How to Utilize PVDF in Aerospace Components Fabrication?

PVDF in Aerospace: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in aerospace applications due to its unique combination of properties. The aerospace industry has long sought materials that can withstand extreme conditions while maintaining structural integrity and performance. PVDF, a fluoropolymer, has garnered attention for its exceptional chemical resistance, thermal stability, and mechanical strength.

The evolution of PVDF in aerospace can be traced back to the 1960s when fluoropolymers were first introduced in this sector. Initially used in small-scale applications, PVDF's potential for broader use in aerospace components has grown significantly over the past decades. This growth is largely attributed to advancements in polymer science and manufacturing technologies, which have enhanced PVDF's properties and processability.

The primary objective of utilizing PVDF in aerospace components fabrication is to improve the overall performance and longevity of aircraft and spacecraft. By incorporating PVDF into various components, manufacturers aim to reduce weight, increase fuel efficiency, and enhance resistance to harsh environmental conditions encountered during flight and space missions.

One of the key drivers for PVDF adoption in aerospace is its excellent resistance to UV radiation, chemicals, and extreme temperatures. These properties make it particularly suitable for exterior components and fuel system parts. Additionally, PVDF's low moisture absorption and high dielectric strength make it an attractive option for electrical insulation in aerospace applications.

The aerospace industry's push towards more sustainable and environmentally friendly practices has also contributed to the increased interest in PVDF. As a recyclable material with a lower environmental impact compared to some traditional aerospace materials, PVDF aligns well with the industry's sustainability goals.

Recent technological advancements have further expanded the potential applications of PVDF in aerospace. For instance, the development of PVDF nanocomposites has opened up new possibilities for creating multifunctional materials with enhanced mechanical and electrical properties. These innovations are particularly relevant for next-generation aircraft and spacecraft designs that demand materials with superior performance characteristics.

As the aerospace industry continues to evolve, with a focus on lighter, stronger, and more durable materials, PVDF is expected to play an increasingly important role. The ongoing research and development in PVDF formulations and processing techniques aim to overcome current limitations and expand its use in critical aerospace components.

Aerospace Market Demand for PVDF Components

The aerospace industry has witnessed a growing demand for advanced materials that can withstand extreme conditions while offering superior performance. Polyvinylidene fluoride (PVDF), a high-performance thermoplastic, has emerged as a promising candidate for various aerospace applications due to its unique properties. The market demand for PVDF components in the aerospace sector is driven by several factors, including the need for lightweight materials, enhanced fuel efficiency, and improved durability.

The global aerospace market is experiencing steady growth, with projections indicating a significant increase in commercial aircraft production over the next two decades. This growth is accompanied by a rising demand for innovative materials that can meet the stringent requirements of modern aircraft design. PVDF, with its excellent chemical resistance, high thermal stability, and low weight, is well-positioned to address these needs.

One of the primary drivers for PVDF adoption in aerospace is its potential to reduce aircraft weight. As airlines seek to improve fuel efficiency and reduce operating costs, lightweight materials like PVDF offer a compelling solution. The material's high strength-to-weight ratio makes it an attractive option for replacing heavier metal components in various aircraft structures, including interior panels, ducting systems, and electrical insulation.

The aerospace industry's focus on sustainability and environmental performance also contributes to the increasing demand for PVDF components. The material's resistance to UV radiation and weathering makes it suitable for exterior applications, potentially extending the lifespan of aircraft components and reducing maintenance requirements. Additionally, PVDF's recyclability aligns with the industry's efforts to improve the overall environmental footprint of aircraft production and operation.

The market for PVDF components in aerospace is further bolstered by the material's excellent electrical properties. As modern aircraft incorporate more advanced avionics and electrical systems, the demand for high-performance insulation materials grows. PVDF's low dielectric constant and high dielectric strength make it an ideal choice for wire and cable insulation, as well as for components in radar and communication systems.

The defense sector within the aerospace industry also presents significant opportunities for PVDF applications. Military aircraft and unmanned aerial vehicles (UAVs) require materials that can withstand harsh environments and provide enhanced stealth capabilities. PVDF's low radar signature and resistance to chemical warfare agents make it a valuable material for military aerospace applications.

As the aerospace industry continues to evolve, the demand for PVDF components is expected to grow across various segments, including commercial aviation, defense, and space exploration. The material's versatility and performance characteristics position it as a key enabler for next-generation aerospace technologies, driving innovation in aircraft design and manufacturing processes.

PVDF Technology: Current State and Challenges

Polyvinylidene fluoride (PVDF) has emerged as a promising material in aerospace component fabrication, yet its current state and challenges warrant careful examination. The aerospace industry's stringent requirements for lightweight, durable, and high-performance materials have driven the exploration of PVDF's potential applications. Currently, PVDF is utilized in various aerospace components, including fuel systems, hydraulic lines, and electrical insulation, due to its excellent chemical resistance, thermal stability, and mechanical properties.

One of the primary challenges in PVDF technology for aerospace applications is optimizing its processing techniques to meet the industry's exacting standards. While PVDF offers superior properties, achieving consistent quality and performance across large-scale production remains a significant hurdle. Manufacturers are grappling with issues such as uniform crystallinity, precise dimensional control, and minimizing defects during fabrication processes like injection molding and extrusion.

Another critical challenge lies in enhancing PVDF's high-temperature performance. Although PVDF exhibits good thermal stability, aerospace applications often demand materials that can withstand extreme temperature fluctuations and prolonged exposure to high temperatures. Researchers are actively working on developing PVDF composites and blends that can maintain their mechanical and electrical properties under these demanding conditions.

The integration of PVDF into complex aerospace structures presents additional challenges. Ensuring compatibility with other materials, such as metals and composites, is crucial for creating robust and reliable components. Adhesion issues and potential galvanic corrosion at material interfaces are areas of ongoing research and development. Furthermore, the aerospace industry's shift towards more electric aircraft architectures has intensified the need for PVDF materials with improved dielectric properties and electromagnetic shielding capabilities.

Environmental concerns and regulatory pressures also pose challenges to PVDF technology in aerospace applications. The industry is increasingly focused on sustainability and end-of-life considerations for materials. Developing recycling methods for PVDF components and exploring bio-based alternatives are emerging areas of research that aim to address these environmental challenges while maintaining the material's performance characteristics.

Despite these challenges, the current state of PVDF technology in aerospace is marked by continuous innovation and progress. Advanced manufacturing techniques, such as additive manufacturing and precision machining, are being adapted to work with PVDF, opening new possibilities for complex geometries and customized components. Additionally, the development of PVDF nanocomposites is showing promise in enhancing the material's mechanical, thermal, and electrical properties, potentially expanding its applications in aerospace.

Current PVDF Fabrication Techniques for Aerospace

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes are explored, including blending with other polymers, surface treatments, and incorporation of nanoparticles. These modifications aim to enhance properties such as hydrophilicity, fouling resistance, and mechanical strength for applications in water treatment and filtration.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes are explored, including blending with other polymers, surface treatments, and incorporation of nanoparticles. These modifications aim to enhance properties such as hydrophilicity, fouling resistance, and mechanical strength for applications in water treatment and filtration.

- PVDF-based piezoelectric and energy harvesting devices: PVDF's piezoelectric properties are utilized in the development of sensors, actuators, and energy harvesting devices. Research focuses on improving the piezoelectric performance through various methods, including nanocomposite formation and specialized fabrication techniques.

- PVDF in battery and supercapacitor applications: PVDF is investigated as a binder material and separator in lithium-ion batteries and supercapacitors. Studies explore ways to enhance its electrochemical stability, ionic conductivity, and mechanical properties to improve overall device performance and safety.

- PVDF-based coatings and films: Development of PVDF-based coatings and films for various applications, including corrosion protection, self-cleaning surfaces, and electromagnetic shielding. Research focuses on improving adhesion, durability, and functional properties through composition adjustments and processing techniques.

- PVDF in composite materials: Incorporation of PVDF into composite materials for enhanced mechanical, thermal, and electrical properties. Studies explore the use of PVDF in fiber-reinforced composites, nanocomposites, and hybrid materials for applications in aerospace, automotive, and construction industries.

02 PVDF-based piezoelectric and energy harvesting devices

PVDF's piezoelectric properties are utilized in the development of sensors, actuators, and energy harvesting devices. Research focuses on improving the piezoelectric performance through various methods, including nanocomposite formation and specialized fabrication techniques.Expand Specific Solutions03 PVDF in battery and supercapacitor applications

PVDF is investigated as a binder material and separator in lithium-ion batteries and supercapacitors. Studies explore ways to enhance its electrochemical stability, ionic conductivity, and mechanical properties to improve overall device performance and safety.Expand Specific Solutions04 PVDF-based coatings and films

Development of PVDF-based coatings and films for various applications, including corrosion protection, self-cleaning surfaces, and electromagnetic shielding. Research focuses on improving adhesion, durability, and functional properties through composition adjustments and processing techniques.Expand Specific Solutions05 PVDF in composite materials

Incorporation of PVDF into composite materials for enhanced mechanical, thermal, and electrical properties. Studies explore the use of PVDF in fiber-reinforced composites, nanocomposites, and hybrid materials for applications in aerospace, automotive, and construction industries.Expand Specific Solutions

Key Players in PVDF Aerospace Manufacturing

The utilization of PVDF in aerospace components fabrication is in a growth phase, with increasing market size due to its unique properties. The technology's maturity varies across applications, with some areas well-established and others still developing. Key players like Arkema, Inc., Solvay Specialty Polymers Italy SpA, and Saint-Gobain Ceramics & Plastics, Inc. are driving innovation in PVDF aerospace applications. Research institutions such as Massachusetts Institute of Technology and Nanyang Technological University are contributing to advancements. The competitive landscape is characterized by a mix of established chemical companies and specialized materials firms, with ongoing research and development efforts to expand PVDF's potential in aerospace manufacturing.

Arkema, Inc.

Arkema France SA

Innovations in PVDF Aerospace Applications

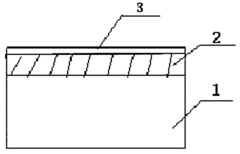

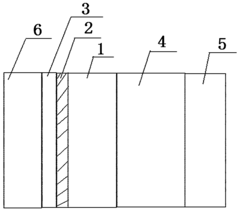

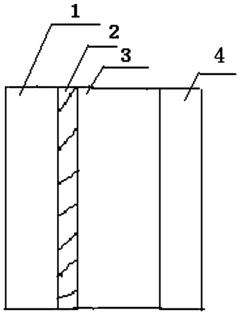

- It adopts a three-layer structure of PVDF film. The base layer is PVDF, the aluminum coating layer and the silicon oxide protective layer are prepared through high-speed mixing, twin-screw extrusion, blown film method and vapor deposition technology. The thickness of the aluminum coating is 30-60 nanometers. , the protective layer thickness is 10-50 nanometers, which improves reflectivity and enhances corrosion resistance.

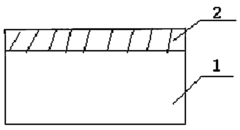

- A high-reflectivity PVDF film with a two-layer structure is used. The base layer is a PVDF layer, which is directly plated with aluminum. The aluminum layer is formed by vacuum evaporation. It is combined with titanium dioxide, PMMA, antioxidants and anti-UV agents, using high-speed mixing and double Screw extruder granulation, film blowing method to prepare the film, and through corona treatment and vacuum evaporation to form an aluminum layer to improve reflectivity.

Environmental Impact of PVDF in Aerospace

The utilization of Polyvinylidene Fluoride (PVDF) in aerospace components fabrication has significant environmental implications that warrant careful consideration. PVDF, a fluoropolymer known for its excellent chemical resistance and durability, offers numerous advantages in aerospace applications. However, its production, use, and disposal also present environmental challenges that must be addressed.

The manufacturing process of PVDF involves the use of fluorine-containing compounds, which can contribute to greenhouse gas emissions if not properly managed. The production of PVDF monomers and subsequent polymerization require energy-intensive processes, potentially increasing the carbon footprint of aerospace components. However, advancements in manufacturing technologies have led to more efficient production methods, reducing overall energy consumption and emissions.

During the fabrication of aerospace components, PVDF's resistance to chemical degradation and high temperatures results in reduced material waste and longer component lifespans. This durability translates to fewer replacements and less frequent maintenance, indirectly lowering the environmental impact associated with manufacturing and transportation of replacement parts.

PVDF's lightweight nature contributes to fuel efficiency in aerospace applications, potentially reducing overall emissions during aircraft operation. The material's resistance to UV radiation and weathering also extends the service life of exterior components, further minimizing the need for replacements and associated environmental costs.

However, the end-of-life management of PVDF-containing aerospace components presents challenges. While PVDF is recyclable, the complex nature of aerospace components often makes separation and recycling difficult. Incineration of PVDF can release harmful substances, including hydrogen fluoride, necessitating specialized disposal methods to mitigate environmental risks.

Recent research has focused on developing more environmentally friendly PVDF formulations and recycling techniques. Bio-based alternatives and improved recycling processes show promise in reducing the environmental footprint of PVDF in aerospace applications. Additionally, efforts to implement closed-loop manufacturing systems for PVDF components are underway, aiming to minimize waste and maximize material recovery.

The aerospace industry's increasing emphasis on sustainability has led to more rigorous life cycle assessments of materials like PVDF. These assessments consider the environmental impact from raw material extraction through to disposal, providing a comprehensive view of PVDF's environmental performance in aerospace applications. Such analyses guide manufacturers in optimizing material selection and processing methods to minimize environmental impact while maintaining the high performance standards required in aerospace.

PVDF Aerospace Certification and Standards

The utilization of PVDF in aerospace components fabrication requires adherence to stringent certification and standards to ensure safety, reliability, and performance in the demanding aerospace environment. The aerospace industry is governed by various regulatory bodies, including the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO), which set forth comprehensive guidelines for materials used in aircraft construction.

For PVDF to be approved for use in aerospace applications, it must meet the requirements outlined in several key standards. The SAE Aerospace Material Specification (AMS) provides detailed guidelines for material properties, manufacturing processes, and quality control measures. Specifically, AMS 3216 addresses the requirements for fluoropolymer films used in aerospace, which includes PVDF. This standard outlines the physical, chemical, and mechanical properties that PVDF must possess to be suitable for aerospace use.

Additionally, the ASTM D7391 standard provides test methods for evaluating the performance of fluoropolymer films in aerospace applications. This standard covers procedures for assessing properties such as tensile strength, elongation, tear resistance, and dielectric strength, which are critical for PVDF components in aircraft.

The certification process for PVDF in aerospace components involves rigorous testing and documentation. Manufacturers must demonstrate compliance with FAR 25.853, which specifies flammability requirements for materials used in aircraft interiors. PVDF must pass vertical burn tests and smoke density tests to ensure it meets the stringent fire safety standards required for aerospace applications.

Furthermore, the qualification of PVDF for aerospace use necessitates extensive environmental testing. This includes exposure to extreme temperatures, humidity, and UV radiation to simulate the harsh conditions encountered during flight. The material must maintain its properties and performance under these conditions to receive certification for use in aircraft components.

Quality control measures play a crucial role in the certification process. Manufacturers must implement robust quality management systems that comply with AS9100, the quality standard specific to the aerospace industry. This ensures consistent production of PVDF components that meet the required specifications and maintain traceability throughout the manufacturing process.

The certification of PVDF for aerospace use also extends to the entire supply chain. Suppliers of PVDF raw materials and manufacturers of PVDF components must undergo audits and maintain certifications to demonstrate their ability to consistently produce materials that meet aerospace standards. This includes adherence to lot traceability requirements and implementation of rigorous testing protocols at various stages of production.