology has advanced, PVDF has found increasing relevance due to its unique characteristics at the nanoscale. The material's ability to form nanofibers, nanoparticles, and thin films has opened up new avenues for its application in various fields, including energy harvesting, sensors, and biomedical devices. The growing interest in PVDF for nanotechnology applications is driven by its excellent mechanical properties, thermal stability, and resistance to chemicals and UV radiation.

The primary objective of exploring PVDF in nanotechnology is to harness its exceptional properties at the nanoscale to develop innovative solutions for complex technological challenges. Researchers aim to optimize PVDF's piezoelectric response, enhance its electroactive properties, and improve its compatibility with other nanomaterials to create high-performance composite systems.

One of the key goals is to develop more efficient energy harvesting devices using PVDF nanostructures. By manipulating the material at the nanoscale, scientists seek to increase the power output and sensitivity of piezoelectric sensors and actuators. Additionally, there is a focus on expanding PVDF's applications in flexible electronics, where its ability to conform to various shapes while maintaining functionality is highly valuable.

In the biomedical field, researchers are exploring PVDF's potential for tissue engineering scaffolds and drug delivery systems. The material's biocompatibility and ability to be fabricated into various nanostructures make it an attractive candidate for these applications. The objective is to create PVDF-based nanoplatforms that can interact with biological systems at the cellular level, potentially revolutionizing targeted drug delivery and tissue regeneration techniques.

Another important aspect of PVDF research in nanotechnology is the development of advanced filtration and separation technologies. By creating PVDF nanomembranes with precisely controlled pore sizes and surface properties, scientists aim to improve water purification processes and enhance the efficiency of gas separation systems.

As we delve deeper into the realm of nanotechnology, the overarching goal is to unlock the full potential of PVDF at the nanoscale. This involves not only improving existing applications but also discovering entirely new uses for this versatile material. The journey of PVDF in nanotechnology is an ongoing process of innovation, with each breakthrough opening up new possibilities for technological advancement across multiple industries.

Market Analysis for PVDF-based Nanotech Applications

The market for PVDF-based nanotechnology applications is experiencing significant growth, driven by the unique properties of PVDF and its versatility in various cutting-edge applications. PVDF, or polyvinylidene fluoride, is a high-performance polymer that exhibits excellent chemical resistance, thermal stability, and piezoelectric properties, making it ideal for use in nanotechnology.

In the electronics sector, PVDF nanofibers and nanocomposites are gaining traction for their potential in flexible electronics, sensors, and energy harvesting devices. The increasing demand for wearable technology and Internet of Things (IoT) devices is expected to fuel the growth of PVDF-based nanomaterials in this segment. The market for PVDF nanofibers in electronic applications is projected to grow steadily over the next five years.

The healthcare and biomedical industries represent another significant market for PVDF-based nanotechnology. PVDF nanofibers are being explored for drug delivery systems, tissue engineering scaffolds, and biosensors. The biocompatibility and non-toxicity of PVDF make it an attractive material for these applications. As personalized medicine and regenerative therapies gain prominence, the demand for PVDF-based nanotech solutions in healthcare is expected to rise.

In the energy sector, PVDF nanocomposites are finding applications in advanced battery technologies, fuel cells, and energy storage systems. The piezoelectric properties of PVDF nanofibers are being harnessed for energy harvesting applications, such as converting mechanical energy from human motion or environmental vibrations into electrical energy. This market segment is anticipated to show robust growth as the world shifts towards renewable energy sources and energy-efficient technologies.

The water treatment industry is another area where PVDF-based nanotechnology is making significant inroads. PVDF nanofiltration membranes are being developed for water purification and desalination processes, offering improved efficiency and durability compared to conventional membranes. With growing concerns over water scarcity and the need for clean water globally, this market segment is expected to expand rapidly in the coming years.

Geographically, North America and Europe currently lead the market for PVDF-based nanotechnology applications, owing to their advanced research infrastructure and early adoption of innovative technologies. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, increasing investments in R&D, and growing demand for advanced materials in countries like China, Japan, and South Korea.

Despite the promising outlook, challenges such as high production costs and scalability issues need to be addressed to fully realize the market potential of PVDF-based nanotechnology applications. As research progresses and manufacturing processes improve, these barriers are expected to diminish, paving the way for wider adoption across various industries.

Current PVDF Nanotechnology Landscape and Challenges

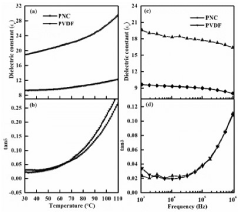

The current PVDF nanotechnology landscape is characterized by rapid advancements and diverse applications across multiple industries. Polyvinylidene fluoride (PVDF) has emerged as a versatile polymer with unique properties that make it particularly suitable for nanotechnology applications. Its piezoelectric, pyroelectric, and ferroelectric properties have led to its widespread use in sensors, actuators, and energy harvesting devices.

In the field of energy storage, PVDF nanocomposites are being extensively researched for their potential in improving the performance of lithium-ion batteries and supercapacitors. The incorporation of PVDF nanofibers into battery separators has shown promise in enhancing thermal stability and ionic conductivity. However, challenges remain in optimizing the interface between PVDF and other battery components to maximize energy density and cycle life.

Biomedical applications represent another frontier for PVDF nanotechnology. The biocompatibility and non-toxicity of PVDF have led to its exploration in tissue engineering scaffolds and drug delivery systems. Electrospun PVDF nanofibers are being investigated for their potential in wound healing and regenerative medicine. Nevertheless, controlling the degradation rate and mechanical properties of PVDF-based biomaterials remains a significant challenge.

In the realm of environmental technology, PVDF membranes are at the forefront of water purification and desalination efforts. The development of PVDF nanofiber membranes with enhanced flux and fouling resistance has shown great promise. However, scaling up these technologies for large-scale water treatment plants while maintaining cost-effectiveness poses a considerable challenge.

The integration of PVDF into flexible electronics and wearable devices is another area of intense research. Its piezoelectric properties make it an excellent candidate for pressure sensors and energy harvesters in smart textiles. Yet, improving the durability and washability of PVDF-based electronic textiles remains an ongoing challenge.

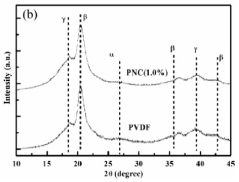

One of the primary technical hurdles in PVDF nanotechnology is achieving precise control over the crystalline structure of PVDF at the nanoscale. The β-phase of PVDF, which exhibits the strongest piezoelectric response, is often difficult to obtain consistently in nanostructures. Researchers are exploring various techniques, including electrospinning and solution casting, to enhance β-phase formation.

Another significant challenge lies in the functionalization of PVDF nanostructures. While PVDF's chemical inertness is beneficial in many applications, it also makes surface modification and functionalization difficult. Developing efficient methods for attaching functional groups or nanoparticles to PVDF surfaces without compromising its inherent properties is crucial for expanding its applications.

The environmental impact of PVDF nanostructures is also a growing concern. As with many nanomaterials, the potential long-term effects of PVDF nanoparticles on ecosystems and human health are not fully understood. Developing sustainable production methods and establishing comprehensive safety protocols for handling and disposing of PVDF nanomaterials are essential challenges that need to be addressed.

Existing PVDF Nanotech Solutions and Implementations

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through the use of additives, surface treatments, or novel processing techniques.

- PVDF-based composites and blends: Development of PVDF-based composite materials and polymer blends to enhance specific properties such as piezoelectricity, thermal stability, or chemical resistance. These composites often incorporate nanofillers, other polymers, or functional additives to achieve desired characteristics for applications in sensors, actuators, or protective coatings.

- PVDF in energy storage applications: Utilization of PVDF as a binder or separator material in energy storage devices such as lithium-ion batteries and supercapacitors. Research focuses on improving the electrochemical performance, stability, and safety of these devices through optimized PVDF formulations and processing methods.

- PVDF in water treatment and filtration: Application of PVDF membranes and fibers in water treatment and filtration processes, including desalination, wastewater treatment, and industrial separations. Research aims to improve membrane fouling resistance, flux, and selectivity through surface modifications or incorporation of functional materials.

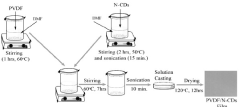

- PVDF processing and manufacturing techniques: Advancements in PVDF processing and manufacturing techniques, including extrusion, electrospinning, and solution casting. These methods aim to produce PVDF materials with controlled morphology, crystallinity, and molecular orientation for specific applications in electronics, textiles, and industrial coatings.

02 PVDF-based piezoelectric and ferroelectric materials

Development of PVDF and its copolymers as piezoelectric and ferroelectric materials for sensors, actuators, and energy harvesting devices. This includes methods for enhancing the piezoelectric properties through various processing techniques, such as stretching, poling, and composite formation with other materials.Expand Specific Solutions03 PVDF in energy storage applications

Utilization of PVDF as a binder material or separator in lithium-ion batteries and other energy storage devices. This includes methods for improving the electrochemical stability, ionic conductivity, and mechanical properties of PVDF-based components in battery systems.Expand Specific Solutions04 PVDF-based coatings and films

Development of PVDF-based coatings and films for various applications, including corrosion protection, weather resistance, and self-cleaning surfaces. This includes methods for improving adhesion, durability, and functional properties of PVDF coatings through formulation adjustments and surface treatments.Expand Specific Solutions05 PVDF in composite materials

Incorporation of PVDF into composite materials for enhanced mechanical, thermal, and electrical properties. This includes the development of PVDF-based nanocomposites, fiber-reinforced composites, and hybrid materials for applications in aerospace, automotive, and electronics industries.Expand Specific Solutions

Key Players in PVDF Nanotechnology Industry

The nanotechnology applications of PVDF are in a rapidly evolving phase, characterized by significant research and development efforts across academia and industry. The market for PVDF in nanotechnology is expanding, driven by its unique properties and versatility. While the technology is still maturing, several key players are making notable advancements. Companies like Arkema, Inc., Wanhua Chemical Group Co., Ltd., and Merck Patent GmbH are at the forefront, leveraging their expertise in materials science. Academic institutions such as Massachusetts Institute of Technology, Nanyang Technological University, and Indian Institute of Technology Kanpur are contributing groundbreaking research. The collaboration between industry and academia, exemplified by partnerships involving UT-Battelle LLC and The Regents of the University of Michigan, is accelerating the development of cutting-edge PVDF nanotechnology applications.

Wanhua Chemical Group Co., Ltd.

Arkema, Inc.

Breakthrough PVDF Nanotech Patents and Research

- A polyvinylidene difluoride (PVDF)/Nitrogen-doped carbon dots (N-CDs) nanocomposite film is developed using citric acid and urea synthesis, with a solution cast process and fast-drying silver paste for electric field application, creating a non-toxic, high dielectric constant, and high breakdown strength capacitive energy storage device.

- Radiation grafting of unsaturated polar monomers onto a specific VDF copolymer with high VDF content, which enhances adhesion to thermoplastic polymers and inorganic materials, and facilitates easier implementation in molten or solvent states, allowing for higher coextrusion line speeds.

Environmental Impact of PVDF Nanotech Applications

The environmental impact of PVDF nanotech applications is a critical consideration as this technology advances. PVDF nanofibers and nanoparticles have shown promising results in various fields, including water treatment, energy harvesting, and biomedical applications. However, their widespread use raises concerns about potential ecological consequences.

One of the primary environmental benefits of PVDF nanotechnology is its application in water purification systems. PVDF nanofiber membranes demonstrate excellent filtration capabilities, effectively removing contaminants and microplastics from water sources. This technology has the potential to significantly improve access to clean water globally, addressing a critical environmental challenge.

However, the production and disposal of PVDF nanomaterials present potential environmental risks. The manufacturing process of PVDF nanofibers and nanoparticles often involves the use of solvents and chemicals that may have negative environmental impacts if not properly managed. Ensuring proper waste treatment and recycling protocols is essential to mitigate these risks.

The durability and chemical stability of PVDF nanomaterials, while advantageous for many applications, raise concerns about their long-term environmental persistence. As these materials degrade, they may release nanoparticles into ecosystems, potentially affecting aquatic and terrestrial organisms. Research is ongoing to understand the potential bioaccumulation and toxicity of PVDF nanoparticles in various environmental compartments.

In energy-related applications, PVDF nanotech offers both benefits and challenges. PVDF-based piezoelectric nanogenerators show promise for harvesting mechanical energy, potentially reducing reliance on traditional energy sources. However, the lifecycle assessment of these devices, including their production, use, and disposal, must be carefully evaluated to ensure a net positive environmental impact.

The biomedical applications of PVDF nanotechnology, such as drug delivery systems and tissue engineering scaffolds, present unique environmental considerations. While these applications can lead to improved healthcare outcomes, the potential release of PVDF nanoparticles into the environment through medical waste disposal requires careful management and regulation.

As research in PVDF nanotechnology progresses, there is a growing emphasis on developing more environmentally friendly production methods and exploring biodegradable alternatives. Some studies are focusing on green synthesis techniques that reduce the use of harmful solvents and minimize waste generation. Additionally, efforts are being made to design PVDF-based nanomaterials that maintain their functional properties while being more easily degradable in natural environments.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for PVDF in cutting-edge nanotechnology applications are promising, driven by the material's unique properties and the growing demand for advanced nanomaterials across various industries.

PVDF's scalability in nanotechnology applications is primarily facilitated by its versatile processing methods. The polymer can be easily fabricated into nanofibers, nanoparticles, and thin films using techniques such as electrospinning, phase inversion, and solution casting. These methods are amenable to large-scale production, allowing for the manufacture of PVDF nanomaterials in industrial quantities.

The electrospinning process, in particular, has shown great potential for scaling up PVDF nanofiber production. Recent advancements in multi-nozzle and needleless electrospinning technologies have significantly increased production rates, making it feasible to manufacture PVDF nanofibers on a commercial scale. This scalability is crucial for applications in energy harvesting, water treatment, and sensor technologies.

In terms of commercialization, PVDF nanomaterials are finding increasing adoption in several high-value markets. The energy sector, for instance, is leveraging PVDF nanocomposites for improved lithium-ion battery separators and piezoelectric energy harvesters. The growing demand for renewable energy solutions and portable electronics is expected to drive the commercial adoption of PVDF-based nanomaterials in this sector.

The water treatment industry represents another significant commercialization opportunity for PVDF nanotechnology. PVDF membranes with nanoscale pores have demonstrated superior performance in water purification and desalination processes. As water scarcity becomes a global concern, the demand for efficient filtration technologies is likely to boost the commercial prospects of PVDF nanomembranes.

In the biomedical field, PVDF nanofibers and nanoparticles are being explored for drug delivery systems, tissue engineering scaffolds, and biosensors. While regulatory hurdles may slow immediate commercialization in this sector, the potential for high-value applications presents long-term commercial opportunities.

However, challenges remain in scaling up production while maintaining consistent quality and performance of PVDF nanomaterials. Addressing these challenges will require continued research and development efforts, as well as investments in advanced manufacturing technologies.

The commercialization of PVDF nanotechnology applications will also depend on cost-effectiveness compared to existing solutions. As production scales up and becomes more efficient, the cost of PVDF nanomaterials is expected to decrease, making them more competitive in the market.

Overall, the scalability and commercialization prospects for PVDF in nanotechnology applications are highly favorable. The material's versatility, coupled with growing demand across multiple industries, positions PVDF as a key player in the future of nanotechnology-enabled products and solutions.